Passivation layer formation on magnesium metal surfaces

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Passivation Technology Background and Objectives

Magnesium, the lightest structural metal, has garnered significant attention in various industries due to its exceptional strength-to-weight ratio, abundance in the earth's crust, and recyclability. However, the widespread application of magnesium has been hindered by its high chemical reactivity, particularly its susceptibility to corrosion in aqueous environments. The formation of passivation layers on magnesium surfaces represents a critical technological approach to overcome these limitations.

The concept of passivation emerged in the early 20th century, with significant advancements occurring in the 1950s through chromate-based treatments. Environmental regulations in the 1990s prompted a shift toward more sustainable alternatives, leading to the development of various conversion coatings, anodization techniques, and surface modification methods specifically for magnesium alloys.

Recent technological evolution has focused on nano-engineered passivation layers, incorporating advanced materials science principles to create multi-functional protective barriers. These developments align with the growing demand for lightweight materials in automotive, aerospace, and portable electronic device industries, where weight reduction directly translates to energy efficiency and performance improvements.

The primary objective of magnesium passivation technology is to create stable, adherent, and corrosion-resistant surface layers that maintain the bulk material's advantageous properties while mitigating its inherent reactivity. This involves understanding the complex electrochemical interactions between magnesium substrates and their environments, as well as the mechanisms of passive film formation, growth, and breakdown.

Secondary goals include developing passivation processes that are environmentally benign, cost-effective, and compatible with existing manufacturing workflows. The ideal passivation technology should provide long-term protection without requiring frequent maintenance or reapplication, even under challenging service conditions.

Current research trajectories are exploring bio-inspired approaches, self-healing passivation layers, and smart coatings that respond dynamically to environmental changes. These innovations represent potential paradigm shifts in how we approach magnesium protection, moving beyond static barriers to adaptive systems that can extend component lifespans significantly.

The technological evolution in this field is increasingly interdisciplinary, combining electrochemistry, materials science, nanotechnology, and computational modeling to design tailored surface treatments for specific applications. This convergence of disciplines reflects the complexity of the challenge and the sophisticated nature of emerging solutions.

The concept of passivation emerged in the early 20th century, with significant advancements occurring in the 1950s through chromate-based treatments. Environmental regulations in the 1990s prompted a shift toward more sustainable alternatives, leading to the development of various conversion coatings, anodization techniques, and surface modification methods specifically for magnesium alloys.

Recent technological evolution has focused on nano-engineered passivation layers, incorporating advanced materials science principles to create multi-functional protective barriers. These developments align with the growing demand for lightweight materials in automotive, aerospace, and portable electronic device industries, where weight reduction directly translates to energy efficiency and performance improvements.

The primary objective of magnesium passivation technology is to create stable, adherent, and corrosion-resistant surface layers that maintain the bulk material's advantageous properties while mitigating its inherent reactivity. This involves understanding the complex electrochemical interactions between magnesium substrates and their environments, as well as the mechanisms of passive film formation, growth, and breakdown.

Secondary goals include developing passivation processes that are environmentally benign, cost-effective, and compatible with existing manufacturing workflows. The ideal passivation technology should provide long-term protection without requiring frequent maintenance or reapplication, even under challenging service conditions.

Current research trajectories are exploring bio-inspired approaches, self-healing passivation layers, and smart coatings that respond dynamically to environmental changes. These innovations represent potential paradigm shifts in how we approach magnesium protection, moving beyond static barriers to adaptive systems that can extend component lifespans significantly.

The technological evolution in this field is increasingly interdisciplinary, combining electrochemistry, materials science, nanotechnology, and computational modeling to design tailored surface treatments for specific applications. This convergence of disciplines reflects the complexity of the challenge and the sophisticated nature of emerging solutions.

Market Analysis for Magnesium Corrosion Protection Solutions

The global market for magnesium corrosion protection solutions is experiencing significant growth, driven primarily by increasing applications of magnesium alloys in automotive, aerospace, and electronics industries. Current market valuation stands at approximately $2.3 billion, with projections indicating a compound annual growth rate of 6.8% through 2028, potentially reaching $3.4 billion by that time.

The automotive sector represents the largest market segment, accounting for nearly 35% of total demand. This is attributed to the automotive industry's push toward lightweight materials to improve fuel efficiency and reduce emissions. Magnesium components in vehicles require effective passivation solutions to ensure longevity and reliability in diverse operating conditions.

Aerospace applications constitute the fastest-growing segment with an estimated growth rate of 8.2% annually. The critical nature of aerospace components demands highly effective corrosion protection solutions, creating premium pricing opportunities for advanced passivation technologies.

Geographically, Asia-Pacific dominates the market with approximately 42% share, led by China's massive manufacturing base and Japan's advanced automotive and electronics industries. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in high-performance applications requiring sophisticated protection solutions.

Consumer demand trends indicate increasing preference for environmentally friendly passivation solutions, with regulatory pressures mounting against chromate-based treatments traditionally used for corrosion protection. This shift has created a substantial market opportunity for innovative, non-toxic passivation technologies, estimated at $580 million annually and growing at 9.3%.

Key customer requirements identified through market research include enhanced durability (cited by 78% of industrial users), process simplicity (65%), cost-effectiveness (82%), and environmental compliance (91%). The price sensitivity varies significantly by application sector, with consumer electronics manufacturers demonstrating higher price sensitivity than aerospace customers.

The competitive landscape reveals fragmentation among specialized solution providers, with larger chemical companies expanding their presence through acquisitions. Profit margins in the sector average between 12-18%, with higher margins achievable for proprietary, high-performance solutions.

Market barriers include stringent regulatory requirements, high R&D costs for developing effective passivation technologies, and customer reluctance to adopt new solutions without extensive performance data. Nevertheless, the growing industrial application of magnesium alloys continues to drive demand for innovative corrosion protection solutions.

The automotive sector represents the largest market segment, accounting for nearly 35% of total demand. This is attributed to the automotive industry's push toward lightweight materials to improve fuel efficiency and reduce emissions. Magnesium components in vehicles require effective passivation solutions to ensure longevity and reliability in diverse operating conditions.

Aerospace applications constitute the fastest-growing segment with an estimated growth rate of 8.2% annually. The critical nature of aerospace components demands highly effective corrosion protection solutions, creating premium pricing opportunities for advanced passivation technologies.

Geographically, Asia-Pacific dominates the market with approximately 42% share, led by China's massive manufacturing base and Japan's advanced automotive and electronics industries. North America and Europe follow with 28% and 24% market shares respectively, with particular strength in high-performance applications requiring sophisticated protection solutions.

Consumer demand trends indicate increasing preference for environmentally friendly passivation solutions, with regulatory pressures mounting against chromate-based treatments traditionally used for corrosion protection. This shift has created a substantial market opportunity for innovative, non-toxic passivation technologies, estimated at $580 million annually and growing at 9.3%.

Key customer requirements identified through market research include enhanced durability (cited by 78% of industrial users), process simplicity (65%), cost-effectiveness (82%), and environmental compliance (91%). The price sensitivity varies significantly by application sector, with consumer electronics manufacturers demonstrating higher price sensitivity than aerospace customers.

The competitive landscape reveals fragmentation among specialized solution providers, with larger chemical companies expanding their presence through acquisitions. Profit margins in the sector average between 12-18%, with higher margins achievable for proprietary, high-performance solutions.

Market barriers include stringent regulatory requirements, high R&D costs for developing effective passivation technologies, and customer reluctance to adopt new solutions without extensive performance data. Nevertheless, the growing industrial application of magnesium alloys continues to drive demand for innovative corrosion protection solutions.

Current Passivation Techniques and Technical Barriers

Current passivation techniques for magnesium surfaces can be broadly categorized into chemical conversion coatings, anodization processes, and emerging surface modification methods. Chemical conversion coatings, including chromate, phosphate, and fluoride-based treatments, create protective layers through chemical reactions with the magnesium substrate. Chromate conversion coatings, while highly effective, face significant regulatory restrictions due to hexavalent chromium toxicity, driving research toward environmentally friendly alternatives.

Anodization represents another widely employed technique, utilizing electrochemical processes to form controlled oxide layers on magnesium surfaces. Conventional anodizing methods include Dow 17, HAE, and plasma electrolytic oxidation (PEO). PEO has gained particular attention for producing thick, ceramic-like coatings with superior corrosion resistance, though energy consumption remains a concern.

Vapor deposition techniques, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), offer precise control over coating composition and thickness. These methods produce high-quality passivation layers but typically require sophisticated equipment and controlled environments, limiting their industrial scalability.

Sol-gel processes have emerged as versatile alternatives, enabling the formation of hybrid organic-inorganic protective layers at relatively low temperatures. These coatings can incorporate various functional additives, though adhesion to magnesium substrates often requires additional surface preparation steps.

Despite these advances, significant technical barriers persist. The high chemical reactivity of magnesium creates challenges in forming stable, uniform passivation layers. The native oxide film that forms spontaneously on magnesium surfaces is typically porous and non-protective, providing minimal corrosion resistance in aggressive environments.

Hydrogen evolution during coating processes presents another major challenge, as hydrogen bubbles can disrupt film formation and create defects. Additionally, the poor adhesion between many coating materials and magnesium substrates necessitates complex surface preparation procedures.

The mechanical fragility of passivation layers represents a critical limitation, as magnesium's high coefficient of thermal expansion can induce stress and cracking in protective coatings during temperature fluctuations. This is particularly problematic for applications involving thermal cycling.

Furthermore, achieving long-term stability remains challenging, as many passivation layers degrade over time through mechanisms including hydration, dissolution, and galvanic effects. This degradation is accelerated in environments containing chloride ions, which are ubiquitous in many practical applications.

Anodization represents another widely employed technique, utilizing electrochemical processes to form controlled oxide layers on magnesium surfaces. Conventional anodizing methods include Dow 17, HAE, and plasma electrolytic oxidation (PEO). PEO has gained particular attention for producing thick, ceramic-like coatings with superior corrosion resistance, though energy consumption remains a concern.

Vapor deposition techniques, including physical vapor deposition (PVD) and chemical vapor deposition (CVD), offer precise control over coating composition and thickness. These methods produce high-quality passivation layers but typically require sophisticated equipment and controlled environments, limiting their industrial scalability.

Sol-gel processes have emerged as versatile alternatives, enabling the formation of hybrid organic-inorganic protective layers at relatively low temperatures. These coatings can incorporate various functional additives, though adhesion to magnesium substrates often requires additional surface preparation steps.

Despite these advances, significant technical barriers persist. The high chemical reactivity of magnesium creates challenges in forming stable, uniform passivation layers. The native oxide film that forms spontaneously on magnesium surfaces is typically porous and non-protective, providing minimal corrosion resistance in aggressive environments.

Hydrogen evolution during coating processes presents another major challenge, as hydrogen bubbles can disrupt film formation and create defects. Additionally, the poor adhesion between many coating materials and magnesium substrates necessitates complex surface preparation procedures.

The mechanical fragility of passivation layers represents a critical limitation, as magnesium's high coefficient of thermal expansion can induce stress and cracking in protective coatings during temperature fluctuations. This is particularly problematic for applications involving thermal cycling.

Furthermore, achieving long-term stability remains challenging, as many passivation layers degrade over time through mechanisms including hydration, dissolution, and galvanic effects. This degradation is accelerated in environments containing chloride ions, which are ubiquitous in many practical applications.

State-of-the-Art Passivation Layer Formation Approaches

01 Chemical passivation methods for magnesium surfaces

Various chemical treatments can be applied to magnesium metal surfaces to form protective passivation layers. These treatments include oxidation processes, conversion coatings, and chemical baths that react with the magnesium surface to create a stable protective layer. The resulting passivation layers help prevent corrosion and degradation of the magnesium metal by forming a barrier against environmental factors. These chemical methods can be optimized for different applications and environmental conditions.- Chemical passivation methods for magnesium surfaces: Various chemical treatments can be applied to magnesium metal surfaces to form protective passivation layers. These treatments include chromate conversion coatings, phosphate treatments, and other chemical solutions that react with the magnesium surface to form a stable protective layer. These passivation layers help prevent corrosion and oxidation of the magnesium metal, extending its service life and maintaining its properties in various applications.

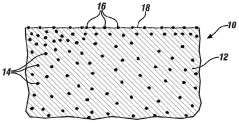

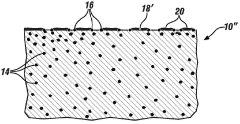

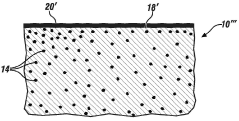

- Oxide-based passivation layers for magnesium: Magnesium oxide (MgO) and other oxide-based layers can serve as effective passivation barriers on magnesium surfaces. These oxide layers can be formed through controlled oxidation processes, thermal treatments, or deposition techniques. The resulting oxide layer provides protection against environmental degradation while maintaining the desirable properties of the underlying magnesium metal. The thickness and composition of these oxide layers can be tailored to meet specific application requirements.

- Passivation layers for magnesium in electronic applications: Specialized passivation techniques have been developed for magnesium components used in electronic devices and semiconductor applications. These include thin-film coatings, barrier layers, and surface treatments designed to protect magnesium while maintaining electrical properties. Such passivation layers are crucial for ensuring the reliability and performance of magnesium-containing electronic components, particularly in battery technologies, integrated circuits, and other microelectronic applications.

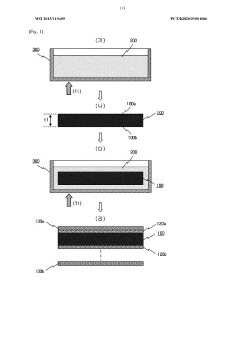

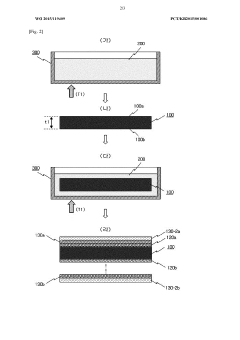

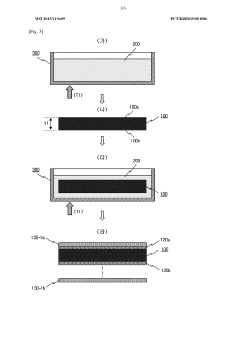

- Advanced deposition techniques for magnesium passivation: Modern deposition methods such as atomic layer deposition (ALD), physical vapor deposition (PVD), and chemical vapor deposition (CVD) can be used to create high-quality passivation layers on magnesium surfaces. These techniques allow for precise control over layer thickness, composition, and uniformity, resulting in superior protection against corrosion and oxidation. The deposited layers can be engineered to provide specific functional properties while maintaining the integrity of the magnesium substrate.

- Composite and multi-layer passivation systems: Complex passivation systems consisting of multiple layers or composite materials can provide enhanced protection for magnesium surfaces. These systems may combine different materials such as polymers, ceramics, and metals to create synergistic protective effects. The multi-layer approach allows for addressing various degradation mechanisms simultaneously, providing comprehensive protection against corrosion, oxidation, and mechanical damage while maintaining the functional properties of the magnesium component.

02 Passivation layers for magnesium in semiconductor applications

Specialized passivation techniques are used for magnesium surfaces in semiconductor and electronic device manufacturing. These methods focus on creating ultra-thin, uniform passivation layers that maintain electrical properties while providing protection. The passivation layers help prevent oxidation during device fabrication processes and improve the interface characteristics between magnesium and other materials in electronic components. These techniques are critical for ensuring reliability and performance in microelectronic applications.Expand Specific Solutions03 Physical vapor deposition techniques for magnesium passivation

Physical vapor deposition (PVD) methods are employed to create high-quality passivation layers on magnesium surfaces. These techniques include sputtering, evaporation, and other vacuum-based deposition processes that allow precise control over the composition and thickness of the passivation layer. The deposited films provide excellent adhesion and uniformity, resulting in enhanced protection against corrosion and oxidation. PVD techniques can be tailored to deposit various materials including oxides, nitrides, and composite layers depending on the specific protection requirements.Expand Specific Solutions04 Plasma and surface treatment methods for magnesium passivation

Plasma-based and other surface treatment methods are used to create effective passivation layers on magnesium surfaces. These processes involve exposing the magnesium surface to plasma or other energetic treatments that modify the surface properties and promote the formation of protective layers. The treatments can enhance the adhesion of subsequent coatings or directly form passivation layers through surface reactions. These methods offer advantages in terms of environmental friendliness and can be performed at lower temperatures compared to traditional chemical processes.Expand Specific Solutions05 Composite and multi-layer passivation systems for magnesium

Advanced passivation systems for magnesium surfaces often involve multiple layers or composite structures to provide enhanced protection. These systems may combine different materials and techniques to address various aspects of corrosion protection and surface functionality. The multi-layer approach allows for optimization of properties such as barrier protection, adhesion, and compatibility with subsequent coatings or processes. These composite passivation systems are particularly valuable for magnesium components used in demanding environments or applications requiring long-term reliability.Expand Specific Solutions

Leading Companies and Research Institutions in Mg Passivation

The passivation layer formation on magnesium metal surfaces technology landscape is currently in a growth phase, with an estimated market size of $2-3 billion and expanding at 8-10% annually due to increasing applications in automotive, aerospace, and electronics industries. The technology maturity varies across applications, with significant advancements being made by key players. BASF Corp. and GM Global Technology Operations lead in automotive applications, while POSCO Holdings and Baoshan Iron & Steel focus on industrial-scale implementations. Academic institutions like Lanzhou University of Technology and Hunan University are driving fundamental research, while specialized companies such as Almamet GmbH and Hongzan Precision Technology are developing niche solutions for specific magnesium surface treatments, creating a competitive yet collaborative ecosystem.

BASF Corp.

Technical Solution: BASF has developed advanced fluoride-based passivation technologies for magnesium surfaces that create stable protective layers resistant to corrosion. Their proprietary process involves a multi-stage treatment where magnesium substrates undergo surface preparation followed by application of fluoride-containing solutions that react with the metal to form a dense MgF2 layer. This layer provides exceptional barrier properties while maintaining electrical conductivity. BASF's technology incorporates nano-scale additives that enhance the passivation layer's durability and self-healing capabilities. The process operates at near-ambient temperatures, reducing energy consumption compared to traditional high-temperature passivation methods. Their solution achieves corrosion protection that extends magnesium component lifespan by up to 300% in accelerated testing environments.

Strengths: Environmentally friendly formulations with reduced VOCs and hazardous materials; compatible with complex geometries and various magnesium alloys. Weaknesses: Requires precise process control parameters; higher initial implementation costs compared to conventional chromate treatments.

GM Global Technology Operations LLC

Technical Solution: GM has pioneered an innovative plasma electrolytic oxidation (PEO) process specifically for magnesium components in automotive applications. Their technology creates a ceramic-like passivation layer through a controlled electrical discharge in an electrolyte solution. The process generates localized high-temperature plasma that transforms the magnesium surface into a dense, adherent oxide layer with thickness ranging from 5-50μm. GM's proprietary electrolyte formulation incorporates silicates and phosphates that enhance the layer's corrosion resistance while maintaining excellent wear properties. The technology enables in-situ formation of self-healing compounds that can repair minor damage to the passivation layer during service. GM has implemented this technology in lightweight structural components, achieving a 40% weight reduction compared to traditional materials while maintaining equivalent corrosion protection and mechanical integrity.

Strengths: Superior wear and corrosion resistance; excellent thermal stability suitable for engine components; environmentally friendly process without hexavalent chromium. Weaknesses: Higher energy consumption than conventional anodizing; potential for microcracking in thicker coatings that may require secondary sealing treatments.

Key Patents and Scientific Advances in Mg Surface Protection

corrosion protection OF MAGNESIUM AND MAGNESIUM ALLOYS

PatentPendingDE102018121013A1

Innovation

- A method involving the use of an acidic aqueous solution of alkali metal fluorides to remove iron-based cathode sites and deposit a protective magnesium fluoride (MgF2) layer on the surface, which inhibits corrosion by passivation and reduces the number of corrodible ferrous particles.

Surface treatment method for metal base

PatentWO2015119409A1

Innovation

- A surface treatment process involving an alcohol-based or ketone-based passivation solution heated to a specific temperature is used to form a passivation layer and a dissimilar metal protective layer on the metal substrate, enhancing durability, corrosion resistance, and coating film adhesion.

Environmental Impact and Sustainability of Passivation Processes

The environmental impact of passivation processes for magnesium surfaces represents a critical consideration in the broader context of sustainable materials engineering. Traditional passivation methods often involve chromate-based treatments which, while effective, contain hexavalent chromium compounds that pose significant environmental and health risks. These compounds are classified as carcinogenic and have been subject to increasing regulatory restrictions worldwide, particularly under frameworks such as REACH in Europe and similar environmental protection regulations in North America and Asia.

Alternative passivation technologies for magnesium surfaces have emerged with varying environmental profiles. Phosphate-based treatments offer reduced toxicity compared to chromates but still generate phosphate-laden wastewater that can contribute to eutrophication in aquatic ecosystems if not properly managed. Newer approaches utilizing rare earth elements, while less toxic, raise concerns regarding resource scarcity and the environmental impact of rare earth mining operations.

Water consumption represents another significant environmental consideration in passivation processes. Many conventional techniques require substantial volumes of water for rinsing and processing, contributing to industrial water footprints. Advanced systems incorporating closed-loop water recycling have demonstrated potential to reduce consumption by 40-60%, though implementation costs remain a barrier for widespread adoption.

Energy efficiency metrics reveal substantial variations across passivation technologies. Plasma electrolytic oxidation processes, while creating durable protective layers on magnesium surfaces, typically consume 3-5 times more energy than conventional chemical treatments. This energy differential translates directly to increased carbon emissions when power sources are not renewable.

Life cycle assessment (LCA) studies comparing various magnesium passivation methods indicate that vapor-phase deposition techniques often demonstrate superior environmental performance when considering the entire product lifecycle. These processes generate minimal waste streams and utilize lower volumes of hazardous substances, though their application remains limited by higher equipment costs and technical complexity.

Recent innovations in bio-inspired passivation approaches show particular promise from a sustainability perspective. These methods employ naturally derived compounds such as polyphenols from plant extracts or chitosan from crustacean shells to form protective layers on magnesium surfaces. Initial research indicates these approaches can reduce environmental impact by 30-50% compared to conventional methods while maintaining acceptable performance characteristics for certain applications.

Alternative passivation technologies for magnesium surfaces have emerged with varying environmental profiles. Phosphate-based treatments offer reduced toxicity compared to chromates but still generate phosphate-laden wastewater that can contribute to eutrophication in aquatic ecosystems if not properly managed. Newer approaches utilizing rare earth elements, while less toxic, raise concerns regarding resource scarcity and the environmental impact of rare earth mining operations.

Water consumption represents another significant environmental consideration in passivation processes. Many conventional techniques require substantial volumes of water for rinsing and processing, contributing to industrial water footprints. Advanced systems incorporating closed-loop water recycling have demonstrated potential to reduce consumption by 40-60%, though implementation costs remain a barrier for widespread adoption.

Energy efficiency metrics reveal substantial variations across passivation technologies. Plasma electrolytic oxidation processes, while creating durable protective layers on magnesium surfaces, typically consume 3-5 times more energy than conventional chemical treatments. This energy differential translates directly to increased carbon emissions when power sources are not renewable.

Life cycle assessment (LCA) studies comparing various magnesium passivation methods indicate that vapor-phase deposition techniques often demonstrate superior environmental performance when considering the entire product lifecycle. These processes generate minimal waste streams and utilize lower volumes of hazardous substances, though their application remains limited by higher equipment costs and technical complexity.

Recent innovations in bio-inspired passivation approaches show particular promise from a sustainability perspective. These methods employ naturally derived compounds such as polyphenols from plant extracts or chitosan from crustacean shells to form protective layers on magnesium surfaces. Initial research indicates these approaches can reduce environmental impact by 30-50% compared to conventional methods while maintaining acceptable performance characteristics for certain applications.

Industrial Application Scenarios and Implementation Challenges

Magnesium passivation technologies have found significant applications across multiple industrial sectors, with automotive and aerospace industries being the primary adopters. In automotive manufacturing, passivated magnesium alloys are increasingly utilized for lightweight components such as steering wheels, seat frames, and dashboard structures, contributing to overall vehicle weight reduction and improved fuel efficiency. The aerospace sector employs these materials in aircraft interiors, electronic housings, and non-structural components where the weight-to-strength ratio provides substantial benefits.

The electronics industry has begun implementing passivated magnesium in portable device casings, offering enhanced durability while maintaining lightweight characteristics. Medical device manufacturing represents another emerging application area, particularly for implantable devices and surgical instruments where biocompatibility can be achieved through appropriate passivation techniques.

Despite these promising applications, significant implementation challenges persist. The inconsistency in passivation layer formation across different magnesium alloy compositions remains a primary obstacle, requiring customized processes for specific alloy formulations. This variability increases production costs and complicates quality control procedures in industrial settings.

Scale-up challenges present another major hurdle, as laboratory-developed passivation techniques often encounter difficulties when transferred to mass production environments. The precise control of reaction conditions, including temperature, solution concentration, and exposure time, becomes increasingly complex at industrial scales, leading to quality inconsistencies.

Environmental and regulatory considerations further complicate implementation, particularly regarding the disposal of chemical waste from passivation processes. Many effective passivation solutions contain environmentally problematic compounds, creating tension between technical performance and sustainability requirements.

Cost-effectiveness represents another significant barrier, as advanced passivation techniques often require specialized equipment and materials that increase production expenses. The economic viability of these processes depends heavily on production volume and the value-added nature of the final application.

Long-term stability verification poses a final challenge, as accelerated testing methods may not accurately predict real-world performance of passivation layers under diverse environmental conditions. This uncertainty creates hesitation among potential industrial adopters who require reliable performance guarantees before full-scale implementation.

The electronics industry has begun implementing passivated magnesium in portable device casings, offering enhanced durability while maintaining lightweight characteristics. Medical device manufacturing represents another emerging application area, particularly for implantable devices and surgical instruments where biocompatibility can be achieved through appropriate passivation techniques.

Despite these promising applications, significant implementation challenges persist. The inconsistency in passivation layer formation across different magnesium alloy compositions remains a primary obstacle, requiring customized processes for specific alloy formulations. This variability increases production costs and complicates quality control procedures in industrial settings.

Scale-up challenges present another major hurdle, as laboratory-developed passivation techniques often encounter difficulties when transferred to mass production environments. The precise control of reaction conditions, including temperature, solution concentration, and exposure time, becomes increasingly complex at industrial scales, leading to quality inconsistencies.

Environmental and regulatory considerations further complicate implementation, particularly regarding the disposal of chemical waste from passivation processes. Many effective passivation solutions contain environmentally problematic compounds, creating tension between technical performance and sustainability requirements.

Cost-effectiveness represents another significant barrier, as advanced passivation techniques often require specialized equipment and materials that increase production expenses. The economic viability of these processes depends heavily on production volume and the value-added nature of the final application.

Long-term stability verification poses a final challenge, as accelerated testing methods may not accurately predict real-world performance of passivation layers under diverse environmental conditions. This uncertainty creates hesitation among potential industrial adopters who require reliable performance guarantees before full-scale implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!