How Boron Nitride Ceramics Achieve Hermetic Bonds Without Thermal Mismatch Cracking?

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Boron Nitride Ceramic Bonding Evolution and Objectives

Boron nitride (BN) ceramics have emerged as a critical material in high-performance applications requiring thermal stability and electrical insulation. The evolution of BN ceramic bonding technologies represents a fascinating journey through materials science innovation, driven by increasing demands in aerospace, electronics, and energy sectors. Initially, conventional ceramic joining methods relied heavily on metal brazing and glass-ceramic sealing, which often resulted in thermal expansion mismatches and subsequent cracking during thermal cycling.

The 1980s marked the beginning of focused research on BN-specific bonding techniques, with early attempts utilizing metal interlayers that provided mechanical strength but failed to maintain hermetic seals at elevated temperatures. The 1990s witnessed significant advancements with the introduction of active metal brazing alloys containing titanium and zirconium, which formed chemical bonds with the typically inert BN surface.

A paradigm shift occurred in the early 2000s when researchers began exploring phase-compatible ceramic adhesives and diffusion bonding techniques specifically tailored for BN ceramics. These approaches aimed to minimize thermal expansion differentials by creating gradient interfaces or utilizing materials with closely matched thermal expansion coefficients.

The development of hexagonal boron nitride (h-BN) and cubic boron nitride (c-BN) composite systems in the 2010s represented another milestone, enabling more sophisticated bonding strategies that could accommodate thermal stresses through engineered microstructures. Concurrently, novel surface activation methods, including plasma treatment and chemical functionalization, enhanced bonding capabilities without compromising the inherent properties of BN ceramics.

Current technical objectives focus on achieving truly hermetic bonds that maintain integrity across extreme temperature gradients (-200°C to 1500°C) while preserving the electrical insulation properties of BN ceramics. Researchers aim to develop bonding solutions with thermal expansion coefficients within ±1×10^-6/K of the base materials to prevent stress-induced cracking during thermal cycling.

Additional objectives include creating bonds with mechanical strength exceeding 100 MPa, helium leak rates below 10^-9 mbar·L/s, and resistance to oxidation and corrosion in harsh environments. The ultimate goal is to establish standardized, reproducible bonding protocols that can be implemented in industrial settings without specialized equipment or prohibitively expensive processes.

Future research trajectories point toward nano-engineered interfaces that can dynamically respond to thermal stresses, self-healing bond systems that can repair microcracks in situ, and computational modeling approaches that can predict optimal bonding parameters for specific application requirements. These advancements will be crucial for enabling next-generation technologies in quantum computing, fusion energy, and hypersonic flight systems.

The 1980s marked the beginning of focused research on BN-specific bonding techniques, with early attempts utilizing metal interlayers that provided mechanical strength but failed to maintain hermetic seals at elevated temperatures. The 1990s witnessed significant advancements with the introduction of active metal brazing alloys containing titanium and zirconium, which formed chemical bonds with the typically inert BN surface.

A paradigm shift occurred in the early 2000s when researchers began exploring phase-compatible ceramic adhesives and diffusion bonding techniques specifically tailored for BN ceramics. These approaches aimed to minimize thermal expansion differentials by creating gradient interfaces or utilizing materials with closely matched thermal expansion coefficients.

The development of hexagonal boron nitride (h-BN) and cubic boron nitride (c-BN) composite systems in the 2010s represented another milestone, enabling more sophisticated bonding strategies that could accommodate thermal stresses through engineered microstructures. Concurrently, novel surface activation methods, including plasma treatment and chemical functionalization, enhanced bonding capabilities without compromising the inherent properties of BN ceramics.

Current technical objectives focus on achieving truly hermetic bonds that maintain integrity across extreme temperature gradients (-200°C to 1500°C) while preserving the electrical insulation properties of BN ceramics. Researchers aim to develop bonding solutions with thermal expansion coefficients within ±1×10^-6/K of the base materials to prevent stress-induced cracking during thermal cycling.

Additional objectives include creating bonds with mechanical strength exceeding 100 MPa, helium leak rates below 10^-9 mbar·L/s, and resistance to oxidation and corrosion in harsh environments. The ultimate goal is to establish standardized, reproducible bonding protocols that can be implemented in industrial settings without specialized equipment or prohibitively expensive processes.

Future research trajectories point toward nano-engineered interfaces that can dynamically respond to thermal stresses, self-healing bond systems that can repair microcracks in situ, and computational modeling approaches that can predict optimal bonding parameters for specific application requirements. These advancements will be crucial for enabling next-generation technologies in quantum computing, fusion energy, and hypersonic flight systems.

Market Applications for Hermetic BN Ceramic Bonds

The hermetic bonding capabilities of Boron Nitride (BN) ceramics have opened significant market opportunities across multiple industries where airtight, vacuum-tight seals are critical for component performance and longevity. The aerospace sector represents one of the largest application markets, with BN ceramic bonds being utilized in satellite components, spacecraft thermal management systems, and high-altitude aircraft sensors where extreme temperature fluctuations and vacuum conditions demand reliable hermetic sealing solutions.

In the semiconductor manufacturing industry, BN hermetic bonds are increasingly deployed in wafer processing equipment, particularly in plasma chambers and high-temperature processing environments. The ability of these bonds to maintain integrity without cracking due to thermal cycling provides extended equipment uptime and reduced maintenance costs, delivering substantial operational advantages in high-volume manufacturing settings.

The medical device sector has embraced BN ceramic hermetic bonds for implantable electronic devices such as pacemakers, cochlear implants, and neurostimulators. These applications benefit from BN's biocompatibility combined with its hermetic sealing properties, ensuring long-term device reliability within the human body while preventing moisture ingress that could compromise sensitive electronics.

Energy applications represent another significant market, with BN hermetic bonds finding use in solid oxide fuel cells, high-temperature batteries, and nuclear power components. The thermal stability of these bonds at temperatures exceeding 1000°C while maintaining gas-tight seals makes them particularly valuable in next-generation energy systems where efficiency depends on operating at elevated temperatures.

Defense applications have also adopted BN ceramic hermetic bonds for missile guidance systems, radar components, and electronic warfare equipment. These applications benefit from the material's resistance to thermal shock and ability to protect sensitive electronics in extreme operational environments.

The telecommunications industry utilizes BN hermetic bonds in high-frequency signal transmission components, particularly in base station equipment and satellite communication systems where signal integrity must be maintained across wide temperature ranges. The dielectric properties of BN combined with its hermetic sealing capabilities make it particularly suitable for these applications.

Emerging markets include quantum computing hardware, where ultra-stable hermetic environments are required for maintaining quantum coherence, and advanced MEMS devices that require vacuum packaging. As these technologies mature, the demand for specialized BN ceramic hermetic bonds is expected to grow substantially, creating new application opportunities beyond traditional markets.

In the semiconductor manufacturing industry, BN hermetic bonds are increasingly deployed in wafer processing equipment, particularly in plasma chambers and high-temperature processing environments. The ability of these bonds to maintain integrity without cracking due to thermal cycling provides extended equipment uptime and reduced maintenance costs, delivering substantial operational advantages in high-volume manufacturing settings.

The medical device sector has embraced BN ceramic hermetic bonds for implantable electronic devices such as pacemakers, cochlear implants, and neurostimulators. These applications benefit from BN's biocompatibility combined with its hermetic sealing properties, ensuring long-term device reliability within the human body while preventing moisture ingress that could compromise sensitive electronics.

Energy applications represent another significant market, with BN hermetic bonds finding use in solid oxide fuel cells, high-temperature batteries, and nuclear power components. The thermal stability of these bonds at temperatures exceeding 1000°C while maintaining gas-tight seals makes them particularly valuable in next-generation energy systems where efficiency depends on operating at elevated temperatures.

Defense applications have also adopted BN ceramic hermetic bonds for missile guidance systems, radar components, and electronic warfare equipment. These applications benefit from the material's resistance to thermal shock and ability to protect sensitive electronics in extreme operational environments.

The telecommunications industry utilizes BN hermetic bonds in high-frequency signal transmission components, particularly in base station equipment and satellite communication systems where signal integrity must be maintained across wide temperature ranges. The dielectric properties of BN combined with its hermetic sealing capabilities make it particularly suitable for these applications.

Emerging markets include quantum computing hardware, where ultra-stable hermetic environments are required for maintaining quantum coherence, and advanced MEMS devices that require vacuum packaging. As these technologies mature, the demand for specialized BN ceramic hermetic bonds is expected to grow substantially, creating new application opportunities beyond traditional markets.

Technical Challenges in Ceramic-to-Metal Hermetic Sealing

Ceramic-to-metal hermetic sealing represents one of the most challenging aspects in advanced materials engineering, particularly when utilizing boron nitride ceramics. The fundamental challenge stems from the significant coefficient of thermal expansion (CTE) mismatch between ceramics and metals. While metals typically exhibit CTEs ranging from 10-25 ppm/K, ceramics like boron nitride have much lower values of 1-8 ppm/K. This disparity creates substantial stress concentrations during thermal cycling, often resulting in crack formation and seal failure.

Traditional joining methods such as brazing and active metal brazing have historically struggled with this mismatch. When the assembly cools from bonding temperatures (often exceeding 800°C) to room temperature, the differential contraction rates generate shear stresses at the interface that can exceed the fracture strength of the ceramic component. This phenomenon is particularly problematic in applications requiring thermal cycling, where repeated expansion and contraction accelerate failure mechanisms.

Another significant challenge involves wettability issues between ceramics and conventional brazing alloys. Boron nitride, being covalently bonded with a highly stable hexagonal crystal structure, presents an exceptionally inert surface that resists wetting by most metallic solders and brazes. This poor wettability compromises the formation of continuous, void-free bonds necessary for hermetic sealing. Various surface activation techniques have been developed to address this issue, including metallization layers and active metal additions, but each introduces additional process complexity and potential failure modes.

The chemical compatibility between boron nitride and metals presents further complications. At elevated temperatures required for bonding, undesirable interfacial reactions can occur, forming brittle intermetallic compounds or causing degradation of the ceramic structure. These reactions not only weaken the mechanical integrity of the joint but can also compromise hermeticity through the formation of micropores or reaction channels.

Environmental stability of ceramic-to-metal seals represents another critical challenge. Many applications require these seals to maintain hermeticity under extreme conditions, including high temperatures, corrosive environments, or radiation exposure. The differential response of ceramics and metals to these conditions can accelerate degradation mechanisms at the interface, leading to premature seal failure.

Manufacturing consistency presents a practical challenge in industrial applications. The precise control required for surface preparation, alignment, temperature profiles, and cooling rates makes high-volume production of reliable ceramic-to-metal seals technically demanding and economically challenging. Small variations in process parameters can significantly impact seal quality and long-term reliability.

Traditional joining methods such as brazing and active metal brazing have historically struggled with this mismatch. When the assembly cools from bonding temperatures (often exceeding 800°C) to room temperature, the differential contraction rates generate shear stresses at the interface that can exceed the fracture strength of the ceramic component. This phenomenon is particularly problematic in applications requiring thermal cycling, where repeated expansion and contraction accelerate failure mechanisms.

Another significant challenge involves wettability issues between ceramics and conventional brazing alloys. Boron nitride, being covalently bonded with a highly stable hexagonal crystal structure, presents an exceptionally inert surface that resists wetting by most metallic solders and brazes. This poor wettability compromises the formation of continuous, void-free bonds necessary for hermetic sealing. Various surface activation techniques have been developed to address this issue, including metallization layers and active metal additions, but each introduces additional process complexity and potential failure modes.

The chemical compatibility between boron nitride and metals presents further complications. At elevated temperatures required for bonding, undesirable interfacial reactions can occur, forming brittle intermetallic compounds or causing degradation of the ceramic structure. These reactions not only weaken the mechanical integrity of the joint but can also compromise hermeticity through the formation of micropores or reaction channels.

Environmental stability of ceramic-to-metal seals represents another critical challenge. Many applications require these seals to maintain hermeticity under extreme conditions, including high temperatures, corrosive environments, or radiation exposure. The differential response of ceramics and metals to these conditions can accelerate degradation mechanisms at the interface, leading to premature seal failure.

Manufacturing consistency presents a practical challenge in industrial applications. The precise control required for surface preparation, alignment, temperature profiles, and cooling rates makes high-volume production of reliable ceramic-to-metal seals technically demanding and economically challenging. Small variations in process parameters can significantly impact seal quality and long-term reliability.

Current Methodologies for Thermal Mismatch Mitigation

01 Boron nitride ceramic bonding methods

Various methods for creating hermetic bonds with boron nitride ceramics involve specific processing techniques. These include high-temperature sintering processes, hot pressing, and specialized bonding agents that create strong interfaces between boron nitride and other materials. The bonding methods often require precise temperature control and pressure application to achieve hermetic seals with excellent thermal and mechanical properties.- Boron nitride ceramic bonding methods: Various methods for creating hermetic bonds with boron nitride ceramics, including high-temperature sintering processes, hot pressing techniques, and specialized bonding agents. These methods ensure strong adhesion between boron nitride components and other materials while maintaining the ceramic's unique properties such as thermal conductivity and electrical insulation. The bonding processes often involve careful temperature control and pressure application to achieve optimal hermetic sealing.

- Metal-ceramic interface bonding for hermetic seals: Techniques for creating reliable hermetic bonds between boron nitride ceramics and metals, which is critical for applications requiring gas-tight seals. These interfaces often utilize intermediate layers or specialized alloys that accommodate the different thermal expansion coefficients between ceramics and metals. The bonding processes may include active metal brazing, diffusion bonding, or the use of glass-ceramic interlayers to ensure long-term stability of the hermetic seal under thermal cycling conditions.

- Composite materials with boron nitride for enhanced hermeticity: Development of composite materials incorporating boron nitride ceramics to achieve superior hermetic properties. These composites often combine boron nitride with other ceramic materials, polymers, or metals to create structures with tailored thermal, mechanical, and sealing characteristics. The composite approach allows for optimization of properties such as crack resistance, thermal shock resistance, and long-term stability, which are essential for maintaining hermetic integrity in demanding environments.

- Surface treatment and preparation for improved bonding: Methods for treating and preparing boron nitride ceramic surfaces to enhance bonding capabilities and hermetic seal quality. These treatments may include chemical etching, plasma activation, laser texturing, or application of coupling agents to modify surface energy and improve wettability. Proper surface preparation is crucial for achieving strong adhesion and preventing leakage paths at the interface, thereby ensuring long-term hermeticity of the bonded assembly.

- Advanced sealing technologies for extreme environments: Specialized hermetic bonding technologies for boron nitride ceramics designed to withstand extreme operating conditions such as high temperatures, corrosive environments, or radiation exposure. These advanced sealing solutions often incorporate novel materials such as specialized glass frits, refractory metal brazes, or engineered interlayers. The resulting hermetic bonds maintain their integrity under challenging conditions where conventional sealing methods would fail, making them suitable for aerospace, nuclear, or high-temperature industrial applications.

02 Composite materials with boron nitride for hermetic applications

Composite materials incorporating boron nitride particles or phases can enhance hermetic bonding properties. These composites often combine boron nitride with metals, glass, or other ceramic materials to create interfaces with controlled thermal expansion coefficients and improved hermeticity. The resulting materials exhibit excellent thermal conductivity while maintaining electrical insulation properties, making them suitable for electronic packaging and sealing applications.Expand Specific Solutions03 Surface treatments for improved boron nitride bonding

Surface modification techniques can significantly improve the bonding capabilities of boron nitride ceramics. These treatments include chemical activation, plasma processing, metallization layers, and specialized coatings that enhance wettability and adhesion. By modifying the typically inert boron nitride surface, stronger hermetic bonds can be achieved with various substrate materials, resulting in more reliable seals for demanding applications.Expand Specific Solutions04 Boron nitride-based sealing materials for extreme environments

Specialized boron nitride formulations have been developed for hermetic sealing in extreme environments. These materials maintain their integrity under high temperatures, corrosive conditions, and thermal cycling. The unique combination of thermal stability, chemical resistance, and controlled thermal expansion makes these materials particularly valuable for applications in aerospace, semiconductor processing, and nuclear industries where conventional sealing materials would fail.Expand Specific Solutions05 Novel joining techniques for boron nitride ceramic components

Innovative joining techniques have been developed specifically for creating hermetic bonds between boron nitride ceramic components and dissimilar materials. These include active metal brazing, glass-ceramic bonding, diffusion bonding, and specialized adhesive systems. The techniques often employ interlayers or gradient structures to accommodate differences in thermal expansion and create reliable, gas-tight seals that can withstand thermal cycling and mechanical stress.Expand Specific Solutions

Leading Manufacturers and Research Institutions in BN Ceramics

The boron nitride ceramics hermetic bonding market is in a growth phase, with increasing applications in high-temperature electronics and aerospace sectors. The global technical ceramics market, which includes boron nitride ceramics, is projected to reach approximately $8-10 billion by 2025, growing at 6-8% CAGR. Technology maturity varies across players, with research institutions like Shanghai Institute of Ceramics and Harbin Institute of Technology focusing on fundamental research, while established manufacturers such as Mitsubishi Materials, NGK Insulators, and SCHOTT AG have commercialized advanced solutions. These companies have developed proprietary techniques to address thermal mismatch challenges through gradient structures, specialized interlayers, and nano-engineered interfaces. Recent innovations from Max Planck Society and National University of Defense Technology demonstrate promising approaches to eliminate cracking in hermetic seals under extreme thermal cycling conditions.

Shanghai Institute of Ceramics, Chinese Academy of Sciences

Technical Solution: Shanghai Institute of Ceramics has developed a novel approach to achieving hermetic bonds with boron nitride ceramics through a gradient interface design. Their technique involves creating a compositionally graded BN-based ceramic structure where the coefficient of thermal expansion (CTE) gradually changes across the interface. This is achieved by incorporating secondary phases like silicon nitride or aluminum oxide in varying concentrations to create a smooth transition between the BN ceramic and the joining material. The institute has also pioneered a pressure-assisted sintering method that promotes strong interfacial bonding while minimizing residual stresses. Their research demonstrates that controlling the microstructure at the nanoscale through precise powder processing and sintering parameters allows for hermetic seals that maintain integrity across a wide temperature range (-50°C to 800°C). Additionally, they've developed specialized surface treatments that enhance wettability and bonding strength without compromising the thermal shock resistance inherent to BN ceramics.

Strengths: The gradient interface approach effectively eliminates sharp CTE discontinuities, preventing crack formation during thermal cycling. Their pressure-assisted sintering technique achieves nearly theoretical density (>99%) at the bond interface, ensuring hermeticity. Weaknesses: The process requires precise control of multiple processing parameters and is relatively time-consuming, potentially limiting industrial scalability. The technique may also require specialized equipment not commonly available in standard manufacturing facilities.

NGK Insulators, Ltd.

Technical Solution: NGK Insulators has developed a proprietary active metal brazing technology specifically for boron nitride ceramic hermetic sealing applications. Their approach utilizes titanium-based active braze alloys that chemically react with the boron nitride surface to form strong chemical bonds rather than relying solely on mechanical adhesion. The company has engineered specialized braze compositions that include elements like zirconium and hafnium which promote wetting and bonding to the typically difficult-to-join BN surface. NGK's process involves a carefully controlled brazing cycle with precise temperature profiles that allow for stress relaxation during cooling. Their technology incorporates a compliant interlayer system that accommodates the CTE mismatch between BN ceramics and metal components. This interlayer typically consists of a ductile metal phase that can deform plastically to absorb thermal stresses. NGK has successfully implemented this technology in high-temperature electronic packages, vacuum interrupters, and semiconductor processing equipment where hermetic seals must withstand extreme thermal cycling without failure.

Strengths: The active metal brazing approach creates chemical bonds that are significantly stronger than conventional mechanical joints. The compliant interlayer effectively absorbs thermal stresses, preventing crack propagation during thermal cycling. Weaknesses: The specialized braze alloys contain expensive elements like titanium and zirconium, increasing production costs. The process requires very clean surfaces and controlled atmosphere conditions, making it sensitive to manufacturing variations.

Key Patents in Stress-Free Ceramic Bonding Techniques

Ceramic structure, flow passage body, and electrode internal plate

PatentWO2016002852A1

Innovation

- A ceramic structure is developed where two aluminum nitride ceramic members are bonded using an aluminum nitride ceramic bonding layer with a specific pore structure, featuring 1000 to 1400 pores per square millimeter and an average pore diameter of 2 to 6 micrometers, which acts as a stress reliever during thermal cycles, and includes annular recesses for fluid flow and embedded electrodes.

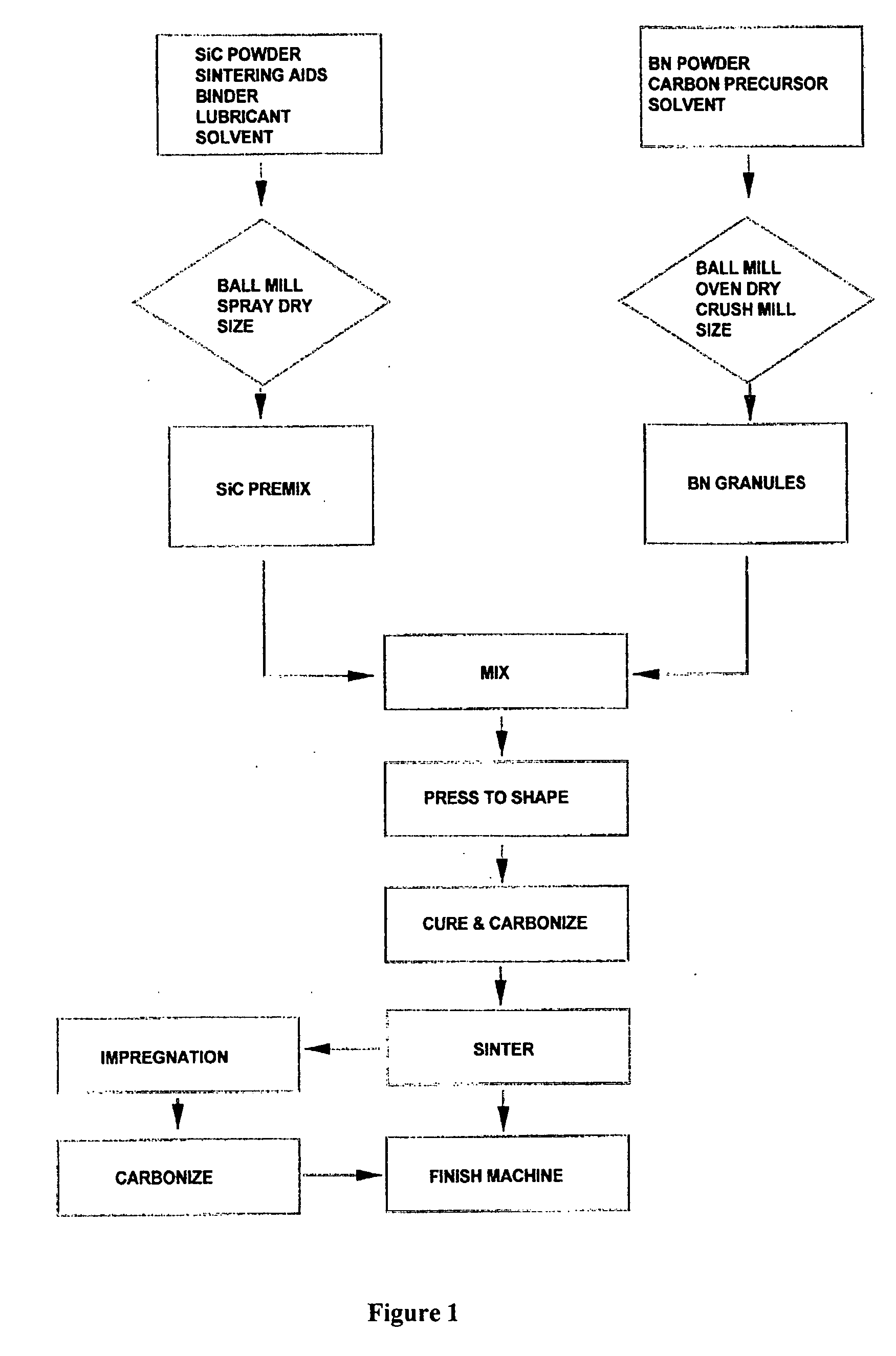

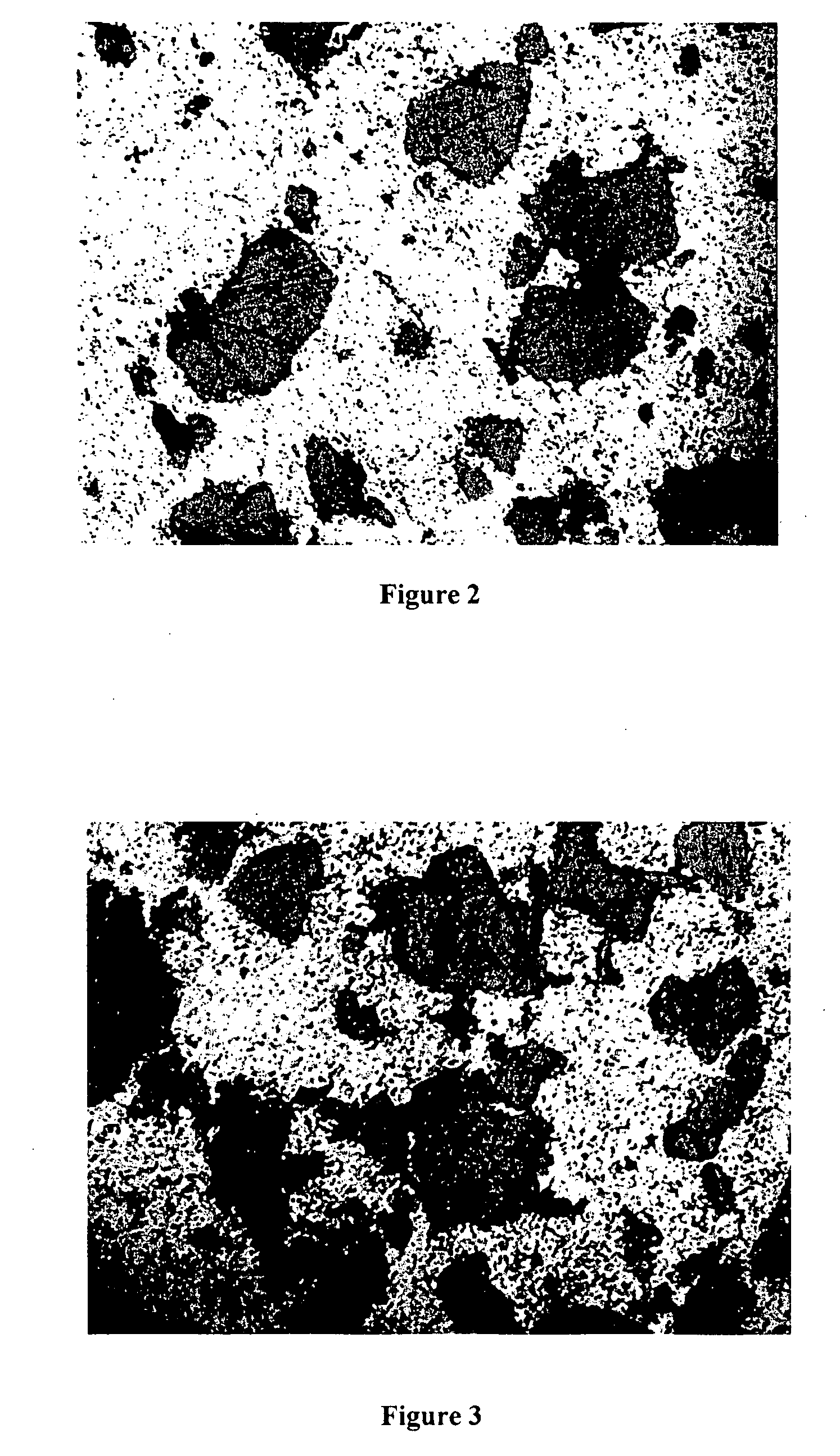

Ceramic composite body of silicon carbide/boron nitride/carbon

PatentInactiveUS20060154800A1

Innovation

- A dense silicon carbide composite body is produced using pressureless sintering with hexagonal phase boron nitride granules bonded by glassy carbon, allowing high boron nitride loadings up to 30 weight percent, and the use of glassy carbon precursors to enhance bonding and retain boron nitride inclusions, achieving high density and self-lubricity.

Material Science Considerations for Advanced Ceramic Interfaces

The interface between boron nitride ceramics and other materials represents a critical junction where material science principles must be carefully applied to achieve successful hermetic bonds. Understanding the fundamental properties of these interfaces requires examination at multiple scales - from atomic interactions to macroscopic behavior patterns.

Boron nitride (BN) ceramics exhibit exceptional thermal stability and chemical resistance, making them ideal candidates for hermetic sealing applications. However, their hexagonal crystal structure creates anisotropic thermal expansion characteristics that must be addressed when forming bonds with dissimilar materials. The thermal expansion coefficient mismatch between BN ceramics and common bonding materials like metals or other ceramics typically ranges from 2-8 ppm/K, creating significant stress concentrations at interface boundaries.

The key to achieving crack-free hermetic bonds lies in the manipulation of interfacial chemistry and microstructure. Recent advances in surface functionalization techniques have enabled the creation of gradient interfaces where composition transitions gradually rather than abruptly. These gradient interfaces distribute thermal stresses over a wider region, preventing localized stress concentrations that would otherwise lead to crack initiation.

Nano-scale engineering of BN ceramic surfaces has emerged as another promising approach. By creating controlled surface roughness patterns at the micro and nano scales, researchers have demonstrated improved mechanical interlocking between BN ceramics and bonding materials. This mechanical interlocking provides additional resistance to crack propagation while maintaining hermetic integrity.

The incorporation of compliant interlayers represents a third strategy for mitigating thermal mismatch issues. These interlayers, often composed of glass-ceramics or specialized metal alloys with intermediate thermal expansion coefficients, act as stress-absorbing buffer zones. Recent studies have shown that multi-layer approaches with carefully selected thickness ratios can effectively eliminate cracking even under extreme thermal cycling conditions.

Advanced characterization techniques including high-resolution transmission electron microscopy and in-situ thermal mechanical analysis have revealed that successful hermetic bonds often feature controlled interfacial diffusion zones. These zones, typically 1-5 μm thick, allow for gradual accommodation of thermal expansion differences while maintaining chemical compatibility between the joined materials.

The crystallographic orientation relationship between BN ceramics and bonding materials also plays a crucial role in bond integrity. Experimental evidence suggests that aligning specific crystallographic planes can reduce interfacial energy and improve bond strength by up to 40% compared to random orientations, while simultaneously reducing susceptibility to thermal cracking.

Boron nitride (BN) ceramics exhibit exceptional thermal stability and chemical resistance, making them ideal candidates for hermetic sealing applications. However, their hexagonal crystal structure creates anisotropic thermal expansion characteristics that must be addressed when forming bonds with dissimilar materials. The thermal expansion coefficient mismatch between BN ceramics and common bonding materials like metals or other ceramics typically ranges from 2-8 ppm/K, creating significant stress concentrations at interface boundaries.

The key to achieving crack-free hermetic bonds lies in the manipulation of interfacial chemistry and microstructure. Recent advances in surface functionalization techniques have enabled the creation of gradient interfaces where composition transitions gradually rather than abruptly. These gradient interfaces distribute thermal stresses over a wider region, preventing localized stress concentrations that would otherwise lead to crack initiation.

Nano-scale engineering of BN ceramic surfaces has emerged as another promising approach. By creating controlled surface roughness patterns at the micro and nano scales, researchers have demonstrated improved mechanical interlocking between BN ceramics and bonding materials. This mechanical interlocking provides additional resistance to crack propagation while maintaining hermetic integrity.

The incorporation of compliant interlayers represents a third strategy for mitigating thermal mismatch issues. These interlayers, often composed of glass-ceramics or specialized metal alloys with intermediate thermal expansion coefficients, act as stress-absorbing buffer zones. Recent studies have shown that multi-layer approaches with carefully selected thickness ratios can effectively eliminate cracking even under extreme thermal cycling conditions.

Advanced characterization techniques including high-resolution transmission electron microscopy and in-situ thermal mechanical analysis have revealed that successful hermetic bonds often feature controlled interfacial diffusion zones. These zones, typically 1-5 μm thick, allow for gradual accommodation of thermal expansion differences while maintaining chemical compatibility between the joined materials.

The crystallographic orientation relationship between BN ceramics and bonding materials also plays a crucial role in bond integrity. Experimental evidence suggests that aligning specific crystallographic planes can reduce interfacial energy and improve bond strength by up to 40% compared to random orientations, while simultaneously reducing susceptibility to thermal cracking.

Reliability Testing Standards for Hermetic Ceramic Bonds

Reliability testing standards for hermetic ceramic bonds involving boron nitride materials must be comprehensive and rigorous to ensure long-term performance in demanding applications. These standards typically encompass multiple testing methodologies designed to evaluate the integrity of the hermetic seal under various environmental conditions.

The Military Standard MIL-STD-883, Method 1014 serves as a foundational framework for hermeticity testing, though it requires adaptation for boron nitride ceramic applications. This standard prescribes fine and gross leak detection methods using helium mass spectrometry and fluorocarbon bubble testing, which are particularly relevant for evaluating the quality of hermetic bonds in boron nitride ceramic packages.

ASTM F1269 and F2391 standards provide specific protocols for hermeticity testing that can be applied to boron nitride ceramic bonds, offering quantitative metrics for leak rates that indicate successful hermetic sealing. These standards define acceptable leak rate thresholds, typically in the range of 10^-8 to 10^-9 atm-cc/sec for high-reliability applications.

Thermal cycling tests, as outlined in JEDEC JESD22-A104, are crucial for evaluating the thermal mismatch resistance of boron nitride ceramic bonds. These tests subject the bonded components to extreme temperature variations (typically -65°C to +150°C) over hundreds or thousands of cycles to verify that the hermetic integrity remains intact despite thermal expansion differentials.

Mechanical shock and vibration testing according to MIL-STD-810 protocols helps assess the robustness of the hermetic bond under physical stress conditions. Boron nitride ceramic bonds must maintain their hermetic properties when subjected to acceleration forces of 500-1500G and vibration frequencies ranging from 10Hz to 2000Hz.

High-pressure and high-temperature testing standards, including ASTM E1003 for high-pressure testing and ASTM F1980 for accelerated aging, provide methods to evaluate long-term reliability under extreme conditions. These tests are particularly important for boron nitride ceramic applications in aerospace, defense, and deep-well drilling environments.

Non-destructive evaluation techniques, such as those described in ASTM E1742 for radiographic inspection and ASTM E1417 for liquid penetrant examination, offer means to inspect hermetic bonds without compromising their integrity. Advanced acoustic microscopy methods following ASTM E2580 guidelines are increasingly utilized for detecting subsurface defects in ceramic-to-metal bonds.

Corrosion resistance testing standards, including ASTM B117 for salt spray testing and ASTM G85 for modified salt spray testing, help evaluate the hermetic bond's resistance to environmental degradation. These tests are essential for applications where boron nitride ceramic components may be exposed to corrosive environments.

Qualification and acceptance criteria must be established based on application-specific requirements, with more stringent standards applied to critical applications in medical implants, aerospace systems, and nuclear environments where hermetic failure could have catastrophic consequences.

The Military Standard MIL-STD-883, Method 1014 serves as a foundational framework for hermeticity testing, though it requires adaptation for boron nitride ceramic applications. This standard prescribes fine and gross leak detection methods using helium mass spectrometry and fluorocarbon bubble testing, which are particularly relevant for evaluating the quality of hermetic bonds in boron nitride ceramic packages.

ASTM F1269 and F2391 standards provide specific protocols for hermeticity testing that can be applied to boron nitride ceramic bonds, offering quantitative metrics for leak rates that indicate successful hermetic sealing. These standards define acceptable leak rate thresholds, typically in the range of 10^-8 to 10^-9 atm-cc/sec for high-reliability applications.

Thermal cycling tests, as outlined in JEDEC JESD22-A104, are crucial for evaluating the thermal mismatch resistance of boron nitride ceramic bonds. These tests subject the bonded components to extreme temperature variations (typically -65°C to +150°C) over hundreds or thousands of cycles to verify that the hermetic integrity remains intact despite thermal expansion differentials.

Mechanical shock and vibration testing according to MIL-STD-810 protocols helps assess the robustness of the hermetic bond under physical stress conditions. Boron nitride ceramic bonds must maintain their hermetic properties when subjected to acceleration forces of 500-1500G and vibration frequencies ranging from 10Hz to 2000Hz.

High-pressure and high-temperature testing standards, including ASTM E1003 for high-pressure testing and ASTM F1980 for accelerated aging, provide methods to evaluate long-term reliability under extreme conditions. These tests are particularly important for boron nitride ceramic applications in aerospace, defense, and deep-well drilling environments.

Non-destructive evaluation techniques, such as those described in ASTM E1742 for radiographic inspection and ASTM E1417 for liquid penetrant examination, offer means to inspect hermetic bonds without compromising their integrity. Advanced acoustic microscopy methods following ASTM E2580 guidelines are increasingly utilized for detecting subsurface defects in ceramic-to-metal bonds.

Corrosion resistance testing standards, including ASTM B117 for salt spray testing and ASTM G85 for modified salt spray testing, help evaluate the hermetic bond's resistance to environmental degradation. These tests are essential for applications where boron nitride ceramic components may be exposed to corrosive environments.

Qualification and acceptance criteria must be established based on application-specific requirements, with more stringent standards applied to critical applications in medical implants, aerospace systems, and nuclear environments where hermetic failure could have catastrophic consequences.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!