Performance modeling of magnesium battery full cells

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg Battery Technology Background and Objectives

Magnesium batteries have emerged as a promising alternative to lithium-ion technology due to their potential advantages in safety, cost, and energy density. The development of magnesium battery technology can be traced back to the early 1990s, but significant progress has been made only in the past decade. The fundamental appeal of magnesium batteries lies in magnesium's abundance in the Earth's crust (approximately 13.9% compared to lithium's 0.0065%), making it substantially more economical and sustainable for large-scale energy storage applications.

The evolution of magnesium battery technology has been marked by several key milestones, including the development of non-nucleophilic electrolytes in 2000, the discovery of Chevrel phase cathodes with reversible Mg intercalation in 2007, and recent advancements in understanding the complex electrochemistry of magnesium deposition and dissolution. Despite these achievements, the technology remains in its nascent stages compared to the mature lithium-ion ecosystem.

Current technical objectives in magnesium battery research focus on overcoming several critical challenges. Primary among these is the development of high-performance cathode materials that can accommodate the divalent nature of magnesium ions, which creates stronger electrostatic interactions with host lattices compared to monovalent lithium ions. This fundamental difference results in slower diffusion kinetics and structural limitations that must be addressed through innovative material design and engineering.

Another key objective is the formulation of stable electrolytes that enable efficient magnesium ion transport while maintaining compatibility with both anode and cathode materials. The high reduction potential of magnesium often leads to passivation layers that impede ion transport, necessitating novel electrolyte compositions that can facilitate reversible magnesium plating and stripping.

Performance modeling of magnesium battery full cells represents a critical objective in advancing this technology toward commercial viability. Accurate models that can predict cell behavior under various operating conditions are essential for optimizing battery design, identifying performance bottlenecks, and accelerating the development cycle. These models must account for the unique characteristics of magnesium electrochemistry, including the divalent nature of magnesium ions and their distinct transport mechanisms.

The ultimate goal of magnesium battery technology development is to create energy storage systems that exceed the performance of current lithium-ion batteries while offering improved safety profiles and reduced environmental impact. This includes achieving energy densities above 500 Wh/kg at the cell level, cycle life exceeding 1000 cycles, and cost reduction to below $100/kWh to enable widespread adoption in applications ranging from portable electronics to electric vehicles and grid-scale energy storage.

The evolution of magnesium battery technology has been marked by several key milestones, including the development of non-nucleophilic electrolytes in 2000, the discovery of Chevrel phase cathodes with reversible Mg intercalation in 2007, and recent advancements in understanding the complex electrochemistry of magnesium deposition and dissolution. Despite these achievements, the technology remains in its nascent stages compared to the mature lithium-ion ecosystem.

Current technical objectives in magnesium battery research focus on overcoming several critical challenges. Primary among these is the development of high-performance cathode materials that can accommodate the divalent nature of magnesium ions, which creates stronger electrostatic interactions with host lattices compared to monovalent lithium ions. This fundamental difference results in slower diffusion kinetics and structural limitations that must be addressed through innovative material design and engineering.

Another key objective is the formulation of stable electrolytes that enable efficient magnesium ion transport while maintaining compatibility with both anode and cathode materials. The high reduction potential of magnesium often leads to passivation layers that impede ion transport, necessitating novel electrolyte compositions that can facilitate reversible magnesium plating and stripping.

Performance modeling of magnesium battery full cells represents a critical objective in advancing this technology toward commercial viability. Accurate models that can predict cell behavior under various operating conditions are essential for optimizing battery design, identifying performance bottlenecks, and accelerating the development cycle. These models must account for the unique characteristics of magnesium electrochemistry, including the divalent nature of magnesium ions and their distinct transport mechanisms.

The ultimate goal of magnesium battery technology development is to create energy storage systems that exceed the performance of current lithium-ion batteries while offering improved safety profiles and reduced environmental impact. This includes achieving energy densities above 500 Wh/kg at the cell level, cycle life exceeding 1000 cycles, and cost reduction to below $100/kWh to enable widespread adoption in applications ranging from portable electronics to electric vehicles and grid-scale energy storage.

Market Analysis for Next-Generation Battery Solutions

The global battery market is experiencing a significant shift towards more sustainable and efficient energy storage solutions, with magnesium batteries emerging as a promising alternative to conventional lithium-ion technology. Current market projections indicate that the next-generation battery market, including magnesium-based systems, could reach $25 billion by 2030, growing at a CAGR of approximately 18% from 2023 to 2030.

The demand for magnesium batteries is primarily driven by several key factors. First, concerns about lithium supply chain vulnerabilities and price volatility have intensified the search for alternative battery chemistries. Magnesium is the eighth most abundant element in the Earth's crust, offering significantly better resource security compared to lithium.

Safety considerations represent another major market driver. Unlike lithium-ion batteries, magnesium-based systems demonstrate superior thermal stability and reduced fire risk, addressing a critical concern for electric vehicle manufacturers and grid storage applications. This safety profile could potentially reduce insurance costs and regulatory hurdles for implementation.

The automotive sector presents the largest immediate market opportunity for magnesium battery technology. With global electric vehicle sales projected to reach 45 million units annually by 2030, battery technologies that offer higher energy density, faster charging capabilities, and improved safety profiles stand to capture significant market share. Magnesium batteries' theoretical energy density exceeds that of lithium-ion, making them particularly attractive for this application.

Grid-scale energy storage represents another substantial market segment. As renewable energy integration accelerates worldwide, the demand for efficient, long-duration storage solutions continues to grow. The projected stability and longer cycle life of magnesium batteries align well with these requirements, potentially offering lower lifetime costs despite higher initial investments.

Consumer electronics manufacturers are also showing interest in magnesium battery technology, particularly for applications where safety and energy density are paramount concerns. This segment could serve as an early adoption pathway, allowing for technology refinement before scaling to larger applications.

Regional analysis indicates that Asia-Pacific currently leads in next-generation battery research and manufacturing capacity, with China, Japan, and South Korea making significant investments. However, both North America and Europe are rapidly expanding their capabilities through public-private partnerships and dedicated research initiatives focused on reducing dependency on imported battery technologies.

Market barriers include the current high cost of magnesium battery production, technical challenges in electrolyte formulation, and the established infrastructure supporting lithium-ion technology. However, the performance modeling of magnesium battery full cells suggests that with continued R&D investment, these barriers could be substantially reduced within the next 3-5 years.

The demand for magnesium batteries is primarily driven by several key factors. First, concerns about lithium supply chain vulnerabilities and price volatility have intensified the search for alternative battery chemistries. Magnesium is the eighth most abundant element in the Earth's crust, offering significantly better resource security compared to lithium.

Safety considerations represent another major market driver. Unlike lithium-ion batteries, magnesium-based systems demonstrate superior thermal stability and reduced fire risk, addressing a critical concern for electric vehicle manufacturers and grid storage applications. This safety profile could potentially reduce insurance costs and regulatory hurdles for implementation.

The automotive sector presents the largest immediate market opportunity for magnesium battery technology. With global electric vehicle sales projected to reach 45 million units annually by 2030, battery technologies that offer higher energy density, faster charging capabilities, and improved safety profiles stand to capture significant market share. Magnesium batteries' theoretical energy density exceeds that of lithium-ion, making them particularly attractive for this application.

Grid-scale energy storage represents another substantial market segment. As renewable energy integration accelerates worldwide, the demand for efficient, long-duration storage solutions continues to grow. The projected stability and longer cycle life of magnesium batteries align well with these requirements, potentially offering lower lifetime costs despite higher initial investments.

Consumer electronics manufacturers are also showing interest in magnesium battery technology, particularly for applications where safety and energy density are paramount concerns. This segment could serve as an early adoption pathway, allowing for technology refinement before scaling to larger applications.

Regional analysis indicates that Asia-Pacific currently leads in next-generation battery research and manufacturing capacity, with China, Japan, and South Korea making significant investments. However, both North America and Europe are rapidly expanding their capabilities through public-private partnerships and dedicated research initiatives focused on reducing dependency on imported battery technologies.

Market barriers include the current high cost of magnesium battery production, technical challenges in electrolyte formulation, and the established infrastructure supporting lithium-ion technology. However, the performance modeling of magnesium battery full cells suggests that with continued R&D investment, these barriers could be substantially reduced within the next 3-5 years.

Current Status and Technical Barriers in Mg Battery Development

Magnesium battery technology has gained significant attention as a promising alternative to lithium-ion batteries due to its theoretical advantages including higher energy density, improved safety, and abundant material resources. However, the current development status reveals several critical challenges that have hindered widespread commercialization.

The state-of-the-art magnesium battery systems predominantly employ Mg metal anodes, various cathode materials (including Chevrel phases, sulfur, and oxide-based materials), and electrolytes based on organohaloaluminate complexes or non-nucleophilic electrolytes. Performance metrics of laboratory-scale cells typically show specific capacities ranging from 100-200 mAh/g, with cycle life generally limited to a few hundred cycles under optimal conditions.

A primary technical barrier in magnesium battery development is the formation of a passivation layer on the magnesium anode surface. Unlike the beneficial SEI layer in lithium-ion batteries, this passivation layer blocks Mg2+ ion transport, significantly increasing interfacial resistance and hampering electrochemical performance. This phenomenon makes accurate performance modeling particularly challenging, as the interface properties evolve dynamically during cycling.

Electrolyte limitations represent another significant obstacle. Current electrolyte systems suffer from narrow electrochemical stability windows, poor ionic conductivity, and compatibility issues with conventional cathode materials. These constraints severely restrict the operating voltage range and power capability of full cells, creating discrepancies between theoretical models and actual performance.

Cathode materials face challenges related to slow diffusion kinetics of divalent Mg2+ ions within host structures. The strong electrostatic interactions between Mg2+ ions and host lattices result in high migration barriers, leading to sluggish insertion/extraction processes. This manifests as significant voltage hysteresis and rate capability limitations in full cell configurations, complicating performance predictions.

Performance modeling of magnesium battery full cells is further complicated by the lack of standardized testing protocols and limited understanding of degradation mechanisms. Current models struggle to account for the complex interplay between electrode microstructure evolution, electrolyte decomposition, and interfacial phenomena across multiple time scales.

The geographical distribution of magnesium battery research shows concentration in North America, Europe, and East Asia, with notable contributions from research institutions in the United States, Germany, Japan, and China. Industry engagement remains primarily at the research level, with few companies advancing toward commercialization due to the aforementioned technical barriers.

The state-of-the-art magnesium battery systems predominantly employ Mg metal anodes, various cathode materials (including Chevrel phases, sulfur, and oxide-based materials), and electrolytes based on organohaloaluminate complexes or non-nucleophilic electrolytes. Performance metrics of laboratory-scale cells typically show specific capacities ranging from 100-200 mAh/g, with cycle life generally limited to a few hundred cycles under optimal conditions.

A primary technical barrier in magnesium battery development is the formation of a passivation layer on the magnesium anode surface. Unlike the beneficial SEI layer in lithium-ion batteries, this passivation layer blocks Mg2+ ion transport, significantly increasing interfacial resistance and hampering electrochemical performance. This phenomenon makes accurate performance modeling particularly challenging, as the interface properties evolve dynamically during cycling.

Electrolyte limitations represent another significant obstacle. Current electrolyte systems suffer from narrow electrochemical stability windows, poor ionic conductivity, and compatibility issues with conventional cathode materials. These constraints severely restrict the operating voltage range and power capability of full cells, creating discrepancies between theoretical models and actual performance.

Cathode materials face challenges related to slow diffusion kinetics of divalent Mg2+ ions within host structures. The strong electrostatic interactions between Mg2+ ions and host lattices result in high migration barriers, leading to sluggish insertion/extraction processes. This manifests as significant voltage hysteresis and rate capability limitations in full cell configurations, complicating performance predictions.

Performance modeling of magnesium battery full cells is further complicated by the lack of standardized testing protocols and limited understanding of degradation mechanisms. Current models struggle to account for the complex interplay between electrode microstructure evolution, electrolyte decomposition, and interfacial phenomena across multiple time scales.

The geographical distribution of magnesium battery research shows concentration in North America, Europe, and East Asia, with notable contributions from research institutions in the United States, Germany, Japan, and China. Industry engagement remains primarily at the research level, with few companies advancing toward commercialization due to the aforementioned technical barriers.

Current Performance Modeling Approaches for Mg Full Cells

01 Electrode materials for magnesium batteries

Various electrode materials can significantly impact the performance of magnesium batteries. These materials include specialized cathodes and anodes designed to enhance magnesium ion intercalation and extraction. Innovations in electrode composition, such as using composite materials or novel structures, can improve energy density, cycling stability, and rate capability of magnesium batteries. These advancements address key challenges in magnesium battery technology related to electrode performance.- Electrode materials for magnesium batteries: Various electrode materials can significantly impact the performance of magnesium batteries. These materials include specialized cathodes and anodes designed to facilitate magnesium ion intercalation and extraction. Innovations in electrode composition, such as using composite materials or novel structures, can enhance capacity, cycling stability, and rate capability of magnesium batteries. These advancements address key challenges in magnesium battery technology related to electrode kinetics and reversibility.

- Electrolyte formulations for improved performance: Electrolyte composition plays a crucial role in magnesium battery performance. Novel electrolyte formulations can enhance ionic conductivity, electrochemical stability, and compatibility with electrode materials. These formulations may include specific salts, solvents, and additives designed to facilitate magnesium ion transport while preventing unwanted side reactions. Improved electrolytes can address issues such as passivation layer formation and slow diffusion kinetics that typically limit magnesium battery performance.

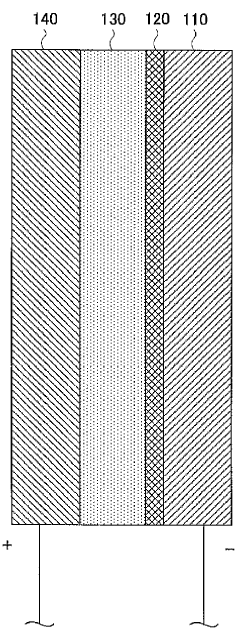

- Battery cell design and architecture: The physical design and architecture of magnesium battery cells can significantly impact their overall performance. Innovations in cell configuration, component arrangement, and packaging can improve energy density, power output, and thermal management. Advanced cell designs may incorporate features to accommodate the unique characteristics of magnesium electrochemistry, such as volume changes during cycling or specific current collection requirements, resulting in enhanced battery performance and reliability.

- Performance enhancement through additives and dopants: Various additives and dopants can be incorporated into magnesium battery components to enhance specific performance aspects. These materials may improve conductivity, stability, or reaction kinetics within the battery. For example, certain additives in the electrolyte can modify the solid-electrolyte interphase formation, while dopants in electrode materials can enhance structural stability or electronic conductivity. These approaches can address performance limitations related to capacity fade, internal resistance, or cycle life.

- Advanced manufacturing techniques for magnesium batteries: Manufacturing processes and techniques significantly impact the performance of magnesium batteries. Advanced fabrication methods can improve component quality, consistency, and integration. These techniques may include specialized coating processes, precise control of material morphology, or novel assembly approaches. Innovations in manufacturing can address challenges related to interfacial resistance, material utilization, and structural integrity, ultimately enhancing battery performance metrics such as energy density, power capability, and operational lifetime.

02 Electrolyte formulations for magnesium batteries

Electrolyte composition plays a crucial role in magnesium battery performance. Novel electrolyte formulations can enhance ionic conductivity, reduce corrosion, and improve the electrochemical stability window. These formulations may include non-aqueous solvents, ionic liquids, or solid-state electrolytes specifically designed for magnesium ion transport. Optimized electrolytes can address issues such as passivation layer formation and slow diffusion kinetics, leading to improved overall battery performance.Expand Specific Solutions03 Cell design and architecture for magnesium batteries

The physical design and architecture of magnesium battery cells can significantly influence their performance metrics. Innovations in cell configuration, component arrangement, and manufacturing techniques can lead to better thermal management, reduced internal resistance, and improved energy efficiency. Advanced cell designs may incorporate novel separators, current collectors, or housing materials specifically optimized for magnesium battery chemistry.Expand Specific Solutions04 Performance enhancement additives for magnesium batteries

Various additives can be incorporated into magnesium battery components to enhance specific performance aspects. These additives may include surface modifiers, stabilizing agents, or functional materials that improve interfacial properties, prevent dendrite formation, or enhance charge transfer kinetics. Strategic use of additives can address performance limitations related to capacity fading, self-discharge, or operational temperature range.Expand Specific Solutions05 Novel magnesium battery systems and configurations

Innovative magnesium battery systems explore alternative configurations beyond traditional designs. These may include hybrid systems combining magnesium with other metal ions, dual-salt electrolytes, or novel cell architectures. Such configurations aim to leverage the advantages of magnesium chemistry while mitigating its inherent limitations. These novel approaches can lead to breakthroughs in energy density, power capability, and cycle life of magnesium-based energy storage systems.Expand Specific Solutions

Key Industry Players in Magnesium Battery Research

The magnesium battery full cell performance modeling market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size remains relatively small compared to lithium-ion technologies, though projections indicate significant expansion potential as magnesium batteries offer theoretical advantages in energy density and safety. Technologically, the field is still evolving from fundamental research toward practical applications, with key players demonstrating varying levels of maturity. Toyota, Samsung, and BMW are leading automotive manufacturers investing heavily in this technology, while specialized companies like Pellion Technologies and SES Holdings focus on breakthrough innovations. Academic institutions including MIT, Carnegie Mellon, and Shanghai Jiao Tong University contribute fundamental research, often collaborating with industrial partners like Hitachi and Furukawa Battery to bridge the gap between theoretical modeling and practical implementation.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced performance modeling capabilities for magnesium battery full cells as part of their diversified energy storage research portfolio. Their approach combines electrochemical modeling with system-level simulations to evaluate magnesium batteries for automotive applications. Toyota's models incorporate detailed representations of ion transport phenomena, electrode kinetics, and degradation mechanisms specific to magnesium chemistry. Their simulation framework can predict battery performance under realistic driving cycles, accounting for varying temperature conditions and power demands. Toyota has integrated their magnesium battery models with vehicle energy management systems to optimize overall powertrain efficiency. Their modeling approach also includes manufacturing process simulations to identify scalable production methods for magnesium battery components. Toyota's research has particularly focused on modeling the interfaces between magnesium metal anodes and electrolytes to address dendrite formation and passivation layer issues that have historically limited magnesium battery performance.

Strengths: Extensive automotive integration expertise allows for realistic performance modeling under actual vehicle operating conditions. Their models benefit from Toyota's deep understanding of practical battery requirements for transportation applications. Weaknesses: Conservative approach to battery technology adoption may limit aggressive exploration of more experimental magnesium battery chemistries in their modeling work.

Samsung Electronics Co., Ltd.

Technical Solution: Samsung has developed sophisticated performance modeling tools for magnesium battery full cells as part of their next-generation energy storage research. Their approach integrates electrochemical impedance spectroscopy data with physics-based models to accurately predict cell behavior under various operating conditions. Samsung's modeling framework incorporates detailed representations of electrode microstructures, electrolyte transport properties, and interfacial kinetics specific to magnesium chemistry. Their models can simulate the impact of different cathode materials, electrolyte formulations, and cell designs on energy density, power capability, and cycle life. Samsung has implemented digital twin technology that combines real-time sensor data with their predictive models to enable continuous optimization of battery performance. Their modeling platform also includes thermal management simulations to predict and mitigate safety risks associated with magnesium battery operation.

Strengths: Extensive resources for both computational modeling and experimental validation, with the capability to scale promising technologies to commercial production. Their models benefit from integration with Samsung's broader battery manufacturing expertise. Weaknesses: Primary focus remains on lithium-ion technology, with magnesium battery modeling representing a smaller portion of their research portfolio.

Critical Technical Innovations in Mg Battery Modeling

Magnesium fuel body, magnesium-air battery, and electronic apparatus

PatentWO2015151311A1

Innovation

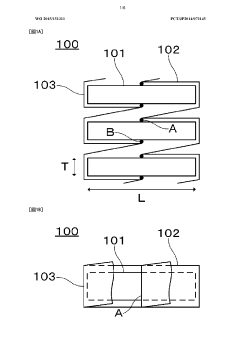

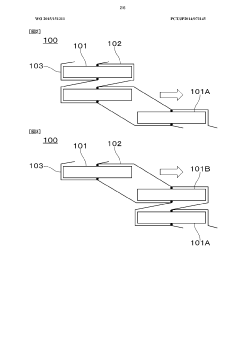

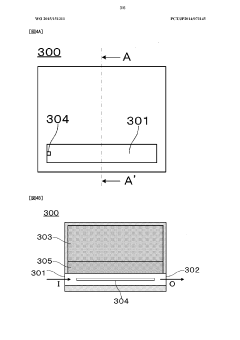

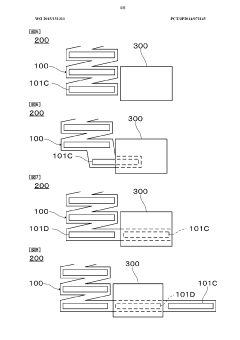

- A magnesium fuel assembly comprising multiple thin plates connected by foldable surface separators that allow for arbitrary thickness, enabling continuous insertion and withdrawal of magnesium plates into an electrode portion, where an oxidation-reduction reaction generates electromotive force.

Magnesium battery

PatentWO2012020791A1

Innovation

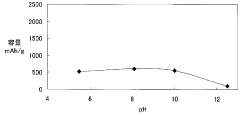

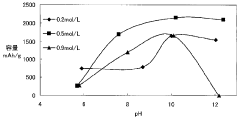

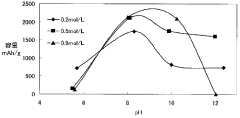

- A magnesium battery design utilizing a citrate aqueous solution as the electrolyte, which complexes magnesium ions to increase solubility, suppress magnesium oxide deposition, and maintain pH within a specific range to prevent hydrogen generation and film formation, along with an aluminum hydroxide complex to enhance hydrogenation voltage and self-discharge suppression.

Material Science Challenges in Mg Battery Electrochemistry

The development of magnesium batteries faces significant material science challenges that must be addressed to achieve commercially viable performance. The fundamental electrochemistry of magnesium presents unique obstacles compared to lithium-ion systems, primarily due to the divalent nature of Mg2+ ions and their strong interaction with host materials.

Cathode materials for Mg batteries suffer from slow diffusion kinetics, as the high charge density of Mg2+ ions creates strong electrostatic interactions with host lattices. This results in significant structural distortion during intercalation/deintercalation processes, leading to mechanical stress and potential structural collapse after multiple cycles. Current cathode materials like Chevrel phases (Mo6S8) show reasonable performance but limited capacity, while V2O5 and MnO2 structures face stability issues despite theoretical promise.

Anode challenges are equally critical, with metallic magnesium anodes prone to passivation layer formation when in contact with conventional electrolytes. These surface films, unlike the beneficial SEI layer in lithium batteries, are often non-conductive to Mg2+ ions, effectively blocking further electrochemical reactions. Additionally, dendrite formation, though less severe than in lithium systems, remains a concern for long-term cycling stability and safety.

Electrolyte development represents perhaps the most significant material science challenge. Conventional electrolytes that work well with lithium systems are largely incompatible with magnesium chemistry. Magnesium organohaloaluminate complexes in ethereal solvents show promising conductivity but suffer from narrow electrochemical windows and corrosivity issues. Newer boron-based electrolytes offer improved stability but often at the cost of ionic conductivity.

Interface phenomena between electrodes and electrolytes create additional complications. The formation of passivation layers at these interfaces significantly impacts cell performance, affecting charge transfer kinetics and overall cell impedance. Understanding and controlling these interfacial reactions remains a critical research focus, as they directly influence coulombic efficiency and cycle life.

Computational modeling approaches have become essential tools for understanding these material challenges. Density Functional Theory (DFT) calculations help predict ion diffusion pathways and energetics, while molecular dynamics simulations provide insights into electrolyte behavior and interface phenomena. However, bridging the gap between atomic-scale simulations and full-cell performance models remains challenging due to the multiscale nature of the processes involved.

Cathode materials for Mg batteries suffer from slow diffusion kinetics, as the high charge density of Mg2+ ions creates strong electrostatic interactions with host lattices. This results in significant structural distortion during intercalation/deintercalation processes, leading to mechanical stress and potential structural collapse after multiple cycles. Current cathode materials like Chevrel phases (Mo6S8) show reasonable performance but limited capacity, while V2O5 and MnO2 structures face stability issues despite theoretical promise.

Anode challenges are equally critical, with metallic magnesium anodes prone to passivation layer formation when in contact with conventional electrolytes. These surface films, unlike the beneficial SEI layer in lithium batteries, are often non-conductive to Mg2+ ions, effectively blocking further electrochemical reactions. Additionally, dendrite formation, though less severe than in lithium systems, remains a concern for long-term cycling stability and safety.

Electrolyte development represents perhaps the most significant material science challenge. Conventional electrolytes that work well with lithium systems are largely incompatible with magnesium chemistry. Magnesium organohaloaluminate complexes in ethereal solvents show promising conductivity but suffer from narrow electrochemical windows and corrosivity issues. Newer boron-based electrolytes offer improved stability but often at the cost of ionic conductivity.

Interface phenomena between electrodes and electrolytes create additional complications. The formation of passivation layers at these interfaces significantly impacts cell performance, affecting charge transfer kinetics and overall cell impedance. Understanding and controlling these interfacial reactions remains a critical research focus, as they directly influence coulombic efficiency and cycle life.

Computational modeling approaches have become essential tools for understanding these material challenges. Density Functional Theory (DFT) calculations help predict ion diffusion pathways and energetics, while molecular dynamics simulations provide insights into electrolyte behavior and interface phenomena. However, bridging the gap between atomic-scale simulations and full-cell performance models remains challenging due to the multiscale nature of the processes involved.

Sustainability and Life Cycle Assessment of Mg Battery Systems

The sustainability aspects of magnesium battery systems represent a critical dimension in evaluating their viability as alternatives to conventional lithium-ion technologies. Life cycle assessment (LCA) studies of magnesium battery systems indicate significant environmental advantages compared to lithium-based counterparts, primarily due to the abundance of magnesium in the Earth's crust (2.1% versus lithium's 0.0017%) and its widespread geographical distribution, reducing geopolitical supply risks.

Magnesium extraction and processing demonstrate lower environmental impacts across several categories, including greenhouse gas emissions, energy consumption, and water usage. Preliminary LCA data suggests that magnesium battery production could generate 15-30% less carbon dioxide equivalent emissions compared to lithium-ion batteries with similar energy storage capacities, largely attributable to less energy-intensive mining and refining processes.

The recyclability of magnesium battery components presents another sustainability advantage. Unlike lithium-ion batteries, which contain complex mixtures of materials that complicate end-of-life processing, magnesium batteries potentially offer simpler recycling pathways. Research indicates recovery rates for magnesium from spent batteries could reach 85-95%, significantly higher than current lithium recovery rates. This circular economy potential reduces the need for virgin material extraction and minimizes waste generation.

Water consumption metrics also favor magnesium battery systems, with estimates suggesting 30-40% lower water requirements throughout the production chain compared to lithium technologies. This advantage becomes particularly significant in water-stressed regions where battery manufacturing facilities might be located.

Safety considerations further enhance the sustainability profile of magnesium batteries. The non-flammable nature of many magnesium electrolyte systems reduces fire hazards associated with thermal runaway events, potentially decreasing the environmental impact of battery failures and extending useful service life through safer operation parameters.

However, challenges remain in fully quantifying the life cycle impacts of emerging magnesium battery technologies. Current performance modeling of full cells indicates that cycle life limitations may offset some sustainability advantages if magnesium batteries require more frequent replacement than their lithium counterparts. Additionally, the energy density achievements in laboratory settings must translate to commercial-scale production while maintaining the projected environmental benefits.

Future sustainability assessments must incorporate comprehensive cradle-to-grave analyses that account for performance parameters identified in full-cell modeling studies, including capacity retention, cycle life, and operational efficiency under various conditions. These factors directly influence the total environmental footprint when normalized by lifetime energy throughput rather than simply initial capacity.

Magnesium extraction and processing demonstrate lower environmental impacts across several categories, including greenhouse gas emissions, energy consumption, and water usage. Preliminary LCA data suggests that magnesium battery production could generate 15-30% less carbon dioxide equivalent emissions compared to lithium-ion batteries with similar energy storage capacities, largely attributable to less energy-intensive mining and refining processes.

The recyclability of magnesium battery components presents another sustainability advantage. Unlike lithium-ion batteries, which contain complex mixtures of materials that complicate end-of-life processing, magnesium batteries potentially offer simpler recycling pathways. Research indicates recovery rates for magnesium from spent batteries could reach 85-95%, significantly higher than current lithium recovery rates. This circular economy potential reduces the need for virgin material extraction and minimizes waste generation.

Water consumption metrics also favor magnesium battery systems, with estimates suggesting 30-40% lower water requirements throughout the production chain compared to lithium technologies. This advantage becomes particularly significant in water-stressed regions where battery manufacturing facilities might be located.

Safety considerations further enhance the sustainability profile of magnesium batteries. The non-flammable nature of many magnesium electrolyte systems reduces fire hazards associated with thermal runaway events, potentially decreasing the environmental impact of battery failures and extending useful service life through safer operation parameters.

However, challenges remain in fully quantifying the life cycle impacts of emerging magnesium battery technologies. Current performance modeling of full cells indicates that cycle life limitations may offset some sustainability advantages if magnesium batteries require more frequent replacement than their lithium counterparts. Additionally, the energy density achievements in laboratory settings must translate to commercial-scale production while maintaining the projected environmental benefits.

Future sustainability assessments must incorporate comprehensive cradle-to-grave analyses that account for performance parameters identified in full-cell modeling studies, including capacity retention, cycle life, and operational efficiency under various conditions. These factors directly influence the total environmental footprint when normalized by lifetime energy throughput rather than simply initial capacity.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!