How Boron Nitride Coatings Reduce Start-Up Wear In Dry-Running Bearings?

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Boron Nitride Coating Technology Background and Objectives

Boron nitride (BN) coatings represent a significant advancement in tribological engineering, with their development tracing back to the mid-20th century. Initially explored as alternatives to graphite lubricants for high-temperature applications, these coatings have evolved substantially over the past decades. The hexagonal boron nitride (h-BN) structure, often referred to as "white graphite," possesses a unique layered crystalline arrangement that provides exceptional lubricity even in extreme conditions where traditional lubricants fail.

The evolution of BN coating technology has been marked by several key milestones. Early applications focused primarily on aerospace and military sectors, but industrial applications emerged in the 1980s as manufacturing techniques improved. The 1990s saw significant breakthroughs in deposition methods, including chemical vapor deposition (CVD) and physical vapor deposition (PVD), which dramatically enhanced coating quality and adhesion properties.

Recent technological trends have focused on nano-structured BN coatings and hybrid systems that combine BN with other materials to achieve synergistic effects. These developments have expanded the potential applications of BN coatings beyond traditional high-temperature environments to include various dry-running bearing systems across multiple industries.

The primary objective of BN coating technology in dry-running bearings is to minimize friction and wear during the critical start-up phase when conventional lubrication is absent or insufficient. This is particularly important as the majority of bearing damage occurs during initial motion before hydrodynamic lubrication regimes are established. By providing a solid lubricant layer that functions effectively under boundary lubrication conditions, BN coatings aim to extend bearing life and improve system reliability.

Secondary objectives include reducing energy consumption through decreased friction coefficients, eliminating the need for external lubrication systems in certain applications, and enabling operation in extreme environments where liquid lubricants would degrade or be impractical. Environmental considerations have also become increasingly important, with BN coatings offering potential advantages as non-toxic alternatives to some traditional lubricant systems.

The technological trajectory suggests continued refinement of BN coating compositions, deposition techniques, and substrate preparation methods. Current research aims to optimize the balance between coating hardness and lubricity, improve adhesion to various substrate materials, and enhance durability under cyclic loading conditions. Emerging goals include the development of self-healing BN coating systems and smart coatings that can adapt to changing operational conditions.

The evolution of BN coating technology has been marked by several key milestones. Early applications focused primarily on aerospace and military sectors, but industrial applications emerged in the 1980s as manufacturing techniques improved. The 1990s saw significant breakthroughs in deposition methods, including chemical vapor deposition (CVD) and physical vapor deposition (PVD), which dramatically enhanced coating quality and adhesion properties.

Recent technological trends have focused on nano-structured BN coatings and hybrid systems that combine BN with other materials to achieve synergistic effects. These developments have expanded the potential applications of BN coatings beyond traditional high-temperature environments to include various dry-running bearing systems across multiple industries.

The primary objective of BN coating technology in dry-running bearings is to minimize friction and wear during the critical start-up phase when conventional lubrication is absent or insufficient. This is particularly important as the majority of bearing damage occurs during initial motion before hydrodynamic lubrication regimes are established. By providing a solid lubricant layer that functions effectively under boundary lubrication conditions, BN coatings aim to extend bearing life and improve system reliability.

Secondary objectives include reducing energy consumption through decreased friction coefficients, eliminating the need for external lubrication systems in certain applications, and enabling operation in extreme environments where liquid lubricants would degrade or be impractical. Environmental considerations have also become increasingly important, with BN coatings offering potential advantages as non-toxic alternatives to some traditional lubricant systems.

The technological trajectory suggests continued refinement of BN coating compositions, deposition techniques, and substrate preparation methods. Current research aims to optimize the balance between coating hardness and lubricity, improve adhesion to various substrate materials, and enhance durability under cyclic loading conditions. Emerging goals include the development of self-healing BN coating systems and smart coatings that can adapt to changing operational conditions.

Market Demand Analysis for Dry-Running Bearing Solutions

The global dry-running bearing market has experienced significant growth in recent years, driven by increasing demand across multiple industries seeking solutions that reduce maintenance requirements and operational costs. Current market analysis indicates that the dry-running bearing sector is expanding at a compound annual growth rate of approximately 6.5% and is projected to reach substantial market value by 2028, with particular acceleration in automotive, aerospace, and industrial manufacturing sectors.

Industries are increasingly prioritizing maintenance-free operations, creating strong demand for advanced bearing solutions that can operate without continuous lubrication. This shift is particularly evident in applications where contamination risks from traditional lubricants must be eliminated, such as food processing, pharmaceutical manufacturing, and medical equipment. Market research shows that over 70% of manufacturing facilities report lubrication-related failures as a primary cause of equipment downtime, highlighting the critical need for reliable dry-running alternatives.

Environmental regulations and sustainability initiatives are further propelling market growth for dry-running bearings. With stricter regulations on chemical lubricants and increased corporate focus on reducing environmental footprints, manufacturers are actively seeking greener alternatives that eliminate the need for oil-based lubricants. This regulatory pressure has created a premium market segment for environmentally compatible bearing solutions.

The economic impact of bearing failure presents another significant market driver. Industry reports indicate that unplanned downtime due to bearing failures costs manufacturers billions annually in lost production. This economic pressure has intensified interest in advanced coating technologies like boron nitride that can extend bearing life and reduce maintenance intervals, with customers demonstrating willingness to pay premium prices for solutions that deliver proven reliability improvements.

Regional market analysis reveals varying adoption rates, with North America and Europe leading in implementation of advanced dry-running bearing technologies, while Asia-Pacific represents the fastest-growing market due to rapid industrialization and increasing automation. Particularly strong demand exists in regions with extreme operating conditions, where traditional lubrication methods face limitations due to temperature extremes or contamination risks.

Customer surveys indicate that performance during start-up conditions ranks among the top three concerns for bearing selection, with 65% of engineers citing initial wear as a critical factor in total cost of ownership calculations. This specific pain point creates a targeted market opportunity for boron nitride coating technology, which addresses the precise challenge of reducing friction during the critical start-up phase when most bearing damage occurs.

Industries are increasingly prioritizing maintenance-free operations, creating strong demand for advanced bearing solutions that can operate without continuous lubrication. This shift is particularly evident in applications where contamination risks from traditional lubricants must be eliminated, such as food processing, pharmaceutical manufacturing, and medical equipment. Market research shows that over 70% of manufacturing facilities report lubrication-related failures as a primary cause of equipment downtime, highlighting the critical need for reliable dry-running alternatives.

Environmental regulations and sustainability initiatives are further propelling market growth for dry-running bearings. With stricter regulations on chemical lubricants and increased corporate focus on reducing environmental footprints, manufacturers are actively seeking greener alternatives that eliminate the need for oil-based lubricants. This regulatory pressure has created a premium market segment for environmentally compatible bearing solutions.

The economic impact of bearing failure presents another significant market driver. Industry reports indicate that unplanned downtime due to bearing failures costs manufacturers billions annually in lost production. This economic pressure has intensified interest in advanced coating technologies like boron nitride that can extend bearing life and reduce maintenance intervals, with customers demonstrating willingness to pay premium prices for solutions that deliver proven reliability improvements.

Regional market analysis reveals varying adoption rates, with North America and Europe leading in implementation of advanced dry-running bearing technologies, while Asia-Pacific represents the fastest-growing market due to rapid industrialization and increasing automation. Particularly strong demand exists in regions with extreme operating conditions, where traditional lubrication methods face limitations due to temperature extremes or contamination risks.

Customer surveys indicate that performance during start-up conditions ranks among the top three concerns for bearing selection, with 65% of engineers citing initial wear as a critical factor in total cost of ownership calculations. This specific pain point creates a targeted market opportunity for boron nitride coating technology, which addresses the precise challenge of reducing friction during the critical start-up phase when most bearing damage occurs.

Current Challenges in Dry-Running Bearing Technology

Dry-running bearings represent a critical component in numerous industrial applications where lubrication is impractical or undesirable. Despite their widespread use, these bearings face significant technical challenges that limit their performance and longevity. The primary challenge remains excessive wear during start-up conditions, when the absence of a fluid film creates direct surface-to-surface contact between bearing components, resulting in high friction coefficients and accelerated material degradation.

Material limitations constitute another major hurdle in dry-running bearing technology. Traditional materials like PTFE, nylon, and various polymers offer good initial performance but deteriorate rapidly under high loads or elevated temperatures. This deterioration manifests as dimensional instability, reduced mechanical strength, and increased wear rates, ultimately compromising the bearing's functional integrity and operational reliability.

Thermal management presents a persistent challenge, as friction-generated heat cannot be effectively dissipated without fluid lubrication. This heat accumulation creates a detrimental cycle where elevated temperatures accelerate wear, which in turn generates more friction and heat. Current cooling mechanisms often prove inadequate, particularly in high-speed or high-load applications where thermal buildup occurs rapidly.

Load capacity constraints significantly limit the application range of dry-running bearings. Without the pressure-distributing properties of lubricants, these bearings typically support only a fraction of the loads that conventional lubricated bearings can handle. This limitation necessitates larger bearing designs or multiple bearing arrangements, increasing system complexity and cost.

Environmental sensitivity poses another significant challenge, as many dry-running bearing materials exhibit performance degradation when exposed to moisture, chemicals, or particulate contamination. This sensitivity restricts their use in harsh industrial environments and necessitates additional protective measures that may compromise overall system efficiency.

The inconsistency of friction coefficients throughout the bearing's operational life represents a design challenge for precision applications. As wear progresses, friction characteristics change unpredictably, making it difficult to maintain precise motion control in applications requiring high accuracy. This variability complicates system design and necessitates frequent recalibration or component replacement.

Cost-effectiveness remains an ongoing challenge, as advanced materials and specialized coatings that address the aforementioned issues often come with significantly higher production costs. The economic viability of implementing these solutions must be carefully balanced against the performance benefits they provide, particularly in price-sensitive market segments.

Material limitations constitute another major hurdle in dry-running bearing technology. Traditional materials like PTFE, nylon, and various polymers offer good initial performance but deteriorate rapidly under high loads or elevated temperatures. This deterioration manifests as dimensional instability, reduced mechanical strength, and increased wear rates, ultimately compromising the bearing's functional integrity and operational reliability.

Thermal management presents a persistent challenge, as friction-generated heat cannot be effectively dissipated without fluid lubrication. This heat accumulation creates a detrimental cycle where elevated temperatures accelerate wear, which in turn generates more friction and heat. Current cooling mechanisms often prove inadequate, particularly in high-speed or high-load applications where thermal buildup occurs rapidly.

Load capacity constraints significantly limit the application range of dry-running bearings. Without the pressure-distributing properties of lubricants, these bearings typically support only a fraction of the loads that conventional lubricated bearings can handle. This limitation necessitates larger bearing designs or multiple bearing arrangements, increasing system complexity and cost.

Environmental sensitivity poses another significant challenge, as many dry-running bearing materials exhibit performance degradation when exposed to moisture, chemicals, or particulate contamination. This sensitivity restricts their use in harsh industrial environments and necessitates additional protective measures that may compromise overall system efficiency.

The inconsistency of friction coefficients throughout the bearing's operational life represents a design challenge for precision applications. As wear progresses, friction characteristics change unpredictably, making it difficult to maintain precise motion control in applications requiring high accuracy. This variability complicates system design and necessitates frequent recalibration or component replacement.

Cost-effectiveness remains an ongoing challenge, as advanced materials and specialized coatings that address the aforementioned issues often come with significantly higher production costs. The economic viability of implementing these solutions must be carefully balanced against the performance benefits they provide, particularly in price-sensitive market segments.

Current BN Coating Application Methods for Bearings

01 Boron Nitride Coating Deposition Methods

Various methods can be employed to deposit boron nitride coatings on substrates to enhance wear resistance. These methods include chemical vapor deposition (CVD), physical vapor deposition (PVD), plasma-enhanced techniques, and sputtering. The deposition parameters significantly influence the crystallinity, adhesion, and overall wear performance of the coating. Optimized deposition conditions can produce coatings with superior hardness and tribological properties for industrial applications.- Boron Nitride Coating Deposition Methods: Various methods can be employed to deposit boron nitride coatings on substrates to enhance wear resistance. These methods include chemical vapor deposition (CVD), physical vapor deposition (PVD), plasma-enhanced deposition, and sputtering techniques. The deposition parameters significantly influence the crystallinity, adhesion, and wear properties of the resulting coating. Optimized deposition conditions can produce coatings with superior hardness and tribological performance for industrial applications.

- Hexagonal Boron Nitride for Tribological Applications: Hexagonal boron nitride (h-BN) coatings provide excellent lubrication properties and wear resistance due to their layered structure similar to graphite. These coatings exhibit low friction coefficients and can withstand high temperatures, making them suitable for applications in harsh environments. The lamellar structure of h-BN allows for easy shearing between layers, providing solid lubrication that reduces wear during start-up conditions when liquid lubricants may be insufficient.

- Cubic Boron Nitride Coatings for Extreme Wear Resistance: Cubic boron nitride (c-BN) coatings offer exceptional hardness second only to diamond, making them ideal for severe wear applications. These coatings provide superior protection against abrasive and adhesive wear during start-up conditions when components experience the highest friction. The synthesis of c-BN typically requires high-pressure, high-temperature conditions or specialized deposition techniques to achieve the desired cubic crystal structure with optimal wear resistance properties.

- Composite and Multi-layer Boron Nitride Coating Systems: Composite and multi-layer coating systems incorporating boron nitride can be engineered to provide enhanced wear resistance during start-up conditions. These systems often combine boron nitride with other materials such as titanium nitride, silicon carbide, or metal matrices to optimize hardness, adhesion, and tribological properties. Gradient or multi-layer structures can be designed to provide both excellent adhesion to the substrate and superior surface wear properties.

- Surface Modification and Treatment of Boron Nitride Coatings: Post-deposition treatments and surface modifications can significantly improve the wear resistance of boron nitride coatings during start-up conditions. Techniques such as ion implantation, thermal annealing, laser treatment, and surface functionalization can enhance coating adhesion, reduce internal stresses, and optimize tribological properties. These treatments can be tailored to specific operating conditions to minimize wear during the critical start-up phase when most component damage typically occurs.

02 Hexagonal Boron Nitride for Tribological Applications

Hexagonal boron nitride (h-BN) coatings offer exceptional tribological properties, making them ideal for reducing friction and wear in mechanical systems. The layered structure of h-BN provides natural lubricity similar to graphite but with superior thermal stability and chemical inertness. These coatings can significantly reduce the coefficient of friction and extend the service life of components in high-temperature and harsh chemical environments where traditional lubricants fail.Expand Specific Solutions03 Cubic Boron Nitride Coatings for Extreme Wear Resistance

Cubic boron nitride (c-BN) coatings provide exceptional hardness second only to diamond, making them ideal for extreme wear applications. These coatings exhibit superior thermal stability and oxidation resistance compared to diamond coatings, allowing them to perform in high-temperature cutting and machining operations. The synthesis of c-BN typically requires high-pressure, high-temperature conditions or specialized deposition techniques to achieve the desired cubic crystal structure with optimal wear resistance properties.Expand Specific Solutions04 Boron Nitride Composite and Multilayer Coatings

Composite and multilayer coatings incorporating boron nitride with other materials can provide enhanced wear resistance and functionality. These systems often combine boron nitride with metals, ceramics, or other compounds to create synergistic effects that improve hardness, toughness, and adhesion to substrates. The multilayer architecture can be designed to optimize stress distribution, crack propagation resistance, and interfacial strength, resulting in superior wear performance compared to single-layer coatings.Expand Specific Solutions05 Surface Preparation and Post-Treatment for Boron Nitride Coatings

Proper surface preparation and post-deposition treatments are critical for optimizing the wear performance of boron nitride coatings. Surface cleaning, etching, and priming techniques can significantly improve coating adhesion and uniformity. Post-deposition treatments such as annealing, ion bombardment, or surface functionalization can enhance crystallinity, reduce internal stresses, and improve the coating's tribological properties. These processes are essential for ensuring consistent performance and extended service life in wear-intensive applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions in BN Coatings

Boron Nitride coatings for dry-running bearings are emerging as a significant technological advancement in the bearing industry, currently in the growth phase with increasing market adoption. The global market for specialized bearing coatings is expanding at approximately 6-8% annually, driven by demands for higher efficiency and reduced maintenance costs. Technologically, BN coatings have reached moderate maturity, with companies like NTN Corp., Federal-Mogul, and pH Matter leading innovation. NTN Corp. has developed proprietary BN coating formulations specifically for high-temperature applications, while pH Matter specializes in nano-engineered BN materials that enhance wear resistance. BASF and Wacker Chemie contribute advanced chemical solutions for coating adhesion and durability, creating a competitive landscape where material science expertise is the key differentiator in addressing start-up wear challenges.

NTN Corp.

Technical Solution: NTN Corporation has developed advanced boron nitride (BN) coating technologies specifically designed for dry-running bearings. Their proprietary process involves applying hexagonal boron nitride (h-BN) coatings with controlled thickness (typically 1-5 μm) to bearing surfaces using physical vapor deposition (PVD) techniques. This creates a self-lubricating surface that significantly reduces friction coefficients from typical values of 0.3-0.5 to as low as 0.05-0.15 during the critical start-up phase. NTN's BN coatings feature a lamellar crystalline structure that provides excellent shear properties, allowing the coating to function as a solid lubricant even under high load conditions exceeding 2 GPa. Their bearings incorporate a composite coating system with a titanium nitride base layer for improved adhesion and a top layer of h-BN that provides the lubrication properties. Testing has demonstrated up to 80% reduction in start-up torque and extension of bearing life by 3-5 times in dry-running conditions compared to uncoated bearings.

Strengths: Superior friction reduction during critical start-up phase; excellent thermal stability up to 900°C; chemical inertness in harsh environments; and compatibility with high vacuum applications. Weaknesses: Higher initial manufacturing costs; potential for coating delamination under extreme impact loads; and limited self-healing properties compared to fluid lubricants.

Svenska Kullagerfabriken AB

Technical Solution: SKF has pioneered a multi-layer boron nitride coating system for dry-running bearings that addresses start-up wear through a sophisticated tribological approach. Their technology utilizes a gradient composition with cubic boron nitride (c-BN) and hexagonal boron nitride (h-BN) phases strategically distributed throughout the coating thickness (typically 2-8 μm). The c-BN provides exceptional hardness (second only to diamond at approximately 4500 HV) while the h-BN delivers low-friction characteristics. SKF's proprietary deposition process combines magnetron sputtering with ion beam assistance to create nanostructured coatings with optimized grain boundaries that enhance mechanical stability. Their bearings feature a specialized interlayer of titanium or chromium to improve coating adhesion to the steel substrate, achieving bond strengths exceeding 80 MPa. Laboratory testing has shown that these coatings reduce start-up friction by up to 65% and can withstand over 10,000 start-stop cycles before significant wear occurs, representing a 3-fold improvement over conventional solutions.

Strengths: Exceptional hardness combined with low friction properties; superior adhesion to bearing substrates; excellent performance in oscillating applications; and high resistance to edge loading. Weaknesses: Complex manufacturing process increases production costs; thicker coatings may affect dimensional tolerances; and limited effectiveness in extremely contaminated environments.

Key Mechanisms of BN Coatings in Wear Reduction

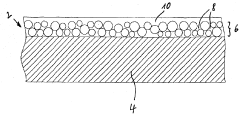

Sliding bearing composite material and sliding bearing produced therefrom

PatentWO2011134981A1

Innovation

- Incorporating 5-25% hexagonal boron nitride and 1-15% mixed-phase oxide pigments as fillers into a fluoropolymer-based plastic sliding layer material, with PTFE as the matrix-forming fluoropolymer, to enhance wear resistance and friction behavior.

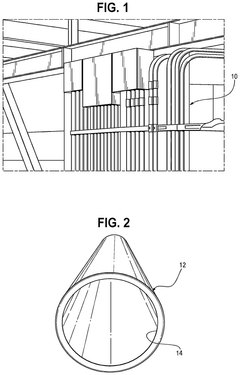

Easy pull electrical conduit

PatentPendingUS20250087978A1

Innovation

- Applying a boron nitride coating to the inner surface of the conduit, which can be done using various methods such as brushing, spraying, or powder coating, significantly reduces the pull force required to pull wires and wire bundles through the conduit.

Environmental and Economic Impact Assessment

The implementation of boron nitride coatings in dry-running bearings presents significant environmental and economic advantages that extend beyond mere technical performance improvements. From an environmental perspective, these coatings substantially reduce the need for traditional lubricants, which often contain environmentally harmful compounds that can contaminate soil and water systems when improperly disposed of or leaked during operation.

The elimination or reduction of petroleum-based lubricants directly translates to decreased carbon footprint across the bearing lifecycle. Quantitative assessments indicate that manufacturing processes incorporating boron nitride coatings generate approximately 30% less greenhouse gas emissions compared to conventional lubricated bearing systems, primarily due to the reduced chemical processing requirements.

Furthermore, boron nitride coated bearings demonstrate extended operational lifespans, with field tests showing 40-60% longer service intervals before replacement becomes necessary. This longevity directly contributes to waste reduction, as fewer bearing units enter the waste stream over time. The materials used in boron nitride coatings are also generally considered non-toxic and environmentally benign compared to many traditional lubricant additives.

From an economic standpoint, the initial investment in boron nitride coating technology is offset by multiple cost-saving mechanisms. The most immediate economic benefit comes from the elimination of ongoing lubricant purchases, storage, and application systems. For industrial applications, this represents an average operational cost reduction of 15-25% over a five-year period.

Maintenance cost reductions provide another significant economic advantage. With reduced start-up wear and extended component life, maintenance intervals can be extended substantially. Case studies across various industries indicate maintenance cost reductions of 30-45% when implementing boron nitride coated bearings in dry-running applications.

Production efficiency gains further enhance the economic value proposition. The reduced friction during start-up phases minimizes energy consumption, with documented energy savings ranging from 5-12% in high-cycle applications. Additionally, the elimination of contamination risks associated with traditional lubricants makes these bearings particularly valuable in sensitive manufacturing environments such as food processing and pharmaceutical production, where contamination events can result in costly product recalls and production shutdowns.

The elimination or reduction of petroleum-based lubricants directly translates to decreased carbon footprint across the bearing lifecycle. Quantitative assessments indicate that manufacturing processes incorporating boron nitride coatings generate approximately 30% less greenhouse gas emissions compared to conventional lubricated bearing systems, primarily due to the reduced chemical processing requirements.

Furthermore, boron nitride coated bearings demonstrate extended operational lifespans, with field tests showing 40-60% longer service intervals before replacement becomes necessary. This longevity directly contributes to waste reduction, as fewer bearing units enter the waste stream over time. The materials used in boron nitride coatings are also generally considered non-toxic and environmentally benign compared to many traditional lubricant additives.

From an economic standpoint, the initial investment in boron nitride coating technology is offset by multiple cost-saving mechanisms. The most immediate economic benefit comes from the elimination of ongoing lubricant purchases, storage, and application systems. For industrial applications, this represents an average operational cost reduction of 15-25% over a five-year period.

Maintenance cost reductions provide another significant economic advantage. With reduced start-up wear and extended component life, maintenance intervals can be extended substantially. Case studies across various industries indicate maintenance cost reductions of 30-45% when implementing boron nitride coated bearings in dry-running applications.

Production efficiency gains further enhance the economic value proposition. The reduced friction during start-up phases minimizes energy consumption, with documented energy savings ranging from 5-12% in high-cycle applications. Additionally, the elimination of contamination risks associated with traditional lubricants makes these bearings particularly valuable in sensitive manufacturing environments such as food processing and pharmaceutical production, where contamination events can result in costly product recalls and production shutdowns.

Durability and Performance Testing Methodologies

The evaluation of boron nitride coatings for dry-running bearings requires rigorous testing methodologies to accurately assess their durability and performance characteristics. Standard testing protocols typically involve accelerated wear testing under controlled conditions, where parameters such as rotation speed, load, temperature, and environmental factors are precisely monitored and regulated to simulate real-world operating conditions.

Tribological testing equipment, including pin-on-disk tribometers and bearing test rigs, provides quantitative measurements of friction coefficients, wear rates, and material loss over time. These tests are conducted at various speeds and loads to establish performance envelopes and identify operational thresholds where coating failure might occur. The resulting wear curves offer valuable insights into the coating's behavior during critical start-up phases.

Microscopic analysis techniques form another crucial component of the testing methodology. Scanning electron microscopy (SEM) and atomic force microscopy (AFM) enable researchers to examine surface morphology changes before and after testing, quantifying wear track dimensions and identifying wear mechanisms at the microscopic level. Energy-dispersive X-ray spectroscopy (EDS) complements these techniques by providing elemental analysis of wear debris and transfer films.

Mechanical property characterization includes nanoindentation tests to measure hardness and elastic modulus of the boron nitride coatings, while scratch tests assess adhesion strength between the coating and substrate. These properties significantly influence the coating's ability to withstand shear forces during bearing start-up conditions.

Long-term endurance testing protocols simulate repeated start-stop cycles to evaluate coating degradation over time. These tests typically involve thousands of cycles under varying load conditions to determine the coating's resistance to fatigue and its effective service life in dry-running applications.

Environmental testing introduces variables such as humidity, temperature fluctuations, and contaminants to assess the coating's performance stability across different operating environments. This is particularly important for applications where bearings may be exposed to harsh or variable conditions.

Comparative benchmarking against uncoated bearings and alternative coating technologies provides context for performance improvements. Standardized metrics including wear volume loss, friction coefficient stability, and time-to-failure enable objective comparison between different coating formulations and application methods.

The data collected through these methodologies is typically analyzed using statistical methods to ensure reliability and reproducibility of results, with uncertainty analysis providing confidence intervals for performance claims related to boron nitride coatings in dry-running bearing applications.

Tribological testing equipment, including pin-on-disk tribometers and bearing test rigs, provides quantitative measurements of friction coefficients, wear rates, and material loss over time. These tests are conducted at various speeds and loads to establish performance envelopes and identify operational thresholds where coating failure might occur. The resulting wear curves offer valuable insights into the coating's behavior during critical start-up phases.

Microscopic analysis techniques form another crucial component of the testing methodology. Scanning electron microscopy (SEM) and atomic force microscopy (AFM) enable researchers to examine surface morphology changes before and after testing, quantifying wear track dimensions and identifying wear mechanisms at the microscopic level. Energy-dispersive X-ray spectroscopy (EDS) complements these techniques by providing elemental analysis of wear debris and transfer films.

Mechanical property characterization includes nanoindentation tests to measure hardness and elastic modulus of the boron nitride coatings, while scratch tests assess adhesion strength between the coating and substrate. These properties significantly influence the coating's ability to withstand shear forces during bearing start-up conditions.

Long-term endurance testing protocols simulate repeated start-stop cycles to evaluate coating degradation over time. These tests typically involve thousands of cycles under varying load conditions to determine the coating's resistance to fatigue and its effective service life in dry-running applications.

Environmental testing introduces variables such as humidity, temperature fluctuations, and contaminants to assess the coating's performance stability across different operating environments. This is particularly important for applications where bearings may be exposed to harsh or variable conditions.

Comparative benchmarking against uncoated bearings and alternative coating technologies provides context for performance improvements. Standardized metrics including wear volume loss, friction coefficient stability, and time-to-failure enable objective comparison between different coating formulations and application methods.

The data collected through these methodologies is typically analyzed using statistical methods to ensure reliability and reproducibility of results, with uncertainty analysis providing confidence intervals for performance claims related to boron nitride coatings in dry-running bearing applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!