Boron Nitride In Vacuum Systems: Outgassing, Cleanliness And Electrical Isolation

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Vacuum Applications Background and Objectives

Boron Nitride (BN) has emerged as a critical material in vacuum system applications due to its unique combination of properties including high thermal conductivity, excellent electrical insulation, and chemical stability. The evolution of vacuum technology has continuously demanded materials that can withstand extreme conditions while maintaining system integrity, leading to increased interest in advanced ceramics like BN.

Historically, vacuum systems relied primarily on traditional materials such as stainless steel, alumina, and quartz. However, as applications became more sophisticated—particularly in semiconductor manufacturing, aerospace, and scientific research—the limitations of these conventional materials became apparent. The introduction of BN into vacuum applications represents a significant technological advancement addressing these limitations.

The primary technical objective in utilizing BN in vacuum systems is to achieve optimal performance in three critical areas: minimizing outgassing, maintaining cleanliness, and providing reliable electrical isolation. Outgassing—the release of trapped gases from materials under vacuum—can compromise vacuum quality and contaminate sensitive processes. BN's crystalline structure offers potentially lower outgassing rates compared to many alternative materials, making it particularly valuable for ultra-high vacuum (UHV) applications.

System cleanliness is another paramount concern, especially in semiconductor fabrication and scientific instrumentation where even microscopic contaminants can cause catastrophic failures. BN's chemical inertness and stability at high temperatures suggest excellent compatibility with clean vacuum environments, though comprehensive characterization remains necessary.

Electrical isolation within vacuum systems presents unique challenges, as many traditional insulators exhibit problematic behaviors under vacuum conditions, including surface charging, tracking, or breakdown. BN's exceptional dielectric properties and stability under vacuum make it a promising candidate for electrical isolation components in these demanding environments.

The technological trajectory of BN in vacuum applications has accelerated in recent years, driven by increasing demands in semiconductor manufacturing, space technology, and particle physics research. Each of these fields requires progressively more stringent vacuum conditions, pushing the boundaries of material performance.

This technical investigation aims to comprehensively evaluate BN's capabilities and limitations specifically related to outgassing characteristics, cleanliness standards, and electrical isolation properties in vacuum environments. By establishing a clear understanding of these parameters, we can better determine optimal applications and identify areas requiring further development to maximize BN's utility in advanced vacuum systems.

Historically, vacuum systems relied primarily on traditional materials such as stainless steel, alumina, and quartz. However, as applications became more sophisticated—particularly in semiconductor manufacturing, aerospace, and scientific research—the limitations of these conventional materials became apparent. The introduction of BN into vacuum applications represents a significant technological advancement addressing these limitations.

The primary technical objective in utilizing BN in vacuum systems is to achieve optimal performance in three critical areas: minimizing outgassing, maintaining cleanliness, and providing reliable electrical isolation. Outgassing—the release of trapped gases from materials under vacuum—can compromise vacuum quality and contaminate sensitive processes. BN's crystalline structure offers potentially lower outgassing rates compared to many alternative materials, making it particularly valuable for ultra-high vacuum (UHV) applications.

System cleanliness is another paramount concern, especially in semiconductor fabrication and scientific instrumentation where even microscopic contaminants can cause catastrophic failures. BN's chemical inertness and stability at high temperatures suggest excellent compatibility with clean vacuum environments, though comprehensive characterization remains necessary.

Electrical isolation within vacuum systems presents unique challenges, as many traditional insulators exhibit problematic behaviors under vacuum conditions, including surface charging, tracking, or breakdown. BN's exceptional dielectric properties and stability under vacuum make it a promising candidate for electrical isolation components in these demanding environments.

The technological trajectory of BN in vacuum applications has accelerated in recent years, driven by increasing demands in semiconductor manufacturing, space technology, and particle physics research. Each of these fields requires progressively more stringent vacuum conditions, pushing the boundaries of material performance.

This technical investigation aims to comprehensively evaluate BN's capabilities and limitations specifically related to outgassing characteristics, cleanliness standards, and electrical isolation properties in vacuum environments. By establishing a clear understanding of these parameters, we can better determine optimal applications and identify areas requiring further development to maximize BN's utility in advanced vacuum systems.

Market Demand Analysis for High-Performance Vacuum Materials

The global market for high-performance vacuum materials, particularly boron nitride (BN), has witnessed substantial growth driven by increasing demands across multiple industries. The semiconductor manufacturing sector represents the largest market segment, valued at approximately $2.3 billion in 2022, with projections indicating a compound annual growth rate (CAGR) of 6.8% through 2028. This growth is primarily attributed to the critical need for materials that maintain exceptional electrical isolation properties while minimizing outgassing in ultra-high vacuum (UHV) environments.

Aerospace and defense industries constitute the second-largest market segment, where vacuum system components must withstand extreme conditions while maintaining structural integrity and cleanliness. Market research indicates this segment reached $1.7 billion in 2022, with anticipated growth exceeding 7% annually over the next five years, driven by increased satellite deployments and advanced propulsion systems development.

The research and scientific instrumentation market, though smaller at $850 million, demonstrates the highest growth potential at 9.2% CAGR, as advanced materials science and quantum computing research facilities require increasingly sophisticated vacuum systems with superior electrical isolation capabilities.

Regional analysis reveals Asia-Pacific dominates the market with 42% share, led by semiconductor manufacturing hubs in Taiwan, South Korea, and Japan. North America follows at 31%, with significant demand from aerospace, defense, and research institutions. Europe accounts for 22% of the market, primarily driven by scientific research facilities and precision manufacturing.

Customer requirements analysis indicates five critical performance parameters driving market demand: outgassing rates below 1×10^-10 Torr·L/s·cm², electrical breakdown strength exceeding 20 kV/mm, thermal stability above 1500°C, particle generation below Class 10 cleanroom standards, and resistance to plasma erosion in reactive environments.

Industry surveys reveal growing demand for customized boron nitride components that address specific vacuum application challenges, with 78% of respondents indicating willingness to pay premium prices for materials demonstrating superior outgassing characteristics and electrical isolation properties simultaneously.

The market landscape is further shaped by increasingly stringent requirements in semiconductor manufacturing, where process nodes below 3nm demand unprecedented vacuum purity levels. This trend is expected to accelerate demand for advanced boron nitride formulations that offer improved performance over traditional alumina and other ceramic materials in vacuum environments.

Aerospace and defense industries constitute the second-largest market segment, where vacuum system components must withstand extreme conditions while maintaining structural integrity and cleanliness. Market research indicates this segment reached $1.7 billion in 2022, with anticipated growth exceeding 7% annually over the next five years, driven by increased satellite deployments and advanced propulsion systems development.

The research and scientific instrumentation market, though smaller at $850 million, demonstrates the highest growth potential at 9.2% CAGR, as advanced materials science and quantum computing research facilities require increasingly sophisticated vacuum systems with superior electrical isolation capabilities.

Regional analysis reveals Asia-Pacific dominates the market with 42% share, led by semiconductor manufacturing hubs in Taiwan, South Korea, and Japan. North America follows at 31%, with significant demand from aerospace, defense, and research institutions. Europe accounts for 22% of the market, primarily driven by scientific research facilities and precision manufacturing.

Customer requirements analysis indicates five critical performance parameters driving market demand: outgassing rates below 1×10^-10 Torr·L/s·cm², electrical breakdown strength exceeding 20 kV/mm, thermal stability above 1500°C, particle generation below Class 10 cleanroom standards, and resistance to plasma erosion in reactive environments.

Industry surveys reveal growing demand for customized boron nitride components that address specific vacuum application challenges, with 78% of respondents indicating willingness to pay premium prices for materials demonstrating superior outgassing characteristics and electrical isolation properties simultaneously.

The market landscape is further shaped by increasingly stringent requirements in semiconductor manufacturing, where process nodes below 3nm demand unprecedented vacuum purity levels. This trend is expected to accelerate demand for advanced boron nitride formulations that offer improved performance over traditional alumina and other ceramic materials in vacuum environments.

Current Challenges in BN Implementation for Vacuum Systems

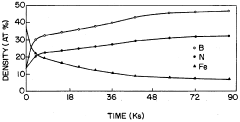

Despite the promising properties of Boron Nitride (BN) in vacuum systems, several significant challenges impede its widespread implementation. The foremost concern relates to outgassing behavior, as BN materials can release adsorbed gases when placed in vacuum environments. This phenomenon is particularly problematic in ultra-high vacuum (UHV) applications where even minimal gas release can compromise system performance. Research indicates that hexagonal BN (h-BN) exhibits lower outgassing rates compared to cubic BN (c-BN), yet both forms require extensive pre-treatment protocols including vacuum baking at elevated temperatures (typically 800-1000°C) to achieve acceptable outgassing levels.

Cleanliness requirements present another substantial hurdle. BN materials often contain manufacturing impurities that can contaminate sensitive vacuum environments. These contaminants include metallic particles, boron oxides, and various organic compounds introduced during synthesis or handling. The porous nature of certain BN formulations exacerbates this issue by trapping contaminants within the material structure, making thorough cleaning procedures essential yet challenging to implement effectively.

The electrical isolation properties of BN, while theoretically excellent, face practical limitations in vacuum system applications. Surface charging effects can develop under certain conditions, particularly when BN components are subjected to electron or ion bombardment. This charging phenomenon can disrupt sensitive measurements and affect the trajectory of charged particles in analytical instruments. Additionally, the electrical resistivity of BN can decrease at elevated temperatures, compromising its insulating performance in high-temperature vacuum applications.

Mechanical stability represents another significant challenge. BN components, particularly those with complex geometries, may experience dimensional changes or develop microcracks when subjected to thermal cycling in vacuum environments. The differential thermal expansion between BN and metal mounting hardware can induce mechanical stress, potentially leading to component failure during system operation or maintenance cycles.

Manufacturing consistency poses ongoing difficulties for vacuum system designers. Variations in BN material properties between production batches can lead to unpredictable performance in vacuum applications. These inconsistencies stem from differences in grain size, density, crystalline orientation, and impurity concentrations that occur during the manufacturing process. The lack of standardized testing protocols specifically designed for vacuum applications further complicates material selection and quality control procedures.

Cleanliness requirements present another substantial hurdle. BN materials often contain manufacturing impurities that can contaminate sensitive vacuum environments. These contaminants include metallic particles, boron oxides, and various organic compounds introduced during synthesis or handling. The porous nature of certain BN formulations exacerbates this issue by trapping contaminants within the material structure, making thorough cleaning procedures essential yet challenging to implement effectively.

The electrical isolation properties of BN, while theoretically excellent, face practical limitations in vacuum system applications. Surface charging effects can develop under certain conditions, particularly when BN components are subjected to electron or ion bombardment. This charging phenomenon can disrupt sensitive measurements and affect the trajectory of charged particles in analytical instruments. Additionally, the electrical resistivity of BN can decrease at elevated temperatures, compromising its insulating performance in high-temperature vacuum applications.

Mechanical stability represents another significant challenge. BN components, particularly those with complex geometries, may experience dimensional changes or develop microcracks when subjected to thermal cycling in vacuum environments. The differential thermal expansion between BN and metal mounting hardware can induce mechanical stress, potentially leading to component failure during system operation or maintenance cycles.

Manufacturing consistency poses ongoing difficulties for vacuum system designers. Variations in BN material properties between production batches can lead to unpredictable performance in vacuum applications. These inconsistencies stem from differences in grain size, density, crystalline orientation, and impurity concentrations that occur during the manufacturing process. The lack of standardized testing protocols specifically designed for vacuum applications further complicates material selection and quality control procedures.

Current BN Solutions for Outgassing and Electrical Isolation

01 Boron Nitride Outgassing Properties and Control Methods

Boron nitride materials exhibit low outgassing characteristics, making them suitable for high-vacuum and clean environments. Various processing techniques can further reduce outgassing, including high-temperature treatment, purification processes, and specialized sintering methods. These treatments remove volatile impurities and stabilize the material structure, resulting in boron nitride components with minimal contamination release under vacuum or high-temperature conditions.- Boron Nitride for Electrical Isolation Applications: Boron nitride materials are utilized for their excellent electrical isolation properties in various electronic and semiconductor applications. The high electrical resistivity and dielectric strength of boron nitride make it an ideal material for insulating components in high-temperature and high-voltage environments. These materials can be formulated into various forms such as films, coatings, or substrates to provide reliable electrical isolation while maintaining thermal conductivity, which is crucial for heat dissipation in electronic devices.

- Outgassing Characteristics and Control Methods for Boron Nitride: The outgassing behavior of boron nitride materials is critical in high-vacuum and clean environments. Various processing techniques have been developed to minimize outgassing, including high-temperature annealing, specialized purification methods, and surface treatments. These processes help remove volatile impurities and adsorbed gases from the boron nitride structure, resulting in materials suitable for space applications, semiconductor manufacturing, and other environments where gas release could compromise system performance or contaminate sensitive components.

- Cleanliness Standards and Purification of Boron Nitride: Achieving high cleanliness levels in boron nitride materials involves specialized purification techniques to remove metallic impurities, carbon contaminants, and other unwanted elements. Methods such as chemical vapor deposition, hot isostatic pressing, and acid leaching are employed to produce ultra-pure boron nitride suitable for critical applications. The purification processes are designed to maintain the structural integrity and beneficial properties of boron nitride while enhancing its cleanliness for use in environments with stringent contamination requirements.

- Boron Nitride Composites for Enhanced Performance: Boron nitride can be combined with other materials to create composites with enhanced properties for specific applications. These composites often feature improved mechanical strength, thermal stability, and reduced outgassing compared to pure boron nitride. By incorporating materials such as silicon carbide, aluminum oxide, or various polymers, the resulting composites can be tailored to provide optimal electrical isolation while addressing challenges related to outgassing and cleanliness in demanding operational environments.

- Testing and Characterization Methods for Boron Nitride Properties: Various analytical techniques are employed to evaluate the electrical isolation properties, outgassing characteristics, and cleanliness of boron nitride materials. These methods include thermal desorption spectroscopy, residual gas analysis, surface resistivity measurements, and dielectric breakdown testing. Advanced microscopy and spectroscopy techniques are also utilized to characterize the microstructure and composition of boron nitride, ensuring that the material meets the required specifications for high-performance applications where electrical isolation and minimal outgassing are critical.

02 Electrical Isolation Properties of Boron Nitride Composites

Boron nitride possesses excellent electrical insulation properties while maintaining good thermal conductivity. This combination makes it valuable for applications requiring electrical isolation in high-temperature or high-power environments. Various composite formulations enhance these properties through the addition of specific dopants or by controlling the crystalline structure. The electrical resistivity can be tailored by adjusting composition and processing parameters to meet specific application requirements.Expand Specific Solutions03 Cleanliness Standards and Purification Techniques

Achieving high cleanliness levels in boron nitride materials involves specialized purification techniques including chemical treatments, high-temperature processing, and controlled atmosphere sintering. These methods effectively remove metallic impurities, carbon contaminants, and other unwanted elements that could affect performance. Ultra-high purity boron nitride can be produced through multi-stage purification processes, resulting in materials suitable for semiconductor manufacturing, aerospace applications, and other cleanliness-critical environments.Expand Specific Solutions04 Thermal Stability and High-Temperature Applications

Boron nitride exhibits exceptional thermal stability with minimal degradation at elevated temperatures, maintaining its structural integrity and low outgassing characteristics. This property makes it ideal for high-temperature applications in aerospace, semiconductor processing, and advanced manufacturing. The material's resistance to thermal shock and chemical stability at high temperatures contribute to its reliability in extreme environments where cleanliness and dimensional stability are critical requirements.Expand Specific Solutions05 Surface Treatment and Coating Technologies

Surface modification techniques for boron nitride materials can enhance their electrical isolation properties and reduce outgassing. These include specialized coatings, chemical treatments, and plasma processing that create barrier layers or modify surface chemistry. Such treatments improve the material's compatibility with other components, enhance its resistance to environmental factors, and optimize its performance in specific applications requiring high cleanliness standards and reliable electrical isolation.Expand Specific Solutions

Key Industry Players in Advanced Vacuum Components

Boron Nitride in vacuum systems is currently in an early growth phase, with increasing applications in high-performance vacuum environments requiring electrical isolation and minimal contamination. The market size is expanding as industries recognize BN's exceptional thermal stability and low outgassing properties. Technologically, companies like BNNT Materials LLC are pioneering specialized BN nanotubes, while established corporations including Toyota Motor Corp., General Electric, and Mitsubishi Heavy Industries are integrating BN components into advanced vacuum systems. Research institutions such as the National Research Council of Canada and Industrial Technology Research Institute are advancing fundamental understanding of BN behavior in vacuum environments. The competitive landscape features both specialized materials providers and large industrial conglomerates developing proprietary BN formulations for vacuum applications where cleanliness and electrical isolation are critical.

BNNT Materials LLC

Technical Solution: BNNT Materials LLC has developed proprietary high-temperature, high-pressure (HTHP) synthesis technology for producing high-quality boron nitride nanotubes (BNNTs) specifically engineered for vacuum system applications. Their BNNTs exhibit exceptional thermal stability up to 900°C in vacuum environments with minimal outgassing rates (<10^-9 Torr·L/s·cm²), making them ideal for ultra-high vacuum (UHV) applications. The company's purification process removes residual catalysts and amorphous boron nitride, resulting in >99% pure BNNTs with superior electrical isolation properties (resistance >10^14 Ω·cm) while maintaining thermal conductivity of approximately 200-300 W/m·K. Their surface treatment technology further reduces moisture absorption and outgassing through hydrophobic functionalization, enabling faster pump-down times in vacuum chambers.

Strengths: Industry-leading purity levels specifically optimized for UHV environments; proprietary surface treatments that minimize outgassing; excellent electrical isolation properties while maintaining thermal conductivity. Weaknesses: Higher production costs compared to conventional hexagonal boron nitride (h-BN); limited scalability for very large vacuum system components; requires specialized handling protocols.

General Electric Company

Technical Solution: General Electric has developed advanced boron nitride ceramic composites for vacuum system applications in their power generation and aerospace divisions. Their technology incorporates cubic boron nitride (c-BN) and hexagonal boron nitride (h-BN) in specialized matrices that demonstrate outgassing rates below 10^-8 Torr·L/s·cm² after standard vacuum bakeout procedures. GE's proprietary hot isostatic pressing (HIP) manufacturing process creates high-density BN components (>98% theoretical density) with minimal internal porosity, significantly reducing trapped gases and improving vacuum performance. Their BN components maintain electrical resistivity exceeding 10^12 Ω·cm at elevated temperatures (up to 800°C), making them suitable for high-voltage vacuum applications in power systems. GE has also developed specialized surface cleaning and passivation treatments that minimize hydrocarbon contamination and water vapor adsorption on BN surfaces.

Strengths: Extensive industrial application experience in harsh environments; highly engineered composites with optimized density and outgassing characteristics; established manufacturing infrastructure for complex geometries. Weaknesses: Higher cost compared to traditional ceramic insulators; requires specialized processing equipment; limited flexibility for custom formulations outside established product lines.

Critical Patents and Research on BN Vacuum Performance

Method of sputtering a mixture of hexagonal boron nitride and stainless steel onto a steel vessel and heating the film so as to precipitate the boron nitride onto the film surface

PatentInactiveUS5192409A

Innovation

- A low-temperature sputtering/vacuum deposition method using a mixture of stainless steel and boron nitride is applied to metal or alloy surfaces, allowing hexagonal boron nitride to precipitate at around 300°C, enabling coating on a wide range of materials without structural degradation.

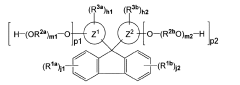

Boron nitride dispersant

PatentActiveJP2015199064A

Innovation

- A dispersant comprising a fluorene compound with specific structural features, such as organic ammonium salts or alkali metal salts, is used to disperse boron nitride in water at high concentrations, allowing easy removal and reuse.

Vacuum System Cleanliness Standards and Compliance

Maintaining cleanliness in vacuum systems is paramount for ensuring optimal performance, particularly when incorporating materials like boron nitride. The semiconductor and aerospace industries have established stringent standards that govern vacuum system cleanliness, with organizations such as SEMI, ASTM International, and ISO providing comprehensive guidelines.

The SEMI standards, particularly SEMI E49.6, define acceptable contamination levels for high-vacuum systems used in semiconductor manufacturing. These standards specify maximum allowable particle counts, hydrocarbon residues, and outgassing rates that directly impact the performance of boron nitride components within vacuum environments.

ASTM E1559 offers standardized test methods for measuring outgassing rates of materials intended for space applications, including boron nitride ceramics. This standard provides crucial protocols for evaluating the mass loss and condensable outgassing characteristics under vacuum conditions, enabling engineers to predict long-term performance.

ISO 14644 standards, while primarily focused on cleanroom classifications, extend to vacuum system cleanliness requirements. These standards establish protocols for testing, monitoring, and maintaining cleanliness levels that are essential when working with electrically isolating materials like boron nitride in vacuum chambers.

Compliance with these standards necessitates rigorous cleaning procedures for boron nitride components. Typical protocols include ultrasonic cleaning with specialized solvents, vacuum baking at controlled temperatures to accelerate outgassing, and surface treatment techniques that minimize contaminant adsorption. Documentation of these cleaning processes is mandatory for quality assurance and traceability.

Verification methods for cleanliness compliance include residual gas analysis (RGA), which identifies and quantifies outgassing species from boron nitride surfaces. Particle counting techniques and surface analysis methods such as X-ray photoelectron spectroscopy (XPS) provide additional verification of surface cleanliness levels.

The electrical isolation properties of boron nitride introduce unique considerations for cleanliness standards. Static charge accumulation on boron nitride surfaces can attract contaminants, potentially compromising vacuum integrity. Therefore, specialized handling procedures and antistatic treatments are often incorporated into cleanliness protocols.

Recent advancements in cleanliness standards have begun addressing nanoscale contamination concerns, particularly relevant for high-precision applications utilizing boron nitride. These emerging standards recognize that even molecular-level contamination can significantly impact electrical isolation properties and overall vacuum system performance.

The SEMI standards, particularly SEMI E49.6, define acceptable contamination levels for high-vacuum systems used in semiconductor manufacturing. These standards specify maximum allowable particle counts, hydrocarbon residues, and outgassing rates that directly impact the performance of boron nitride components within vacuum environments.

ASTM E1559 offers standardized test methods for measuring outgassing rates of materials intended for space applications, including boron nitride ceramics. This standard provides crucial protocols for evaluating the mass loss and condensable outgassing characteristics under vacuum conditions, enabling engineers to predict long-term performance.

ISO 14644 standards, while primarily focused on cleanroom classifications, extend to vacuum system cleanliness requirements. These standards establish protocols for testing, monitoring, and maintaining cleanliness levels that are essential when working with electrically isolating materials like boron nitride in vacuum chambers.

Compliance with these standards necessitates rigorous cleaning procedures for boron nitride components. Typical protocols include ultrasonic cleaning with specialized solvents, vacuum baking at controlled temperatures to accelerate outgassing, and surface treatment techniques that minimize contaminant adsorption. Documentation of these cleaning processes is mandatory for quality assurance and traceability.

Verification methods for cleanliness compliance include residual gas analysis (RGA), which identifies and quantifies outgassing species from boron nitride surfaces. Particle counting techniques and surface analysis methods such as X-ray photoelectron spectroscopy (XPS) provide additional verification of surface cleanliness levels.

The electrical isolation properties of boron nitride introduce unique considerations for cleanliness standards. Static charge accumulation on boron nitride surfaces can attract contaminants, potentially compromising vacuum integrity. Therefore, specialized handling procedures and antistatic treatments are often incorporated into cleanliness protocols.

Recent advancements in cleanliness standards have begun addressing nanoscale contamination concerns, particularly relevant for high-precision applications utilizing boron nitride. These emerging standards recognize that even molecular-level contamination can significantly impact electrical isolation properties and overall vacuum system performance.

Thermal Management Considerations for BN in Vacuum Applications

Thermal management represents a critical consideration when implementing boron nitride (BN) materials in vacuum systems. BN's exceptional thermal conductivity, particularly in its hexagonal form (h-BN), enables efficient heat dissipation within vacuum environments where conventional cooling mechanisms are limited. The thermal conductivity of high-purity h-BN can reach 180-200 W/m·K in-plane, while maintaining electrical isolation properties that distinguish it from metallic thermal conductors.

In vacuum applications, the absence of convective cooling places greater demands on conductive heat transfer pathways. BN components serve as effective thermal interfaces between heat-generating elements and cooling structures while maintaining electrical isolation. This dual functionality proves particularly valuable in applications such as semiconductor processing equipment, particle accelerators, and space-based systems where thermal management and electrical isolation must coexist.

The anisotropic thermal properties of BN require careful orientation consideration during implementation. The in-plane thermal conductivity significantly exceeds through-plane values, necessitating strategic component design and placement to maximize heat transfer efficiency. Advanced manufacturing techniques, including hot pressing and spark plasma sintering, can optimize the microstructure of BN components to enhance thermal performance while maintaining vacuum compatibility.

Temperature stability represents another crucial aspect of BN thermal management in vacuum systems. BN maintains its structural integrity and thermal properties at temperatures exceeding 1000°C in vacuum, with minimal degradation or phase transformation. This high-temperature stability enables BN components to function reliably in extreme thermal environments where alternative materials would fail.

Interface thermal resistance between BN and adjacent materials requires careful consideration to maximize overall system thermal performance. Surface preparation techniques, including precision machining and specialized coatings, can minimize contact resistance at BN interfaces. Some applications employ thin metal films or specialized thermal interface materials compatible with vacuum environments to enhance thermal coupling between BN and adjacent components.

The thermal expansion behavior of BN in vacuum systems must be addressed during design phases to prevent mechanical stress or failure during thermal cycling. With a coefficient of thermal expansion of approximately 1-4 × 10^-6/K (depending on grade and direction), BN offers relatively low expansion rates compared to many metals, potentially creating stress at material interfaces during temperature fluctuations. Designers must incorporate appropriate mounting and interface strategies to accommodate differential thermal expansion.

Recent advancements in BN composite materials have yielded enhanced thermal management solutions for vacuum applications. BN-polymer composites with tailored thermal conductivity and BN-ceramic matrices provide customizable thermal management options while maintaining vacuum compatibility and electrical isolation properties.

In vacuum applications, the absence of convective cooling places greater demands on conductive heat transfer pathways. BN components serve as effective thermal interfaces between heat-generating elements and cooling structures while maintaining electrical isolation. This dual functionality proves particularly valuable in applications such as semiconductor processing equipment, particle accelerators, and space-based systems where thermal management and electrical isolation must coexist.

The anisotropic thermal properties of BN require careful orientation consideration during implementation. The in-plane thermal conductivity significantly exceeds through-plane values, necessitating strategic component design and placement to maximize heat transfer efficiency. Advanced manufacturing techniques, including hot pressing and spark plasma sintering, can optimize the microstructure of BN components to enhance thermal performance while maintaining vacuum compatibility.

Temperature stability represents another crucial aspect of BN thermal management in vacuum systems. BN maintains its structural integrity and thermal properties at temperatures exceeding 1000°C in vacuum, with minimal degradation or phase transformation. This high-temperature stability enables BN components to function reliably in extreme thermal environments where alternative materials would fail.

Interface thermal resistance between BN and adjacent materials requires careful consideration to maximize overall system thermal performance. Surface preparation techniques, including precision machining and specialized coatings, can minimize contact resistance at BN interfaces. Some applications employ thin metal films or specialized thermal interface materials compatible with vacuum environments to enhance thermal coupling between BN and adjacent components.

The thermal expansion behavior of BN in vacuum systems must be addressed during design phases to prevent mechanical stress or failure during thermal cycling. With a coefficient of thermal expansion of approximately 1-4 × 10^-6/K (depending on grade and direction), BN offers relatively low expansion rates compared to many metals, potentially creating stress at material interfaces during temperature fluctuations. Designers must incorporate appropriate mounting and interface strategies to accommodate differential thermal expansion.

Recent advancements in BN composite materials have yielded enhanced thermal management solutions for vacuum applications. BN-polymer composites with tailored thermal conductivity and BN-ceramic matrices provide customizable thermal management options while maintaining vacuum compatibility and electrical isolation properties.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!