Cathode–anode compatibility optimization in magnesium batteries

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg Battery Cathode-Anode Compatibility Background & Objectives

Magnesium batteries have emerged as a promising alternative to lithium-ion batteries due to their potential advantages in energy density, safety, and cost-effectiveness. The development of magnesium batteries traces back to the early 1990s, but significant progress has been made in the past decade with increased research focus on post-lithium energy storage solutions. The fundamental challenge in magnesium battery technology lies in the complex electrochemical interactions between cathode and anode materials, which directly impact battery performance, cycle life, and safety characteristics.

The evolution of magnesium battery technology has been marked by several key milestones, including the discovery of Chevrel phase cathodes in the early 2000s, the development of non-nucleophilic electrolytes in the 2010s, and recent advancements in high-voltage cathode materials. Despite these achievements, the compatibility between cathode and anode materials remains a critical bottleneck for commercial viability.

Current technical objectives in magnesium battery research center on addressing the fundamental challenges of cathode-anode compatibility. Primary goals include developing cathode materials that can accommodate the divalent nature of magnesium ions while maintaining structural stability, designing anode materials that minimize dendrite formation and passivation issues, and creating electrolyte systems that facilitate efficient ion transport between electrodes without degradation.

The compatibility optimization between cathode and anode components requires a multidisciplinary approach, combining electrochemistry, materials science, and computational modeling. Researchers aim to understand and control interfacial reactions, mitigate electrolyte decomposition, and enhance magnesium ion diffusion kinetics across the electrode-electrolyte interfaces.

Recent technological trends indicate a shift toward hybrid systems that leverage the advantages of both magnesium and other metal ions, as well as the exploration of conversion-type cathodes that can overcome the limitations of intercalation mechanisms. Additionally, there is growing interest in solid-state magnesium batteries as a potential solution to compatibility issues.

The ultimate technical objective is to develop a magnesium battery system with cathode-anode compatibility that enables energy densities exceeding 400 Wh/kg, cycle life greater than 1000 cycles, and operation across a wide temperature range. Achieving these targets would position magnesium batteries as a viable alternative to current lithium-ion technology, particularly for applications requiring high energy density, improved safety, and reduced cost.

The evolution of magnesium battery technology has been marked by several key milestones, including the discovery of Chevrel phase cathodes in the early 2000s, the development of non-nucleophilic electrolytes in the 2010s, and recent advancements in high-voltage cathode materials. Despite these achievements, the compatibility between cathode and anode materials remains a critical bottleneck for commercial viability.

Current technical objectives in magnesium battery research center on addressing the fundamental challenges of cathode-anode compatibility. Primary goals include developing cathode materials that can accommodate the divalent nature of magnesium ions while maintaining structural stability, designing anode materials that minimize dendrite formation and passivation issues, and creating electrolyte systems that facilitate efficient ion transport between electrodes without degradation.

The compatibility optimization between cathode and anode components requires a multidisciplinary approach, combining electrochemistry, materials science, and computational modeling. Researchers aim to understand and control interfacial reactions, mitigate electrolyte decomposition, and enhance magnesium ion diffusion kinetics across the electrode-electrolyte interfaces.

Recent technological trends indicate a shift toward hybrid systems that leverage the advantages of both magnesium and other metal ions, as well as the exploration of conversion-type cathodes that can overcome the limitations of intercalation mechanisms. Additionally, there is growing interest in solid-state magnesium batteries as a potential solution to compatibility issues.

The ultimate technical objective is to develop a magnesium battery system with cathode-anode compatibility that enables energy densities exceeding 400 Wh/kg, cycle life greater than 1000 cycles, and operation across a wide temperature range. Achieving these targets would position magnesium batteries as a viable alternative to current lithium-ion technology, particularly for applications requiring high energy density, improved safety, and reduced cost.

Market Analysis for Next-Generation Mg Battery Technologies

The global magnesium battery market is experiencing significant growth potential, driven by increasing demand for sustainable energy storage solutions. Current market valuations indicate that the magnesium battery sector is positioned to expand at a compound annual growth rate of 12.5% between 2023 and 2030, with projections suggesting a market size reaching approximately $2.3 billion by 2030. This growth trajectory is substantially influenced by the rising adoption of electric vehicles and renewable energy systems worldwide.

Magnesium batteries represent a promising alternative to lithium-ion technology due to their theoretical advantages in energy density, safety, and resource availability. Magnesium is the eighth most abundant element in Earth's crust, offering significant cost advantages over lithium, with current raw material costs approximately 24 times lower. This economic factor is particularly attractive to automotive manufacturers and grid storage developers seeking cost-effective solutions for large-scale energy storage applications.

Regional market analysis reveals varying adoption patterns and investment priorities. North America and Europe are leading in research investments, with substantial funding directed toward academic-industrial partnerships focused on cathode-anode compatibility challenges. The Asia-Pacific region, particularly China, Japan, and South Korea, dominates in terms of manufacturing capacity development and commercial implementation strategies, leveraging their established battery production infrastructure.

Consumer electronics represents the current primary application segment for early magnesium battery technologies, accounting for approximately 38% of development focus. However, the electric vehicle sector is projected to become the fastest-growing application segment, with major automotive manufacturers including Toyota, Volkswagen, and General Motors investing in magnesium battery research programs as part of their long-term electrification strategies.

Market barriers include technical challenges related to cathode-anode compatibility, electrolyte stability, and cycling performance. These technical limitations currently position magnesium batteries at a technology readiness level of 4-5, indicating that significant development is still required before widespread commercial adoption. Industry surveys indicate that 67% of battery manufacturers consider cathode-anode compatibility as the most critical challenge to overcome for market viability.

Investment trends show increasing venture capital interest, with funding for magnesium battery startups growing by approximately 35% annually since 2020. Strategic partnerships between material science companies, battery manufacturers, and end-users are becoming more prevalent, creating an ecosystem that supports accelerated technology development and market entry strategies for next-generation magnesium battery technologies.

Magnesium batteries represent a promising alternative to lithium-ion technology due to their theoretical advantages in energy density, safety, and resource availability. Magnesium is the eighth most abundant element in Earth's crust, offering significant cost advantages over lithium, with current raw material costs approximately 24 times lower. This economic factor is particularly attractive to automotive manufacturers and grid storage developers seeking cost-effective solutions for large-scale energy storage applications.

Regional market analysis reveals varying adoption patterns and investment priorities. North America and Europe are leading in research investments, with substantial funding directed toward academic-industrial partnerships focused on cathode-anode compatibility challenges. The Asia-Pacific region, particularly China, Japan, and South Korea, dominates in terms of manufacturing capacity development and commercial implementation strategies, leveraging their established battery production infrastructure.

Consumer electronics represents the current primary application segment for early magnesium battery technologies, accounting for approximately 38% of development focus. However, the electric vehicle sector is projected to become the fastest-growing application segment, with major automotive manufacturers including Toyota, Volkswagen, and General Motors investing in magnesium battery research programs as part of their long-term electrification strategies.

Market barriers include technical challenges related to cathode-anode compatibility, electrolyte stability, and cycling performance. These technical limitations currently position magnesium batteries at a technology readiness level of 4-5, indicating that significant development is still required before widespread commercial adoption. Industry surveys indicate that 67% of battery manufacturers consider cathode-anode compatibility as the most critical challenge to overcome for market viability.

Investment trends show increasing venture capital interest, with funding for magnesium battery startups growing by approximately 35% annually since 2020. Strategic partnerships between material science companies, battery manufacturers, and end-users are becoming more prevalent, creating an ecosystem that supports accelerated technology development and market entry strategies for next-generation magnesium battery technologies.

Current Challenges in Mg Battery Electrode Compatibility

Despite significant advancements in magnesium battery technology, electrode compatibility remains a critical challenge hindering commercial viability. The fundamental issue stems from the complex electrochemical behavior of magnesium, particularly the formation of passivation layers at electrode interfaces that impede ion transport. Unlike lithium-ion systems, magnesium ions carry a divalent charge, resulting in stronger electrostatic interactions with electrode materials and electrolytes, which significantly affects charge transfer kinetics.

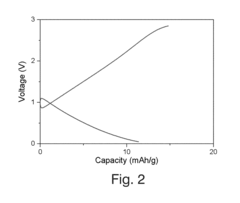

At the cathode interface, materials struggle to accommodate the insertion and extraction of divalent Mg2+ ions due to their high charge density. Conventional cathode materials like transition metal oxides experience severe structural distortion during magnesium intercalation, leading to capacity fading and poor cycling stability. The strong coulombic interactions between Mg2+ and host lattices create high diffusion barriers, resulting in sluggish kinetics and limited practical capacity.

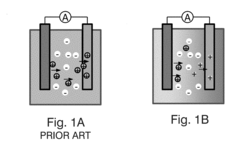

The anode-electrolyte interface presents equally challenging compatibility issues. Magnesium metal anodes, while offering high theoretical capacity, form passivation layers in conventional electrolytes that are impermeable to Mg2+ ions. This passivation phenomenon differs fundamentally from the beneficial SEI formation in lithium batteries, instead creating a barrier that prevents continuous electrochemical reactions. The chemical composition of these passivation layers, primarily consisting of insoluble magnesium salts, effectively terminates battery function.

Electrolyte compatibility represents another significant hurdle. Most conventional electrolytes that demonstrate reasonable conductivity for Mg2+ ions exhibit narrow electrochemical stability windows, limiting the operating voltage of the battery system. Additionally, many electrolyte formulations that enable reversible magnesium plating/stripping at the anode are corrosive toward current collectors and incompatible with high-voltage cathode materials.

The challenge extends to current collectors and other cell components. Materials traditionally used in lithium-ion batteries often undergo corrosion in magnesium battery environments, particularly with chloride-containing electrolytes that enable reversible magnesium deposition. This corrosion compromises the structural integrity of the battery and introduces contaminants that further complicate electrode-electrolyte interactions.

Recent research has identified interfacial engineering as a promising approach to address these compatibility issues. Surface modifications, protective coatings, and artificial interphases have shown potential in mitigating the formation of detrimental passivation layers while facilitating Mg2+ transport. However, developing comprehensive solutions requires deeper understanding of the fundamental interfacial chemistry and ion transport mechanisms specific to magnesium battery systems.

At the cathode interface, materials struggle to accommodate the insertion and extraction of divalent Mg2+ ions due to their high charge density. Conventional cathode materials like transition metal oxides experience severe structural distortion during magnesium intercalation, leading to capacity fading and poor cycling stability. The strong coulombic interactions between Mg2+ and host lattices create high diffusion barriers, resulting in sluggish kinetics and limited practical capacity.

The anode-electrolyte interface presents equally challenging compatibility issues. Magnesium metal anodes, while offering high theoretical capacity, form passivation layers in conventional electrolytes that are impermeable to Mg2+ ions. This passivation phenomenon differs fundamentally from the beneficial SEI formation in lithium batteries, instead creating a barrier that prevents continuous electrochemical reactions. The chemical composition of these passivation layers, primarily consisting of insoluble magnesium salts, effectively terminates battery function.

Electrolyte compatibility represents another significant hurdle. Most conventional electrolytes that demonstrate reasonable conductivity for Mg2+ ions exhibit narrow electrochemical stability windows, limiting the operating voltage of the battery system. Additionally, many electrolyte formulations that enable reversible magnesium plating/stripping at the anode are corrosive toward current collectors and incompatible with high-voltage cathode materials.

The challenge extends to current collectors and other cell components. Materials traditionally used in lithium-ion batteries often undergo corrosion in magnesium battery environments, particularly with chloride-containing electrolytes that enable reversible magnesium deposition. This corrosion compromises the structural integrity of the battery and introduces contaminants that further complicate electrode-electrolyte interactions.

Recent research has identified interfacial engineering as a promising approach to address these compatibility issues. Surface modifications, protective coatings, and artificial interphases have shown potential in mitigating the formation of detrimental passivation layers while facilitating Mg2+ transport. However, developing comprehensive solutions requires deeper understanding of the fundamental interfacial chemistry and ion transport mechanisms specific to magnesium battery systems.

Current Approaches to Cathode-Anode Interface Optimization

01 Cathode materials for magnesium batteries

Various cathode materials can be used in magnesium batteries to ensure compatibility with magnesium anodes. These materials include transition metal oxides, sulfides, and phosphates that can accommodate magnesium ion insertion and extraction. The selection of appropriate cathode materials is crucial for achieving high energy density and good cycling stability in magnesium batteries. Proper cathode design can mitigate issues related to slow magnesium ion diffusion and enhance overall battery performance.- Cathode materials for magnesium batteries: Various cathode materials can be used in magnesium batteries to ensure compatibility with magnesium anodes. These materials include transition metal oxides, sulfides, and phosphates that can accommodate magnesium ions during charge and discharge cycles. The selection of appropriate cathode materials is crucial for achieving high energy density and good cycling stability in magnesium batteries, as they must allow for efficient magnesium ion insertion and extraction while maintaining structural integrity.

- Electrolyte solutions for magnesium batteries: Specialized electrolyte solutions are essential for ensuring compatibility between magnesium anodes and various cathode materials. These electrolytes typically contain magnesium salts dissolved in appropriate solvents that facilitate magnesium ion transport while preventing passivation layer formation on the anode surface. The composition of the electrolyte significantly affects the electrochemical performance of magnesium batteries, including the reversibility of magnesium deposition/dissolution and the overall battery efficiency.

- Interface engineering for improved compatibility: Interface engineering techniques can be employed to enhance the compatibility between magnesium anodes and cathode materials. These techniques include surface modifications, protective coatings, and the use of interlayers that mitigate unwanted side reactions at the electrode-electrolyte interfaces. By controlling the interfacial chemistry, issues such as electrolyte decomposition, cathode dissolution, and anode passivation can be minimized, leading to improved battery performance and longevity.

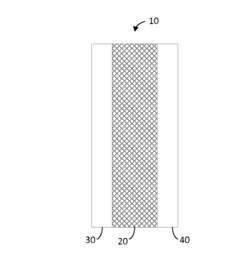

- Novel anode materials and designs: Alternative anode materials and designs can be developed to improve compatibility with various cathode materials in magnesium battery systems. These include magnesium alloys, composite anodes, and structured magnesium electrodes that offer enhanced electrochemical properties compared to pure magnesium. The design of the anode structure can significantly impact the battery's rate capability, cycle life, and energy density by facilitating more efficient magnesium ion transport and reducing unwanted side reactions.

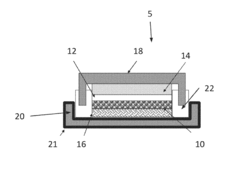

- Battery system architecture for optimized performance: The overall architecture of magnesium battery systems can be designed to optimize the compatibility between cathodes and anodes. This includes considerations such as electrode spacing, current collector materials, cell configuration, and thermal management systems. By carefully engineering the battery system architecture, issues related to cathode-anode compatibility can be mitigated, resulting in improved performance metrics such as power density, energy efficiency, and operational stability across various operating conditions.

02 Electrolyte solutions for magnesium batteries

Electrolyte solutions play a critical role in ensuring compatibility between cathode and anode in magnesium batteries. Non-corrosive electrolytes that facilitate magnesium ion transport while preventing passivation layer formation on the magnesium anode are essential. These electrolytes typically contain magnesium salts dissolved in appropriate solvents, sometimes with additives to improve performance. The electrolyte composition directly affects the interfacial stability between electrodes and influences the overall electrochemical performance of the battery system.Expand Specific Solutions03 Interface engineering for electrode compatibility

Interface engineering techniques can be employed to improve compatibility between cathodes and anodes in magnesium batteries. This includes surface modifications of electrodes, application of protective coatings, and introduction of buffer layers to mitigate unwanted side reactions. These approaches help to stabilize the electrode-electrolyte interfaces, reduce impedance, and prevent degradation during cycling. Effective interface engineering can significantly enhance the cycle life and performance of magnesium battery systems.Expand Specific Solutions04 Novel anode designs for magnesium batteries

Innovative anode designs can improve compatibility with various cathode materials in magnesium battery systems. These designs include magnesium alloys, composite anodes, and structured magnesium electrodes that address issues such as dendrite formation and slow kinetics. Some approaches involve the use of additives or dopants to enhance the electrochemical properties of magnesium anodes. These novel anode designs aim to improve the reversibility of magnesium deposition/dissolution and enhance overall battery performance.Expand Specific Solutions05 Battery system architecture for improved compatibility

The overall architecture of magnesium battery systems can be designed to enhance cathode-anode compatibility. This includes considerations of cell configuration, electrode spacing, current collector selection, and separator properties. Some designs incorporate dual-salt or hybrid electrolyte systems to create favorable conditions at both electrodes. Advanced battery management systems can also be employed to control charging/discharging protocols that minimize compatibility issues between cathode and anode materials.Expand Specific Solutions

Key Industry Players in Magnesium Battery Development

The magnesium battery cathode-anode compatibility optimization market is currently in an early growth phase, with an estimated market size of $300-500 million that's projected to expand significantly as technology matures. Research intensity is accelerating across academic and industrial sectors, with Toyota Motor Corp. leading commercial development alongside Samsung Electronics and Sony Group Corp. Academic institutions like Dalian Institute of Chemical Physics and KIST Corp. are advancing fundamental research, while specialized players such as Pellion Technologies focus on breakthrough solutions. Technical challenges remain in electrolyte stability and interface management, with most technologies at TRL 4-6, indicating promising but not yet fully commercialized solutions. Collaborative industry-academia partnerships are emerging as the dominant innovation model in this specialized energy storage segment.

Toyota Motor Corp.

Technical Solution: Toyota has developed a comprehensive approach to cathode-anode compatibility in magnesium batteries, focusing on electrolyte engineering to address the key challenge of passivation layers. Their technology employs non-nucleophilic electrolytes based on magnesium bis(trifluoromethanesulfonyl)imide (Mg(TFSI)2) combined with MgCl2 in ether solvents to enable reversible magnesium deposition and stripping. This system minimizes the formation of passivation films while maintaining compatibility with high-voltage cathode materials such as sulfur and metal oxides. Toyota has also pioneered the use of ionic liquid-based electrolytes containing specific additives that modify the solvation structure around Mg2+ ions, facilitating faster ion transport at the electrode interfaces and reducing interfacial resistance[1]. Their approach includes surface modification of cathode materials with nanoscale coatings to prevent direct contact between cathode active materials and electrolyte components that might cause degradation.

Strengths: Toyota's approach effectively addresses the critical passivation layer issue while maintaining compatibility with high-voltage cathodes, enabling higher energy density. Their electrolyte formulations demonstrate excellent stability against both cathode and anode materials. Weaknesses: The complex electrolyte systems may increase production costs and face challenges in scaling up manufacturing. Some of their solutions rely on expensive materials that might limit commercial viability.

Dalian Institute of Chemical Physics of CAS

Technical Solution: Dalian Institute has pioneered an innovative approach to magnesium battery cathode-anode compatibility through their "dual-salt electrolyte" technology. This system utilizes a combination of magnesium bis(hexamethyldisilazide) (Mg(HMDS)2) and magnesium chloride in tetrahydrofuran, creating a synergistic effect that enables highly reversible magnesium deposition while preventing cathode material dissolution. Their research has demonstrated that this electrolyte formulation creates a thin, ion-conductive interphase layer on the magnesium anode that prevents continuous electrolyte decomposition while allowing efficient Mg2+ transport[2]. For cathode compatibility, they've developed surface modification techniques using atomic layer deposition of Al2O3 and other metal oxides on various cathode materials (including Chevrel phases and sulfur) to prevent direct reactions with electrolyte components. Additionally, they've explored the use of specific solvent mixtures that maintain stability at high voltages (>3V vs. Mg/Mg2+) while remaining compatible with metallic magnesium anodes, addressing one of the fundamental challenges in magnesium battery development[3].

Strengths: Their dual-salt electrolyte approach effectively solves the critical passivation issue while maintaining compatibility with various cathode materials. The surface modification techniques provide excellent protection for cathode materials without significantly impacting ionic conductivity. Weaknesses: The complex synthesis procedures for their specialized electrolytes may present challenges for large-scale production. Some of their solutions still show limitations in long-term cycling stability, particularly at elevated temperatures.

Critical Patents in Mg Battery Electrode Compatibility

Magnesium battery having an electrolyte containing cations of magnesium and sodium

PatentActiveUS20170279151A1

Innovation

- A magnesium-ion battery with a dual ion electrolyte composed of a magnesium salt and a sodium salt, specifically using sodium hexamethyl disalazide, sodium carborane, and magnesium hexamethyl disalazide chloride in a nonaqueous solvent like tetrahydrofuran, combined with a sodium ion cathode capable of absorbing and releasing sodium ions, to create a rechargeable battery with high capacity and cycle lifetime.

Mixed electrolytes for hybrid magnesium-alkali metal ion batteries

PatentInactiveUS20150140422A1

Innovation

- A mixed magnesium-alkali metal electrolyte comprising a magnesium salt, a Lewis acid, and an alkali metal salt, along with a solvent, is used in hybrid magnesium-alkali metal ion batteries, which includes specific combinations such as MgCl2, Al(C6H5)3, and LiCl or NaCl, to create a chemically and electrochemically stable environment, avoiding nucleophilic Mg2+ species and anion metathesis, thereby enabling stable battery operation.

Environmental Impact of Mg Battery Materials

The environmental impact of magnesium battery materials represents a critical consideration in the broader adoption of this technology. Magnesium batteries offer significant environmental advantages compared to conventional lithium-ion batteries, primarily due to the natural abundance of magnesium in the Earth's crust. Magnesium is the eighth most abundant element, constituting approximately 2.7% of the Earth's crust, which substantially reduces the environmental footprint associated with resource extraction compared to lithium mining operations.

The extraction processes for magnesium materials generally require less energy and produce fewer toxic byproducts than those for lithium and cobalt, which are essential components in conventional batteries. Magnesium can be sourced from seawater through electrolysis or from magnesite and dolomite minerals, processes that typically have lower environmental impacts than the extraction of lithium from brines or hard rock mining.

Furthermore, the cathode-anode compatibility optimization in magnesium batteries has direct environmental implications. Current research focuses on developing electrolytes that enable reversible magnesium deposition without corrosion, which could significantly extend battery lifespans. Longer-lasting batteries reduce waste generation and resource consumption associated with battery replacement and manufacturing.

The development of non-corrosive electrolytes also reduces the need for environmentally harmful additives and solvents commonly used in battery production. Many conventional electrolytes contain fluorinated compounds that pose significant environmental risks due to their persistence and potential toxicity. Magnesium battery research increasingly focuses on developing more environmentally benign alternatives, such as non-nucleophilic electrolytes based on magnesium borohydride or magnesium aluminum chloride complexes.

End-of-life considerations also favor magnesium batteries from an environmental perspective. The recycling potential for magnesium battery components is promising, with established industrial processes already in place for magnesium metal recovery. The absence of toxic heavy metals in many magnesium battery designs further reduces environmental risks associated with improper disposal or recycling processes.

However, challenges remain in optimizing the full life-cycle environmental performance of magnesium batteries. The energy-intensive nature of some magnesium processing methods, particularly electrolytic production from seawater, can offset some environmental benefits if powered by fossil fuel energy sources. Additionally, some current magnesium battery prototypes utilize organic solvents that may present environmental hazards if released during manufacturing or disposal.

The extraction processes for magnesium materials generally require less energy and produce fewer toxic byproducts than those for lithium and cobalt, which are essential components in conventional batteries. Magnesium can be sourced from seawater through electrolysis or from magnesite and dolomite minerals, processes that typically have lower environmental impacts than the extraction of lithium from brines or hard rock mining.

Furthermore, the cathode-anode compatibility optimization in magnesium batteries has direct environmental implications. Current research focuses on developing electrolytes that enable reversible magnesium deposition without corrosion, which could significantly extend battery lifespans. Longer-lasting batteries reduce waste generation and resource consumption associated with battery replacement and manufacturing.

The development of non-corrosive electrolytes also reduces the need for environmentally harmful additives and solvents commonly used in battery production. Many conventional electrolytes contain fluorinated compounds that pose significant environmental risks due to their persistence and potential toxicity. Magnesium battery research increasingly focuses on developing more environmentally benign alternatives, such as non-nucleophilic electrolytes based on magnesium borohydride or magnesium aluminum chloride complexes.

End-of-life considerations also favor magnesium batteries from an environmental perspective. The recycling potential for magnesium battery components is promising, with established industrial processes already in place for magnesium metal recovery. The absence of toxic heavy metals in many magnesium battery designs further reduces environmental risks associated with improper disposal or recycling processes.

However, challenges remain in optimizing the full life-cycle environmental performance of magnesium batteries. The energy-intensive nature of some magnesium processing methods, particularly electrolytic production from seawater, can offset some environmental benefits if powered by fossil fuel energy sources. Additionally, some current magnesium battery prototypes utilize organic solvents that may present environmental hazards if released during manufacturing or disposal.

Scalability and Manufacturing Considerations

The scalability of magnesium battery technology from laboratory to industrial production presents significant challenges that must be addressed for commercial viability. Current manufacturing processes for magnesium batteries remain largely confined to small-scale laboratory settings, with limited examples of successful scale-up operations. The transition to mass production requires substantial optimization of both cathode and anode materials processing techniques to maintain performance while achieving cost efficiency.

Material synthesis methods for magnesium battery components often involve complex procedures that are difficult to replicate at industrial scale. For cathodes, conventional methods like solid-state reactions and sol-gel processes may require adaptation for continuous production lines. Similarly, anode materials preparation often involves specialized techniques that must be simplified for large-scale manufacturing without compromising electrochemical performance or compatibility with cathode materials.

Equipment requirements represent another critical consideration. Current laboratory-scale equipment for electrode fabrication, cell assembly, and electrolyte preparation differs substantially from industrial production machinery. The development of specialized equipment capable of maintaining precise control over processing parameters while handling larger material volumes is essential for preserving the cathode-anode compatibility achieved in research settings.

Quality control systems must evolve to monitor the critical parameters affecting cathode-anode compatibility during mass production. This includes developing in-line testing methods to verify material properties, interface characteristics, and electrochemical performance throughout the manufacturing process. Standardized testing protocols specific to magnesium battery systems are currently underdeveloped compared to lithium-ion technology.

Cost analysis indicates that current magnesium battery manufacturing processes remain prohibitively expensive for mass market applications. The specialized materials and processing techniques required for optimizing cathode-anode compatibility contribute significantly to overall costs. Economic viability will depend on identifying alternative materials and streamlining production methods while maintaining electrochemical performance.

Environmental and safety considerations in manufacturing must also be addressed. Some processes used in laboratory settings for creating compatible cathode-anode pairs involve hazardous materials or energy-intensive steps that may face regulatory challenges at industrial scale. Developing greener synthesis routes and safer processing methods will be crucial for sustainable large-scale production of magnesium batteries with optimized electrode compatibility.

Material synthesis methods for magnesium battery components often involve complex procedures that are difficult to replicate at industrial scale. For cathodes, conventional methods like solid-state reactions and sol-gel processes may require adaptation for continuous production lines. Similarly, anode materials preparation often involves specialized techniques that must be simplified for large-scale manufacturing without compromising electrochemical performance or compatibility with cathode materials.

Equipment requirements represent another critical consideration. Current laboratory-scale equipment for electrode fabrication, cell assembly, and electrolyte preparation differs substantially from industrial production machinery. The development of specialized equipment capable of maintaining precise control over processing parameters while handling larger material volumes is essential for preserving the cathode-anode compatibility achieved in research settings.

Quality control systems must evolve to monitor the critical parameters affecting cathode-anode compatibility during mass production. This includes developing in-line testing methods to verify material properties, interface characteristics, and electrochemical performance throughout the manufacturing process. Standardized testing protocols specific to magnesium battery systems are currently underdeveloped compared to lithium-ion technology.

Cost analysis indicates that current magnesium battery manufacturing processes remain prohibitively expensive for mass market applications. The specialized materials and processing techniques required for optimizing cathode-anode compatibility contribute significantly to overall costs. Economic viability will depend on identifying alternative materials and streamlining production methods while maintaining electrochemical performance.

Environmental and safety considerations in manufacturing must also be addressed. Some processes used in laboratory settings for creating compatible cathode-anode pairs involve hazardous materials or energy-intensive steps that may face regulatory challenges at industrial scale. Developing greener synthesis routes and safer processing methods will be crucial for sustainable large-scale production of magnesium batteries with optimized electrode compatibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!