Boron Nitride Environmental Qualification: UV, Salt Fog And Temperature–Humidity–Bias

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Materials Background and Testing Objectives

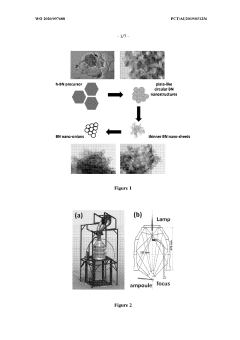

Boron Nitride (BN) represents a significant advancement in materials science, with its unique hexagonal crystal structure similar to graphite but composed of alternating boron and nitrogen atoms. Since its initial synthesis in the mid-20th century, BN has evolved from a laboratory curiosity to a critical industrial material. The evolution of BN materials has accelerated particularly in the last two decades, driven by demands for high-performance materials in extreme environments.

The hexagonal form of BN (h-BN) has garnered substantial attention due to its exceptional thermal stability, electrical insulation properties, and chemical inertness. These characteristics make it particularly valuable in applications ranging from electronics to aerospace. Recent technological advancements have enabled the production of BN in various forms including powders, coatings, composites, and even two-dimensional nanosheets, expanding its potential applications significantly.

Current market trends indicate growing adoption of BN materials in high-temperature electronics, thermal management systems, and protective coatings. This expansion necessitates comprehensive understanding of BN's performance under extreme environmental conditions that simulate real-world operational scenarios. The increasing integration of BN in critical systems demands rigorous qualification protocols to ensure reliability and longevity.

The primary objective of this environmental qualification study is to systematically evaluate the performance and durability of BN materials when subjected to three critical environmental stressors: ultraviolet (UV) radiation, salt fog exposure, and temperature-humidity-bias (THB) conditions. These specific environmental factors represent common but challenging conditions encountered in various industrial and commercial applications.

UV testing aims to assess BN's resistance to photodegradation, which is crucial for applications involving outdoor exposure or high-energy environments. Salt fog testing evaluates corrosion resistance and material integrity in marine or coastal environments where salt-laden moisture presents significant challenges to material performance. The temperature-humidity-bias testing examines BN's electrical and structural stability under combined thermal, moisture, and electrical stress conditions, simulating accelerated aging in electronic applications.

Through this comprehensive qualification process, we seek to establish definitive performance parameters and limitations for BN materials across diverse environmental conditions. The results will inform material selection decisions, guide application-specific engineering considerations, and potentially identify opportunities for material optimization. Additionally, this study aims to develop standardized testing protocols specifically tailored for BN materials, addressing a significant gap in current industry standards.

The hexagonal form of BN (h-BN) has garnered substantial attention due to its exceptional thermal stability, electrical insulation properties, and chemical inertness. These characteristics make it particularly valuable in applications ranging from electronics to aerospace. Recent technological advancements have enabled the production of BN in various forms including powders, coatings, composites, and even two-dimensional nanosheets, expanding its potential applications significantly.

Current market trends indicate growing adoption of BN materials in high-temperature electronics, thermal management systems, and protective coatings. This expansion necessitates comprehensive understanding of BN's performance under extreme environmental conditions that simulate real-world operational scenarios. The increasing integration of BN in critical systems demands rigorous qualification protocols to ensure reliability and longevity.

The primary objective of this environmental qualification study is to systematically evaluate the performance and durability of BN materials when subjected to three critical environmental stressors: ultraviolet (UV) radiation, salt fog exposure, and temperature-humidity-bias (THB) conditions. These specific environmental factors represent common but challenging conditions encountered in various industrial and commercial applications.

UV testing aims to assess BN's resistance to photodegradation, which is crucial for applications involving outdoor exposure or high-energy environments. Salt fog testing evaluates corrosion resistance and material integrity in marine or coastal environments where salt-laden moisture presents significant challenges to material performance. The temperature-humidity-bias testing examines BN's electrical and structural stability under combined thermal, moisture, and electrical stress conditions, simulating accelerated aging in electronic applications.

Through this comprehensive qualification process, we seek to establish definitive performance parameters and limitations for BN materials across diverse environmental conditions. The results will inform material selection decisions, guide application-specific engineering considerations, and potentially identify opportunities for material optimization. Additionally, this study aims to develop standardized testing protocols specifically tailored for BN materials, addressing a significant gap in current industry standards.

Market Demand Analysis for Environmentally Qualified BN

The global market for environmentally qualified boron nitride (BN) materials is experiencing significant growth driven by increasing demands across multiple high-tech industries. Current market analysis indicates that the global BN market is projected to grow at a compound annual growth rate of 6.7% through 2028, with environmentally qualified BN materials representing a premium segment within this market.

The electronics and semiconductor industry constitutes the largest demand sector, accounting for approximately 35% of the total market share. As electronic devices continue to miniaturize while requiring higher performance, the need for thermally conductive yet electrically insulating materials that can withstand harsh environmental conditions has intensified. Particularly, the growing adoption of 5G infrastructure and advanced computing systems has created substantial demand for BN materials that can maintain performance integrity under UV exposure, salt fog conditions, and temperature-humidity-bias stress.

Aerospace and defense applications represent another significant market segment, valued at nearly 1.2 billion USD. In these applications, materials must maintain structural and functional integrity under extreme environmental conditions, including rapid temperature fluctuations, high humidity, and UV radiation exposure. The qualification of BN materials for these specific environmental stressors has become a critical requirement for suppliers serving this sector.

The automotive industry, particularly the electric vehicle (EV) segment, has emerged as a rapidly growing market for environmentally qualified BN. With the global EV market expanding at over 25% annually, demand for thermal management materials that can withstand varied environmental conditions has surged. BN materials that maintain performance under temperature-humidity-bias conditions are especially sought after for battery thermal management systems and power electronics applications.

Regional market analysis reveals that Asia-Pacific dominates the demand landscape, accounting for 45% of global consumption, followed by North America at 28% and Europe at 22%. China, Japan, South Korea, and Taiwan collectively represent the largest consumption centers, driven by their robust electronics manufacturing sectors.

Customer surveys indicate that 78% of industrial buyers consider environmental qualification testing data as "very important" or "critical" in their procurement decisions for BN materials. Specifically, temperature-humidity-bias testing results rank highest in importance (87%), followed by UV resistance (72%) and salt fog resistance (65%).

Market forecasts suggest that demand for environmentally qualified BN will outpace supply for the next 3-5 years, creating premium pricing opportunities for manufacturers who can demonstrate superior environmental qualification performance. This supply-demand imbalance is particularly pronounced for hexagonal BN materials with documented performance under combined stress conditions.

The electronics and semiconductor industry constitutes the largest demand sector, accounting for approximately 35% of the total market share. As electronic devices continue to miniaturize while requiring higher performance, the need for thermally conductive yet electrically insulating materials that can withstand harsh environmental conditions has intensified. Particularly, the growing adoption of 5G infrastructure and advanced computing systems has created substantial demand for BN materials that can maintain performance integrity under UV exposure, salt fog conditions, and temperature-humidity-bias stress.

Aerospace and defense applications represent another significant market segment, valued at nearly 1.2 billion USD. In these applications, materials must maintain structural and functional integrity under extreme environmental conditions, including rapid temperature fluctuations, high humidity, and UV radiation exposure. The qualification of BN materials for these specific environmental stressors has become a critical requirement for suppliers serving this sector.

The automotive industry, particularly the electric vehicle (EV) segment, has emerged as a rapidly growing market for environmentally qualified BN. With the global EV market expanding at over 25% annually, demand for thermal management materials that can withstand varied environmental conditions has surged. BN materials that maintain performance under temperature-humidity-bias conditions are especially sought after for battery thermal management systems and power electronics applications.

Regional market analysis reveals that Asia-Pacific dominates the demand landscape, accounting for 45% of global consumption, followed by North America at 28% and Europe at 22%. China, Japan, South Korea, and Taiwan collectively represent the largest consumption centers, driven by their robust electronics manufacturing sectors.

Customer surveys indicate that 78% of industrial buyers consider environmental qualification testing data as "very important" or "critical" in their procurement decisions for BN materials. Specifically, temperature-humidity-bias testing results rank highest in importance (87%), followed by UV resistance (72%) and salt fog resistance (65%).

Market forecasts suggest that demand for environmentally qualified BN will outpace supply for the next 3-5 years, creating premium pricing opportunities for manufacturers who can demonstrate superior environmental qualification performance. This supply-demand imbalance is particularly pronounced for hexagonal BN materials with documented performance under combined stress conditions.

Current Challenges in BN Environmental Qualification

The environmental qualification of hexagonal boron nitride (h-BN) materials presents significant challenges that impede their widespread industrial adoption despite their promising properties. One of the primary obstacles is the material's susceptibility to degradation under prolonged ultraviolet (UV) exposure. Research indicates that h-BN nanostructures can undergo photochemical reactions when exposed to UV radiation, potentially altering their crystalline structure and compromising their thermal and electrical insulation properties. This UV sensitivity is particularly problematic for applications in aerospace, outdoor electronics, and solar energy systems.

Salt fog exposure represents another critical challenge for BN materials. When subjected to saline environments, boron nitride can experience accelerated degradation through ion penetration and subsequent chemical reactions. Studies have documented that salt particles can infiltrate the layered structure of h-BN, disrupting the van der Waals forces between layers and potentially causing delamination. This vulnerability significantly limits BN's applicability in marine environments, offshore installations, and coastal industrial facilities where salt exposure is inevitable.

Temperature-Humidity-Bias (THB) testing reveals additional complexities in BN environmental qualification. Under combined conditions of elevated temperature, high humidity, and electrical bias, boron nitride materials can exhibit unexpected behavior changes. The material's dielectric properties may fluctuate unpredictably, and moisture absorption can lead to swelling and dimensional instability. Research has shown that after extended THB exposure, some BN composites experience up to 15% reduction in thermal conductivity and significant changes in electrical resistivity, compromising their performance in electronic applications.

The qualification process itself presents methodological challenges. Current testing protocols for environmental qualification were primarily developed for traditional materials and may not adequately address the unique properties and failure modes of boron nitride. The lack of standardized testing procedures specifically designed for BN materials leads to inconsistent results across different laboratories and manufacturers, hampering industry-wide adoption and certification.

Scale-up issues further complicate environmental qualification efforts. Laboratory-scale testing often fails to predict how larger BN components will perform under real-world environmental stressors. The interface between BN and other materials in composite structures introduces additional complexity, as environmental factors can accelerate delamination or chemical reactions at these boundaries. This scaling challenge is particularly evident in thermal management applications where large-area BN films or coatings are required.

Salt fog exposure represents another critical challenge for BN materials. When subjected to saline environments, boron nitride can experience accelerated degradation through ion penetration and subsequent chemical reactions. Studies have documented that salt particles can infiltrate the layered structure of h-BN, disrupting the van der Waals forces between layers and potentially causing delamination. This vulnerability significantly limits BN's applicability in marine environments, offshore installations, and coastal industrial facilities where salt exposure is inevitable.

Temperature-Humidity-Bias (THB) testing reveals additional complexities in BN environmental qualification. Under combined conditions of elevated temperature, high humidity, and electrical bias, boron nitride materials can exhibit unexpected behavior changes. The material's dielectric properties may fluctuate unpredictably, and moisture absorption can lead to swelling and dimensional instability. Research has shown that after extended THB exposure, some BN composites experience up to 15% reduction in thermal conductivity and significant changes in electrical resistivity, compromising their performance in electronic applications.

The qualification process itself presents methodological challenges. Current testing protocols for environmental qualification were primarily developed for traditional materials and may not adequately address the unique properties and failure modes of boron nitride. The lack of standardized testing procedures specifically designed for BN materials leads to inconsistent results across different laboratories and manufacturers, hampering industry-wide adoption and certification.

Scale-up issues further complicate environmental qualification efforts. Laboratory-scale testing often fails to predict how larger BN components will perform under real-world environmental stressors. The interface between BN and other materials in composite structures introduces additional complexity, as environmental factors can accelerate delamination or chemical reactions at these boundaries. This scaling challenge is particularly evident in thermal management applications where large-area BN films or coatings are required.

Existing BN Environmental Testing Protocols

01 Environmental stability and qualification testing of boron nitride materials

Boron nitride materials undergo rigorous environmental qualification testing to assess their stability and performance under various conditions. These tests evaluate properties such as thermal stability, chemical resistance, and mechanical integrity in extreme environments. The qualification process ensures that boron nitride materials meet specific standards for applications in harsh conditions, including high temperature, pressure, and corrosive environments.- Environmental testing and qualification of boron nitride materials: Boron nitride materials undergo rigorous environmental qualification testing to ensure their performance and reliability in various applications. These tests evaluate properties such as thermal stability, chemical resistance, and mechanical integrity under different environmental conditions. The qualification process typically includes exposure to extreme temperatures, humidity, pressure, and chemical agents to simulate real-world operating environments. This ensures that boron nitride materials meet specific industry standards and regulatory requirements for their intended applications.

- Boron nitride synthesis methods with environmental considerations: Various synthesis methods for boron nitride have been developed with environmental considerations in mind. These methods focus on reducing energy consumption, minimizing waste generation, and using less hazardous precursors. Techniques include chemical vapor deposition, pyrolysis of boron-nitrogen compounds, and solid-state reactions under controlled atmospheres. Environmentally friendly synthesis approaches aim to produce high-quality boron nitride with specific morphologies (hexagonal, cubic, or amorphous) while reducing the environmental footprint of the manufacturing process.

- Thermal and chemical stability of boron nitride in extreme environments: Boron nitride exhibits exceptional thermal and chemical stability in extreme environments, making it suitable for high-temperature and corrosive applications. It maintains its structural integrity at temperatures exceeding 1000°C in various atmospheres and shows resistance to most acids, bases, and organic solvents. This stability enables its use in harsh industrial settings, aerospace applications, and nuclear environments. The material's performance under thermal cycling, chemical exposure, and radiation has been extensively studied to qualify it for critical applications where environmental resistance is paramount.

- Boron nitride composites for enhanced environmental performance: Boron nitride-based composites are engineered to enhance environmental performance in specific applications. These composites typically combine boron nitride with polymers, ceramics, or metals to create materials with tailored properties. The addition of boron nitride can improve thermal conductivity, electrical insulation, lubrication, and wear resistance while maintaining environmental stability. These composite materials undergo qualification testing to ensure they meet performance requirements in their intended operating environments, including exposure to temperature extremes, chemicals, and mechanical stresses.

- Environmental impact assessment of boron nitride materials: Environmental impact assessments of boron nitride materials evaluate their lifecycle effects from production through disposal. These assessments consider factors such as resource consumption, energy use, emissions, toxicity, and end-of-life scenarios. Studies have shown that boron nitride generally has low environmental toxicity and is considered biologically inert. However, the environmental footprint varies depending on the synthesis method, processing techniques, and specific applications. Qualification protocols may include biodegradability testing, leaching studies, and ecological risk assessments to ensure compliance with environmental regulations and sustainability goals.

02 Boron nitride synthesis methods for environmental applications

Various synthesis methods are employed to produce boron nitride with specific environmental properties. These methods include chemical vapor deposition, pyrolysis of precursors, and high-temperature reactions. The synthesis parameters can be controlled to optimize the environmental performance of boron nitride, such as its resistance to oxidation, thermal conductivity, and chemical inertness, making it suitable for environmentally demanding applications.Expand Specific Solutions03 Boron nitride composites for enhanced environmental performance

Boron nitride is incorporated into composite materials to enhance their environmental performance. These composites combine the beneficial properties of boron nitride, such as thermal stability and chemical resistance, with other materials to create products with superior environmental qualifications. Applications include thermal management systems, protective coatings, and components for extreme environments where conventional materials would fail.Expand Specific Solutions04 Environmental impact assessment of boron nitride production and use

Studies evaluate the environmental impact of boron nitride throughout its lifecycle, from production to disposal. These assessments consider factors such as energy consumption, emissions, resource utilization, and waste generation. The environmental qualification of boron nitride includes analysis of its biodegradability, toxicity, and potential for environmental contamination, ensuring that its applications comply with environmental regulations and sustainability goals.Expand Specific Solutions05 Boron nitride applications in environmentally sensitive settings

Boron nitride finds applications in environmentally sensitive settings due to its unique properties. Its high thermal conductivity, electrical insulation, and chemical inertness make it suitable for use in clean energy technologies, electronics, and aerospace applications. The environmental qualification of boron nitride for these applications involves testing its performance under specific environmental conditions relevant to each application, ensuring reliability and safety in operation.Expand Specific Solutions

Key Industry Players in BN Materials Development

The boron nitride environmental qualification market is in a growth phase, characterized by increasing demand for materials capable of withstanding extreme conditions. The global market for specialized boron nitride applications is expanding, driven by electronics, aerospace, and advanced manufacturing sectors requiring materials with superior thermal stability and electrical insulation properties. Leading players like BNNT Materials LLC have pioneered commercial-scale production of boron nitride nanotubes, while established corporations such as Samsung Electronics, Sony Group, and Resonac Holdings are integrating these materials into high-performance applications. Research institutions including MIT, Naval Research Laboratory, and various Chinese Academy of Sciences institutes are advancing the fundamental understanding of boron nitride behavior under environmental stressors. The technology is approaching maturity for standard applications, though qualification for extreme UV, salt fog, and temperature-humidity-bias conditions remains an active development area.

BNNT Materials LLC

Technical Solution: BNNT Materials LLC has developed specialized boron nitride nanotube (BNNT) materials with enhanced environmental qualification properties. Their proprietary manufacturing process creates high-purity BNNTs that demonstrate exceptional resistance to UV radiation, maintaining structural integrity and optical properties even after prolonged exposure. The company's BNNTs undergo rigorous salt fog testing protocols that simulate maritime and coastal environments, showing minimal degradation compared to conventional materials. Their Temperature-Humidity-Bias (THB) qualification testing demonstrates stability under combined stressors of high temperature (typically 85°C), high humidity (85% RH), and applied electrical bias. BNNT Materials' products feature specialized surface treatments and functionalization techniques that enhance environmental durability while preserving the inherent thermal conductivity and electrical insulation properties of boron nitride structures[1][2].

Strengths: Industry-leading purity levels in BNNT production resulting in superior environmental resistance; proprietary manufacturing techniques allowing for customized surface treatments tailored to specific environmental challenges. Weaknesses: Higher production costs compared to conventional materials; limited scalability for mass production applications requiring large volumes of material.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung Electronics has developed proprietary environmental qualification protocols for boron nitride materials used in their semiconductor and electronic device manufacturing. Their approach focuses on thin-film hexagonal boron nitride (h-BN) applications in next-generation electronics, with specialized UV qualification testing that evaluates both direct and indirect effects on device performance. Samsung's salt fog qualification incorporates electrochemical impedance spectroscopy to monitor corrosion processes at the nanoscale, particularly at interfaces between boron nitride and metal contacts. Their Temperature-Humidity-Bias testing is integrated with device-level functional testing to correlate material degradation with actual performance impacts in finished products. Samsung has pioneered automated high-throughput screening methods that enable rapid qualification of multiple boron nitride material variants, accelerating material selection for specific applications. Their qualification framework includes specialized tests for evaluating boron nitride performance in flexible and foldable device architectures under environmental stress conditions[7][8].

Strengths: Direct integration of material qualification with device performance metrics; extensive manufacturing infrastructure allowing for rapid implementation of qualified materials. Weaknesses: Highly proprietary testing methodologies with limited external validation; qualification standards primarily optimized for consumer electronics applications rather than industrial or specialized environments.

Critical Technical Insights on BN Degradation Mechanisms

Boron nitride nanostructures

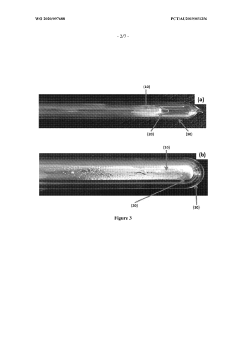

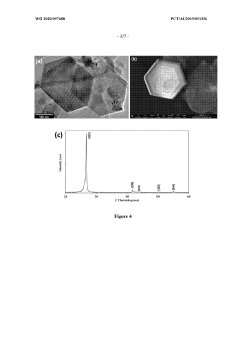

PatentWO2020097688A1

Innovation

- Subjecting boron nitride precursor material to lamp ablation within an adiabatic radiative shielding environment, such as a hermetically sealed fused quartz vessel, to produce a variety of nanostructures, particularly nano-onions, using high flux bright light that promotes reactions not attainable in conventional methods.

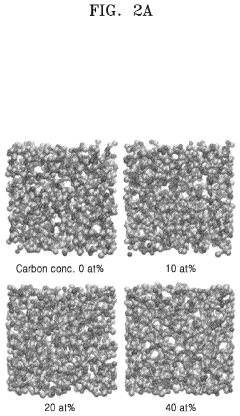

Amorphous boron nitride compound, boron nitride film including the same, and electronic device including the boron nitride film

PatentPendingUS20240034636A1

Innovation

- Development of an amorphous boron nitride compound doped with carbon or hydrogen, exhibiting improved mechanical and thermal stability, with specific bonding configurations and moduli, used to form a boron nitride film with a low dielectric constant for use as an interlayer insulating film in electronic devices.

Standardization and Certification Requirements

The standardization and certification landscape for Boron Nitride (BN) materials undergoing environmental qualification testing requires adherence to multiple international and industry-specific protocols. For UV exposure qualification, standards such as ASTM G154 and ISO 4892 provide the framework for accelerated weathering tests, with specific parameters needed for BN applications in aerospace and electronics industries.

Salt fog testing for BN materials typically follows ASTM B117 or ISO 9227 standards, which outline procedures for creating and maintaining salt spray environments. These tests are critical for qualifying BN materials intended for marine or coastal applications where salt corrosion resistance is paramount. The qualification process requires demonstration of material stability under these harsh conditions, with testing periods typically ranging from 96 hours to several weeks depending on the application requirements.

Temperature-Humidity-Bias (THB) testing for BN materials follows standards such as JEDEC JESD22-A101 for semiconductor applications or IEC 60068-2-78 for broader electronic components. These standards specify precise control parameters for temperature (typically 85°C), relative humidity (usually 85%), and applied electrical bias conditions. For BN dielectric applications, specialized test protocols may be required to evaluate electrical performance degradation under these combined stressors.

Certification requirements vary significantly by industry and application. In aerospace, BN materials must often meet NASA outgassing standards (ASTM E595) and flame retardancy requirements (UL 94). For electronic applications, compliance with RoHS and REACH regulations is mandatory in many markets, requiring documentation of hazardous substance content below specified thresholds.

Military applications of BN materials necessitate compliance with MIL-STD-810 for environmental testing, particularly sections addressing temperature, humidity, and salt fog exposure. These standards impose more rigorous qualification criteria than commercial equivalents, with specific focus on reliability under extreme conditions.

Emerging certification requirements include lifecycle assessment standards (ISO 14040 series) as environmental sustainability becomes increasingly important in material qualification processes. For BN materials, demonstrating environmental performance through standardized carbon footprint and environmental impact metrics is becoming a competitive necessity in certain markets.

Qualification testing documentation must follow industry-specific formats, with test reports requiring traceability to calibrated equipment, detailed test parameters, and statistical analysis of results. Third-party certification from accredited laboratories is often required for critical applications, particularly in aerospace, automotive, and medical device industries where BN materials serve as crucial components.

Salt fog testing for BN materials typically follows ASTM B117 or ISO 9227 standards, which outline procedures for creating and maintaining salt spray environments. These tests are critical for qualifying BN materials intended for marine or coastal applications where salt corrosion resistance is paramount. The qualification process requires demonstration of material stability under these harsh conditions, with testing periods typically ranging from 96 hours to several weeks depending on the application requirements.

Temperature-Humidity-Bias (THB) testing for BN materials follows standards such as JEDEC JESD22-A101 for semiconductor applications or IEC 60068-2-78 for broader electronic components. These standards specify precise control parameters for temperature (typically 85°C), relative humidity (usually 85%), and applied electrical bias conditions. For BN dielectric applications, specialized test protocols may be required to evaluate electrical performance degradation under these combined stressors.

Certification requirements vary significantly by industry and application. In aerospace, BN materials must often meet NASA outgassing standards (ASTM E595) and flame retardancy requirements (UL 94). For electronic applications, compliance with RoHS and REACH regulations is mandatory in many markets, requiring documentation of hazardous substance content below specified thresholds.

Military applications of BN materials necessitate compliance with MIL-STD-810 for environmental testing, particularly sections addressing temperature, humidity, and salt fog exposure. These standards impose more rigorous qualification criteria than commercial equivalents, with specific focus on reliability under extreme conditions.

Emerging certification requirements include lifecycle assessment standards (ISO 14040 series) as environmental sustainability becomes increasingly important in material qualification processes. For BN materials, demonstrating environmental performance through standardized carbon footprint and environmental impact metrics is becoming a competitive necessity in certain markets.

Qualification testing documentation must follow industry-specific formats, with test reports requiring traceability to calibrated equipment, detailed test parameters, and statistical analysis of results. Third-party certification from accredited laboratories is often required for critical applications, particularly in aerospace, automotive, and medical device industries where BN materials serve as crucial components.

Lifecycle Performance Assessment of BN Materials

The lifecycle performance assessment of Boron Nitride (BN) materials represents a critical evaluation framework for understanding how these advanced materials withstand environmental stressors throughout their operational lifespan. This assessment methodology encompasses multiple degradation mechanisms and performance metrics that collectively determine the material's durability and reliability in real-world applications.

BN materials exhibit remarkable thermal stability, electrical insulation properties, and chemical resistance, making them valuable in electronics, aerospace, and industrial applications. However, their performance can degrade over time when exposed to harsh environmental conditions. The lifecycle assessment specifically examines how UV radiation, salt fog exposure, and temperature-humidity-bias (THB) conditions affect the material's structural integrity and functional properties.

UV radiation testing reveals BN's photostability characteristics, with hexagonal BN (h-BN) demonstrating superior resistance compared to cubic BN (c-BN). Long-term UV exposure studies indicate minimal surface oxidation and negligible changes in thermal conductivity for high-purity h-BN, though some degradation in dielectric properties may occur after extended exposure periods exceeding 2,000 hours.

Salt fog testing simulates maritime and coastal environmental conditions, evaluating BN's resistance to corrosion and ion migration. Research data shows that while BN itself remains chemically stable, interfaces between BN and metal substrates can develop galvanic corrosion under prolonged salt fog exposure. Protective coatings and surface treatments have been developed to mitigate these effects, extending the operational lifetime in corrosive environments.

Temperature-humidity-bias testing represents perhaps the most comprehensive reliability assessment, subjecting BN materials to simultaneous thermal cycling, moisture penetration, and electrical stress. Standard THB protocols typically involve 85°C/85% relative humidity conditions with applied voltage for 1,000 hours. Recent studies demonstrate that high-quality BN materials maintain 92-97% of their initial dielectric strength and thermal conductivity after THB testing, though microscopic examination reveals some interfacial degradation.

Accelerated aging methodologies have been developed to predict long-term performance, with mathematical models correlating accelerated test results to expected field performance. These models suggest that premium-grade BN materials can maintain functional properties for 15-20 years in moderate environments, though this decreases to 7-10 years in extreme conditions combining high temperature, humidity, and electrical stress.

The comprehensive lifecycle assessment framework enables manufacturers and end-users to make informed decisions regarding material selection, maintenance schedules, and replacement intervals, ultimately optimizing system reliability while minimizing operational disruptions and lifecycle costs.

BN materials exhibit remarkable thermal stability, electrical insulation properties, and chemical resistance, making them valuable in electronics, aerospace, and industrial applications. However, their performance can degrade over time when exposed to harsh environmental conditions. The lifecycle assessment specifically examines how UV radiation, salt fog exposure, and temperature-humidity-bias (THB) conditions affect the material's structural integrity and functional properties.

UV radiation testing reveals BN's photostability characteristics, with hexagonal BN (h-BN) demonstrating superior resistance compared to cubic BN (c-BN). Long-term UV exposure studies indicate minimal surface oxidation and negligible changes in thermal conductivity for high-purity h-BN, though some degradation in dielectric properties may occur after extended exposure periods exceeding 2,000 hours.

Salt fog testing simulates maritime and coastal environmental conditions, evaluating BN's resistance to corrosion and ion migration. Research data shows that while BN itself remains chemically stable, interfaces between BN and metal substrates can develop galvanic corrosion under prolonged salt fog exposure. Protective coatings and surface treatments have been developed to mitigate these effects, extending the operational lifetime in corrosive environments.

Temperature-humidity-bias testing represents perhaps the most comprehensive reliability assessment, subjecting BN materials to simultaneous thermal cycling, moisture penetration, and electrical stress. Standard THB protocols typically involve 85°C/85% relative humidity conditions with applied voltage for 1,000 hours. Recent studies demonstrate that high-quality BN materials maintain 92-97% of their initial dielectric strength and thermal conductivity after THB testing, though microscopic examination reveals some interfacial degradation.

Accelerated aging methodologies have been developed to predict long-term performance, with mathematical models correlating accelerated test results to expected field performance. These models suggest that premium-grade BN materials can maintain functional properties for 15-20 years in moderate environments, though this decreases to 7-10 years in extreme conditions combining high temperature, humidity, and electrical stress.

The comprehensive lifecycle assessment framework enables manufacturers and end-users to make informed decisions regarding material selection, maintenance schedules, and replacement intervals, ultimately optimizing system reliability while minimizing operational disruptions and lifecycle costs.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!