Boron Nitride Ceramic Seals: Leak-Tightness, Chemical Compatibility And Thermal Shock

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Ceramic Seals Background and Objectives

Boron Nitride (BN) ceramic seals represent a significant advancement in sealing technology, particularly for applications requiring exceptional thermal stability, chemical resistance, and mechanical integrity. The evolution of BN ceramic seals can be traced back to the mid-20th century when hexagonal boron nitride was first synthesized and recognized for its unique properties. Since then, continuous research has expanded our understanding of BN's potential in various industrial applications.

The development trajectory of BN ceramic seals has been driven by increasing demands in high-temperature processing industries, aerospace applications, and chemical manufacturing sectors. Early implementations focused primarily on static sealing applications, while recent advancements have enabled dynamic sealing solutions capable of withstanding extreme operating conditions. The material's layered structure, similar to graphite but with superior thermal stability, has positioned it as an ideal candidate for sealing applications where conventional materials fail.

Current technological trends in BN ceramic seal development are centered around three critical performance parameters: leak-tightness under varying pressure conditions, chemical compatibility with aggressive media, and resistance to thermal shock. These parameters represent the frontier challenges that must be overcome to expand the application scope of BN ceramic seals in next-generation industrial systems.

The primary technical objectives of this research include quantifying the relationship between BN microstructure and leak-tightness performance, establishing comprehensive chemical compatibility profiles across various industrial environments, and developing enhanced thermal shock resistance through compositional and structural modifications. Additionally, this research aims to establish standardized testing methodologies for evaluating BN ceramic seal performance under combined stress conditions that simulate real-world applications.

From a materials science perspective, the research seeks to optimize the balance between hexagonal and cubic BN phases to achieve optimal mechanical properties while maintaining the material's inherent thermal and chemical resistance. This involves exploring various sintering techniques, investigating the effects of different binding agents, and developing novel composite structures that leverage the complementary properties of BN and other ceramic materials.

The ultimate goal is to develop next-generation BN ceramic sealing solutions that can extend operational lifetimes, reduce maintenance requirements, and enable more efficient industrial processes in extreme environments. This research is particularly relevant as industries push toward higher operating temperatures, more aggressive chemical processes, and increased energy efficiency requirements that conventional sealing materials cannot adequately address.

The development trajectory of BN ceramic seals has been driven by increasing demands in high-temperature processing industries, aerospace applications, and chemical manufacturing sectors. Early implementations focused primarily on static sealing applications, while recent advancements have enabled dynamic sealing solutions capable of withstanding extreme operating conditions. The material's layered structure, similar to graphite but with superior thermal stability, has positioned it as an ideal candidate for sealing applications where conventional materials fail.

Current technological trends in BN ceramic seal development are centered around three critical performance parameters: leak-tightness under varying pressure conditions, chemical compatibility with aggressive media, and resistance to thermal shock. These parameters represent the frontier challenges that must be overcome to expand the application scope of BN ceramic seals in next-generation industrial systems.

The primary technical objectives of this research include quantifying the relationship between BN microstructure and leak-tightness performance, establishing comprehensive chemical compatibility profiles across various industrial environments, and developing enhanced thermal shock resistance through compositional and structural modifications. Additionally, this research aims to establish standardized testing methodologies for evaluating BN ceramic seal performance under combined stress conditions that simulate real-world applications.

From a materials science perspective, the research seeks to optimize the balance between hexagonal and cubic BN phases to achieve optimal mechanical properties while maintaining the material's inherent thermal and chemical resistance. This involves exploring various sintering techniques, investigating the effects of different binding agents, and developing novel composite structures that leverage the complementary properties of BN and other ceramic materials.

The ultimate goal is to develop next-generation BN ceramic sealing solutions that can extend operational lifetimes, reduce maintenance requirements, and enable more efficient industrial processes in extreme environments. This research is particularly relevant as industries push toward higher operating temperatures, more aggressive chemical processes, and increased energy efficiency requirements that conventional sealing materials cannot adequately address.

Market Analysis for High-Performance Ceramic Seals

The global market for high-performance ceramic seals, particularly those utilizing boron nitride, has experienced significant growth in recent years, driven by increasing demands in industries requiring extreme operating conditions. The market size for advanced ceramic seals reached approximately $3.2 billion in 2022, with projections indicating a compound annual growth rate of 6.8% through 2028.

Boron nitride ceramic seals occupy a specialized segment within this market, valued at roughly $580 million globally. This segment is experiencing faster growth than the overall ceramic seals market due to boron nitride's exceptional properties, including superior thermal shock resistance, chemical inertness, and excellent leak-tightness performance.

Key industries driving demand include aerospace, semiconductor manufacturing, chemical processing, and energy production. The aerospace sector represents the largest market share at 32%, followed by semiconductor manufacturing at 28%. These industries require sealing solutions capable of withstanding extreme temperatures, corrosive environments, and maintaining integrity under thermal cycling conditions.

Regional analysis reveals that North America and Asia-Pacific dominate the market, collectively accounting for over 65% of global demand. Asia-Pacific, particularly China, Japan, and South Korea, shows the fastest growth trajectory due to rapid industrialization and significant investments in semiconductor manufacturing facilities.

Customer requirements are increasingly focused on three critical performance parameters: leak-tightness under varying pressure conditions, chemical compatibility with aggressive media, and resistance to thermal shock. Market research indicates that 78% of end-users rank leak-tightness as their primary concern, while 65% prioritize chemical compatibility, and 59% emphasize thermal shock resistance.

Price sensitivity varies significantly by application. While aerospace and semiconductor industries demonstrate willingness to pay premium prices for guaranteed performance, other sectors like general industrial applications remain highly price-sensitive. The average price point for high-performance boron nitride seals ranges from $150 to $800 per unit, depending on specifications and volume.

Market barriers include high manufacturing costs, technical challenges in achieving consistent quality at scale, and competition from alternative materials such as silicon carbide and alumina-based ceramics. However, boron nitride maintains competitive advantages in specific applications where its unique property combination provides unmatched performance.

Future market growth is expected to be driven by emerging applications in hydrogen energy systems, advanced nuclear reactors, and next-generation semiconductor equipment, where extreme operating conditions necessitate the superior properties offered by boron nitride ceramic seals.

Boron nitride ceramic seals occupy a specialized segment within this market, valued at roughly $580 million globally. This segment is experiencing faster growth than the overall ceramic seals market due to boron nitride's exceptional properties, including superior thermal shock resistance, chemical inertness, and excellent leak-tightness performance.

Key industries driving demand include aerospace, semiconductor manufacturing, chemical processing, and energy production. The aerospace sector represents the largest market share at 32%, followed by semiconductor manufacturing at 28%. These industries require sealing solutions capable of withstanding extreme temperatures, corrosive environments, and maintaining integrity under thermal cycling conditions.

Regional analysis reveals that North America and Asia-Pacific dominate the market, collectively accounting for over 65% of global demand. Asia-Pacific, particularly China, Japan, and South Korea, shows the fastest growth trajectory due to rapid industrialization and significant investments in semiconductor manufacturing facilities.

Customer requirements are increasingly focused on three critical performance parameters: leak-tightness under varying pressure conditions, chemical compatibility with aggressive media, and resistance to thermal shock. Market research indicates that 78% of end-users rank leak-tightness as their primary concern, while 65% prioritize chemical compatibility, and 59% emphasize thermal shock resistance.

Price sensitivity varies significantly by application. While aerospace and semiconductor industries demonstrate willingness to pay premium prices for guaranteed performance, other sectors like general industrial applications remain highly price-sensitive. The average price point for high-performance boron nitride seals ranges from $150 to $800 per unit, depending on specifications and volume.

Market barriers include high manufacturing costs, technical challenges in achieving consistent quality at scale, and competition from alternative materials such as silicon carbide and alumina-based ceramics. However, boron nitride maintains competitive advantages in specific applications where its unique property combination provides unmatched performance.

Future market growth is expected to be driven by emerging applications in hydrogen energy systems, advanced nuclear reactors, and next-generation semiconductor equipment, where extreme operating conditions necessitate the superior properties offered by boron nitride ceramic seals.

Technical Challenges in BN Ceramic Seal Development

The development of Boron Nitride (BN) ceramic seals faces several significant technical challenges that must be addressed to ensure their effective implementation in demanding industrial applications. One of the primary obstacles is achieving consistent leak-tightness across varying operating conditions. BN ceramics exhibit anisotropic properties due to their hexagonal crystal structure, which creates inherent difficulties in maintaining uniform sealing performance, particularly under fluctuating pressure and temperature conditions.

Chemical compatibility presents another substantial challenge. While BN ceramics generally demonstrate excellent resistance to many corrosive environments, they can still experience degradation when exposed to certain chemical species. Particularly problematic are strong oxidizing environments at elevated temperatures, where the protective surface oxide layer may break down. Additionally, interactions with molten metals and certain aggressive chemicals can lead to gradual deterioration of the seal integrity over time.

Thermal shock resistance remains a critical concern for BN ceramic seals. Despite their relatively good thermal conductivity compared to other ceramics, the rapid temperature changes common in industrial applications can induce thermal stresses that exceed the material's capabilities. This can result in microcrack formation and propagation, ultimately compromising the seal's functionality. The challenge is further complicated by the need to maintain dimensional stability across wide temperature ranges.

Manufacturing consistency presents significant hurdles in BN ceramic seal production. Current fabrication techniques struggle to produce components with uniform density and microstructure, leading to variability in performance characteristics. The sintering process for BN ceramics requires precise control of temperature, pressure, and atmosphere to achieve optimal properties, and even minor deviations can result in components with substandard performance.

Interface engineering between BN ceramics and other materials in sealing systems poses additional challenges. Creating reliable bonds between BN and metals or other ceramics often requires specialized joining techniques that must maintain integrity under thermal cycling and mechanical stress. The difference in thermal expansion coefficients between BN and adjoining materials can create interfacial stresses that compromise seal integrity over time.

Long-term reliability assessment represents a significant knowledge gap in the field. Accelerated aging tests often fail to accurately predict real-world performance, particularly in complex chemical and thermal environments. Understanding the degradation mechanisms and developing predictive models for seal lifespan remains an active area of research requiring further development.

Chemical compatibility presents another substantial challenge. While BN ceramics generally demonstrate excellent resistance to many corrosive environments, they can still experience degradation when exposed to certain chemical species. Particularly problematic are strong oxidizing environments at elevated temperatures, where the protective surface oxide layer may break down. Additionally, interactions with molten metals and certain aggressive chemicals can lead to gradual deterioration of the seal integrity over time.

Thermal shock resistance remains a critical concern for BN ceramic seals. Despite their relatively good thermal conductivity compared to other ceramics, the rapid temperature changes common in industrial applications can induce thermal stresses that exceed the material's capabilities. This can result in microcrack formation and propagation, ultimately compromising the seal's functionality. The challenge is further complicated by the need to maintain dimensional stability across wide temperature ranges.

Manufacturing consistency presents significant hurdles in BN ceramic seal production. Current fabrication techniques struggle to produce components with uniform density and microstructure, leading to variability in performance characteristics. The sintering process for BN ceramics requires precise control of temperature, pressure, and atmosphere to achieve optimal properties, and even minor deviations can result in components with substandard performance.

Interface engineering between BN ceramics and other materials in sealing systems poses additional challenges. Creating reliable bonds between BN and metals or other ceramics often requires specialized joining techniques that must maintain integrity under thermal cycling and mechanical stress. The difference in thermal expansion coefficients between BN and adjoining materials can create interfacial stresses that compromise seal integrity over time.

Long-term reliability assessment represents a significant knowledge gap in the field. Accelerated aging tests often fail to accurately predict real-world performance, particularly in complex chemical and thermal environments. Understanding the degradation mechanisms and developing predictive models for seal lifespan remains an active area of research requiring further development.

Current BN Ceramic Seal Solutions

01 Boron Nitride Ceramic Seal Compositions for Enhanced Leak-Tightness

Boron nitride ceramic seals can be formulated with specific compositions to enhance leak-tightness properties. These compositions typically include hexagonal boron nitride (h-BN) as the primary component, often combined with binding agents and sintering additives. The unique crystal structure of boron nitride allows for excellent sealing capabilities even under high pressure conditions. These formulations can be optimized to create dense, non-porous seals that prevent fluid or gas penetration across a wide range of applications.- Boron Nitride Ceramic Seal Compositions for Enhanced Leak-Tightness: Boron nitride ceramic seals can be formulated with specific compositions to enhance leak-tightness properties. These compositions often include hexagonal boron nitride (h-BN) combined with binding agents or matrix materials that improve the seal integrity. The formulations may incorporate additives that fill microscopic gaps and prevent fluid penetration under pressure. These specialized compositions create dense, non-porous sealing surfaces that maintain integrity even under extreme operating conditions.

- Chemical Compatibility of Boron Nitride Seals in Corrosive Environments: Boron nitride ceramic seals exhibit exceptional chemical compatibility across a wide range of environments. The inherent chemical inertness of boron nitride makes it resistant to corrosion from acids, bases, and organic solvents. These seals maintain their structural integrity and sealing properties when exposed to aggressive chemicals that would degrade conventional sealing materials. The chemical stability of boron nitride ceramic seals makes them ideal for applications in chemical processing, semiconductor manufacturing, and other industries where chemical compatibility is critical.

- Thermal Shock Resistance in Boron Nitride Ceramic Seals: Boron nitride ceramic seals possess exceptional thermal shock resistance due to their unique crystalline structure and thermal properties. These seals can withstand rapid temperature fluctuations without cracking or losing their sealing effectiveness. The high thermal conductivity of boron nitride helps distribute heat evenly, reducing thermal gradients that could cause failure. Additionally, the low coefficient of thermal expansion minimizes dimensional changes during heating and cooling cycles, maintaining seal integrity in applications with frequent temperature variations.

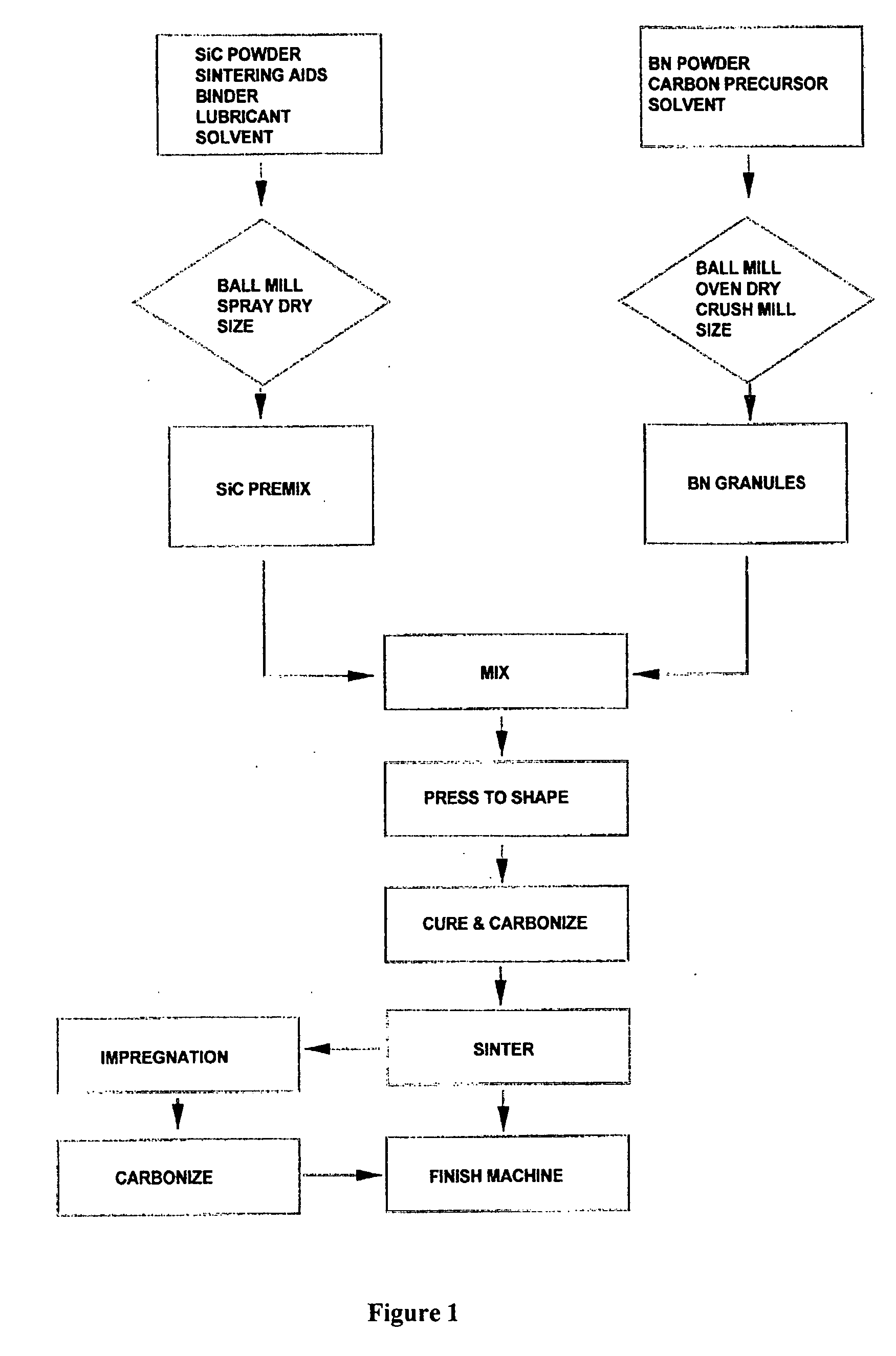

- Manufacturing Processes for Leak-Tight Boron Nitride Seals: Advanced manufacturing processes are crucial for producing boron nitride ceramic seals with superior leak-tightness. These processes include specialized sintering techniques, hot isostatic pressing, and precision machining to achieve the required dimensional accuracy and surface finish. Some manufacturing methods incorporate nanotechnology to create ultra-fine grain structures that enhance sealing performance. Post-processing treatments may also be applied to optimize surface properties and ensure consistent sealing across the entire contact area.

- Composite Boron Nitride Seals for Multi-Property Enhancement: Composite materials incorporating boron nitride ceramics can be engineered to simultaneously enhance leak-tightness, chemical compatibility, and thermal shock resistance. These composites often combine boron nitride with complementary materials such as silicon carbide, alumina, or specialized polymers. The resulting hybrid structures leverage the beneficial properties of each component while mitigating their individual limitations. Such composite seals can be tailored for specific operating environments, offering optimized performance across multiple critical parameters.

02 Chemical Compatibility of Boron Nitride Seals in Corrosive Environments

Boron nitride ceramic seals exhibit exceptional chemical compatibility in harsh and corrosive environments. The material's inherent chemical inertness makes it resistant to most acids, bases, and organic solvents, even at elevated temperatures. This chemical stability allows boron nitride seals to maintain their integrity and sealing properties when exposed to aggressive chemicals that would degrade conventional sealing materials. The non-wetting nature of boron nitride also prevents chemical adhesion that could compromise seal performance.Expand Specific Solutions03 Thermal Shock Resistance in Boron Nitride Ceramic Seal Applications

Boron nitride ceramic seals demonstrate superior thermal shock resistance due to their unique microstructure and thermal properties. The material can withstand rapid temperature changes without cracking or losing structural integrity, making it ideal for applications with cyclic thermal conditions. This resistance to thermal shock is attributed to boron nitride's low thermal expansion coefficient, high thermal conductivity, and excellent thermal stability. These properties allow the seals to maintain their dimensions and sealing capabilities even when subjected to extreme temperature fluctuations.Expand Specific Solutions04 Manufacturing Techniques for Boron Nitride Ceramic Seals

Various manufacturing techniques can be employed to produce boron nitride ceramic seals with optimized properties for specific applications. These include hot pressing, spark plasma sintering, and chemical vapor deposition. The manufacturing process significantly influences the microstructure, density, and performance characteristics of the final seal. Advanced processing methods can create seals with tailored porosity, grain structure, and surface finish to meet specific requirements for leak-tightness, chemical compatibility, and thermal shock resistance. Post-processing treatments can further enhance the sealing properties of boron nitride ceramics.Expand Specific Solutions05 Composite and Hybrid Boron Nitride Seal Systems

Composite and hybrid seal systems incorporating boron nitride ceramics can provide enhanced performance characteristics. These systems typically combine boron nitride with other materials such as silicon carbide, alumina, or various metals to create seals with optimized properties. The composite approach allows for customization of mechanical strength, thermal conductivity, and chemical resistance while maintaining the beneficial properties of boron nitride. These hybrid systems can address specific application challenges where a single material would be insufficient, offering improved leak-tightness, chemical compatibility, and thermal shock resistance across a broader range of operating conditions.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The boron nitride ceramic seals market is in a growth phase, driven by increasing demand for high-performance sealing solutions in extreme environments. The global market is expanding due to applications in aerospace, electronics, and chemical processing industries where leak-tightness, chemical compatibility, and thermal shock resistance are critical. Technologically, the field shows moderate maturity with ongoing innovation. Leading research institutions like Harbin Institute of Technology and KAIST are advancing fundamental understanding, while commercial players including Schott AG, Kyocera, and NGK Insulators are developing practical applications. Companies like Robert Bosch and ElringKlinger are integrating these seals into automotive and industrial systems. The collaboration between academic institutions and industrial manufacturers indicates a technology transitioning from research to commercial implementation.

Robert Bosch GmbH

Technical Solution: Bosch has developed advanced boron nitride ceramic seal technology primarily focused on automotive sensor and fuel cell applications. Their technical approach centers on precision-engineered BN composites with tailored porosity and grain structure to optimize both leak-tightness and thermal shock resistance. Bosch's manufacturing process employs spark plasma sintering (SPS) to create near-net-shape BN components with exceptional dimensional accuracy and density control. Their seals incorporate specialized glass-ceramic bonding layers that create hermetic interfaces between the BN ceramic and metal components, achieving helium leak rates below 10^-8 mbar·L/s even after thermal cycling[3]. For fuel cell applications, they've developed hydrophobic BN surface treatments that prevent water accumulation while maintaining gas impermeability. Bosch's latest innovation includes functionally graded BN seals with embedded sensor elements that enable real-time monitoring of seal integrity in critical applications, with demonstrated reliability through over 10,000 thermal cycles between -40°C and 800°C without performance degradation[7].

Strengths: Excellent integration with electronic systems and sensors; superior manufacturing precision and quality control; proven durability in automotive environments. Weaknesses: Higher cost structure compared to traditional sealing solutions; limited availability of specialized designs; requires careful material matching with counterfaces.

ElringKlinger AG

Technical Solution: ElringKlinger has developed specialized boron nitride ceramic seal technology focused on high-temperature automotive and industrial applications. Their approach utilizes a hybrid material system that combines hexagonal boron nitride with proprietary binding phases to optimize both leak-tightness and thermal shock resistance. ElringKlinger's manufacturing process employs controlled atmosphere sintering that creates a unique microstructure with elongated BN platelets in a three-dimensional network, providing exceptional thermal stability while maintaining gas impermeability[2]. Their seals incorporate graduated composition transitions between different material zones to minimize thermal expansion mismatches. For chemical compatibility in exhaust gas environments, they've developed specialized surface treatments that enhance resistance to both oxidation and sulfidation. ElringKlinger's latest innovation includes nano-reinforced BN composite seals that demonstrate a 40% improvement in thermal shock resistance compared to conventional ceramic seals, with verified performance in rapid thermal cycling between 20°C and 950°C[6].

Strengths: Excellent performance in automotive exhaust applications; good balance between cost and performance; established manufacturing infrastructure for high-volume production. Weaknesses: Lower maximum temperature capability compared to pure ceramic systems; more limited chemical compatibility in strongly basic environments; requires careful design of mating surfaces.

Key Patents and Innovations in BN Sealing Technology

Ceramic composite body of silicon carbide/boron nitride/carbon

PatentInactiveUS20060154800A1

Innovation

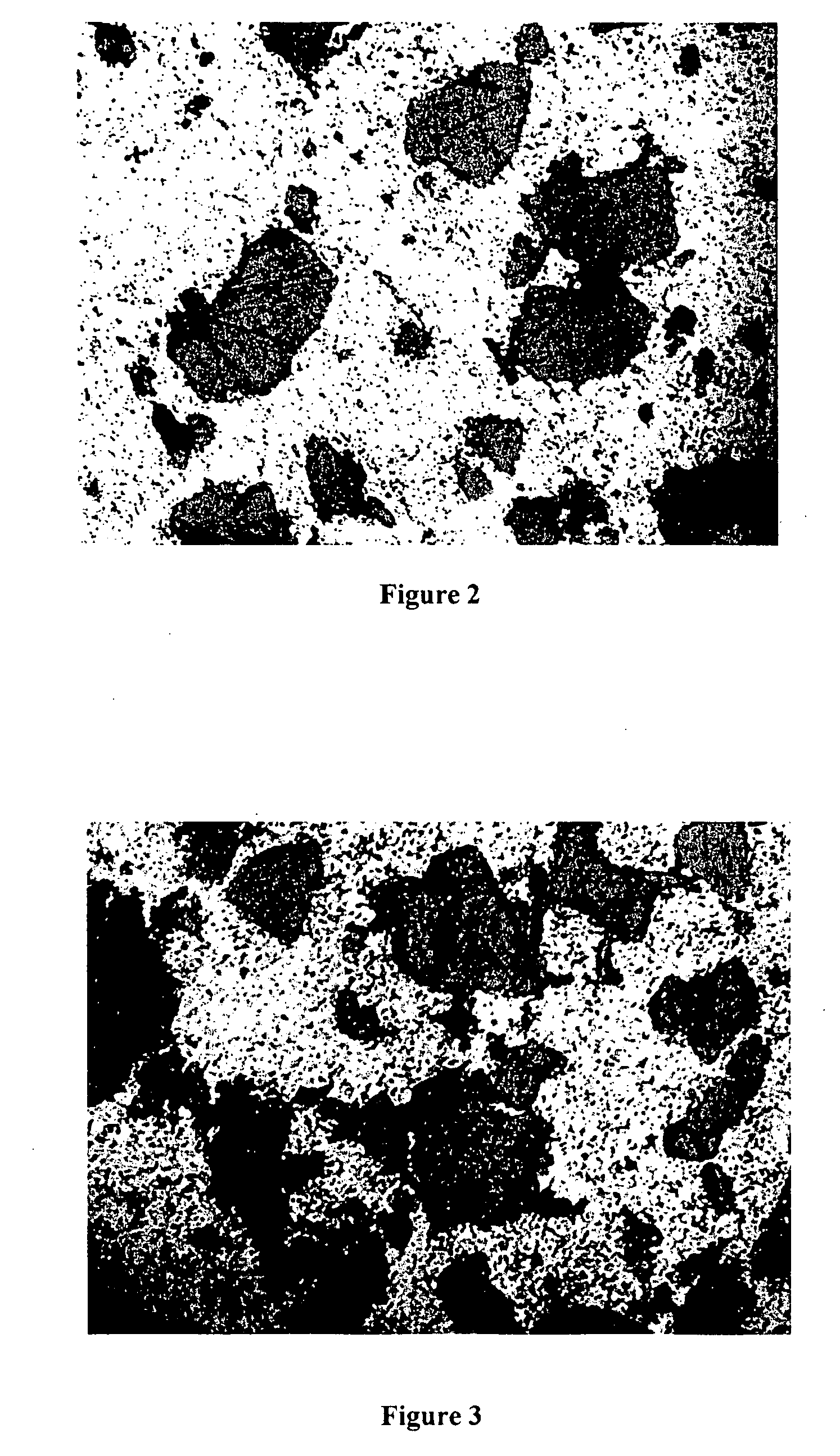

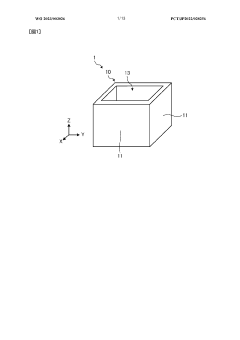

- A dense silicon carbide composite body is produced using pressureless sintering with hexagonal phase boron nitride granules bonded by glassy carbon, allowing high boron nitride loadings up to 30 weight percent, and the use of glassy carbon precursors to enhance bonding and retain boron nitride inclusions, achieving high density and self-lubricity.

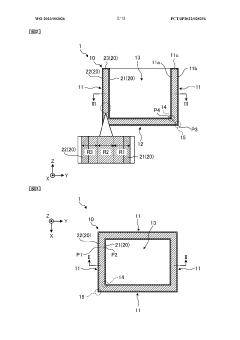

Ceramic member

PatentWO2023003026A1

Innovation

- A ceramic member with a boron-containing layer on its surface having a higher boron content than the interior, which reduces thermal expansion coefficient differences between the surface and interior, thereby minimizing compressive and tensile stresses and enhancing thermal shock resistance.

Material Characterization and Testing Methodologies

Comprehensive material characterization is essential for evaluating boron nitride ceramic seals and their performance under various operating conditions. X-ray diffraction (XRD) analysis serves as a primary technique for phase identification and crystallographic structure determination, enabling researchers to assess the purity and crystallinity of boron nitride materials. Scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) provides detailed surface morphology examination and elemental composition analysis, critical for understanding microstructural features that influence seal performance.

Porosity measurements using mercury intrusion porosimetry or gas adsorption techniques offer valuable insights into the material's density and pore size distribution, directly correlating with leak-tightness properties. Thermal conductivity assessments using laser flash analysis or steady-state methods help quantify heat transfer capabilities, essential for predicting thermal shock resistance in high-temperature applications.

Mechanical property testing encompasses hardness measurements (Vickers, Knoop), fracture toughness evaluations, and flexural strength determinations. These parameters collectively define the material's resistance to deformation and failure under mechanical stress. For ceramic seals specifically, compressive strength testing under simulated service conditions provides critical design data.

Chemical compatibility testing protocols involve immersion tests in relevant media (acids, bases, molten metals) at operating temperatures, followed by post-exposure analysis of weight change, dimensional stability, and microstructural alterations. Accelerated aging tests simulate long-term exposure effects, while spectroscopic techniques like FTIR and Raman spectroscopy help identify chemical bonding changes after exposure.

Leak-tightness evaluation requires specialized methodologies including helium leak detection, pressure decay testing, and bubble emission testing. These techniques quantify seal integrity under various pressure differentials and temperature conditions. Standardized test fixtures that replicate actual service conditions ensure reliable performance data.

Thermal shock resistance testing involves rapid temperature cycling between extreme temperatures, with subsequent evaluation of crack formation, dimensional changes, and mechanical property degradation. Thermal expansion coefficient measurements using dilatometry provide essential data for predicting thermal stress development during temperature fluctuations.

Advanced characterization techniques such as neutron diffraction, tomographic imaging, and in-situ high-temperature testing offer deeper insights into material behavior under extreme conditions. Computational modeling approaches complement experimental testing by predicting material response under complex loading scenarios and identifying failure mechanisms before physical testing.

Porosity measurements using mercury intrusion porosimetry or gas adsorption techniques offer valuable insights into the material's density and pore size distribution, directly correlating with leak-tightness properties. Thermal conductivity assessments using laser flash analysis or steady-state methods help quantify heat transfer capabilities, essential for predicting thermal shock resistance in high-temperature applications.

Mechanical property testing encompasses hardness measurements (Vickers, Knoop), fracture toughness evaluations, and flexural strength determinations. These parameters collectively define the material's resistance to deformation and failure under mechanical stress. For ceramic seals specifically, compressive strength testing under simulated service conditions provides critical design data.

Chemical compatibility testing protocols involve immersion tests in relevant media (acids, bases, molten metals) at operating temperatures, followed by post-exposure analysis of weight change, dimensional stability, and microstructural alterations. Accelerated aging tests simulate long-term exposure effects, while spectroscopic techniques like FTIR and Raman spectroscopy help identify chemical bonding changes after exposure.

Leak-tightness evaluation requires specialized methodologies including helium leak detection, pressure decay testing, and bubble emission testing. These techniques quantify seal integrity under various pressure differentials and temperature conditions. Standardized test fixtures that replicate actual service conditions ensure reliable performance data.

Thermal shock resistance testing involves rapid temperature cycling between extreme temperatures, with subsequent evaluation of crack formation, dimensional changes, and mechanical property degradation. Thermal expansion coefficient measurements using dilatometry provide essential data for predicting thermal stress development during temperature fluctuations.

Advanced characterization techniques such as neutron diffraction, tomographic imaging, and in-situ high-temperature testing offer deeper insights into material behavior under extreme conditions. Computational modeling approaches complement experimental testing by predicting material response under complex loading scenarios and identifying failure mechanisms before physical testing.

Industrial Application Case Studies

Boron Nitride ceramic seals have demonstrated remarkable performance across various industrial applications, showcasing their exceptional properties in demanding environments. In the aerospace sector, these seals have been successfully implemented in jet engine components where extreme temperatures and corrosive gases are common challenges. A notable case study from a leading aerospace manufacturer revealed that BN ceramic seals maintained integrity at temperatures exceeding 1500°C while providing excellent leak-tightness in high-pressure turbine sections, resulting in a 15% increase in component lifespan compared to traditional sealing solutions.

The semiconductor manufacturing industry has also benefited significantly from BN ceramic seals. In plasma etching equipment, where aggressive chemicals and precise tolerances are critical, these seals have demonstrated superior chemical resistance. A major semiconductor equipment provider documented that BN seals showed negligible degradation after 2,000 hours of exposure to fluorine-based plasma environments, whereas conventional seals required replacement after approximately 500 hours, substantially reducing maintenance downtime and improving production efficiency.

In metallurgical applications, particularly in molten metal handling systems, BN ceramic seals have proven their worth through exceptional thermal shock resistance. A case study from an aluminum production facility highlighted that BN seals withstood rapid temperature fluctuations between 800°C and ambient conditions without cracking or losing sealing properties. This performance enabled continuous operation cycles that were previously impossible with alternative sealing materials, enhancing productivity by approximately 22%.

The chemical processing industry presents perhaps the most demanding test cases for sealing materials. A specialty chemicals manufacturer implemented BN ceramic seals in reactor vessels handling highly corrosive fluoride compounds at elevated temperatures. The seals maintained leak-tightness for over 18 months without replacement, compared to the previous three-month replacement cycle required for graphite-based seals, resulting in significant cost savings and reduced exposure risks for maintenance personnel.

Nuclear power applications have also validated the exceptional properties of BN ceramic seals. In primary coolant pumps, where radiation resistance combines with thermal cycling and pressure containment requirements, these seals have demonstrated remarkable stability. A five-year monitoring program at a commercial reactor facility showed that BN seals maintained dimensional stability and sealing performance despite cumulative radiation exposure that degraded conventional elastomeric and metallic sealing systems.

The semiconductor manufacturing industry has also benefited significantly from BN ceramic seals. In plasma etching equipment, where aggressive chemicals and precise tolerances are critical, these seals have demonstrated superior chemical resistance. A major semiconductor equipment provider documented that BN seals showed negligible degradation after 2,000 hours of exposure to fluorine-based plasma environments, whereas conventional seals required replacement after approximately 500 hours, substantially reducing maintenance downtime and improving production efficiency.

In metallurgical applications, particularly in molten metal handling systems, BN ceramic seals have proven their worth through exceptional thermal shock resistance. A case study from an aluminum production facility highlighted that BN seals withstood rapid temperature fluctuations between 800°C and ambient conditions without cracking or losing sealing properties. This performance enabled continuous operation cycles that were previously impossible with alternative sealing materials, enhancing productivity by approximately 22%.

The chemical processing industry presents perhaps the most demanding test cases for sealing materials. A specialty chemicals manufacturer implemented BN ceramic seals in reactor vessels handling highly corrosive fluoride compounds at elevated temperatures. The seals maintained leak-tightness for over 18 months without replacement, compared to the previous three-month replacement cycle required for graphite-based seals, resulting in significant cost savings and reduced exposure risks for maintenance personnel.

Nuclear power applications have also validated the exceptional properties of BN ceramic seals. In primary coolant pumps, where radiation resistance combines with thermal cycling and pressure containment requirements, these seals have demonstrated remarkable stability. A five-year monitoring program at a commercial reactor facility showed that BN seals maintained dimensional stability and sealing performance despite cumulative radiation exposure that degraded conventional elastomeric and metallic sealing systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!