Boron Nitride Lubricants: Film Formation, Oxidation Stability And Component Life

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Lubricant Technology Background and Objectives

Boron nitride (BN) lubricants represent a significant advancement in the field of high-performance lubrication technology, with a history dating back to the mid-20th century. The evolution of BN as a lubricant material has been driven by increasing demands for lubricants capable of withstanding extreme conditions where conventional oil-based lubricants fail. Initially developed for aerospace and military applications, BN lubricants have gradually expanded into various industrial sectors due to their exceptional thermal stability and tribological properties.

The technological trajectory of BN lubricants has been characterized by continuous improvements in synthesis methods, formulation techniques, and application processes. Early BN lubricants suffered from poor adhesion and limited film formation capabilities, but advancements in material science and nanotechnology have significantly enhanced these properties. The incorporation of BN into various matrices, including oils, greases, and solid composites, has broadened its application spectrum while improving performance metrics.

Recent technological trends indicate a growing focus on hexagonal boron nitride (h-BN) due to its graphite-like layered structure that facilitates excellent lubricity. The two-dimensional nature of h-BN sheets allows for easy shearing between layers, providing low friction coefficients even under extreme pressure and temperature conditions. This characteristic makes BN particularly valuable in applications where traditional lubricants oxidize or decompose.

The oxidation stability of BN lubricants represents a critical advantage over carbon-based alternatives. While graphite-based lubricants typically begin to oxidize at temperatures around 400°C, BN remains stable up to approximately 900°C in air and even higher in inert environments. This exceptional thermal stability directly translates to extended component life in high-temperature applications, which constitutes a primary objective in the development of advanced BN lubricant systems.

The primary technical objectives in BN lubricant development currently focus on three interconnected areas: enhancing film formation mechanisms to ensure consistent coverage and adhesion to substrate materials; improving oxidation stability to extend operational temperature ranges; and ultimately maximizing component life through reduced wear and friction. These objectives align with broader industrial trends toward energy efficiency, extended maintenance intervals, and reduced total cost of ownership for mechanical systems.

Additionally, environmental considerations have emerged as an important driver in BN lubricant technology development. As regulatory frameworks increasingly restrict certain traditional lubricant additives due to environmental concerns, BN offers a potentially more sustainable alternative with lower toxicity and environmental impact. This aspect has accelerated research into water-based BN dispersions and environmentally friendly formulations that maintain performance while reducing ecological footprint.

The technological trajectory of BN lubricants has been characterized by continuous improvements in synthesis methods, formulation techniques, and application processes. Early BN lubricants suffered from poor adhesion and limited film formation capabilities, but advancements in material science and nanotechnology have significantly enhanced these properties. The incorporation of BN into various matrices, including oils, greases, and solid composites, has broadened its application spectrum while improving performance metrics.

Recent technological trends indicate a growing focus on hexagonal boron nitride (h-BN) due to its graphite-like layered structure that facilitates excellent lubricity. The two-dimensional nature of h-BN sheets allows for easy shearing between layers, providing low friction coefficients even under extreme pressure and temperature conditions. This characteristic makes BN particularly valuable in applications where traditional lubricants oxidize or decompose.

The oxidation stability of BN lubricants represents a critical advantage over carbon-based alternatives. While graphite-based lubricants typically begin to oxidize at temperatures around 400°C, BN remains stable up to approximately 900°C in air and even higher in inert environments. This exceptional thermal stability directly translates to extended component life in high-temperature applications, which constitutes a primary objective in the development of advanced BN lubricant systems.

The primary technical objectives in BN lubricant development currently focus on three interconnected areas: enhancing film formation mechanisms to ensure consistent coverage and adhesion to substrate materials; improving oxidation stability to extend operational temperature ranges; and ultimately maximizing component life through reduced wear and friction. These objectives align with broader industrial trends toward energy efficiency, extended maintenance intervals, and reduced total cost of ownership for mechanical systems.

Additionally, environmental considerations have emerged as an important driver in BN lubricant technology development. As regulatory frameworks increasingly restrict certain traditional lubricant additives due to environmental concerns, BN offers a potentially more sustainable alternative with lower toxicity and environmental impact. This aspect has accelerated research into water-based BN dispersions and environmentally friendly formulations that maintain performance while reducing ecological footprint.

Market Analysis for High-Performance Lubricants

The high-performance lubricants market has experienced substantial growth in recent years, driven by increasing demands from automotive, aerospace, industrial machinery, and electronics sectors. The global high-performance lubricants market was valued at approximately 2.2 billion USD in 2022 and is projected to reach 3.1 billion USD by 2028, growing at a CAGR of around 5.8% during the forecast period.

Boron Nitride (BN) based lubricants represent a significant segment within this market, particularly in applications requiring extreme temperature resistance and superior tribological properties. These advanced lubricants have gained traction in industries where conventional lubricants fail to deliver adequate performance under severe operating conditions.

The automotive sector remains the largest consumer of high-performance lubricants, accounting for roughly 38% of the market share. This dominance is attributed to the increasing production of electric vehicles and the growing emphasis on fuel efficiency and emission reduction. BN lubricants specifically address these concerns by reducing friction and wear in critical engine components, thereby extending component life and improving overall efficiency.

The industrial machinery segment follows closely, representing approximately 27% of the market. In this sector, the demand for BN lubricants is primarily driven by the need for extended maintenance intervals and reduced downtime in manufacturing operations. The superior oxidation stability of BN lubricants makes them particularly valuable in high-temperature industrial applications.

Regionally, North America and Europe currently lead the high-performance lubricants market, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India at the forefront. This growth is fueled by rapid industrialization, increasing automotive production, and significant investments in manufacturing infrastructure.

Market trends indicate a growing preference for environmentally friendly and sustainable lubricant solutions. This shift presents both challenges and opportunities for BN lubricants, as manufacturers must balance performance characteristics with environmental considerations. The development of water-based BN lubricant formulations represents a promising direction in addressing these market demands.

Competition in the high-performance lubricants market is intense, with major players including ExxonMobil, Shell, Chevron, and specialized manufacturers like Saint-Gobain and Momentive Performance Materials focusing on BN-based products. These companies are investing heavily in R&D to enhance film formation properties and oxidation stability of BN lubricants, recognizing these as key differentiators in the premium lubricants segment.

Boron Nitride (BN) based lubricants represent a significant segment within this market, particularly in applications requiring extreme temperature resistance and superior tribological properties. These advanced lubricants have gained traction in industries where conventional lubricants fail to deliver adequate performance under severe operating conditions.

The automotive sector remains the largest consumer of high-performance lubricants, accounting for roughly 38% of the market share. This dominance is attributed to the increasing production of electric vehicles and the growing emphasis on fuel efficiency and emission reduction. BN lubricants specifically address these concerns by reducing friction and wear in critical engine components, thereby extending component life and improving overall efficiency.

The industrial machinery segment follows closely, representing approximately 27% of the market. In this sector, the demand for BN lubricants is primarily driven by the need for extended maintenance intervals and reduced downtime in manufacturing operations. The superior oxidation stability of BN lubricants makes them particularly valuable in high-temperature industrial applications.

Regionally, North America and Europe currently lead the high-performance lubricants market, collectively accounting for over 60% of global consumption. However, the Asia-Pacific region is emerging as the fastest-growing market, with China and India at the forefront. This growth is fueled by rapid industrialization, increasing automotive production, and significant investments in manufacturing infrastructure.

Market trends indicate a growing preference for environmentally friendly and sustainable lubricant solutions. This shift presents both challenges and opportunities for BN lubricants, as manufacturers must balance performance characteristics with environmental considerations. The development of water-based BN lubricant formulations represents a promising direction in addressing these market demands.

Competition in the high-performance lubricants market is intense, with major players including ExxonMobil, Shell, Chevron, and specialized manufacturers like Saint-Gobain and Momentive Performance Materials focusing on BN-based products. These companies are investing heavily in R&D to enhance film formation properties and oxidation stability of BN lubricants, recognizing these as key differentiators in the premium lubricants segment.

Current Challenges in BN Lubricant Development

Despite significant advancements in boron nitride (BN) lubricant technology, several critical challenges continue to impede its widespread industrial adoption. The primary obstacle remains the optimization of film formation mechanisms under diverse operating conditions. Current BN lubricants often exhibit inconsistent film deposition patterns, particularly at the boundary lubrication regime where surface interactions are most critical. This inconsistency leads to unpredictable performance across varying temperature ranges and load conditions.

The oxidation stability of BN lubricants presents another significant challenge. While hexagonal boron nitride (h-BN) demonstrates excellent thermal stability in inert environments, its performance deteriorates in oxidative conditions above 800°C. This limitation restricts its application in high-temperature environments such as aerospace components and advanced manufacturing processes. The oxidation products can potentially alter the tribological properties and compromise the lubricating film integrity.

Dispersion stability remains problematic for BN-based lubricant formulations. The inherent hydrophobicity of h-BN particles makes achieving uniform and stable dispersions in carrier fluids challenging. Current dispersion techniques often rely on surfactants or chemical modifications that may degrade under extreme operating conditions, leading to particle agglomeration and sedimentation. This phenomenon significantly reduces the lubricant's effectiveness and can accelerate component wear.

Compatibility issues between BN particles and base oils or greases constitute another substantial hurdle. The chemical interactions between modified BN surfaces and additives in lubricant formulations are not fully understood, leading to potential antagonistic effects that compromise overall performance. These interactions become particularly problematic in applications requiring long service intervals or those exposed to contaminants.

Scale-up and manufacturing consistency present industrial implementation challenges. The production of BN particles with controlled morphology, size distribution, and surface properties at commercial scales remains difficult. Variations in these parameters significantly impact film formation characteristics and ultimately component life. Current manufacturing processes struggle to maintain the precise quality control required for high-performance applications.

Cost-effectiveness represents a persistent barrier to widespread adoption. The production of high-quality BN materials involves complex processes and expensive precursors, resulting in lubricant formulations that are often prohibitively expensive compared to conventional alternatives. This economic factor limits BN lubricants primarily to specialized applications where performance benefits clearly justify the increased cost.

Standardized testing methodologies specific to BN lubricants are also lacking. Current industry standards for evaluating lubricant performance do not adequately capture the unique film formation mechanisms and tribological behaviors of BN-based systems, making performance comparisons and quality assurance challenging for manufacturers and end-users alike.

The oxidation stability of BN lubricants presents another significant challenge. While hexagonal boron nitride (h-BN) demonstrates excellent thermal stability in inert environments, its performance deteriorates in oxidative conditions above 800°C. This limitation restricts its application in high-temperature environments such as aerospace components and advanced manufacturing processes. The oxidation products can potentially alter the tribological properties and compromise the lubricating film integrity.

Dispersion stability remains problematic for BN-based lubricant formulations. The inherent hydrophobicity of h-BN particles makes achieving uniform and stable dispersions in carrier fluids challenging. Current dispersion techniques often rely on surfactants or chemical modifications that may degrade under extreme operating conditions, leading to particle agglomeration and sedimentation. This phenomenon significantly reduces the lubricant's effectiveness and can accelerate component wear.

Compatibility issues between BN particles and base oils or greases constitute another substantial hurdle. The chemical interactions between modified BN surfaces and additives in lubricant formulations are not fully understood, leading to potential antagonistic effects that compromise overall performance. These interactions become particularly problematic in applications requiring long service intervals or those exposed to contaminants.

Scale-up and manufacturing consistency present industrial implementation challenges. The production of BN particles with controlled morphology, size distribution, and surface properties at commercial scales remains difficult. Variations in these parameters significantly impact film formation characteristics and ultimately component life. Current manufacturing processes struggle to maintain the precise quality control required for high-performance applications.

Cost-effectiveness represents a persistent barrier to widespread adoption. The production of high-quality BN materials involves complex processes and expensive precursors, resulting in lubricant formulations that are often prohibitively expensive compared to conventional alternatives. This economic factor limits BN lubricants primarily to specialized applications where performance benefits clearly justify the increased cost.

Standardized testing methodologies specific to BN lubricants are also lacking. Current industry standards for evaluating lubricant performance do not adequately capture the unique film formation mechanisms and tribological behaviors of BN-based systems, making performance comparisons and quality assurance challenging for manufacturers and end-users alike.

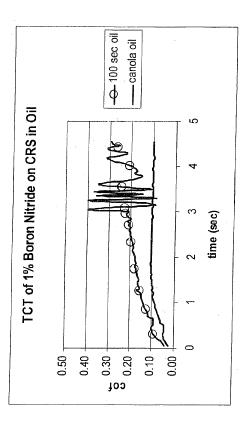

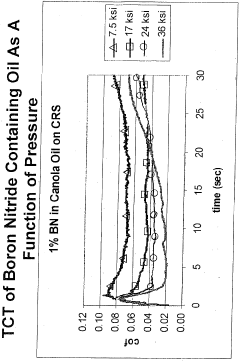

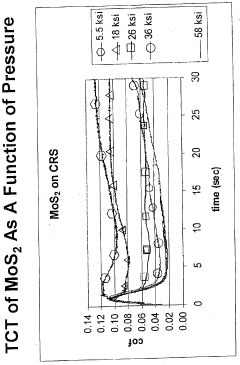

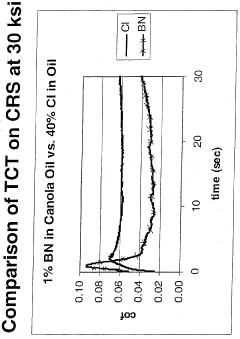

Film Formation Mechanisms and Application Methods

01 Boron nitride film formation techniques

Various methods for forming boron nitride films as lubricants, including chemical vapor deposition (CVD), physical vapor deposition (PVD), and sputtering techniques. These processes create thin, uniform films with excellent lubricating properties on component surfaces. The formation techniques significantly impact the film's adhesion, thickness uniformity, and overall performance as a lubricant.- Boron nitride film formation techniques: Various methods for forming boron nitride films on surfaces to enhance lubrication properties. These techniques include chemical vapor deposition, physical vapor deposition, and sputtering processes that create uniform and adherent boron nitride layers. The resulting films provide low friction coefficients and can be applied to various substrate materials, creating durable lubricating surfaces for mechanical components.

- Oxidation stability of boron nitride lubricants: Boron nitride exhibits exceptional oxidation stability at high temperatures compared to conventional lubricants. This property makes it suitable for applications in extreme environments where thermal degradation is a concern. The chemical structure of boron nitride resists oxidative breakdown, maintaining lubricating properties even under severe operating conditions, which helps prevent component failure due to lubricant degradation.

- Component life extension through boron nitride lubrication: The application of boron nitride lubricants significantly extends the operational life of mechanical components by reducing friction and wear. The lubricating films minimize metal-to-metal contact, decrease energy losses, and prevent premature component failure. Studies show improved durability in various applications including bearings, gears, and high-temperature machinery parts, resulting in reduced maintenance requirements and longer service intervals.

- Composite formulations with boron nitride: Advanced lubricant formulations incorporate boron nitride with other materials to enhance performance characteristics. These composite lubricants combine boron nitride with polymers, other solid lubricants, or carrier fluids to optimize friction reduction, load-bearing capacity, and film formation. The synergistic effects of these combinations provide superior lubrication performance across a wider range of operating conditions than boron nitride alone.

- Nano-structured boron nitride lubricants: Nano-scale boron nitride particles and structures offer enhanced lubricating properties compared to conventional forms. These nanomaterials provide improved film formation, better adhesion to surfaces, and superior load distribution. The unique properties of nano-boron nitride allow for more effective penetration into surface irregularities, creating more uniform lubricating films that significantly reduce friction and improve component performance under demanding conditions.

02 Oxidation stability enhancement of boron nitride lubricants

Approaches to improve the oxidation resistance of boron nitride lubricants, particularly at high temperatures. This includes doping with stabilizing elements, creating composite structures, and surface treatments that prevent oxidation. Enhanced oxidation stability allows these lubricants to maintain their performance in extreme environments, such as high-temperature industrial applications and aerospace components.Expand Specific Solutions03 Component life extension through boron nitride lubrication

The application of boron nitride lubricants significantly extends the operational life of mechanical components by reducing friction and wear. These lubricants create a protective barrier between moving parts, minimizing metal-to-metal contact and associated damage. Studies demonstrate reduced maintenance requirements and longer service intervals for components treated with boron nitride lubricants compared to conventional options.Expand Specific Solutions04 Hexagonal boron nitride (h-BN) in advanced lubricant formulations

Hexagonal boron nitride (h-BN) is particularly effective in lubricant formulations due to its layered structure similar to graphite. These formulations can include h-BN in various forms such as nanosheets, particles, or composites mixed with carrier oils or incorporated into greases. The hexagonal structure allows for easy shearing between layers, providing excellent lubricity while maintaining stability under pressure and temperature variations.Expand Specific Solutions05 Boron nitride composite lubricants for extreme conditions

Development of composite lubricants combining boron nitride with other materials such as molybdenum disulfide, graphene, or ceramic particles to enhance performance under extreme conditions. These composites offer synergistic benefits including improved load-bearing capacity, extended temperature range stability, and resistance to harsh chemical environments. The composite approach allows for customization of lubricant properties to meet specific application requirements.Expand Specific Solutions

Leading Manufacturers and Research Institutions

Boron Nitride Lubricants technology is currently in a growth phase, with increasing market adoption across industrial applications. The global market for advanced lubricants is expanding at approximately 5-7% annually, with boron nitride-based solutions gaining traction due to their superior thermal stability and oxidation resistance. The technology has reached moderate maturity, with companies like Tokyo Electron, Baker Hughes, and Sumitomo Chemical leading commercial applications, while research institutions such as MIT, Naval Research Laboratory, and KIST are advancing fundamental understanding of film formation mechanisms. Denka Corp. and The Lubrizol Corp. have made significant progress in enhancing oxidation stability, while ASM IP Holding and KLA Corp. are developing specialized applications for semiconductor manufacturing that extend component life under extreme conditions.

Denka Corp.

Technical Solution: Denka Corporation has developed proprietary boron nitride powder manufacturing technologies specifically optimized for lubricant applications. Their approach centers on producing high-purity hexagonal BN particles with controlled morphology and surface characteristics. Denka's technology involves a two-stage process: first synthesizing BN precursors through boric acid and nitrogen-containing compounds reaction, then high-temperature treatment (1500-1800°C) to create highly crystalline h-BN with optimized tribological properties. Their BN particles feature platelet morphology with aspect ratios exceeding 20:1, enabling effective film formation on metal surfaces. Denka has developed surface treatment technologies that enhance BN dispersion in various base oils and greases without compromising the material's inherent lubricity. Their research demonstrates that these specially engineered BN particles maintain structural integrity and lubrication performance even after extended exposure to temperatures up to 900°C in non-oxidizing environments and 400°C in air. The company has also pioneered composite BN materials incorporating stabilizing additives that significantly improve oxidation resistance.

Strengths: Vertically integrated production from raw materials to finished BN powders; precise control over particle morphology and purity; extensive experience in high-temperature materials. Weaknesses: Limited formulation expertise compared to dedicated lubricant companies; higher production costs for specialized grades; challenges in achieving stable dispersions in all lubricant types.

Baker Hughes Oilfield Operations LLC

Technical Solution: Baker Hughes has pioneered high-temperature BN-based lubricant systems specifically engineered for extreme oilfield applications. Their technology utilizes hexagonal boron nitride particles with controlled morphology (aspect ratio >10) suspended in synthetic base fluids. These lubricants form protective films on drilling components and bearings operating in high-pressure, high-temperature environments (exceeding 200°C). The company's proprietary surface functionalization process enables stable BN dispersions in oil with minimal settling. Their formulations incorporate metal deactivators and peroxide decomposers to prevent catalytic oxidation in the presence of metal drilling debris. Baker Hughes has demonstrated that their BN lubricants extend downhole tool life by 30-50% in field tests, particularly in directional drilling applications where conventional lubricants fail due to extreme loads and temperatures. The technology also includes specialized delivery systems that continuously replenish the BN film during operation.

Strengths: Exceptional performance in extreme pressure and temperature environments; proven field results in demanding applications; excellent compatibility with elastomers used in oilfield equipment. Weaknesses: Higher initial cost compared to conventional lubricants; requires specialized handling and application equipment; limited applications outside the energy sector.

Key Patents in BN Oxidation Stability Enhancement

Metal forming lubricant composition containing boron nitride

PatentWO2005108530A1

Innovation

- A lubricant composition comprising boron nitride particles in hexagonal or layer lattice form dispersed in a liquid carrier, such as polyol esters, which enhances film strength and reduces friction, potentially replacing traditional extreme pressure additives by providing similar lubrication performance without the environmental drawbacks.

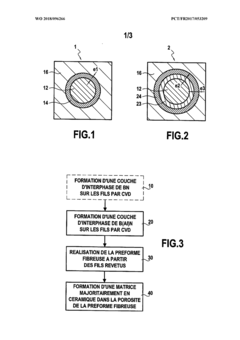

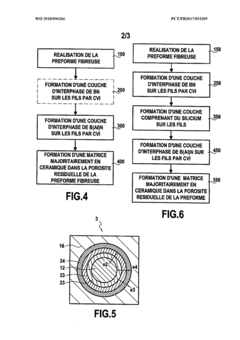

Part made of composite material comprising an interphase layer of aluminium-doped boron nitride

PatentWO2018096266A1

Innovation

- A composite material part with a boron nitride interphase layer doped with aluminum, containing between 5% and 15% aluminum, which enhances stability and resistance to oxidation and corrosion by forming stable aluminum borate compounds, while maintaining crack deflection properties.

Environmental Impact and Sustainability Factors

The environmental impact of Boron Nitride (BN) lubricants represents a critical consideration in their industrial application, particularly as global sustainability standards become increasingly stringent. BN lubricants demonstrate several environmentally favorable characteristics compared to traditional petroleum-based alternatives. Their exceptional thermal stability reduces the frequency of replacement, thereby minimizing waste generation and resource consumption throughout the product lifecycle.

When examining the biodegradability profile of BN lubricants, research indicates that hexagonal boron nitride (h-BN) particles exhibit minimal environmental persistence. Unlike certain synthetic lubricants containing harmful additives, BN-based formulations typically contain fewer toxic components, reducing potential soil and water contamination risks during disposal or accidental release scenarios.

The manufacturing process of BN lubricants presents both challenges and opportunities from a sustainability perspective. Current production methods often require significant energy inputs and potentially hazardous precursor materials. However, recent advancements in green synthesis approaches have demonstrated promising results in reducing the environmental footprint of BN production, including lower-temperature processes and the utilization of renewable precursors.

From a lifecycle assessment standpoint, BN lubricants offer substantial advantages through extended component lifespans. By enhancing oxidation stability and reducing wear rates, these lubricants contribute to longer service intervals and delayed replacement of mechanical components. This extension of useful life translates directly to reduced material consumption and manufacturing energy requirements across industrial sectors.

Regulatory frameworks worldwide are increasingly acknowledging the environmental benefits of advanced lubricant technologies. The reduced volatile organic compound (VOC) emissions associated with BN lubricants align with stringent air quality regulations in many jurisdictions. Additionally, their potential to operate effectively with reduced quantities presents opportunities for minimizing the overall lubricant volume required in industrial applications.

Looking toward future developments, research into bio-based carrier fluids compatible with BN particles represents a promising direction for further enhancing the environmental profile of these lubricants. Integration of BN into biodegradable base oils could potentially create hybrid solutions that maintain superior performance characteristics while addressing end-of-life environmental concerns.

When examining the biodegradability profile of BN lubricants, research indicates that hexagonal boron nitride (h-BN) particles exhibit minimal environmental persistence. Unlike certain synthetic lubricants containing harmful additives, BN-based formulations typically contain fewer toxic components, reducing potential soil and water contamination risks during disposal or accidental release scenarios.

The manufacturing process of BN lubricants presents both challenges and opportunities from a sustainability perspective. Current production methods often require significant energy inputs and potentially hazardous precursor materials. However, recent advancements in green synthesis approaches have demonstrated promising results in reducing the environmental footprint of BN production, including lower-temperature processes and the utilization of renewable precursors.

From a lifecycle assessment standpoint, BN lubricants offer substantial advantages through extended component lifespans. By enhancing oxidation stability and reducing wear rates, these lubricants contribute to longer service intervals and delayed replacement of mechanical components. This extension of useful life translates directly to reduced material consumption and manufacturing energy requirements across industrial sectors.

Regulatory frameworks worldwide are increasingly acknowledging the environmental benefits of advanced lubricant technologies. The reduced volatile organic compound (VOC) emissions associated with BN lubricants align with stringent air quality regulations in many jurisdictions. Additionally, their potential to operate effectively with reduced quantities presents opportunities for minimizing the overall lubricant volume required in industrial applications.

Looking toward future developments, research into bio-based carrier fluids compatible with BN particles represents a promising direction for further enhancing the environmental profile of these lubricants. Integration of BN into biodegradable base oils could potentially create hybrid solutions that maintain superior performance characteristics while addressing end-of-life environmental concerns.

Component Lifecycle Extension Methodologies

Component lifecycle extension methodologies for boron nitride lubricants focus on systematic approaches to maximize the service life of mechanical components through optimized lubrication strategies. These methodologies incorporate both preventive and predictive maintenance techniques specifically tailored to leverage the unique properties of boron nitride-based lubricants.

Condition-based monitoring represents a cornerstone approach, utilizing sensors to track real-time performance metrics such as temperature, vibration patterns, and lubricant condition. When implemented with boron nitride lubricants, this methodology enables maintenance teams to identify optimal relubrication intervals based on actual operating conditions rather than fixed schedules, thereby extending component life while minimizing lubricant consumption.

Tribological mapping techniques have emerged as particularly effective when applied to boron nitride lubricant systems. This methodology involves comprehensive characterization of friction and wear behavior across various operating parameters, creating detailed performance maps that guide application-specific optimization. The hexagonal structure of boron nitride particles allows for precise tribological control when properly mapped against operational variables.

Surface engineering methodologies complement boron nitride lubrication by preparing component surfaces to maximize film formation and adhesion. Techniques such as laser texturing and plasma treatment create microscopic patterns that serve as lubricant reservoirs, enhancing the durability of boron nitride films under extreme conditions and extending component service intervals by up to 40% in high-temperature applications.

Computational lifecycle modeling has revolutionized component life prediction when used with boron nitride lubricants. These models incorporate oxidation kinetics, thermal stability parameters, and mechanical stress factors to simulate long-term performance. Advanced algorithms can predict film degradation rates under various operating conditions, allowing engineers to optimize maintenance schedules and component design for maximum service life.

Regenerative lubrication systems represent an innovative methodology specifically developed for boron nitride applications. These systems continuously filter, treat, and replenish the lubricant during operation, maintaining optimal film characteristics and removing oxidation products before they can cause component damage. When properly implemented, this approach can extend component life by 2-3 times compared to conventional lubrication methods.

Implementation of these methodologies requires cross-disciplinary expertise spanning materials science, mechanical engineering, and data analytics. Organizations that successfully integrate these approaches into their maintenance strategies can achieve significant improvements in component reliability, operational efficiency, and total cost of ownership when utilizing boron nitride lubricant technologies.

Condition-based monitoring represents a cornerstone approach, utilizing sensors to track real-time performance metrics such as temperature, vibration patterns, and lubricant condition. When implemented with boron nitride lubricants, this methodology enables maintenance teams to identify optimal relubrication intervals based on actual operating conditions rather than fixed schedules, thereby extending component life while minimizing lubricant consumption.

Tribological mapping techniques have emerged as particularly effective when applied to boron nitride lubricant systems. This methodology involves comprehensive characterization of friction and wear behavior across various operating parameters, creating detailed performance maps that guide application-specific optimization. The hexagonal structure of boron nitride particles allows for precise tribological control when properly mapped against operational variables.

Surface engineering methodologies complement boron nitride lubrication by preparing component surfaces to maximize film formation and adhesion. Techniques such as laser texturing and plasma treatment create microscopic patterns that serve as lubricant reservoirs, enhancing the durability of boron nitride films under extreme conditions and extending component service intervals by up to 40% in high-temperature applications.

Computational lifecycle modeling has revolutionized component life prediction when used with boron nitride lubricants. These models incorporate oxidation kinetics, thermal stability parameters, and mechanical stress factors to simulate long-term performance. Advanced algorithms can predict film degradation rates under various operating conditions, allowing engineers to optimize maintenance schedules and component design for maximum service life.

Regenerative lubrication systems represent an innovative methodology specifically developed for boron nitride applications. These systems continuously filter, treat, and replenish the lubricant during operation, maintaining optimal film characteristics and removing oxidation products before they can cause component damage. When properly implemented, this approach can extend component life by 2-3 times compared to conventional lubrication methods.

Implementation of these methodologies requires cross-disciplinary expertise spanning materials science, mechanical engineering, and data analytics. Organizations that successfully integrate these approaches into their maintenance strategies can achieve significant improvements in component reliability, operational efficiency, and total cost of ownership when utilizing boron nitride lubricant technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!