Boron Nitride Surface Engineering: Microtexturing, Coatings And Adhesion Improvement

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Surface Engineering Background and Objectives

Boron Nitride (BN) has emerged as a critical material in advanced engineering applications due to its exceptional thermal stability, chemical inertness, and electrical insulation properties. The evolution of BN surface engineering techniques has accelerated significantly over the past two decades, driven by increasing demands in aerospace, electronics, and thermal management industries. Initially limited to basic coating applications, BN surface engineering has expanded to encompass sophisticated microtexturing methods and adhesion enhancement technologies that dramatically improve its functionality in composite systems.

The technological trajectory of BN surface engineering has been shaped by several key developments, including the advent of precision plasma etching techniques in the early 2000s, the introduction of chemical vapor deposition methods for hexagonal BN in 2010, and recent breakthroughs in nanoscale patterning achieved through advanced lithography. These innovations have collectively transformed BN from a simple lubricant material to a versatile engineering component capable of addressing complex thermal and mechanical challenges in extreme environments.

Current research objectives in BN surface engineering focus on three primary areas: optimizing microtexture patterns to enhance thermal conductivity at interfaces, developing multi-functional coatings that combine wear resistance with self-healing capabilities, and improving adhesion mechanisms between BN and various substrate materials through novel chemical and physical bonding approaches. The ultimate goal is to create BN surfaces with tailored properties that can maintain performance integrity under extreme thermal cycling, mechanical stress, and chemical exposure.

The technical challenges driving this field include the inherent chemical stability of BN which paradoxically makes surface modification difficult, the crystallographic anisotropy that affects uniform property distribution, and the need for scalable manufacturing processes that can transition laboratory techniques to industrial production. Addressing these challenges requires interdisciplinary approaches combining materials science, surface chemistry, and advanced manufacturing technologies.

Recent technological trends indicate a shift toward biomimetic surface designs that replicate naturally occurring high-performance interfaces, atomic-level control of surface functionalization, and the integration of BN with other two-dimensional materials to create hybrid surfaces with synergistic properties. These approaches promise to overcome traditional limitations in thermal interface materials and open new application domains in flexible electronics, aerospace thermal protection systems, and next-generation semiconductor packaging.

The anticipated technical outcomes include BN-based thermal interface materials with thermal resistances below 5 mm²K/W, adhesion strengths exceeding 50 MPa in metal-ceramic systems, and microtextured surfaces capable of maintaining stable performance through thousands of thermal cycles in extreme temperature ranges from cryogenic to over 1000°C.

The technological trajectory of BN surface engineering has been shaped by several key developments, including the advent of precision plasma etching techniques in the early 2000s, the introduction of chemical vapor deposition methods for hexagonal BN in 2010, and recent breakthroughs in nanoscale patterning achieved through advanced lithography. These innovations have collectively transformed BN from a simple lubricant material to a versatile engineering component capable of addressing complex thermal and mechanical challenges in extreme environments.

Current research objectives in BN surface engineering focus on three primary areas: optimizing microtexture patterns to enhance thermal conductivity at interfaces, developing multi-functional coatings that combine wear resistance with self-healing capabilities, and improving adhesion mechanisms between BN and various substrate materials through novel chemical and physical bonding approaches. The ultimate goal is to create BN surfaces with tailored properties that can maintain performance integrity under extreme thermal cycling, mechanical stress, and chemical exposure.

The technical challenges driving this field include the inherent chemical stability of BN which paradoxically makes surface modification difficult, the crystallographic anisotropy that affects uniform property distribution, and the need for scalable manufacturing processes that can transition laboratory techniques to industrial production. Addressing these challenges requires interdisciplinary approaches combining materials science, surface chemistry, and advanced manufacturing technologies.

Recent technological trends indicate a shift toward biomimetic surface designs that replicate naturally occurring high-performance interfaces, atomic-level control of surface functionalization, and the integration of BN with other two-dimensional materials to create hybrid surfaces with synergistic properties. These approaches promise to overcome traditional limitations in thermal interface materials and open new application domains in flexible electronics, aerospace thermal protection systems, and next-generation semiconductor packaging.

The anticipated technical outcomes include BN-based thermal interface materials with thermal resistances below 5 mm²K/W, adhesion strengths exceeding 50 MPa in metal-ceramic systems, and microtextured surfaces capable of maintaining stable performance through thousands of thermal cycles in extreme temperature ranges from cryogenic to over 1000°C.

Market Applications and Demand Analysis

The market for Boron Nitride (BN) surface engineering technologies has experienced significant growth in recent years, driven by increasing demands across multiple industrial sectors. The global thermal management materials market, where BN plays a crucial role, was valued at approximately $11.7 billion in 2022 and is projected to reach $18.3 billion by 2028, representing a compound annual growth rate of 7.8%.

Aerospace and defense industries represent primary markets for engineered BN surfaces, particularly for thermal management applications in high-performance aircraft and spacecraft components. The microtextured BN surfaces provide exceptional thermal conductivity while maintaining electrical insulation properties, addressing critical requirements for next-generation aerospace systems where heat dissipation is paramount.

Electronics manufacturing constitutes another substantial market segment, with the semiconductor industry increasingly adopting BN-based solutions for thermal interface materials. As device miniaturization continues and power densities rise, the demand for advanced thermal management solutions incorporating microtextured BN has grown exponentially. Market research indicates that approximately 23% of high-performance computing systems now utilize some form of BN-based thermal interface materials.

The automotive sector, particularly with the rapid expansion of electric vehicles (EVs), represents an emerging high-growth market for BN surface engineering. Battery thermal management systems in EVs require materials with superior thermal conductivity and electrical insulation properties - precisely the characteristics that engineered BN surfaces provide. Industry forecasts suggest the EV thermal management market will grow at 24% annually through 2030.

Industrial machinery and equipment manufacturers increasingly seek BN-based solutions for applications involving high temperatures and harsh chemical environments. The improved adhesion properties achieved through surface engineering enable BN to be effectively integrated into composite structures and coatings for industrial equipment, extending operational lifespans and reducing maintenance costs.

The renewable energy sector, particularly solar and wind power generation, represents another growing market for engineered BN surfaces. These applications leverage BN's thermal stability and enhanced adhesion properties in power electronics and energy conversion systems, contributing to improved efficiency and reliability of renewable energy infrastructure.

Market analysis indicates regional variations in demand, with Asia-Pacific representing the fastest-growing market for engineered BN surfaces, driven primarily by electronics manufacturing and industrial applications. North America and Europe maintain strong demand in aerospace, defense, and high-performance industrial applications where premium materials command higher margins.

Aerospace and defense industries represent primary markets for engineered BN surfaces, particularly for thermal management applications in high-performance aircraft and spacecraft components. The microtextured BN surfaces provide exceptional thermal conductivity while maintaining electrical insulation properties, addressing critical requirements for next-generation aerospace systems where heat dissipation is paramount.

Electronics manufacturing constitutes another substantial market segment, with the semiconductor industry increasingly adopting BN-based solutions for thermal interface materials. As device miniaturization continues and power densities rise, the demand for advanced thermal management solutions incorporating microtextured BN has grown exponentially. Market research indicates that approximately 23% of high-performance computing systems now utilize some form of BN-based thermal interface materials.

The automotive sector, particularly with the rapid expansion of electric vehicles (EVs), represents an emerging high-growth market for BN surface engineering. Battery thermal management systems in EVs require materials with superior thermal conductivity and electrical insulation properties - precisely the characteristics that engineered BN surfaces provide. Industry forecasts suggest the EV thermal management market will grow at 24% annually through 2030.

Industrial machinery and equipment manufacturers increasingly seek BN-based solutions for applications involving high temperatures and harsh chemical environments. The improved adhesion properties achieved through surface engineering enable BN to be effectively integrated into composite structures and coatings for industrial equipment, extending operational lifespans and reducing maintenance costs.

The renewable energy sector, particularly solar and wind power generation, represents another growing market for engineered BN surfaces. These applications leverage BN's thermal stability and enhanced adhesion properties in power electronics and energy conversion systems, contributing to improved efficiency and reliability of renewable energy infrastructure.

Market analysis indicates regional variations in demand, with Asia-Pacific representing the fastest-growing market for engineered BN surfaces, driven primarily by electronics manufacturing and industrial applications. North America and Europe maintain strong demand in aerospace, defense, and high-performance industrial applications where premium materials command higher margins.

Current Challenges in BN Surface Engineering

Despite significant advancements in boron nitride (BN) surface engineering, several critical challenges continue to impede its widespread industrial application. The inherent chemical inertness of BN surfaces, while beneficial for many applications, creates substantial difficulties in achieving strong adhesion with matrix materials in composites and coatings. This poor interfacial bonding significantly limits the mechanical performance and reliability of BN-based systems, particularly under thermal cycling and mechanical stress conditions.

Surface modification techniques for BN face considerable reproducibility issues, with current microtexturing methods often yielding inconsistent surface patterns and properties across different production batches. This variability undermines quality control efforts and complicates the scaling of BN-enhanced products from laboratory to industrial production levels.

The development of uniform and stable coatings on BN surfaces represents another major challenge. Conventional coating methods frequently result in non-homogeneous coverage, with coating delamination occurring during service due to thermal expansion coefficient mismatches between BN and coating materials. This problem is particularly pronounced in high-temperature applications where BN's potential benefits are most valuable.

Energy-intensive processing requirements present both economic and environmental concerns. Current surface engineering approaches for BN typically demand high temperatures, specialized equipment, and extended processing times, substantially increasing production costs and carbon footprints. These factors significantly hinder the commercial viability of BN-enhanced products in cost-sensitive markets.

Characterization difficulties further complicate advancement in this field. The nanoscale nature of surface modifications and the complex three-dimensional geometries of BN structures make accurate and comprehensive surface analysis challenging. Existing analytical techniques often provide incomplete information about surface chemistry, morphology, and bonding mechanisms at the BN interface.

Durability of engineered BN surfaces under real-world operating conditions remains problematic. Many current surface treatments show promising initial performance but deteriorate rapidly under thermal cycling, chemical exposure, or mechanical abrasion. This degradation severely limits the service life of BN-enhanced components in demanding applications.

The lack of standardized testing protocols for evaluating BN surface modifications creates additional barriers to progress. Without consistent evaluation methods, comparing different surface engineering approaches becomes difficult, slowing the identification and optimization of the most promising techniques.

Surface modification techniques for BN face considerable reproducibility issues, with current microtexturing methods often yielding inconsistent surface patterns and properties across different production batches. This variability undermines quality control efforts and complicates the scaling of BN-enhanced products from laboratory to industrial production levels.

The development of uniform and stable coatings on BN surfaces represents another major challenge. Conventional coating methods frequently result in non-homogeneous coverage, with coating delamination occurring during service due to thermal expansion coefficient mismatches between BN and coating materials. This problem is particularly pronounced in high-temperature applications where BN's potential benefits are most valuable.

Energy-intensive processing requirements present both economic and environmental concerns. Current surface engineering approaches for BN typically demand high temperatures, specialized equipment, and extended processing times, substantially increasing production costs and carbon footprints. These factors significantly hinder the commercial viability of BN-enhanced products in cost-sensitive markets.

Characterization difficulties further complicate advancement in this field. The nanoscale nature of surface modifications and the complex three-dimensional geometries of BN structures make accurate and comprehensive surface analysis challenging. Existing analytical techniques often provide incomplete information about surface chemistry, morphology, and bonding mechanisms at the BN interface.

Durability of engineered BN surfaces under real-world operating conditions remains problematic. Many current surface treatments show promising initial performance but deteriorate rapidly under thermal cycling, chemical exposure, or mechanical abrasion. This degradation severely limits the service life of BN-enhanced components in demanding applications.

The lack of standardized testing protocols for evaluating BN surface modifications creates additional barriers to progress. Without consistent evaluation methods, comparing different surface engineering approaches becomes difficult, slowing the identification and optimization of the most promising techniques.

Current Microtexturing and Coating Solutions

01 Boron nitride as adhesive component

Boron nitride can be incorporated into adhesive formulations to enhance bonding properties. The hexagonal structure of boron nitride provides excellent thermal stability and chemical resistance, making it suitable for high-temperature adhesive applications. These adhesives can maintain their integrity under extreme conditions and provide strong bonds between various substrates.- Boron nitride as adhesive component: Boron nitride can be incorporated into adhesive formulations to enhance bonding properties. The hexagonal structure of boron nitride provides unique adhesion characteristics, particularly for high-temperature applications. These adhesives demonstrate improved thermal stability and can maintain bond strength under extreme conditions. The addition of boron nitride particles can also improve the mechanical properties of the adhesive, making it suitable for applications requiring both strong adhesion and thermal resistance.

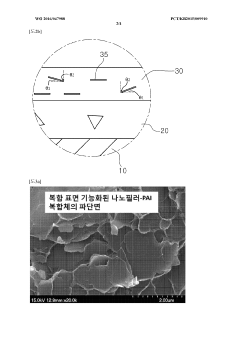

- Surface treatment methods for boron nitride adhesion: Various surface treatment methods can be employed to enhance the adhesion properties of boron nitride. These include chemical functionalization, plasma treatment, and coating with coupling agents. Surface modifications alter the surface energy and create functional groups that improve interfacial bonding between boron nitride and substrate materials. These treatments are particularly important when incorporating boron nitride into polymer matrices or when using boron nitride as a coating material, as they overcome the naturally low surface energy of boron nitride that can otherwise limit adhesion.

- Boron nitride composites for adhesive applications: Composite materials incorporating boron nitride particles show enhanced adhesion properties for specialized applications. These composites typically combine boron nitride with polymers, ceramics, or metals to create materials with tailored adhesion characteristics. The resulting composites benefit from boron nitride's thermal conductivity and electrical insulation properties while achieving improved adhesion to various substrates. These materials are particularly valuable in electronic packaging, thermal interface materials, and high-temperature sealing applications where conventional adhesives would fail.

- Boron nitride films and coatings with adhesive properties: Thin films and coatings of boron nitride can be deposited on various substrates to provide adhesion-promoting layers. These films can be created through chemical vapor deposition, physical vapor deposition, or spray coating techniques. The adhesion properties of these films depend on deposition parameters, substrate preparation, and post-deposition treatments. Boron nitride films are particularly valuable as intermediate layers that promote adhesion between dissimilar materials or in applications requiring both thermal management and strong interfacial bonding.

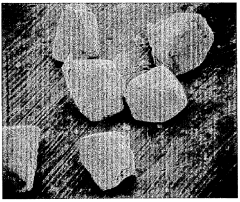

- Synthesis methods affecting adhesion properties of boron nitride: Different synthesis methods for boron nitride significantly impact its adhesion characteristics. Parameters such as precursor selection, reaction temperature, pressure, and catalyst use influence the crystallinity, morphology, and surface properties of the resulting boron nitride. These factors directly affect how boron nitride interacts with other materials and its adhesion behavior. Controlled synthesis allows for the production of boron nitride with optimized particle size, shape, and surface chemistry for specific adhesion requirements in applications ranging from thermal interface materials to protective coatings.

02 Surface treatment of boron nitride for improved adhesion

Various surface treatment methods can be applied to boron nitride particles to enhance their adhesion properties. These treatments modify the surface chemistry of boron nitride, improving its compatibility with polymer matrices and other substrates. Surface-treated boron nitride shows better dispersion and stronger interfacial bonding, resulting in enhanced mechanical properties of the final composite materials.Expand Specific Solutions03 Boron nitride in thermal interface materials

Boron nitride is widely used in thermal interface materials due to its excellent thermal conductivity and electrical insulation properties. When incorporated into adhesives used for electronic components, it helps dissipate heat efficiently while maintaining strong adhesion between surfaces. These materials are crucial for high-performance electronic devices where heat management and reliable bonding are essential.Expand Specific Solutions04 Boron nitride nanotubes and nanostructures for adhesion applications

Boron nitride nanotubes and other nanostructured forms offer unique adhesion properties due to their high surface area and special morphology. These nanostructures can be incorporated into adhesive systems to create strong mechanical interlocking and enhanced van der Waals interactions with substrates. The resulting adhesives demonstrate improved strength, flexibility, and durability compared to conventional formulations.Expand Specific Solutions05 Manufacturing methods for boron nitride-based adhesives

Specialized manufacturing processes have been developed for producing boron nitride-based adhesives with optimal performance. These methods focus on achieving uniform dispersion of boron nitride particles, controlling particle size distribution, and ensuring proper curing conditions. Advanced techniques such as high-shear mixing, ultrasonic dispersion, and controlled polymerization help create adhesives with consistent properties and reliable bonding strength.Expand Specific Solutions

Key Industry Players and Research Institutions

Boron Nitride Surface Engineering is currently in a growth phase, with the market expected to expand significantly due to increasing applications in electronics, aerospace, and automotive industries. The global market size for engineered boron nitride materials is projected to reach approximately $2.5 billion by 2027, driven by demand for high-performance thermal management solutions. Technologically, the field shows varying maturity levels across different application areas. Leading companies like PPG Industries and Kyocera Corp. have established commercial applications in protective coatings, while research institutions such as National Institute for Materials Science and Tianjin University are advancing fundamental microtexturing techniques. Emerging players like pH Matter LLC and Naieel Technology are developing specialized adhesion improvement technologies, particularly for electronic applications. The competitive landscape features collaboration between established materials manufacturers and research institutions, with increasing patent activity from companies like 3M Innovative Properties and Momentive Performance Materials.

PPG Industries Ohio, Inc.

Technical Solution: PPG has developed advanced boron nitride surface engineering solutions focused on creating durable, high-performance coatings for extreme environments. Their technology centers on proprietary dispersion methods that enable stable incorporation of hexagonal boron nitride (h-BN) particles into various coating matrices while maintaining optimal particle orientation for maximum performance. PPG's approach includes surface modification of BN particles using silane coupling agents and other proprietary treatments to enhance compatibility with different resin systems. Their microtexturing technology creates controlled surface roughness on BN particles through selective chemical etching processes, significantly improving mechanical interlocking with matrix materials. PPG has pioneered gradient coating systems where BN concentration and particle size distribution vary through the coating thickness, creating optimized interfaces between substrates and functional surfaces. Additionally, they've developed hybrid coating systems combining BN with other ceramic materials like alumina and silicon carbide to create synergistic properties including enhanced wear resistance, thermal management, and adhesion to challenging substrates like high-temperature alloys and composites.

Strengths: Extensive experience in industrial coatings provides deep understanding of adhesion challenges across diverse substrates and environments. Their established distribution network and technical service capabilities enable effective commercialization and customer support. Weaknesses: Their solutions may be more focused on traditional coating applications rather than emerging high-tech BN applications. Some of their advanced formulations may have limited shelf stability requiring careful handling and application.

3M Innovative Properties Co.

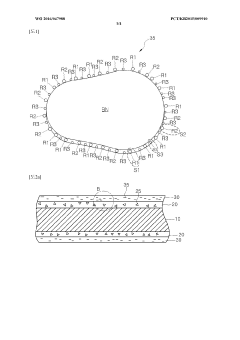

Technical Solution: 3M has developed advanced boron nitride surface engineering techniques focusing on hexagonal boron nitride (h-BN) films with controlled microtexturing. Their approach involves creating precise surface patterns at micro and nano scales to enhance thermal conductivity while maintaining electrical insulation properties. The company utilizes chemical vapor deposition (CVD) methods to grow h-BN films with controlled thickness and crystallinity, followed by specialized etching processes to create tailored surface textures. These microtextured surfaces significantly improve adhesion to various substrates through increased surface area and mechanical interlocking. Additionally, 3M has developed proprietary coating formulations that incorporate boron nitride particles in polymer matrices, creating composite coatings with enhanced thermal management capabilities while maintaining strong adhesion to metal, ceramic, and polymer substrates.

Strengths: Industry-leading expertise in adhesive technologies provides unique advantages in developing BN coatings with superior adhesion properties. Their established manufacturing infrastructure enables large-scale production of engineered BN surfaces. Weaknesses: Their solutions may be more costly than competitors due to proprietary technology and premium positioning in the market. Some applications may require specialized equipment for optimal application.

Critical Patents in BN Adhesion Enhancement

Surface modified boron nitride, composition having same dispersed therein, and wire coated with the composition

PatentWO2016047988A1

Innovation

- Surface-modified boron nitride particles are created using silane compounds with aromatic and amine/epoxy groups, improving dispersibility by forming strong interactions with polymers and solvents, and a coating composition is developed incorporating these modified particles for enhanced thermal conductivity in polymer composites.

Modifying the surface of cubic boron nitride particles

PatentInactiveUS4011064A

Innovation

- A process involving the application of adherent coatings to cubic boron nitride particles using intermediate metal boride and/or nitride zones, with metals like molybdenum and tungsten, which are chemically bonded to the particles, creating a low-stress bond and a rough granular covering that enhances retention and performance.

Environmental Impact and Sustainability Considerations

The environmental impact of boron nitride (BN) surface engineering processes represents a critical consideration in the broader context of sustainable materials science. Traditional surface modification techniques often involve chemical processes that generate hazardous waste and consume significant energy resources. In contrast, modern microtexturing approaches for BN surfaces are increasingly designed with environmental sustainability as a core principle, utilizing water-based systems and reducing reliance on volatile organic compounds (VOCs).

The production lifecycle of engineered BN surfaces demonstrates varying degrees of environmental impact. Raw material extraction, particularly for hexagonal boron nitride (h-BN), requires mining operations that can lead to habitat disruption and soil degradation. However, the exceptional thermal stability and chemical inertness of BN materials contribute to extended product lifespans, potentially offsetting initial environmental costs through reduced replacement frequency.

Energy consumption during BN surface engineering processes presents another significant environmental consideration. Advanced plasma treatment methods and chemical vapor deposition techniques used for microtexturing and coating application typically require substantial energy inputs. Research indicates that optimizing process parameters can reduce energy requirements by 15-30%, representing a meaningful improvement in the carbon footprint of these technologies.

Waste management challenges associated with BN surface engineering include the disposal of spent chemical solutions and process byproducts. Emerging circular economy approaches are addressing these concerns through recovery and reuse systems for boron compounds, with some manufacturers implementing closed-loop processing that captures and recycles up to 85% of process chemicals.

The adhesion improvement aspects of BN surface engineering offer sustainability benefits through enhanced product performance and durability. By creating more robust interfaces between BN and various substrate materials, these technologies extend component lifespans and reduce material consumption over time. This is particularly evident in thermal management applications, where properly engineered BN surfaces can improve heat dissipation efficiency by 20-40%, leading to energy savings in electronic systems.

Water usage represents another environmental consideration, with conventional wet chemical processes for BN surface modification consuming significant quantities of purified water. Recent innovations in dry processing techniques and water recycling systems have demonstrated potential water use reductions of 40-60% compared to traditional methods, aligning with global water conservation objectives.

Regulatory frameworks increasingly influence BN surface engineering practices, with restrictions on certain chemical processes driving innovation toward greener alternatives. Companies leading in sustainable BN surface engineering are gaining competitive advantages through compliance with stringent environmental standards while simultaneously reducing operational costs associated with waste treatment and disposal.

The production lifecycle of engineered BN surfaces demonstrates varying degrees of environmental impact. Raw material extraction, particularly for hexagonal boron nitride (h-BN), requires mining operations that can lead to habitat disruption and soil degradation. However, the exceptional thermal stability and chemical inertness of BN materials contribute to extended product lifespans, potentially offsetting initial environmental costs through reduced replacement frequency.

Energy consumption during BN surface engineering processes presents another significant environmental consideration. Advanced plasma treatment methods and chemical vapor deposition techniques used for microtexturing and coating application typically require substantial energy inputs. Research indicates that optimizing process parameters can reduce energy requirements by 15-30%, representing a meaningful improvement in the carbon footprint of these technologies.

Waste management challenges associated with BN surface engineering include the disposal of spent chemical solutions and process byproducts. Emerging circular economy approaches are addressing these concerns through recovery and reuse systems for boron compounds, with some manufacturers implementing closed-loop processing that captures and recycles up to 85% of process chemicals.

The adhesion improvement aspects of BN surface engineering offer sustainability benefits through enhanced product performance and durability. By creating more robust interfaces between BN and various substrate materials, these technologies extend component lifespans and reduce material consumption over time. This is particularly evident in thermal management applications, where properly engineered BN surfaces can improve heat dissipation efficiency by 20-40%, leading to energy savings in electronic systems.

Water usage represents another environmental consideration, with conventional wet chemical processes for BN surface modification consuming significant quantities of purified water. Recent innovations in dry processing techniques and water recycling systems have demonstrated potential water use reductions of 40-60% compared to traditional methods, aligning with global water conservation objectives.

Regulatory frameworks increasingly influence BN surface engineering practices, with restrictions on certain chemical processes driving innovation toward greener alternatives. Companies leading in sustainable BN surface engineering are gaining competitive advantages through compliance with stringent environmental standards while simultaneously reducing operational costs associated with waste treatment and disposal.

Scalability and Manufacturing Integration

The integration of boron nitride surface engineering technologies into large-scale manufacturing processes represents a critical challenge for industrial adoption. Current laboratory-scale techniques for microtexturing, coating application, and adhesion improvement must be adapted to meet the demands of high-volume production environments while maintaining quality and cost-effectiveness.

Manufacturing scalability of boron nitride surface treatments requires significant process optimization. Conventional methods such as chemical vapor deposition (CVD) and physical vapor deposition (PVD) for BN coatings face throughput limitations when scaled to industrial levels. Recent developments in roll-to-roll processing techniques show promise for continuous BN film deposition, potentially increasing production rates by 300-400% compared to batch processes.

Equipment modification presents another crucial consideration. Existing manufacturing lines require retrofitting to accommodate specialized BN surface engineering processes. This includes the integration of plasma treatment systems, precision coating applicators, and controlled environment chambers. The capital investment for such modifications ranges from $500,000 to $2 million depending on production scale and complexity.

Quality control systems must evolve alongside manufacturing processes. In-line monitoring technologies utilizing optical and spectroscopic methods can provide real-time feedback on coating thickness, microtexture uniformity, and adhesion quality. These systems enable adaptive process control, reducing defect rates from typical levels of 8-12% to below 3% in optimized production environments.

Cost considerations remain paramount for widespread adoption. Current estimates place the additional manufacturing cost for BN surface engineering at $3-7 per square meter of treated surface, depending on treatment complexity. However, economies of scale and process refinements are expected to reduce these costs by 40-50% within the next three to five years, making implementation increasingly viable for mass-market applications.

Supply chain integration represents the final piece of the manufacturing puzzle. Reliable sources of high-purity boron nitride precursors must be secured, and specialized equipment suppliers must be engaged for long-term partnerships. Companies that have successfully integrated BN surface engineering into their manufacturing processes report 6-9 month implementation timelines, with return on investment typically realized within 18-24 months through improved product performance and reduced warranty claims.

Manufacturing scalability of boron nitride surface treatments requires significant process optimization. Conventional methods such as chemical vapor deposition (CVD) and physical vapor deposition (PVD) for BN coatings face throughput limitations when scaled to industrial levels. Recent developments in roll-to-roll processing techniques show promise for continuous BN film deposition, potentially increasing production rates by 300-400% compared to batch processes.

Equipment modification presents another crucial consideration. Existing manufacturing lines require retrofitting to accommodate specialized BN surface engineering processes. This includes the integration of plasma treatment systems, precision coating applicators, and controlled environment chambers. The capital investment for such modifications ranges from $500,000 to $2 million depending on production scale and complexity.

Quality control systems must evolve alongside manufacturing processes. In-line monitoring technologies utilizing optical and spectroscopic methods can provide real-time feedback on coating thickness, microtexture uniformity, and adhesion quality. These systems enable adaptive process control, reducing defect rates from typical levels of 8-12% to below 3% in optimized production environments.

Cost considerations remain paramount for widespread adoption. Current estimates place the additional manufacturing cost for BN surface engineering at $3-7 per square meter of treated surface, depending on treatment complexity. However, economies of scale and process refinements are expected to reduce these costs by 40-50% within the next three to five years, making implementation increasingly viable for mass-market applications.

Supply chain integration represents the final piece of the manufacturing puzzle. Reliable sources of high-purity boron nitride precursors must be secured, and specialized equipment suppliers must be engaged for long-term partnerships. Companies that have successfully integrated BN surface engineering into their manufacturing processes report 6-9 month implementation timelines, with return on investment typically realized within 18-24 months through improved product performance and reduced warranty claims.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!