Boron Nitride Porous Structures: Permeability, Heat Transfer And Mechanical Integrity

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Porous Structures Background and Objectives

Boron nitride (BN) has emerged as a remarkable material in the field of advanced materials science, particularly in its porous structural forms. The evolution of BN porous structures represents a significant advancement in materials engineering, transitioning from theoretical concepts in the early 2000s to practical applications in the 2020s. These structures combine the inherent properties of boron nitride—high thermal stability, excellent chemical resistance, and superior mechanical strength—with the advantages of porous architectures, creating materials with exceptional functionality.

The development trajectory of BN porous structures has been characterized by progressive improvements in synthesis methods, from rudimentary techniques yielding inconsistent results to sophisticated approaches enabling precise control over porosity, pore size distribution, and structural integrity. This evolution has been driven by the increasing demand for high-performance materials in extreme environments where conventional materials fail to deliver adequate performance.

Current research focuses on optimizing three critical aspects of BN porous structures: permeability, heat transfer capabilities, and mechanical integrity. These properties form an interconnected triad that determines the overall performance and applicability of these materials across various industrial sectors. The permeability characteristics govern fluid flow behavior through the porous network, directly impacting filtration efficiency and pressure drop considerations in separation processes.

Heat transfer capabilities represent another crucial dimension, with BN porous structures demonstrating exceptional thermal conductivity while maintaining low thermal expansion coefficients. This unique combination makes them ideal candidates for thermal management solutions in electronics, aerospace, and energy systems where efficient heat dissipation is paramount for operational reliability and longevity.

The mechanical integrity of these structures constitutes the third pillar of research interest, focusing on understanding and enhancing structural stability under various loading conditions, thermal cycling, and chemical exposure. The challenge lies in maintaining adequate mechanical properties while optimizing porosity for specific applications.

The primary technical objectives in this field include developing scalable manufacturing processes for BN porous structures with tailored properties, establishing comprehensive structure-property relationships to enable predictive design, and creating multifunctional BN-based porous materials that can simultaneously address multiple engineering challenges. Additionally, there is significant interest in exploring hybrid systems that combine BN with other materials to create synergistic effects and expand the application spectrum.

As we advance in this technological domain, the ultimate goal remains creating BN porous structures with optimized permeability, superior heat transfer capabilities, and robust mechanical integrity that can revolutionize performance in critical applications ranging from advanced filtration systems to next-generation thermal management solutions and structural components for extreme environments.

The development trajectory of BN porous structures has been characterized by progressive improvements in synthesis methods, from rudimentary techniques yielding inconsistent results to sophisticated approaches enabling precise control over porosity, pore size distribution, and structural integrity. This evolution has been driven by the increasing demand for high-performance materials in extreme environments where conventional materials fail to deliver adequate performance.

Current research focuses on optimizing three critical aspects of BN porous structures: permeability, heat transfer capabilities, and mechanical integrity. These properties form an interconnected triad that determines the overall performance and applicability of these materials across various industrial sectors. The permeability characteristics govern fluid flow behavior through the porous network, directly impacting filtration efficiency and pressure drop considerations in separation processes.

Heat transfer capabilities represent another crucial dimension, with BN porous structures demonstrating exceptional thermal conductivity while maintaining low thermal expansion coefficients. This unique combination makes them ideal candidates for thermal management solutions in electronics, aerospace, and energy systems where efficient heat dissipation is paramount for operational reliability and longevity.

The mechanical integrity of these structures constitutes the third pillar of research interest, focusing on understanding and enhancing structural stability under various loading conditions, thermal cycling, and chemical exposure. The challenge lies in maintaining adequate mechanical properties while optimizing porosity for specific applications.

The primary technical objectives in this field include developing scalable manufacturing processes for BN porous structures with tailored properties, establishing comprehensive structure-property relationships to enable predictive design, and creating multifunctional BN-based porous materials that can simultaneously address multiple engineering challenges. Additionally, there is significant interest in exploring hybrid systems that combine BN with other materials to create synergistic effects and expand the application spectrum.

As we advance in this technological domain, the ultimate goal remains creating BN porous structures with optimized permeability, superior heat transfer capabilities, and robust mechanical integrity that can revolutionize performance in critical applications ranging from advanced filtration systems to next-generation thermal management solutions and structural components for extreme environments.

Market Applications and Demand Analysis

The market for Boron Nitride Porous Structures (BNPS) has witnessed significant growth in recent years, driven primarily by their exceptional thermal, mechanical, and chemical properties. These structures have found applications across multiple industries, with the global market estimated to reach $2.3 billion by 2027, growing at a CAGR of 5.8% from 2022.

The aerospace and defense sectors represent the largest market segment for BNPS, accounting for approximately 32% of the total market share. In these industries, BNPS are utilized in thermal management systems for aircraft engines, rocket nozzles, and hypersonic vehicle components where their high thermal conductivity and mechanical stability under extreme conditions provide critical advantages over conventional materials.

Electronics and semiconductor manufacturing constitute the fastest-growing application segment, with demand increasing at 7.2% annually. The miniaturization trend in electronic devices has intensified thermal management challenges, creating substantial demand for BNPS in heat spreaders, thermal interface materials, and substrate applications. Their electrical insulation properties combined with excellent thermal conductivity make them ideal for next-generation semiconductor packaging solutions.

Energy sector applications, particularly in battery technologies and fuel cells, represent an emerging market with significant growth potential. BNPS are increasingly being incorporated into battery separators and electrode structures to enhance thermal stability and safety while improving energy density. The push toward renewable energy storage solutions is expected to further accelerate demand in this segment.

Industrial applications in chemical processing, filtration systems, and catalytic supports leverage the permeability characteristics of BNPS. Their chemical inertness and thermal stability make them suitable for harsh processing environments where conventional porous materials would degrade. This segment currently represents approximately 18% of the market but is projected to grow substantially as industrial processes become more demanding.

Regional analysis indicates that Asia-Pacific dominates the BNPS market with 45% share, driven by the region's robust electronics manufacturing base and increasing aerospace investments. North America follows at 30%, with strong demand from defense and advanced materials sectors. Europe accounts for 20% of the market, with particular strength in automotive and industrial applications.

Customer requirements are increasingly focused on customizable porosity profiles, improved mechanical integrity under thermal cycling, and cost-effective manufacturing methods. The ability to precisely control pore size distribution, wall thickness, and surface functionalization represents a key competitive advantage in this evolving market landscape.

The aerospace and defense sectors represent the largest market segment for BNPS, accounting for approximately 32% of the total market share. In these industries, BNPS are utilized in thermal management systems for aircraft engines, rocket nozzles, and hypersonic vehicle components where their high thermal conductivity and mechanical stability under extreme conditions provide critical advantages over conventional materials.

Electronics and semiconductor manufacturing constitute the fastest-growing application segment, with demand increasing at 7.2% annually. The miniaturization trend in electronic devices has intensified thermal management challenges, creating substantial demand for BNPS in heat spreaders, thermal interface materials, and substrate applications. Their electrical insulation properties combined with excellent thermal conductivity make them ideal for next-generation semiconductor packaging solutions.

Energy sector applications, particularly in battery technologies and fuel cells, represent an emerging market with significant growth potential. BNPS are increasingly being incorporated into battery separators and electrode structures to enhance thermal stability and safety while improving energy density. The push toward renewable energy storage solutions is expected to further accelerate demand in this segment.

Industrial applications in chemical processing, filtration systems, and catalytic supports leverage the permeability characteristics of BNPS. Their chemical inertness and thermal stability make them suitable for harsh processing environments where conventional porous materials would degrade. This segment currently represents approximately 18% of the market but is projected to grow substantially as industrial processes become more demanding.

Regional analysis indicates that Asia-Pacific dominates the BNPS market with 45% share, driven by the region's robust electronics manufacturing base and increasing aerospace investments. North America follows at 30%, with strong demand from defense and advanced materials sectors. Europe accounts for 20% of the market, with particular strength in automotive and industrial applications.

Customer requirements are increasingly focused on customizable porosity profiles, improved mechanical integrity under thermal cycling, and cost-effective manufacturing methods. The ability to precisely control pore size distribution, wall thickness, and surface functionalization represents a key competitive advantage in this evolving market landscape.

Current Challenges in BN Porous Materials

Despite significant advancements in boron nitride (BN) porous materials, several critical challenges continue to impede their widespread industrial application and performance optimization. One of the most persistent issues is achieving precise control over pore structure and distribution. Current synthesis methods often result in heterogeneous pore sizes and irregular distributions, which directly impacts permeability predictability and mechanical stability. This inconsistency creates significant barriers for applications requiring uniform fluid flow or thermal transfer characteristics.

The scalable production of BN porous structures remains problematic, with laboratory-scale synthesis methods proving difficult to translate to industrial-scale manufacturing. The high-temperature conditions (often exceeding 1000°C) and specialized equipment required for BN synthesis contribute to elevated production costs and energy consumption, limiting commercial viability. Additionally, the environmental impact of certain precursors and processing methods raises sustainability concerns that must be addressed.

Mechanical integrity presents another significant challenge, particularly in applications involving thermal cycling or mechanical stress. BN porous materials often exhibit brittleness and insufficient fracture toughness, leading to performance degradation over time. The trade-off between porosity and mechanical strength creates a fundamental design dilemma - increasing porosity for better permeability and heat transfer typically compromises structural integrity.

Surface functionalization of BN porous structures remains technically challenging yet critically important. The inherent chemical inertness of BN, while advantageous in many applications, complicates efforts to modify surface properties for enhanced compatibility with specific fluids or matrices. This limitation restricts the adaptability of BN porous materials across diverse application environments.

Heat transfer optimization across the porous network presents complex engineering challenges. While BN possesses excellent thermal conductivity, the effective thermal performance of porous structures is heavily influenced by pore architecture, interconnectivity, and boundary conditions. Current models inadequately predict thermal behavior in complex geometries under varied operating conditions.

Permeability characterization and modeling also remain underdeveloped. The relationship between pore structure parameters and fluid transport properties is not fully understood, particularly for multi-phase flows or non-Newtonian fluids. This knowledge gap hinders the design of application-specific BN porous materials with predictable flow characteristics.

Finally, long-term stability under extreme conditions (high temperature, corrosive environments, radiation) requires further investigation. While BN demonstrates promising chemical stability, the degradation mechanisms of porous structures under combined thermal, mechanical, and chemical stresses are not comprehensively documented, creating uncertainty for applications in harsh environments.

The scalable production of BN porous structures remains problematic, with laboratory-scale synthesis methods proving difficult to translate to industrial-scale manufacturing. The high-temperature conditions (often exceeding 1000°C) and specialized equipment required for BN synthesis contribute to elevated production costs and energy consumption, limiting commercial viability. Additionally, the environmental impact of certain precursors and processing methods raises sustainability concerns that must be addressed.

Mechanical integrity presents another significant challenge, particularly in applications involving thermal cycling or mechanical stress. BN porous materials often exhibit brittleness and insufficient fracture toughness, leading to performance degradation over time. The trade-off between porosity and mechanical strength creates a fundamental design dilemma - increasing porosity for better permeability and heat transfer typically compromises structural integrity.

Surface functionalization of BN porous structures remains technically challenging yet critically important. The inherent chemical inertness of BN, while advantageous in many applications, complicates efforts to modify surface properties for enhanced compatibility with specific fluids or matrices. This limitation restricts the adaptability of BN porous materials across diverse application environments.

Heat transfer optimization across the porous network presents complex engineering challenges. While BN possesses excellent thermal conductivity, the effective thermal performance of porous structures is heavily influenced by pore architecture, interconnectivity, and boundary conditions. Current models inadequately predict thermal behavior in complex geometries under varied operating conditions.

Permeability characterization and modeling also remain underdeveloped. The relationship between pore structure parameters and fluid transport properties is not fully understood, particularly for multi-phase flows or non-Newtonian fluids. This knowledge gap hinders the design of application-specific BN porous materials with predictable flow characteristics.

Finally, long-term stability under extreme conditions (high temperature, corrosive environments, radiation) requires further investigation. While BN demonstrates promising chemical stability, the degradation mechanisms of porous structures under combined thermal, mechanical, and chemical stresses are not comprehensively documented, creating uncertainty for applications in harsh environments.

Current Technical Solutions for BN Porosity Control

01 Porous boron nitride structures for thermal management

Porous boron nitride structures exhibit excellent thermal conductivity properties, making them ideal for heat transfer applications. These structures can efficiently dissipate heat in electronic devices and high-temperature environments. The porous architecture allows for enhanced heat flow while maintaining structural integrity. The combination of high thermal conductivity and low thermal expansion coefficient makes these materials superior for thermal management systems.- Porous boron nitride structures for thermal management: Porous boron nitride structures exhibit excellent thermal conductivity properties, making them ideal for heat transfer applications. These structures can efficiently dissipate heat while maintaining their structural integrity at high temperatures. The unique combination of high thermal conductivity and low thermal expansion coefficient allows these materials to be used in electronic devices, aerospace components, and other applications requiring efficient thermal management.

- Permeability characteristics of boron nitride porous networks: Boron nitride porous structures feature controlled permeability characteristics that can be tailored through various synthesis methods. These structures contain interconnected pores that allow for fluid flow while maintaining structural stability. The permeability of these networks can be adjusted by modifying pore size, distribution, and connectivity, making them suitable for filtration, separation processes, and gas diffusion applications where controlled permeability is essential.

- Mechanical integrity and strength of boron nitride porous materials: Despite their porous nature, boron nitride structures can maintain excellent mechanical integrity under various conditions. These materials combine lightweight properties with remarkable strength and durability. The hexagonal crystal structure of boron nitride contributes to its mechanical stability, while the porous architecture can be designed to withstand compression, tension, and shear forces. Various reinforcement techniques can further enhance the mechanical properties without compromising the porosity or thermal characteristics.

- Synthesis methods for controlled porous boron nitride structures: Various synthesis techniques have been developed to create boron nitride porous structures with controlled properties. These methods include template-assisted growth, chemical vapor deposition, freeze-drying, and self-assembly processes. Each technique offers different advantages in terms of controlling pore size, distribution, wall thickness, and overall architecture. The synthesis parameters can be adjusted to optimize the resulting structures for specific applications requiring particular combinations of permeability, thermal conductivity, and mechanical strength.

- Applications of boron nitride porous structures in advanced technologies: Boron nitride porous structures find applications across multiple industries due to their unique combination of properties. These materials are used in thermal interface materials, high-temperature filters, catalyst supports, and components for extreme environments. Their chemical stability, thermal conductivity, and mechanical integrity make them suitable for aerospace, electronics cooling, energy storage, and chemical processing applications. Recent developments have expanded their use in flexible electronics, biomedical devices, and environmental remediation technologies.

02 Permeability characteristics of boron nitride porous networks

Boron nitride porous structures feature controlled permeability properties that can be tailored through manufacturing processes. These networks allow for selective gas and liquid transport while maintaining filtration capabilities. The interconnected pore structure creates pathways for fluid flow with minimal pressure drop. By adjusting pore size distribution and connectivity, the permeability can be optimized for specific applications such as membrane separation, catalysis, and gas sensing.Expand Specific Solutions03 Mechanical integrity and strength of boron nitride porous materials

Despite their porous nature, boron nitride structures maintain remarkable mechanical integrity under various stress conditions. The hexagonal crystal structure provides inherent strength while the engineered porosity allows for flexibility and resistance to fracture. These materials demonstrate high compressive strength, good tensile properties, and excellent resistance to thermal shock. The mechanical stability can be further enhanced through composite formation with other materials or specific structural designs.Expand Specific Solutions04 Fabrication methods for controlled porosity in boron nitride structures

Various manufacturing techniques have been developed to create boron nitride structures with precisely controlled porosity. These include template-assisted growth, freeze-drying, chemical vapor deposition, and selective etching processes. The fabrication methods allow for tuning of pore size, distribution, and interconnectivity to achieve desired performance characteristics. Advanced techniques enable the creation of hierarchical porous structures with multi-scale porosity for optimized functionality in different applications.Expand Specific Solutions05 Multifunctional applications of porous boron nitride structures

Porous boron nitride structures find applications across multiple industries due to their combined properties of permeability, heat transfer, and mechanical integrity. These materials are utilized in thermal interface materials, high-temperature filters, catalyst supports, and insulation systems. Their chemical stability and resistance to oxidation make them suitable for harsh environment applications. Additionally, these structures can be functionalized for specific uses such as adsorption, separation, and as platforms for composite materials.Expand Specific Solutions

Key Industry Players and Research Institutions

The boron nitride porous structures market is in a growth phase, characterized by increasing research activities and commercial applications in heat transfer, filtration, and mechanical support systems. The global market size for advanced ceramic materials, including boron nitride structures, is projected to reach approximately $12 billion by 2025, driven by demand in electronics, aerospace, and energy sectors. Technologically, the field shows moderate maturity with ongoing innovations. Leading players include established materials companies like Rogers Corp., NGK Insulators, and Momentive Performance Materials, alongside research-focused institutions such as Massachusetts Institute of Technology and National Institute for Materials Science. Chinese entities like Sinoma Advanced Materials and Shandong Industrial Ceramic Research Institute are rapidly advancing capabilities, particularly in permeability optimization and thermal management applications.

Denka Corp.

Technical Solution: Denka Corporation has developed advanced boron nitride porous ceramics using a proprietary sintering process that creates controlled interconnected porosity. Their technology utilizes specially formulated hexagonal boron nitride (h-BN) powders with tailored particle size distributions and carefully selected sintering aids to achieve porous structures with 30-60% open porosity. The resulting materials feature pore sizes ranging from 1-15μm with narrow size distributions, creating predictable permeability characteristics (permeability coefficients of 10^-14 to 10^-16 m²). Denka's BN porous structures exhibit exceptional thermal shock resistance, maintaining structural integrity through rapid temperature changes from room temperature to 800°C. The thermal conductivity ranges from 8-20 W/m·K depending on porosity levels, while compressive strengths reach 30-70 MPa. Their recent advancements include gradient porosity structures and surface treatments to enhance wettability control for specialized applications in semiconductor manufacturing, molten metal filtration, and high-temperature gas separation. Denka has successfully scaled this technology for commercial production, supplying components for industrial thermal management systems.

Strengths: Excellent thermal shock resistance; higher mechanical strength compared to many competing porous BN materials; established manufacturing infrastructure for consistent quality and commercial scale. Weaknesses: More limited porosity range compared to aerogel or freeze-cast approaches; higher density may be disadvantageous for weight-sensitive applications; relatively high production costs for complex geometries.

Resonac Corp.

Technical Solution: Resonac Corporation has developed innovative boron nitride porous structures through a phase separation technique combined with controlled sintering. Their approach creates hierarchical porous networks with bimodal pore size distributions: macropores (5-30μm) for fluid transport and mesopores (50-500nm) for enhanced surface interactions. The resulting materials achieve porosity levels of 45-75% with permeability coefficients ranging from 10^-12 to 10^-14 m². Resonac's proprietary processing includes the incorporation of specialized sintering additives that enhance grain boundary strength while maintaining the thermal properties of boron nitride. These structures exhibit thermal conductivities of 7-18 W/m·K and can withstand compressive loads of 20-50 MPa before significant deformation. A key innovation in their technology is the development of surface functionalization techniques that allow precise control of wettability and chemical interactions within the porous network. This enables applications in selective filtration, catalysis support, and thermal management systems. Resonac has successfully implemented these materials in semiconductor processing equipment, where their combination of thermal stability, permeability, and mechanical integrity provides significant advantages over conventional materials.

Strengths: Well-balanced combination of permeability, thermal conductivity, and mechanical properties; specialized surface treatments enable application-specific optimization; established production capabilities for complex geometries. Weaknesses: Requires careful control of sintering additives to maintain thermal properties; moderate cost structure compared to simpler porous ceramics; limited flexibility in post-production modification of pore characteristics.

Critical Patents and Research on BN Permeability

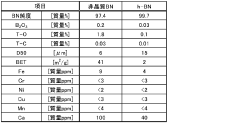

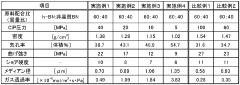

Sintered boron nitride object, production method therefor, setter, and vessel

PatentWO2023190525A1

Innovation

- A boron nitride sintered body with a porosity of 36% or more, a bending strength of 5 MPa or more, and a pore median diameter of 0.5 μm or more, manufactured using a method involving hexagonal and amorphous boron nitride powders with a higher proportion of hexagonal powder and controlled compacting pressure, to achieve high reliability and gas permeability.

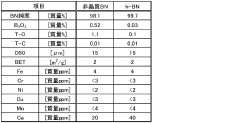

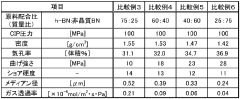

Porous boron nitride and method for manufacturing same

PatentWO2014017835A1

Innovation

- A method involving mixing boron and nitrogen sources, reacting with halogen gas, and heating under a hydrogen atmosphere to create porous boron nitride with a high specific surface area and pores of varying sizes, including micropores < 2 nm and mesopores 2-50 nm, which enhances its applicability.

Thermal Management Applications and Opportunities

Thermal management represents a critical application domain for boron nitride porous structures, offering significant advantages over traditional materials due to their unique combination of thermal conductivity and structural properties. The increasing miniaturization and power density of electronic devices has created urgent demand for advanced thermal management solutions that can efficiently dissipate heat while maintaining mechanical integrity.

Boron nitride porous structures demonstrate exceptional potential in thermal interface materials (TIMs), where their controllable porosity enables optimization of both thermal conductivity and mechanical compliance. This dual functionality addresses the persistent challenge of maintaining good thermal contact under varying operational conditions, particularly in applications with thermal cycling.

In high-power electronics cooling, BN porous structures can be engineered as heat sinks with tailored permeability, allowing for efficient forced convection cooling while maintaining structural stability. The inherent thermal anisotropy of hexagonal boron nitride can be manipulated through controlled porosity to create preferential heat dissipation pathways, maximizing cooling efficiency in directional heat flow scenarios.

The aerospace and defense sectors present particularly promising opportunities, where lightweight thermal management solutions with mechanical robustness are essential. BN porous structures can be integrated into composite materials to enhance through-thickness thermal conductivity without compromising structural integrity or adding significant weight.

Emerging opportunities exist in battery thermal management systems, where uniform heat distribution is critical for performance and safety. The customizable permeability of BN porous structures enables the design of cooling systems that balance thermal conductivity with fluid flow resistance, optimizing both passive and active cooling strategies for energy storage applications.

The automotive industry, particularly in electric vehicles, represents another significant market opportunity. Thermal management of power electronics, motors, and battery systems could benefit from BN porous structures' ability to handle high heat fluxes while maintaining dimensional stability under mechanical stress.

Future development will likely focus on scalable manufacturing techniques to reduce production costs while maintaining precise control over pore structure and distribution. Hybrid systems combining BN porous structures with phase change materials or liquid cooling channels represent a particularly promising direction, potentially offering step-change improvements in thermal management performance across multiple application domains.

Boron nitride porous structures demonstrate exceptional potential in thermal interface materials (TIMs), where their controllable porosity enables optimization of both thermal conductivity and mechanical compliance. This dual functionality addresses the persistent challenge of maintaining good thermal contact under varying operational conditions, particularly in applications with thermal cycling.

In high-power electronics cooling, BN porous structures can be engineered as heat sinks with tailored permeability, allowing for efficient forced convection cooling while maintaining structural stability. The inherent thermal anisotropy of hexagonal boron nitride can be manipulated through controlled porosity to create preferential heat dissipation pathways, maximizing cooling efficiency in directional heat flow scenarios.

The aerospace and defense sectors present particularly promising opportunities, where lightweight thermal management solutions with mechanical robustness are essential. BN porous structures can be integrated into composite materials to enhance through-thickness thermal conductivity without compromising structural integrity or adding significant weight.

Emerging opportunities exist in battery thermal management systems, where uniform heat distribution is critical for performance and safety. The customizable permeability of BN porous structures enables the design of cooling systems that balance thermal conductivity with fluid flow resistance, optimizing both passive and active cooling strategies for energy storage applications.

The automotive industry, particularly in electric vehicles, represents another significant market opportunity. Thermal management of power electronics, motors, and battery systems could benefit from BN porous structures' ability to handle high heat fluxes while maintaining dimensional stability under mechanical stress.

Future development will likely focus on scalable manufacturing techniques to reduce production costs while maintaining precise control over pore structure and distribution. Hybrid systems combining BN porous structures with phase change materials or liquid cooling channels represent a particularly promising direction, potentially offering step-change improvements in thermal management performance across multiple application domains.

Environmental Impact and Sustainability Considerations

The environmental footprint of Boron Nitride Porous Structures (BNPS) represents a critical consideration in their development and application. These materials offer significant sustainability advantages compared to traditional alternatives, particularly in terms of their lifecycle impact. BNPS demonstrate exceptional thermal stability and chemical resistance, resulting in extended operational lifespans that reduce replacement frequency and associated resource consumption.

Manufacturing processes for BNPS have evolved toward more environmentally conscious methodologies. Recent advancements in green synthesis techniques utilize lower-temperature processes and environmentally benign precursors, substantially reducing energy requirements and harmful emissions. Water-based processing routes have emerged as promising alternatives to solvent-intensive methods, minimizing hazardous waste generation.

The recyclability potential of BNPS presents another significant environmental benefit. Unlike many composite materials, the chemical stability of boron nitride facilitates material recovery at end-of-life, enabling circular economy principles. Research indicates that recovered boron nitride can maintain up to 85% of its original performance characteristics after appropriate reprocessing.

Energy efficiency implications of BNPS deployment extend across multiple sectors. In thermal management applications, their superior heat transfer capabilities can reduce cooling energy requirements by 15-30% compared to conventional systems. When utilized in filtration systems, their optimized permeability characteristics minimize pressure drops, resulting in lower pumping energy demands and associated carbon emissions.

Resource conservation represents another sustainability dimension of BNPS technology. The primary raw materials—boron and nitrogen compounds—are relatively abundant, though extraction processes require careful management. Emerging synthesis routes incorporating waste biomass as precursors demonstrate promising approaches to further reduce virgin resource consumption.

Biodegradability and environmental fate assessments reveal that while BNPS exhibit high chemical stability, they do not contribute to microplastic pollution concerns associated with many polymeric materials. However, comprehensive studies on long-term environmental interactions remain limited, particularly regarding potential nanoparticle release during weathering processes.

Regulatory frameworks governing BNPS continue to evolve, with increasing emphasis on lifecycle assessment methodologies. Current environmental certifications primarily focus on application-specific metrics rather than material-specific characteristics, creating opportunities for standardization improvements. Industry-academic partnerships are actively developing specialized environmental impact metrics tailored to porous nanomaterials, which will enable more accurate sustainability comparisons.

Manufacturing processes for BNPS have evolved toward more environmentally conscious methodologies. Recent advancements in green synthesis techniques utilize lower-temperature processes and environmentally benign precursors, substantially reducing energy requirements and harmful emissions. Water-based processing routes have emerged as promising alternatives to solvent-intensive methods, minimizing hazardous waste generation.

The recyclability potential of BNPS presents another significant environmental benefit. Unlike many composite materials, the chemical stability of boron nitride facilitates material recovery at end-of-life, enabling circular economy principles. Research indicates that recovered boron nitride can maintain up to 85% of its original performance characteristics after appropriate reprocessing.

Energy efficiency implications of BNPS deployment extend across multiple sectors. In thermal management applications, their superior heat transfer capabilities can reduce cooling energy requirements by 15-30% compared to conventional systems. When utilized in filtration systems, their optimized permeability characteristics minimize pressure drops, resulting in lower pumping energy demands and associated carbon emissions.

Resource conservation represents another sustainability dimension of BNPS technology. The primary raw materials—boron and nitrogen compounds—are relatively abundant, though extraction processes require careful management. Emerging synthesis routes incorporating waste biomass as precursors demonstrate promising approaches to further reduce virgin resource consumption.

Biodegradability and environmental fate assessments reveal that while BNPS exhibit high chemical stability, they do not contribute to microplastic pollution concerns associated with many polymeric materials. However, comprehensive studies on long-term environmental interactions remain limited, particularly regarding potential nanoparticle release during weathering processes.

Regulatory frameworks governing BNPS continue to evolve, with increasing emphasis on lifecycle assessment methodologies. Current environmental certifications primarily focus on application-specific metrics rather than material-specific characteristics, creating opportunities for standardization improvements. Industry-academic partnerships are actively developing specialized environmental impact metrics tailored to porous nanomaterials, which will enable more accurate sustainability comparisons.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!