Boron Nitride In Optical Assemblies: Stray-Light Control, Cleanliness And Bake-Out

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

BN Optical Applications Background and Objectives

Boron Nitride (BN) has emerged as a critical material in advanced optical assemblies over the past three decades, evolving from a niche ceramic to an essential component in high-performance optical systems. The hexagonal form of boron nitride (h-BN) possesses unique properties that make it particularly valuable in optical applications, including excellent thermal stability, high thermal conductivity, low coefficient of thermal expansion, and exceptional chemical inertness.

The evolution of BN in optical systems can be traced back to the 1990s when researchers began exploring alternatives to traditional materials for specialized optical environments. The material gained significant traction in the 2000s as space-based optical systems and high-energy laser applications demanded materials capable of withstanding extreme conditions while maintaining optical performance integrity.

Current technological trends indicate a growing demand for materials that can effectively control stray light in optical assemblies - a critical factor in ensuring image quality and system performance. BN's unique combination of properties makes it particularly suitable for baffles, apertures, and other stray-light control components in sophisticated optical systems.

The primary technical objectives for BN in optical assemblies center around three key areas: stray-light control, cleanliness maintenance, and thermal stability during bake-out procedures. For stray-light control, the goal is to develop BN components with ultra-low reflectivity across broad spectral ranges while maintaining structural integrity. This requires precise control of surface properties and geometry at the microscopic level.

Regarding cleanliness, the objective is to minimize particle generation and outgassing in vacuum environments, particularly critical for space-based optical systems and semiconductor lithography equipment. The material must maintain its integrity without contributing contaminants that could compromise optical performance.

For bake-out procedures, which are essential for removing volatile compounds before deployment in vacuum environments, the technical goal is to develop BN formulations that can withstand high-temperature processing while maintaining dimensional stability and optical properties. This includes minimizing structural changes during thermal cycling and preventing the release of contaminants that could deposit on optical surfaces.

The intersection of these objectives presents significant technical challenges, as optimizing for one parameter often requires compromises in others. The ultimate aim is to develop BN-based solutions that balance these competing requirements while providing superior performance compared to traditional materials such as anodized aluminum, carbon composites, or specialized coatings.

The evolution of BN in optical systems can be traced back to the 1990s when researchers began exploring alternatives to traditional materials for specialized optical environments. The material gained significant traction in the 2000s as space-based optical systems and high-energy laser applications demanded materials capable of withstanding extreme conditions while maintaining optical performance integrity.

Current technological trends indicate a growing demand for materials that can effectively control stray light in optical assemblies - a critical factor in ensuring image quality and system performance. BN's unique combination of properties makes it particularly suitable for baffles, apertures, and other stray-light control components in sophisticated optical systems.

The primary technical objectives for BN in optical assemblies center around three key areas: stray-light control, cleanliness maintenance, and thermal stability during bake-out procedures. For stray-light control, the goal is to develop BN components with ultra-low reflectivity across broad spectral ranges while maintaining structural integrity. This requires precise control of surface properties and geometry at the microscopic level.

Regarding cleanliness, the objective is to minimize particle generation and outgassing in vacuum environments, particularly critical for space-based optical systems and semiconductor lithography equipment. The material must maintain its integrity without contributing contaminants that could compromise optical performance.

For bake-out procedures, which are essential for removing volatile compounds before deployment in vacuum environments, the technical goal is to develop BN formulations that can withstand high-temperature processing while maintaining dimensional stability and optical properties. This includes minimizing structural changes during thermal cycling and preventing the release of contaminants that could deposit on optical surfaces.

The intersection of these objectives presents significant technical challenges, as optimizing for one parameter often requires compromises in others. The ultimate aim is to develop BN-based solutions that balance these competing requirements while providing superior performance compared to traditional materials such as anodized aluminum, carbon composites, or specialized coatings.

Market Analysis for BN in Optical Systems

The global market for Boron Nitride (BN) in optical systems is experiencing significant growth, driven by increasing demands for high-performance optical assemblies in various industries. The market size for BN in optical applications was valued at approximately $127 million in 2022 and is projected to reach $215 million by 2028, representing a compound annual growth rate (CAGR) of 9.2% during the forecast period.

Aerospace and defense sectors currently dominate the market share, accounting for nearly 38% of the total demand. These industries require advanced optical systems with superior stray-light control capabilities for satellite imaging, reconnaissance, and targeting systems. The semiconductor industry follows closely, representing 27% of the market, where BN is increasingly utilized in lithography equipment and inspection systems requiring pristine cleanliness standards.

Consumer electronics manufacturers are emerging as significant adopters, particularly for high-end camera systems and augmented reality devices, currently holding about 18% of the market share. Research institutions and astronomical observatories constitute approximately 12% of the market, with the remaining 5% distributed across various other applications.

Regionally, North America leads with 42% of the global market share, followed by Asia-Pacific (31%), Europe (21%), and the rest of the world (6%). China and Japan are showing the fastest growth rates in the Asia-Pacific region, primarily due to expanding semiconductor manufacturing capabilities and government investments in aerospace technologies.

Key market drivers include the growing demand for higher resolution optical systems with minimal interference from stray light, increasingly stringent cleanliness requirements in semiconductor manufacturing, and the expanding space exploration initiatives requiring materials with excellent outgassing properties. The push toward miniaturization in consumer electronics is also fueling demand for BN components that can maintain optical performance in compact assemblies.

Market challenges include the relatively high cost of high-purity BN compared to traditional materials, limited awareness about BN's benefits in optical applications among potential end-users, and technical difficulties in integrating BN components into existing optical assembly processes. Supply chain constraints for high-quality BN materials also present challenges, particularly for specialized grades required in aerospace applications.

The market is expected to witness significant innovations in the coming years, including the development of nano-structured BN coatings for enhanced stray-light absorption, advanced manufacturing techniques for complex BN geometries, and hybrid materials combining BN with other substances for optimized optical performance.

Aerospace and defense sectors currently dominate the market share, accounting for nearly 38% of the total demand. These industries require advanced optical systems with superior stray-light control capabilities for satellite imaging, reconnaissance, and targeting systems. The semiconductor industry follows closely, representing 27% of the market, where BN is increasingly utilized in lithography equipment and inspection systems requiring pristine cleanliness standards.

Consumer electronics manufacturers are emerging as significant adopters, particularly for high-end camera systems and augmented reality devices, currently holding about 18% of the market share. Research institutions and astronomical observatories constitute approximately 12% of the market, with the remaining 5% distributed across various other applications.

Regionally, North America leads with 42% of the global market share, followed by Asia-Pacific (31%), Europe (21%), and the rest of the world (6%). China and Japan are showing the fastest growth rates in the Asia-Pacific region, primarily due to expanding semiconductor manufacturing capabilities and government investments in aerospace technologies.

Key market drivers include the growing demand for higher resolution optical systems with minimal interference from stray light, increasingly stringent cleanliness requirements in semiconductor manufacturing, and the expanding space exploration initiatives requiring materials with excellent outgassing properties. The push toward miniaturization in consumer electronics is also fueling demand for BN components that can maintain optical performance in compact assemblies.

Market challenges include the relatively high cost of high-purity BN compared to traditional materials, limited awareness about BN's benefits in optical applications among potential end-users, and technical difficulties in integrating BN components into existing optical assembly processes. Supply chain constraints for high-quality BN materials also present challenges, particularly for specialized grades required in aerospace applications.

The market is expected to witness significant innovations in the coming years, including the development of nano-structured BN coatings for enhanced stray-light absorption, advanced manufacturing techniques for complex BN geometries, and hybrid materials combining BN with other substances for optimized optical performance.

Current Challenges in Stray-Light Control

Stray-light control represents one of the most critical challenges in modern optical assemblies, particularly in high-precision applications such as space telescopes, semiconductor lithography, and advanced scientific instrumentation. The fundamental issue stems from unwanted light that deviates from the intended optical path, causing degradation in image quality, reduced contrast, and compromised measurement accuracy.

Current optical systems face increasing demands for higher resolution and sensitivity, making stray-light control more challenging than ever. Traditional materials and methods often prove inadequate when dealing with complex optical geometries and extreme operating conditions. Conventional baffles, apertures, and light-absorbing coatings frequently underperform in environments requiring ultra-high vacuum compatibility or extreme temperature stability.

Particulate contamination presents another significant challenge, as even microscopic particles can scatter light unpredictably, creating stray-light paths impossible to model or mitigate through design alone. This issue is particularly problematic in cleanroom environments where maintaining absolute cleanliness throughout assembly and operation remains difficult despite rigorous protocols.

Thermal management further complicates stray-light control, as temperature fluctuations can cause dimensional changes in optical components, altering carefully designed light paths. Materials with different thermal expansion coefficients create additional challenges when integrated into precision optical assemblies, potentially introducing new stray-light paths as temperatures change.

Surface roughness at the microscopic level contributes significantly to stray-light generation through scatter mechanisms. Even with advanced polishing techniques, achieving and maintaining atomically smooth surfaces across all optical elements remains technically challenging and prohibitively expensive for many applications.

Outgassing from materials used in optical assemblies represents another critical concern, particularly in vacuum environments. Traditional light-absorbing materials often contain volatile compounds that can evaporate over time, potentially depositing on optical surfaces and creating new sources of light scatter.

The integration of effective stray-light control with other system requirements presents perhaps the most complex challenge. Engineers must balance optical performance against thermal stability, mechanical robustness, weight constraints, and manufacturing feasibility. This multi-parameter optimization problem rarely yields perfect solutions, forcing compromises that can impact stray-light performance.

Simulation and modeling capabilities, while significantly improved in recent years, still struggle to accurately predict all stray-light paths in complex systems. The computational resources required for comprehensive stray-light analysis remain substantial, limiting the ability to perform iterative design optimizations, especially for large or complex optical systems.

Current optical systems face increasing demands for higher resolution and sensitivity, making stray-light control more challenging than ever. Traditional materials and methods often prove inadequate when dealing with complex optical geometries and extreme operating conditions. Conventional baffles, apertures, and light-absorbing coatings frequently underperform in environments requiring ultra-high vacuum compatibility or extreme temperature stability.

Particulate contamination presents another significant challenge, as even microscopic particles can scatter light unpredictably, creating stray-light paths impossible to model or mitigate through design alone. This issue is particularly problematic in cleanroom environments where maintaining absolute cleanliness throughout assembly and operation remains difficult despite rigorous protocols.

Thermal management further complicates stray-light control, as temperature fluctuations can cause dimensional changes in optical components, altering carefully designed light paths. Materials with different thermal expansion coefficients create additional challenges when integrated into precision optical assemblies, potentially introducing new stray-light paths as temperatures change.

Surface roughness at the microscopic level contributes significantly to stray-light generation through scatter mechanisms. Even with advanced polishing techniques, achieving and maintaining atomically smooth surfaces across all optical elements remains technically challenging and prohibitively expensive for many applications.

Outgassing from materials used in optical assemblies represents another critical concern, particularly in vacuum environments. Traditional light-absorbing materials often contain volatile compounds that can evaporate over time, potentially depositing on optical surfaces and creating new sources of light scatter.

The integration of effective stray-light control with other system requirements presents perhaps the most complex challenge. Engineers must balance optical performance against thermal stability, mechanical robustness, weight constraints, and manufacturing feasibility. This multi-parameter optimization problem rarely yields perfect solutions, forcing compromises that can impact stray-light performance.

Simulation and modeling capabilities, while significantly improved in recent years, still struggle to accurately predict all stray-light paths in complex systems. The computational resources required for comprehensive stray-light analysis remain substantial, limiting the ability to perform iterative design optimizations, especially for large or complex optical systems.

Existing BN Solutions for Optical Assemblies

01 Boron nitride coatings for stray light reduction in optical systems

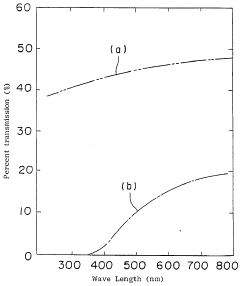

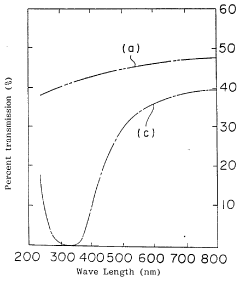

Boron nitride coatings can be applied to optical components and surfaces to reduce stray light in optical systems. These coatings have high absorption properties in specific wavelength ranges and can be formulated to create light-absorbing surfaces that minimize reflections and scattered light. The coatings can be applied to baffles, housekeeping surfaces, and other components in optical instruments to improve signal-to-noise ratio and overall optical performance.- Boron nitride coatings for stray light control in optical systems: Boron nitride coatings can be applied to optical components and surfaces to reduce stray light in optical systems. These coatings have high absorption properties in the visible and infrared spectrum, making them effective at minimizing unwanted reflections and scattered light. The coatings can be applied to baffles, apertures, and other components in optical instruments to improve image quality and reduce noise in sensitive measurements.

- Hexagonal boron nitride for cleanliness in semiconductor applications: Hexagonal boron nitride (h-BN) materials are utilized in semiconductor manufacturing processes where cleanliness is critical. The material's chemical stability, thermal resistance, and low particle generation make it ideal for components that require high purity environments. H-BN can be formulated into ceramics, films, or coatings that maintain cleanliness standards in wafer processing, reducing contamination and improving yield in semiconductor fabrication.

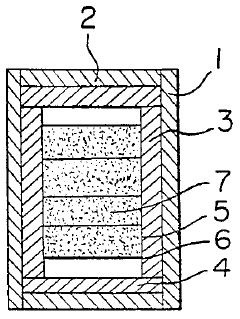

- Boron nitride composites for thermal management and light absorption: Composite materials incorporating boron nitride offer enhanced thermal management while simultaneously providing light absorption properties. These composites combine the high thermal conductivity of boron nitride with the light-absorbing characteristics needed for stray light control. The materials can be engineered with specific particle sizes and distributions to optimize both thermal dissipation and optical performance, making them suitable for applications in space instruments, laser systems, and precision optical equipment.

- Synthesis methods for high-purity boron nitride materials: Advanced synthesis techniques have been developed to produce high-purity boron nitride materials with controlled properties for optical applications. These methods include chemical vapor deposition, hot pressing, and specialized thermal treatments that yield boron nitride with minimal impurities. The resulting materials exhibit excellent cleanliness characteristics with reduced outgassing and particle generation, making them suitable for use in sensitive optical environments where contamination control is critical.

- Surface treatments of boron nitride for enhanced light absorption: Various surface treatment techniques can be applied to boron nitride materials to enhance their light absorption properties for stray light control. These treatments include texturing, chemical modification, and the addition of dopants that increase the material's ability to absorb light across specific wavelength ranges. Treated boron nitride surfaces can achieve ultra-low reflectance while maintaining cleanliness requirements, making them ideal for use in high-precision optical instruments where stray light must be minimized.

02 Hexagonal boron nitride for cleanliness in semiconductor applications

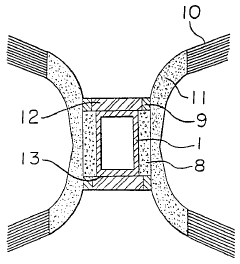

Hexagonal boron nitride (h-BN) materials are utilized in semiconductor manufacturing processes due to their excellent cleanliness properties. These materials can be synthesized with high purity levels and minimal contamination, making them suitable for clean room environments and sensitive electronic applications. The crystalline structure of h-BN provides stable surfaces that resist particle generation and can be processed to meet stringent cleanliness requirements for advanced semiconductor fabrication.Expand Specific Solutions03 Boron nitride composites for thermal management and stray light control

Composite materials incorporating boron nitride can be engineered to provide both thermal management and stray light control properties. These composites combine the high thermal conductivity of boron nitride with light-absorbing additives to create materials that efficiently dissipate heat while minimizing optical reflections. Such composites are particularly valuable in space applications, high-power laser systems, and precision optical instruments where both thermal stability and stray light control are critical.Expand Specific Solutions04 Boron nitride synthesis methods for optical purity and cleanliness

Specialized synthesis methods for boron nitride materials focus on achieving high optical purity and cleanliness. These processes include chemical vapor deposition, controlled pyrolysis of precursors, and post-synthesis purification techniques that remove impurities and defects that could contribute to light scattering. The resulting high-purity boron nitride materials exhibit superior optical properties with minimal contamination, making them ideal for applications requiring stringent cleanliness standards and precise optical performance.Expand Specific Solutions05 Boron nitride surface treatments for enhanced stray light absorption

Surface treatment techniques can be applied to boron nitride materials to enhance their stray light absorption capabilities. These treatments include texturing, etching, and the application of specialized coatings that create micro and nano-scale surface features that trap and absorb incident light. Additionally, doping and functionalization of boron nitride surfaces can modify their optical properties to absorb specific wavelengths of light more effectively, resulting in improved stray light control in sensitive optical systems.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The boron nitride optical assemblies market is in a growth phase, characterized by increasing demand for advanced stray-light control and cleanliness solutions in high-precision optical systems. The global market is expanding as industries like aerospace, semiconductor manufacturing, and scientific research require materials with superior thermal stability and low outgassing properties. Technologically, the field shows varying maturity levels, with established players like SCHOTT AG and Momentive Performance Materials offering commercial solutions, while research institutions such as National Institute for Materials Science and Naval Research Laboratory drive innovation. Specialized companies like BNNT Materials LLC are developing next-generation applications, while optoelectronics manufacturers including Appotronics, Universal Display, and LG Electronics are integrating boron nitride into advanced optical assemblies for enhanced performance in extreme environments.

Momentive Performance Materials, Inc.

Technical Solution: Momentive has developed advanced hexagonal boron nitride (h-BN) based materials specifically engineered for optical assemblies. Their proprietary PolarShield™ technology incorporates highly purified h-BN particles with controlled morphology into coatings that effectively absorb and scatter stray light in optical systems. The company's manufacturing process ensures ultra-high purity (>99.9%) h-BN materials that minimize contamination risks in sensitive optical environments. Their vacuum-compatible formulations can withstand bake-out temperatures exceeding 300°C without outgassing or degradation, making them ideal for space-based optical systems and high-vacuum applications. Momentive's h-BN coatings feature a unique microstructure that creates a highly efficient light trap, reducing reflectivity to below 1% across the visible and near-IR spectrum.

Strengths: Industry-leading purity levels minimize contamination risks; Exceptional thermal stability during bake-out procedures; Proprietary manufacturing process ensures consistent quality. Weaknesses: Higher cost compared to conventional stray light control materials; Requires specialized application techniques for optimal performance.

BNNT Materials LLC

Technical Solution: BNNT Materials has pioneered the commercial production of boron nitride nanotubes (BNNTs) and their application in advanced optical assemblies. Their patented synthesis method produces high-aspect-ratio BNNTs with exceptional optical properties, including near-perfect absorption of stray light across a wide spectral range. The company has developed BNNT-infused coatings that can be applied to optical baffles, lens housings, and detector assemblies to minimize unwanted reflections and scattering. These materials maintain their optical properties even after extensive thermal cycling and vacuum bake-out procedures at temperatures up to 900°C. BNNT Materials' products feature extremely low outgassing characteristics (total mass loss <0.1%) and meet NASA's stringent cleanliness requirements for space optical systems. Their latest generation of BNNT optical coatings incorporates specialized surface treatments that enhance adhesion to various substrates while maintaining excellent stray light absorption.

Strengths: Exceptional thermal stability and vacuum compatibility; Superior stray light absorption compared to traditional materials; Minimal outgassing during bake-out procedures. Weaknesses: Limited production capacity affects availability for large-scale applications; Integration challenges with certain optical system designs.

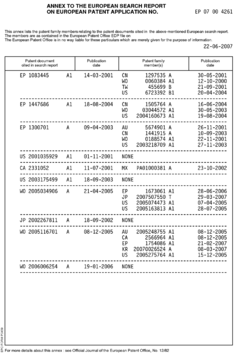

Key BN Technologies for Stray-Light Mitigation

Boron nitride complex and process for its preparation, and process for preparing a light-transmitting dense body of cubic system boron nitride

PatentInactiveUS4562163A

Innovation

- A process where lithium or alkaline earth metal boron nitride is diffused and supported within hexagonal boron nitride (hBN) in a non-oxidizing atmosphere, followed by sintering at high temperatures and pressures, to achieve uniform distribution and high-quality cBN with improved purity, density, and transparency.

Optical substrate comprising boron nitrade particles

PatentInactiveEP1830203A1

Innovation

- Incorporating boron nitride particles into a polymeric or glass matrix within the optical substrate, with concentrations ranging from 0.1 to 10 wt. %, enhancing thermal conductivity and maintaining optical properties such as refractive index and diffusivity.

Thermal Management and Bake-Out Protocols

Thermal management in optical assemblies utilizing boron nitride (BN) requires careful consideration of both heat dissipation properties and outgassing characteristics. BN's exceptional thermal conductivity (up to 400 W/m·K for hexagonal BN) makes it an ideal material for managing heat in sensitive optical systems where temperature stability is critical for maintaining optical alignment and performance.

Effective bake-out protocols for BN components in optical assemblies typically involve a multi-stage process. Initial low-temperature bake-out (80-120°C) removes surface moisture and volatile contaminants, while subsequent higher temperature phases (150-300°C) address more stubborn adsorbed molecules. The precise temperature profile must be carefully controlled to prevent thermal shock to adjacent optical elements.

Vacuum bake-out procedures for BN components require specialized equipment including high-vacuum chambers (10^-6 Torr or better) and temperature-controlled heating elements. Continuous monitoring of pressure changes during bake-out provides critical data on outgassing rates, allowing for optimization of the process duration and temperature profile.

Recent advancements in bake-out methodologies include programmable temperature ramping techniques that minimize thermal stress while maximizing contaminant removal. Research indicates that slow heating rates (1-2°C/min) followed by extended dwell times at target temperatures yield optimal results for BN components in optical assemblies.

Post-bake-out handling protocols are equally important to maintain the achieved cleanliness levels. Implementation of clean-room practices (ISO Class 5 or better) and specialized packaging materials that prevent recontamination are essential components of a comprehensive thermal management strategy.

Thermal interface materials (TIMs) incorporating BN have shown promising results in optical assembly applications. These materials provide efficient heat transfer while maintaining the stringent cleanliness requirements. Studies demonstrate that BN-filled polymer composites can achieve thermal conductivities of 3-10 W/m·K while exhibiting minimal outgassing characteristics after proper bake-out.

Temperature cycling stability represents another critical consideration for BN components in optical systems. Testing protocols typically include repeated thermal cycling between operational extremes (-40°C to +85°C) while monitoring optical performance parameters. BN's low coefficient of thermal expansion contributes to dimensional stability during these thermal excursions.

Integration of temperature sensors and feedback control systems enables real-time thermal management during both bake-out procedures and operational use. This approach allows for adaptive thermal control strategies that respond to changing environmental conditions while maintaining optimal optical performance.

Effective bake-out protocols for BN components in optical assemblies typically involve a multi-stage process. Initial low-temperature bake-out (80-120°C) removes surface moisture and volatile contaminants, while subsequent higher temperature phases (150-300°C) address more stubborn adsorbed molecules. The precise temperature profile must be carefully controlled to prevent thermal shock to adjacent optical elements.

Vacuum bake-out procedures for BN components require specialized equipment including high-vacuum chambers (10^-6 Torr or better) and temperature-controlled heating elements. Continuous monitoring of pressure changes during bake-out provides critical data on outgassing rates, allowing for optimization of the process duration and temperature profile.

Recent advancements in bake-out methodologies include programmable temperature ramping techniques that minimize thermal stress while maximizing contaminant removal. Research indicates that slow heating rates (1-2°C/min) followed by extended dwell times at target temperatures yield optimal results for BN components in optical assemblies.

Post-bake-out handling protocols are equally important to maintain the achieved cleanliness levels. Implementation of clean-room practices (ISO Class 5 or better) and specialized packaging materials that prevent recontamination are essential components of a comprehensive thermal management strategy.

Thermal interface materials (TIMs) incorporating BN have shown promising results in optical assembly applications. These materials provide efficient heat transfer while maintaining the stringent cleanliness requirements. Studies demonstrate that BN-filled polymer composites can achieve thermal conductivities of 3-10 W/m·K while exhibiting minimal outgassing characteristics after proper bake-out.

Temperature cycling stability represents another critical consideration for BN components in optical systems. Testing protocols typically include repeated thermal cycling between operational extremes (-40°C to +85°C) while monitoring optical performance parameters. BN's low coefficient of thermal expansion contributes to dimensional stability during these thermal excursions.

Integration of temperature sensors and feedback control systems enables real-time thermal management during both bake-out procedures and operational use. This approach allows for adaptive thermal control strategies that respond to changing environmental conditions while maintaining optimal optical performance.

Contamination Control Standards and Practices

Contamination control in optical assemblies utilizing boron nitride components requires adherence to rigorous standards and practices to ensure optimal performance. The aerospace and semiconductor industries have established comprehensive guidelines, including ISO 14644 for cleanroom classifications and IEST-STD-CC1246E for surface cleanliness levels. These standards define acceptable particulate and molecular contamination limits critical for optical systems where boron nitride is employed for stray-light control.

For boron nitride components specifically, ASTM E1235 provides testing methodologies to evaluate cleanliness levels before integration into optical assemblies. This standard is particularly relevant as boron nitride's unique surface properties can affect particulate adhesion and outgassing characteristics during thermal cycling.

Implementation of contamination control begins with material selection protocols that evaluate boron nitride variants (hexagonal, cubic, or amorphous) for their specific contamination profiles. High-purity grades (>99.5%) are typically mandated for optical applications to minimize potential contaminant sources. Supplier qualification processes must include verification of manufacturing cleanliness and material certification documentation.

Handling procedures for boron nitride components follow ESD-safe protocols with mandatory use of powder-free nitrile gloves, lint-free garments, and dedicated tools. Component transfer between manufacturing zones requires double-bagging with heat-sealed polyethylene that meets ASTM F2638 standards for particulate barrier properties.

Pre-integration cleaning protocols typically involve multi-stage processes: initial ultrasonic cleaning in semiconductor-grade isopropyl alcohol, followed by vacuum bake-out procedures. The bake-out specifications for boron nitride components are particularly stringent, requiring temperature ramps of <2°C/minute to prevent thermal shock, with plateau temperatures between 150-200°C maintained for 24-48 hours under high vacuum conditions (10^-6 Torr or better).

Verification methodologies include FTIR spectroscopy for molecular contamination detection and optical surface inspection using dark-field illumination techniques at 50-100x magnification. Residual gas analysis (RGA) during bake-out provides real-time monitoring of outgassing species, with particular attention to water vapor, hydrocarbons, and nitrogen compounds that may indicate incomplete purification of the boron nitride material.

Documentation requirements include material traceability records, cleaning process parameters, environmental monitoring data, and non-volatile residue (NVR) test results. These records must be maintained throughout the product lifecycle to support failure analysis and continuous improvement initiatives in contamination control practices for optical assemblies utilizing boron nitride components.

For boron nitride components specifically, ASTM E1235 provides testing methodologies to evaluate cleanliness levels before integration into optical assemblies. This standard is particularly relevant as boron nitride's unique surface properties can affect particulate adhesion and outgassing characteristics during thermal cycling.

Implementation of contamination control begins with material selection protocols that evaluate boron nitride variants (hexagonal, cubic, or amorphous) for their specific contamination profiles. High-purity grades (>99.5%) are typically mandated for optical applications to minimize potential contaminant sources. Supplier qualification processes must include verification of manufacturing cleanliness and material certification documentation.

Handling procedures for boron nitride components follow ESD-safe protocols with mandatory use of powder-free nitrile gloves, lint-free garments, and dedicated tools. Component transfer between manufacturing zones requires double-bagging with heat-sealed polyethylene that meets ASTM F2638 standards for particulate barrier properties.

Pre-integration cleaning protocols typically involve multi-stage processes: initial ultrasonic cleaning in semiconductor-grade isopropyl alcohol, followed by vacuum bake-out procedures. The bake-out specifications for boron nitride components are particularly stringent, requiring temperature ramps of <2°C/minute to prevent thermal shock, with plateau temperatures between 150-200°C maintained for 24-48 hours under high vacuum conditions (10^-6 Torr or better).

Verification methodologies include FTIR spectroscopy for molecular contamination detection and optical surface inspection using dark-field illumination techniques at 50-100x magnification. Residual gas analysis (RGA) during bake-out provides real-time monitoring of outgassing species, with particular attention to water vapor, hydrocarbons, and nitrogen compounds that may indicate incomplete purification of the boron nitride material.

Documentation requirements include material traceability records, cleaning process parameters, environmental monitoring data, and non-volatile residue (NVR) test results. These records must be maintained throughout the product lifecycle to support failure analysis and continuous improvement initiatives in contamination control practices for optical assemblies utilizing boron nitride components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!