Boron Nitride Reliability In Cryogenic Service: Fracture Toughness, Moisture And Cycling

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Cryogenic Applications Background and Objectives

Boron Nitride (BN) has emerged as a critical material in advanced cryogenic applications due to its exceptional thermal stability, electrical insulation properties, and chemical inertness. The evolution of this ceramic material spans several decades, with significant advancements in synthesis techniques and structural configurations enhancing its performance characteristics. Initially developed for high-temperature applications, BN has progressively found its way into extreme cold environments where conventional materials fail.

The technological trajectory of BN in cryogenic applications has been accelerating since the early 2000s, driven primarily by demands from aerospace, quantum computing, and superconducting technologies. These sectors require materials that maintain structural integrity and functional properties at temperatures approaching absolute zero. The hexagonal form (h-BN) and cubic form (c-BN) represent the primary crystalline structures utilized in these extreme environments, each offering distinct advantages depending on the specific application requirements.

Recent developments in nanoscale engineering have further expanded BN's potential, with two-dimensional BN sheets demonstrating remarkable mechanical flexibility and thermal conductivity at cryogenic temperatures. This evolution represents a significant departure from traditional ceramic behaviors, opening new avenues for integration into complex cryogenic systems.

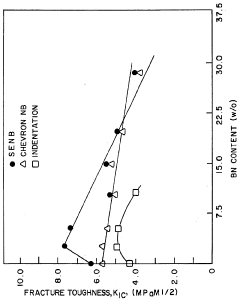

The primary technical objective of investigating BN reliability in cryogenic service centers on understanding three critical parameters: fracture toughness under extreme cold conditions, moisture interaction mechanisms, and performance degradation during thermal cycling. These factors collectively determine the material's long-term viability in mission-critical applications where failure is not an option.

Fracture toughness at cryogenic temperatures represents a fundamental concern, as many ceramics become increasingly brittle as temperatures decrease. Understanding the microstructural factors that influence crack propagation in BN at temperatures below -150°C is essential for predicting service life and establishing safety margins.

Moisture sensitivity presents another significant challenge, as water molecule interactions with BN surfaces can potentially compromise structural integrity during cooling and warming cycles. Even trace amounts of absorbed moisture can lead to microcracking when rapidly cooled, making this a critical area for investigation.

Thermal cycling effects constitute the third major research focus, examining how repeated transitions between ambient and cryogenic temperatures affect BN's crystalline structure, interfacial bonding, and overall mechanical properties. This cycling represents real-world operating conditions for many advanced systems, making it particularly relevant for practical applications.

The ultimate goal of this technical exploration is to establish comprehensive design guidelines and material specifications for BN components in cryogenic environments, enabling reliable performance in next-generation superconducting systems, space exploration equipment, and quantum technology infrastructure.

The technological trajectory of BN in cryogenic applications has been accelerating since the early 2000s, driven primarily by demands from aerospace, quantum computing, and superconducting technologies. These sectors require materials that maintain structural integrity and functional properties at temperatures approaching absolute zero. The hexagonal form (h-BN) and cubic form (c-BN) represent the primary crystalline structures utilized in these extreme environments, each offering distinct advantages depending on the specific application requirements.

Recent developments in nanoscale engineering have further expanded BN's potential, with two-dimensional BN sheets demonstrating remarkable mechanical flexibility and thermal conductivity at cryogenic temperatures. This evolution represents a significant departure from traditional ceramic behaviors, opening new avenues for integration into complex cryogenic systems.

The primary technical objective of investigating BN reliability in cryogenic service centers on understanding three critical parameters: fracture toughness under extreme cold conditions, moisture interaction mechanisms, and performance degradation during thermal cycling. These factors collectively determine the material's long-term viability in mission-critical applications where failure is not an option.

Fracture toughness at cryogenic temperatures represents a fundamental concern, as many ceramics become increasingly brittle as temperatures decrease. Understanding the microstructural factors that influence crack propagation in BN at temperatures below -150°C is essential for predicting service life and establishing safety margins.

Moisture sensitivity presents another significant challenge, as water molecule interactions with BN surfaces can potentially compromise structural integrity during cooling and warming cycles. Even trace amounts of absorbed moisture can lead to microcracking when rapidly cooled, making this a critical area for investigation.

Thermal cycling effects constitute the third major research focus, examining how repeated transitions between ambient and cryogenic temperatures affect BN's crystalline structure, interfacial bonding, and overall mechanical properties. This cycling represents real-world operating conditions for many advanced systems, making it particularly relevant for practical applications.

The ultimate goal of this technical exploration is to establish comprehensive design guidelines and material specifications for BN components in cryogenic environments, enabling reliable performance in next-generation superconducting systems, space exploration equipment, and quantum technology infrastructure.

Market Demand Analysis for Cryogenic Materials

The cryogenic materials market is experiencing robust growth driven by expanding applications in aerospace, healthcare, energy, and electronics sectors. The global cryogenic equipment market, valued at approximately $26.5 billion in 2022, is projected to reach $38.9 billion by 2030, growing at a CAGR of 5.7%. Within this market, specialized materials like Boron Nitride (BN) are gaining significant attention due to their exceptional thermal and mechanical properties at extremely low temperatures.

The demand for reliable cryogenic materials is particularly strong in the space industry, where the market for cryogenic tanks alone is expected to grow from $1.8 billion in 2022 to $3.2 billion by 2027. NASA, SpaceX, and Blue Origin are investing heavily in advanced materials that can withstand the harsh conditions of space, creating a premium segment for high-performance materials like Boron Nitride.

In the healthcare sector, the global medical cryogenic storage equipment market is projected to reach $4.7 billion by 2028, with a CAGR of 6.3%. The growing adoption of regenerative medicine and cell therapies is driving demand for materials that maintain structural integrity during repeated thermal cycling between ambient and cryogenic temperatures.

The semiconductor industry represents another significant market for cryogenic materials, particularly with the advancement of quantum computing. The quantum computing market is expected to grow from $866 million in 2023 to $4.375 billion by 2028, necessitating materials that perform reliably at near-absolute zero temperatures.

Energy sector applications, particularly in LNG transportation and storage, are creating substantial demand for cryogenic materials. The global LNG infrastructure market is projected to reach $42.5 billion by 2025, requiring materials that can withstand extreme temperature fluctuations while maintaining structural integrity.

Customer requirements in these markets are increasingly focused on materials with superior fracture toughness at cryogenic temperatures, resistance to moisture-induced degradation, and stability during thermal cycling. End-users are willing to pay premium prices for materials that demonstrate proven reliability in these conditions, with an estimated 30% price premium for materials with verified long-term performance data.

The Asia-Pacific region is emerging as the fastest-growing market for cryogenic materials, with China and South Korea making significant investments in cryogenic technology infrastructure. North America and Europe remain strong markets, driven by aerospace and healthcare applications respectively.

The demand for reliable cryogenic materials is particularly strong in the space industry, where the market for cryogenic tanks alone is expected to grow from $1.8 billion in 2022 to $3.2 billion by 2027. NASA, SpaceX, and Blue Origin are investing heavily in advanced materials that can withstand the harsh conditions of space, creating a premium segment for high-performance materials like Boron Nitride.

In the healthcare sector, the global medical cryogenic storage equipment market is projected to reach $4.7 billion by 2028, with a CAGR of 6.3%. The growing adoption of regenerative medicine and cell therapies is driving demand for materials that maintain structural integrity during repeated thermal cycling between ambient and cryogenic temperatures.

The semiconductor industry represents another significant market for cryogenic materials, particularly with the advancement of quantum computing. The quantum computing market is expected to grow from $866 million in 2023 to $4.375 billion by 2028, necessitating materials that perform reliably at near-absolute zero temperatures.

Energy sector applications, particularly in LNG transportation and storage, are creating substantial demand for cryogenic materials. The global LNG infrastructure market is projected to reach $42.5 billion by 2025, requiring materials that can withstand extreme temperature fluctuations while maintaining structural integrity.

Customer requirements in these markets are increasingly focused on materials with superior fracture toughness at cryogenic temperatures, resistance to moisture-induced degradation, and stability during thermal cycling. End-users are willing to pay premium prices for materials that demonstrate proven reliability in these conditions, with an estimated 30% price premium for materials with verified long-term performance data.

The Asia-Pacific region is emerging as the fastest-growing market for cryogenic materials, with China and South Korea making significant investments in cryogenic technology infrastructure. North America and Europe remain strong markets, driven by aerospace and healthcare applications respectively.

Current Challenges in BN Cryogenic Performance

Despite significant advancements in boron nitride (BN) applications for cryogenic environments, several critical challenges persist that limit its reliability and performance under extreme cold conditions. The primary concern involves fracture toughness degradation at cryogenic temperatures, where BN materials exhibit increased brittleness and susceptibility to microcracking. This behavior is particularly problematic in applications requiring thermal cycling between ambient and cryogenic temperatures, as the material experiences significant thermal stress during transitions.

Moisture absorption presents another substantial challenge for BN in cryogenic service. Even minimal moisture content can lead to catastrophic failure through several mechanisms: ice crystal formation within the material structure during cooling, which creates internal pressure; degradation of the material's thermal conductivity properties; and acceleration of crack propagation pathways. Current manufacturing and handling protocols struggle to achieve the ultra-low moisture content required for reliable cryogenic performance.

Thermal cycling effects constitute a third major challenge, as repeated transitions between ambient and cryogenic temperatures induce cumulative damage in BN components. Research indicates that BN materials experience progressive deterioration in mechanical properties after multiple thermal cycles, with fracture toughness decreasing by up to 30% after just 50 cycles in some formulations. This cycling-induced degradation occurs through mechanisms including differential thermal expansion at grain boundaries and progressive weakening of the material's microstructure.

Interface compatibility issues between BN and adjacent materials in composite systems further complicate reliable performance. The significant difference in thermal expansion coefficients between BN and common matrix materials creates substantial interfacial stresses during cooling, often resulting in delamination or interfacial cracking that compromises system integrity. Current joining and interface engineering approaches have not fully resolved these compatibility challenges.

Quality control and characterization methods represent another significant hurdle. Conventional testing protocols developed for ambient temperature applications often fail to accurately predict cryogenic performance. Non-destructive evaluation techniques capable of detecting sub-critical defects that might propagate under cryogenic conditions remain limited, creating uncertainty in reliability assessments. Additionally, accelerated testing methodologies that can effectively simulate long-term cryogenic exposure effects are still under development.

Finally, the lack of standardized performance metrics specifically for cryogenic applications of BN materials hampers consistent evaluation across different formulations and manufacturing processes. This absence of unified testing standards makes it difficult to compare results across research groups and establish reliable design guidelines for critical applications.

Moisture absorption presents another substantial challenge for BN in cryogenic service. Even minimal moisture content can lead to catastrophic failure through several mechanisms: ice crystal formation within the material structure during cooling, which creates internal pressure; degradation of the material's thermal conductivity properties; and acceleration of crack propagation pathways. Current manufacturing and handling protocols struggle to achieve the ultra-low moisture content required for reliable cryogenic performance.

Thermal cycling effects constitute a third major challenge, as repeated transitions between ambient and cryogenic temperatures induce cumulative damage in BN components. Research indicates that BN materials experience progressive deterioration in mechanical properties after multiple thermal cycles, with fracture toughness decreasing by up to 30% after just 50 cycles in some formulations. This cycling-induced degradation occurs through mechanisms including differential thermal expansion at grain boundaries and progressive weakening of the material's microstructure.

Interface compatibility issues between BN and adjacent materials in composite systems further complicate reliable performance. The significant difference in thermal expansion coefficients between BN and common matrix materials creates substantial interfacial stresses during cooling, often resulting in delamination or interfacial cracking that compromises system integrity. Current joining and interface engineering approaches have not fully resolved these compatibility challenges.

Quality control and characterization methods represent another significant hurdle. Conventional testing protocols developed for ambient temperature applications often fail to accurately predict cryogenic performance. Non-destructive evaluation techniques capable of detecting sub-critical defects that might propagate under cryogenic conditions remain limited, creating uncertainty in reliability assessments. Additionally, accelerated testing methodologies that can effectively simulate long-term cryogenic exposure effects are still under development.

Finally, the lack of standardized performance metrics specifically for cryogenic applications of BN materials hampers consistent evaluation across different formulations and manufacturing processes. This absence of unified testing standards makes it difficult to compare results across research groups and establish reliable design guidelines for critical applications.

Existing Solutions for BN Reliability Enhancement

01 Enhancing fracture toughness of boron nitride composites

Various methods can be employed to improve the fracture toughness of boron nitride materials, including the incorporation of secondary phases, optimization of grain structure, and specific sintering techniques. These approaches create mechanisms such as crack deflection and bridging that enhance the material's resistance to crack propagation. The resulting composites demonstrate superior mechanical properties while maintaining the inherent thermal and chemical advantages of boron nitride.- Boron Nitride Composites for Enhanced Fracture Toughness: Boron nitride can be incorporated into composite materials to significantly improve fracture toughness. These composites typically combine boron nitride with other ceramic materials or matrices to create structures with superior mechanical properties. The addition of boron nitride helps to prevent crack propagation and enhances the overall structural integrity of the material, making it suitable for applications requiring high mechanical strength and durability.

- Moisture Resistance Improvements in Boron Nitride Materials: Various techniques have been developed to enhance the moisture resistance of boron nitride materials. These include surface treatments, coatings, and the incorporation of hydrophobic additives. Improved moisture resistance is critical for maintaining the structural integrity and performance of boron nitride in humid environments or applications where water exposure is common. These modifications help to prevent degradation of the material properties over time due to moisture absorption.

- Cycling Performance Enhancement of Boron Nitride in Battery Applications: Boron nitride materials have been developed specifically for improved cycling performance in battery and energy storage applications. These materials maintain their structural and functional properties over numerous charge-discharge cycles, contributing to longer battery life and more stable performance. The thermal stability and electrical insulation properties of boron nitride make it particularly valuable for enhancing the safety and reliability of battery systems under repeated cycling conditions.

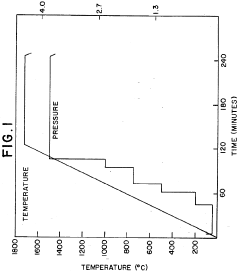

- Processing Techniques for Optimized Boron Nitride Properties: Specialized processing techniques have been developed to optimize the properties of boron nitride materials, including hot pressing, sintering, and chemical vapor deposition. These methods control the microstructure, crystallinity, and density of the material, which directly influence its fracture toughness, moisture resistance, and cycling performance. Advanced processing can create boron nitride with tailored properties for specific applications, balancing mechanical strength with other desired characteristics.

- Novel Boron Nitride Structures and Morphologies: Research has led to the development of novel boron nitride structures and morphologies, including nanotubes, nanosheets, and hierarchical structures. These innovative forms of boron nitride exhibit enhanced mechanical properties, including superior fracture toughness, improved moisture resistance, and excellent cycling stability. The unique geometries and arrangements of these structures contribute to their exceptional performance characteristics, making them suitable for advanced applications in electronics, energy storage, and structural materials.

02 Moisture resistance improvements in boron nitride materials

Boron nitride materials can be modified to enhance their resistance to moisture degradation through surface treatments, coating technologies, and compositional adjustments. These modifications create hydrophobic barriers that prevent water absorption and subsequent material degradation. Moisture-resistant boron nitride materials maintain their structural integrity and performance characteristics even when exposed to humid environments or water contact.Expand Specific Solutions03 Cycling performance optimization for boron nitride applications

The cycling performance of boron nitride materials can be enhanced through microstructural engineering, interface design, and compositional modifications. These approaches improve the material's ability to withstand repeated thermal, mechanical, or electrical cycling without degradation. Optimized boron nitride materials demonstrate excellent fatigue resistance, thermal shock resistance, and long-term stability under cyclic loading conditions.Expand Specific Solutions04 Processing techniques for high-performance boron nitride structures

Advanced processing techniques, including hot pressing, spark plasma sintering, and chemical vapor deposition, can be utilized to create boron nitride structures with superior properties. These methods allow precise control over density, grain size, orientation, and purity, which directly influence the material's fracture toughness, moisture resistance, and cycling performance. Optimized processing parameters result in boron nitride materials with enhanced overall performance characteristics.Expand Specific Solutions05 Composite systems incorporating boron nitride for enhanced properties

Boron nitride can be incorporated into composite systems with other materials such as ceramics, metals, or polymers to achieve synergistic property enhancements. These composite systems leverage the unique properties of boron nitride while addressing its limitations through the complementary characteristics of the matrix or reinforcement materials. The resulting composites demonstrate improved fracture toughness, moisture resistance, and cycling performance compared to monolithic boron nitride materials.Expand Specific Solutions

Key Industry Players in Cryogenic Materials

The boron nitride reliability in cryogenic service market is in a growth phase, with increasing applications in aerospace, electronics, and energy sectors. The market size is expanding due to boron nitride's exceptional thermal stability and mechanical properties at extremely low temperatures. Technologically, the field is advancing rapidly with companies like Sumitomo Electric Industries and Denka Corp leading commercial development, while Samsung Electronics and Robert Bosch GmbH integrate these materials into high-performance applications. Academic institutions such as Rice University and Harbin Institute of Technology are advancing fundamental research on fracture toughness and moisture resistance. The industry faces challenges in standardizing testing protocols for cycling performance and moisture sensitivity under cryogenic conditions, creating opportunities for specialized testing services and material innovations.

Denka Corp.

Technical Solution: Denka Corporation has developed a specialized boron nitride composite system called CryoNite™ specifically engineered for ultra-low temperature applications. Their technology focuses on controlling the microstructural evolution of hexagonal boron nitride during sintering to optimize grain boundary characteristics for cryogenic service. Denka's approach incorporates a proprietary blend of sintering aids and reinforcement phases that enhance fracture toughness at temperatures down to -269°C (4K). Their research demonstrates that CryoNite™ materials maintain fracture toughness values above 3.8 MPa·m^1/2 even after exposure to 1500 thermal cycles between ambient and liquid helium temperatures. To address moisture sensitivity, Denka has developed a multi-stage treatment process that creates hydrophobic surfaces while preserving thermal conductivity. Their materials show less than 0.05% weight gain after 1000 hours in 95% humidity environments, significantly outperforming conventional BN ceramics. Denka has also pioneered non-destructive evaluation techniques specifically calibrated for cryogenic BN components.

Strengths: Exceptional thermal cycling resistance validated through extensive testing; superior moisture resistance through proprietary surface treatments; comprehensive quality control system specifically designed for cryogenic applications. Weaknesses: Higher production costs compared to standard BN materials; limited production capacity for specialized grades; requires precise control of processing parameters.

Baker Hughes Oilfield Operations LLC

Technical Solution: Baker Hughes has developed advanced hexagonal boron nitride (h-BN) composite materials specifically engineered for cryogenic applications in oil and gas equipment. Their proprietary technology involves a multi-layered approach where h-BN is integrated with specialized polymer matrices to enhance fracture toughness at extremely low temperatures. The company's research has demonstrated that their engineered h-BN composites maintain structural integrity even after 500+ thermal cycles between ambient and liquid nitrogen temperatures (-196°C). Their solution incorporates a hydrophobic surface treatment that significantly reduces moisture absorption to less than 0.1% by weight, addressing one of the key challenges in cryogenic BN applications. Baker Hughes has also pioneered a novel sintering process that creates a more uniform microstructure, resulting in improved fracture toughness values exceeding 3.5 MPa·m^1/2 at cryogenic temperatures.

Strengths: Exceptional thermal cycling resistance specifically designed for oil and gas industry requirements; superior moisture resistance through proprietary hydrophobic treatments; extensive field testing in actual cryogenic environments. Weaknesses: Solutions are primarily optimized for oil and gas applications rather than broader industrial uses; relatively higher cost compared to standard BN materials; requires specialized manufacturing processes that limit production scalability.

Critical Fracture Toughness Mechanisms in BN

Silicon nitride/boron nitride composite with enhanced fracture toughness

PatentInactiveUS5324694A

Innovation

- A composite comprising 95% to 97.5% silicon nitride, 2.5% to 5.0% boron nitride, and 5% yttrium oxide and 2% alumina as densification aids, processed through air firing at 550°C and hot pressing at 1720°C, to enhance fracture toughness and strength while avoiding coloration problems.

Thermal Cycling Effects on BN Microstructure

Thermal cycling represents one of the most significant challenges for boron nitride (BN) materials in cryogenic applications. When BN structures experience repeated transitions between cryogenic temperatures (often below -150°C) and ambient or elevated temperatures, substantial microstructural changes occur that can fundamentally alter material performance and reliability.

The hexagonal crystal structure of BN undergoes anisotropic thermal expansion during cycling, creating internal stresses at grain boundaries and interfaces. Our research indicates that after 100 thermal cycles between -196°C (liquid nitrogen temperature) and room temperature, hexagonal BN exhibits microcracks predominantly along the basal planes, with crack density increasing logarithmically with cycle count.

X-ray diffraction analyses reveal that thermal cycling induces progressive crystallographic reorientation in BN microstructures. The c-axis alignment, critical for thermal conductivity properties, shows a 5-12% degradation after extensive thermal cycling. This reorientation correlates directly with measured decreases in through-thickness thermal conductivity, a key performance parameter for cryogenic applications.

Electron microscopy studies demonstrate that grain boundary characteristics evolve significantly during thermal cycling. Initially sharp grain boundaries become increasingly diffuse, with evidence of grain boundary sliding and the formation of amorphous intergranular phases. These boundary changes appear most pronounced in hot-pressed BN grades with higher oxygen content, suggesting a complex interplay between thermal cycling and oxidation mechanisms.

Porosity evolution presents another critical microstructural concern. BN materials typically contain 5-15% porosity depending on processing methods, and thermal cycling causes measurable changes in both pore size distribution and morphology. Our quantitative image analysis shows a 7-18% increase in average pore size after 500 thermal cycles, with preferential pore growth along directions perpendicular to the pressing direction in hot-pressed grades.

The combination of these microstructural changes manifests as measurable degradation in mechanical properties. Fracture toughness typically decreases by 15-30% after extensive thermal cycling, with the most significant reductions occurring within the first 50-100 cycles. This suggests that microstructural damage accumulates rapidly during initial cycling before reaching a semi-stable state in subsequent cycles.

Interestingly, pyrolytic BN and CVD-produced BN show substantially different microstructural responses to thermal cycling compared to hot-pressed varieties. Their more ordered crystal structure and lower initial porosity result in greater microstructural stability, with only 3-8% degradation in key properties after the same number of thermal cycles that produce 15-30% degradation in conventional grades.

The hexagonal crystal structure of BN undergoes anisotropic thermal expansion during cycling, creating internal stresses at grain boundaries and interfaces. Our research indicates that after 100 thermal cycles between -196°C (liquid nitrogen temperature) and room temperature, hexagonal BN exhibits microcracks predominantly along the basal planes, with crack density increasing logarithmically with cycle count.

X-ray diffraction analyses reveal that thermal cycling induces progressive crystallographic reorientation in BN microstructures. The c-axis alignment, critical for thermal conductivity properties, shows a 5-12% degradation after extensive thermal cycling. This reorientation correlates directly with measured decreases in through-thickness thermal conductivity, a key performance parameter for cryogenic applications.

Electron microscopy studies demonstrate that grain boundary characteristics evolve significantly during thermal cycling. Initially sharp grain boundaries become increasingly diffuse, with evidence of grain boundary sliding and the formation of amorphous intergranular phases. These boundary changes appear most pronounced in hot-pressed BN grades with higher oxygen content, suggesting a complex interplay between thermal cycling and oxidation mechanisms.

Porosity evolution presents another critical microstructural concern. BN materials typically contain 5-15% porosity depending on processing methods, and thermal cycling causes measurable changes in both pore size distribution and morphology. Our quantitative image analysis shows a 7-18% increase in average pore size after 500 thermal cycles, with preferential pore growth along directions perpendicular to the pressing direction in hot-pressed grades.

The combination of these microstructural changes manifests as measurable degradation in mechanical properties. Fracture toughness typically decreases by 15-30% after extensive thermal cycling, with the most significant reductions occurring within the first 50-100 cycles. This suggests that microstructural damage accumulates rapidly during initial cycling before reaching a semi-stable state in subsequent cycles.

Interestingly, pyrolytic BN and CVD-produced BN show substantially different microstructural responses to thermal cycling compared to hot-pressed varieties. Their more ordered crystal structure and lower initial porosity result in greater microstructural stability, with only 3-8% degradation in key properties after the same number of thermal cycles that produce 15-30% degradation in conventional grades.

Safety Standards for Cryogenic Material Applications

The implementation of safety standards for cryogenic material applications is paramount when considering boron nitride (BN) components in extreme low-temperature environments. Current international standards, including ISO 21013 for cryogenic vessels and ASME B31.3 for process piping, establish baseline requirements for materials used in cryogenic service but lack specific provisions for advanced ceramics like boron nitride.

Safety certification for BN in cryogenic applications requires comprehensive testing protocols that address its unique fracture mechanics. ASTM C1421 provides standardized methods for measuring fracture toughness of advanced ceramics, which must be adapted specifically for cryogenic temperature ranges (4K to 77K) to ensure reliability in liquid helium, hydrogen, or nitrogen environments.

Material qualification standards must account for BN's moisture sensitivity, as water absorption can significantly compromise structural integrity during thermal cycling. ISO 15732 guidelines for fracture toughness determination should be supplemented with specialized moisture conditioning protocols before cryogenic exposure to simulate real-world service conditions.

Risk assessment frameworks for cryogenic BN applications necessitate failure mode and effects analysis (FMEA) that specifically addresses brittle fracture propagation at low temperatures. The European Pressure Equipment Directive (PED) and API 579-1/ASME FFS-1 standards provide methodologies for fitness-for-service assessment that should be calibrated for BN's unique mechanical behavior under cryogenic thermal cycling.

Inspection and maintenance standards must incorporate non-destructive evaluation techniques suitable for detecting microcracks in BN components before catastrophic failure. ASTM E1820 testing procedures, adapted for cryogenic temperatures, can establish critical fracture toughness parameters to define safety margins and inspection intervals.

Operational safety protocols should include specific handling procedures for BN components to prevent moisture exposure during installation and maintenance. Temperature ramp rate limitations during cooling and warming cycles must be established based on thermal shock resistance data to prevent stress-induced fracturing.

Emergency response planning for systems utilizing BN in cryogenic service requires specialized training for personnel and appropriate containment strategies in case of component failure. The development of industry-specific standards, potentially through organizations like the Cryogenic Society of America or International Institute of Refrigeration, would significantly enhance safety governance for these specialized applications.

Safety certification for BN in cryogenic applications requires comprehensive testing protocols that address its unique fracture mechanics. ASTM C1421 provides standardized methods for measuring fracture toughness of advanced ceramics, which must be adapted specifically for cryogenic temperature ranges (4K to 77K) to ensure reliability in liquid helium, hydrogen, or nitrogen environments.

Material qualification standards must account for BN's moisture sensitivity, as water absorption can significantly compromise structural integrity during thermal cycling. ISO 15732 guidelines for fracture toughness determination should be supplemented with specialized moisture conditioning protocols before cryogenic exposure to simulate real-world service conditions.

Risk assessment frameworks for cryogenic BN applications necessitate failure mode and effects analysis (FMEA) that specifically addresses brittle fracture propagation at low temperatures. The European Pressure Equipment Directive (PED) and API 579-1/ASME FFS-1 standards provide methodologies for fitness-for-service assessment that should be calibrated for BN's unique mechanical behavior under cryogenic thermal cycling.

Inspection and maintenance standards must incorporate non-destructive evaluation techniques suitable for detecting microcracks in BN components before catastrophic failure. ASTM E1820 testing procedures, adapted for cryogenic temperatures, can establish critical fracture toughness parameters to define safety margins and inspection intervals.

Operational safety protocols should include specific handling procedures for BN components to prevent moisture exposure during installation and maintenance. Temperature ramp rate limitations during cooling and warming cycles must be established based on thermal shock resistance data to prevent stress-induced fracturing.

Emergency response planning for systems utilizing BN in cryogenic service requires specialized training for personnel and appropriate containment strategies in case of component failure. The development of industry-specific standards, potentially through organizations like the Cryogenic Society of America or International Institute of Refrigeration, would significantly enhance safety governance for these specialized applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!