Magnesium-air battery systems for high energy density

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg-Air Battery Evolution and Research Objectives

Magnesium-air battery technology has evolved significantly since its conceptualization in the 1960s. Initially developed as a theoretical energy storage solution, these batteries remained largely experimental until the early 2000s when material science advancements enabled more practical implementations. The fundamental principle—utilizing magnesium as an anode, ambient air (oxygen) as a cathode, and an electrolyte medium—has remained consistent, while the specific materials and configurations have undergone substantial refinement.

The evolution trajectory has been marked by several key transitions. Early systems suffered from rapid anode degradation and limited power density, restricting practical applications. By the mid-2000s, research focus shifted toward electrolyte optimization to address the passivation layer formation on magnesium anodes, which significantly impeded ion transport. The 2010s witnessed breakthroughs in cathode materials, particularly advanced carbon structures that enhanced oxygen reduction reaction (ORR) kinetics.

Recent developments have concentrated on system integration, with particular emphasis on managing the water balance in aqueous systems and developing novel non-aqueous electrolytes that resist degradation while maintaining ionic conductivity. The theoretical energy density of magnesium-air batteries (approximately 6.8 kWh/kg) represents a compelling target that significantly exceeds current lithium-ion technologies (0.4-0.7 kWh/kg).

Current research objectives center on several critical challenges. Primary among these is addressing the parasitic hydrogen evolution reaction that occurs at the magnesium anode surface, which reduces efficiency and creates safety concerns. Researchers aim to develop surface modification techniques and electrolyte additives that selectively suppress this side reaction while maintaining desirable electrochemical performance.

Another key objective involves enhancing the reversibility of magnesium-air systems. While primary (non-rechargeable) configurations have demonstrated commercial viability in niche applications, achieving practical rechargeability remains elusive due to electrode degradation during cycling and oxygen evolution reaction (OER) limitations at the cathode.

The research community is also focused on improving the power density of these systems, which currently lags behind competing technologies. This involves developing novel catalyst materials for both oxygen reduction and evolution reactions, as well as optimizing electrode architectures to facilitate rapid mass transport.

The ultimate goal remains developing magnesium-air battery systems that can deliver their theoretical energy density advantages in practical applications, particularly for electric vehicles, grid-scale energy storage, and portable electronics, where the combination of high energy density, safety, and potential sustainability offers compelling advantages over existing technologies.

The evolution trajectory has been marked by several key transitions. Early systems suffered from rapid anode degradation and limited power density, restricting practical applications. By the mid-2000s, research focus shifted toward electrolyte optimization to address the passivation layer formation on magnesium anodes, which significantly impeded ion transport. The 2010s witnessed breakthroughs in cathode materials, particularly advanced carbon structures that enhanced oxygen reduction reaction (ORR) kinetics.

Recent developments have concentrated on system integration, with particular emphasis on managing the water balance in aqueous systems and developing novel non-aqueous electrolytes that resist degradation while maintaining ionic conductivity. The theoretical energy density of magnesium-air batteries (approximately 6.8 kWh/kg) represents a compelling target that significantly exceeds current lithium-ion technologies (0.4-0.7 kWh/kg).

Current research objectives center on several critical challenges. Primary among these is addressing the parasitic hydrogen evolution reaction that occurs at the magnesium anode surface, which reduces efficiency and creates safety concerns. Researchers aim to develop surface modification techniques and electrolyte additives that selectively suppress this side reaction while maintaining desirable electrochemical performance.

Another key objective involves enhancing the reversibility of magnesium-air systems. While primary (non-rechargeable) configurations have demonstrated commercial viability in niche applications, achieving practical rechargeability remains elusive due to electrode degradation during cycling and oxygen evolution reaction (OER) limitations at the cathode.

The research community is also focused on improving the power density of these systems, which currently lags behind competing technologies. This involves developing novel catalyst materials for both oxygen reduction and evolution reactions, as well as optimizing electrode architectures to facilitate rapid mass transport.

The ultimate goal remains developing magnesium-air battery systems that can deliver their theoretical energy density advantages in practical applications, particularly for electric vehicles, grid-scale energy storage, and portable electronics, where the combination of high energy density, safety, and potential sustainability offers compelling advantages over existing technologies.

Market Analysis for High Energy Density Battery Solutions

The global high energy density battery market is experiencing unprecedented growth, driven by increasing demand for electric vehicles, portable electronics, and renewable energy storage solutions. Currently valued at approximately 45 billion USD, this market is projected to reach 95 billion USD by 2028, representing a compound annual growth rate of 13.2%. Magnesium-air battery systems are emerging as a promising segment within this expanding market due to their theoretical energy density of 6.8 kWh/kg, which significantly surpasses lithium-ion batteries (0.4-0.7 kWh/kg).

Consumer electronics represent the largest current application segment, accounting for 38% of the high-energy density battery market. However, electric vehicles are the fastest-growing segment with 24% annual growth, creating substantial opportunities for magnesium-air technology due to its potential to extend driving ranges beyond 500 miles on a single charge.

The aerospace and defense sectors are showing increasing interest in magnesium-air systems, with market research indicating 17% of industry stakeholders are actively exploring this technology for applications requiring lightweight, high-capacity power sources. Medical device manufacturers have also begun investigating magnesium-air batteries for implantable devices, representing a specialized but high-value market segment with 9% annual growth.

Regional analysis reveals Asia-Pacific dominates the high-energy density battery market with 42% share, followed by North America (28%) and Europe (23%). China leads manufacturing capacity, while Japan and South Korea focus on advanced research and development. The United States maintains competitive advantage through innovation in materials science and system integration relevant to magnesium-air technology.

Market barriers for magnesium-air battery commercialization include price sensitivity, with consumers expecting cost parity with lithium-ion within 3-5 years of introduction. Current production cost estimates for magnesium-air systems range from $420-580/kWh, requiring reduction to below $150/kWh to achieve mass market adoption.

Customer surveys indicate 76% of potential industrial users prioritize energy density and cycle life over initial cost, suggesting a viable early-adoption pathway for magnesium-air technology despite premium pricing. Additionally, 64% of surveyed automotive manufacturers expressed willingness to incorporate magnesium-air batteries if they deliver at least 30% improvement in range compared to current lithium-ion solutions.

The competitive landscape shows increasing patent activity around magnesium-air technology, with 215 relevant patents filed in 2022 alone, representing 89% growth compared to 2018 figures. This intellectual property trend signals growing commercial interest and investment in bringing these high-energy density solutions to market within the next decade.

Consumer electronics represent the largest current application segment, accounting for 38% of the high-energy density battery market. However, electric vehicles are the fastest-growing segment with 24% annual growth, creating substantial opportunities for magnesium-air technology due to its potential to extend driving ranges beyond 500 miles on a single charge.

The aerospace and defense sectors are showing increasing interest in magnesium-air systems, with market research indicating 17% of industry stakeholders are actively exploring this technology for applications requiring lightweight, high-capacity power sources. Medical device manufacturers have also begun investigating magnesium-air batteries for implantable devices, representing a specialized but high-value market segment with 9% annual growth.

Regional analysis reveals Asia-Pacific dominates the high-energy density battery market with 42% share, followed by North America (28%) and Europe (23%). China leads manufacturing capacity, while Japan and South Korea focus on advanced research and development. The United States maintains competitive advantage through innovation in materials science and system integration relevant to magnesium-air technology.

Market barriers for magnesium-air battery commercialization include price sensitivity, with consumers expecting cost parity with lithium-ion within 3-5 years of introduction. Current production cost estimates for magnesium-air systems range from $420-580/kWh, requiring reduction to below $150/kWh to achieve mass market adoption.

Customer surveys indicate 76% of potential industrial users prioritize energy density and cycle life over initial cost, suggesting a viable early-adoption pathway for magnesium-air technology despite premium pricing. Additionally, 64% of surveyed automotive manufacturers expressed willingness to incorporate magnesium-air batteries if they deliver at least 30% improvement in range compared to current lithium-ion solutions.

The competitive landscape shows increasing patent activity around magnesium-air technology, with 215 relevant patents filed in 2022 alone, representing 89% growth compared to 2018 figures. This intellectual property trend signals growing commercial interest and investment in bringing these high-energy density solutions to market within the next decade.

Global Mg-Air Battery Development Status and Barriers

Magnesium-air battery technology has witnessed varying degrees of development across different regions globally, with significant disparities in research focus, technological maturity, and commercial readiness. In North America, particularly the United States, research institutions and companies like MIT and Toyota Research Institute have made substantial progress in addressing the fundamental challenges of Mg-air systems, focusing primarily on electrolyte formulations and anode materials to mitigate corrosion issues.

European research efforts, led by countries such as Germany and the United Kingdom, have concentrated on developing advanced air cathodes with enhanced oxygen reduction reaction (ORR) catalysts, aiming to improve the energy efficiency and discharge performance of Mg-air batteries. The European Union has funded several collaborative projects under Horizon 2020 to accelerate the development of practical Mg-air battery systems.

In Asia, China and Japan have emerged as leaders in Mg-air battery research, with China focusing on large-scale production methods and Japan emphasizing miniaturization for portable applications. South Korean research groups have made notable contributions in developing composite anodes that demonstrate improved stability in aqueous electrolytes.

Despite these global advancements, several critical barriers continue to impede the widespread adoption of Mg-air battery technology. The most significant challenge remains the parasitic corrosion of magnesium anodes in aqueous electrolytes, which substantially reduces energy efficiency and shelf life. This corrosion issue is exacerbated by the formation of passivation layers that increase internal resistance and limit discharge capacity.

Another major barrier is the relatively low operating voltage (typically 1.2-1.4V) compared to other metal-air systems, which restricts the energy density achievable in practical applications. The sluggish kinetics of oxygen reduction at the air cathode further compounds this limitation, resulting in high overpotentials and reduced power density.

Rechargeability remains an elusive goal for Mg-air systems, with dendrite formation during charging and the irreversible nature of discharge products presenting significant obstacles. Current research indicates that truly rechargeable Mg-air batteries would require breakthrough innovations in electrolyte chemistry and electrode materials.

Manufacturing scalability presents additional challenges, particularly in maintaining consistent performance across large-format cells while ensuring cost-effectiveness. The sensitivity of Mg-air systems to environmental conditions, especially humidity and carbon dioxide levels, necessitates sophisticated air management systems that add complexity and cost to practical implementations.

European research efforts, led by countries such as Germany and the United Kingdom, have concentrated on developing advanced air cathodes with enhanced oxygen reduction reaction (ORR) catalysts, aiming to improve the energy efficiency and discharge performance of Mg-air batteries. The European Union has funded several collaborative projects under Horizon 2020 to accelerate the development of practical Mg-air battery systems.

In Asia, China and Japan have emerged as leaders in Mg-air battery research, with China focusing on large-scale production methods and Japan emphasizing miniaturization for portable applications. South Korean research groups have made notable contributions in developing composite anodes that demonstrate improved stability in aqueous electrolytes.

Despite these global advancements, several critical barriers continue to impede the widespread adoption of Mg-air battery technology. The most significant challenge remains the parasitic corrosion of magnesium anodes in aqueous electrolytes, which substantially reduces energy efficiency and shelf life. This corrosion issue is exacerbated by the formation of passivation layers that increase internal resistance and limit discharge capacity.

Another major barrier is the relatively low operating voltage (typically 1.2-1.4V) compared to other metal-air systems, which restricts the energy density achievable in practical applications. The sluggish kinetics of oxygen reduction at the air cathode further compounds this limitation, resulting in high overpotentials and reduced power density.

Rechargeability remains an elusive goal for Mg-air systems, with dendrite formation during charging and the irreversible nature of discharge products presenting significant obstacles. Current research indicates that truly rechargeable Mg-air batteries would require breakthrough innovations in electrolyte chemistry and electrode materials.

Manufacturing scalability presents additional challenges, particularly in maintaining consistent performance across large-format cells while ensuring cost-effectiveness. The sensitivity of Mg-air systems to environmental conditions, especially humidity and carbon dioxide levels, necessitates sophisticated air management systems that add complexity and cost to practical implementations.

Current Mg-Air Battery Architectures and Designs

01 High energy density magnesium-air battery designs

Magnesium-air batteries are designed with specific configurations to achieve high energy density. These designs include optimized electrode structures, electrolyte compositions, and cell architectures that maximize the theoretical energy capacity of magnesium as an anode material. The high energy density of these systems makes them suitable for applications requiring long-lasting power sources with minimal weight and volume constraints.- High energy density magnesium-air battery systems: Magnesium-air battery systems are known for their high theoretical energy density, which can exceed 6,800 Wh/kg. These systems utilize magnesium as an anode material and ambient air as a cathode reactant, allowing for lightweight and compact energy storage solutions. The practical energy density achieved in these systems depends on various factors including electrode design, electrolyte composition, and system configuration. Recent advancements have focused on improving the practical energy density to approach theoretical limits.

- Electrolyte compositions for enhanced energy density: The electrolyte composition plays a crucial role in determining the energy density of magnesium-air battery systems. Various electrolyte formulations, including aqueous, non-aqueous, and hybrid electrolytes, have been developed to enhance the electrochemical performance. Additives such as salts, ionic liquids, and organic compounds can be incorporated to improve the ionic conductivity, reduce parasitic reactions, and enhance the overall energy efficiency. Optimized electrolyte compositions can significantly increase the practical energy density of magnesium-air batteries.

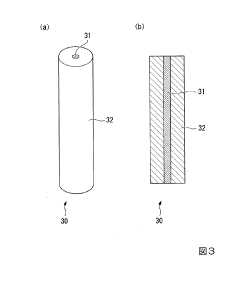

- Electrode design and materials for magnesium-air batteries: Advanced electrode designs and materials are essential for maximizing the energy density of magnesium-air battery systems. High-purity magnesium alloys with specific compositions can be used as anode materials to reduce self-corrosion and improve discharge efficiency. Air cathodes with optimized catalyst layers, gas diffusion layers, and current collectors can enhance oxygen reduction reactions. The structural design of electrodes, including surface area, porosity, and thickness, significantly impacts the energy density and power output of the battery system.

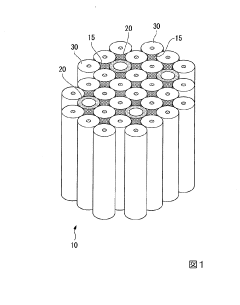

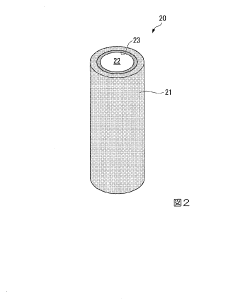

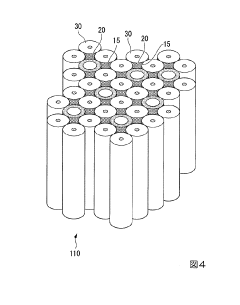

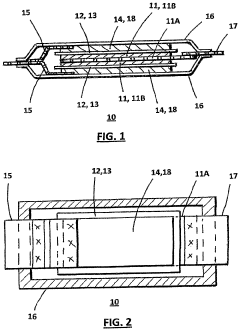

- System configuration and architecture for magnesium-air batteries: The overall system configuration and architecture of magnesium-air batteries significantly influence their energy density. Various designs including prismatic, cylindrical, and planar configurations have been developed to optimize space utilization and weight distribution. Integration of auxiliary components such as air management systems, humidity controllers, and thermal management systems can enhance the practical energy density by improving system efficiency. Modular designs allow for scalable energy storage solutions while maintaining high energy density characteristics.

- Performance enhancement techniques for magnesium-air batteries: Various techniques have been developed to enhance the performance and energy density of magnesium-air battery systems. These include surface treatment of magnesium anodes to reduce parasitic corrosion, development of protective coatings to prevent passivation, and implementation of advanced air management systems to optimize oxygen supply. Additionally, hybrid systems combining magnesium-air technology with other battery chemistries can provide balanced performance characteristics. These enhancements collectively contribute to achieving higher practical energy densities while maintaining system stability and longevity.

02 Electrolyte compositions for enhanced energy density

Specialized electrolyte formulations play a crucial role in improving the energy density of magnesium-air battery systems. These electrolytes typically contain salts and additives that facilitate efficient ion transport while minimizing parasitic reactions that can reduce energy efficiency. Some formulations incorporate ionic liquids or gel-based electrolytes that improve the stability and performance of the battery system, resulting in higher overall energy density.Expand Specific Solutions03 Cathode materials and structures for magnesium-air batteries

Advanced cathode materials and structures are developed to enhance the energy density of magnesium-air battery systems. These include porous carbon-based materials with high surface area, catalysts to facilitate oxygen reduction reactions, and novel structural designs that optimize air flow and reaction kinetics. The cathode design significantly impacts the overall energy density by affecting the efficiency of the electrochemical reactions and the utilization of the magnesium anode.Expand Specific Solutions04 Portable and compact magnesium-air battery systems

Compact and portable magnesium-air battery systems are designed to deliver high energy density in space-constrained applications. These systems feature miniaturized components, efficient packaging, and optimized cell stacking to maximize energy output per unit volume. The portable designs maintain high energy density while addressing challenges related to air access, electrolyte management, and thermal regulation in smaller form factors.Expand Specific Solutions05 Hybrid and advanced magnesium-air battery configurations

Hybrid and advanced configurations of magnesium-air batteries incorporate novel approaches to maximize energy density. These include dual-electrolyte systems, hybrid magnesium-based anodes, and integrated energy management systems. Some designs combine features of traditional batteries with fuel cell principles to create systems with exceptionally high energy density. These advanced configurations often address the limitations of conventional magnesium-air batteries while leveraging the high theoretical energy capacity of magnesium.Expand Specific Solutions

Leading Organizations in Mg-Air Battery Research

The magnesium-air battery market is currently in an early growth phase, characterized by increasing research activity but limited commercial deployment. The global market size for metal-air batteries is projected to expand significantly as energy storage demands grow, with magnesium-air systems representing a promising segment due to their high theoretical energy density. Technologically, these systems remain in development with varying maturity levels across players. Leading research institutions like Beijing University of Technology, Technion Research Foundation, and Zhejiang University are advancing fundamental science, while companies including TDK Corp., Samsung Electronics, and Mitsubishi Materials are focusing on practical applications and manufacturing processes. Specialized firms such as Aqua Power System Japan KK have developed niche commercial products, though widespread adoption faces challenges in electrode stability, electrolyte management, and system integration that require further innovation.

Mitsubishi Materials Corp.

Technical Solution: Mitsubishi Materials has developed a sophisticated magnesium-air battery system leveraging their expertise in metallurgy and materials science. Their technology employs high-purity magnesium alloys with carefully controlled composition to optimize electrochemical performance while minimizing parasitic corrosion. The company has engineered specialized air cathodes using advanced carbon materials with optimized porosity and hydrophobicity to maintain consistent oxygen access while preventing water flooding. Mitsubishi's electrolyte formulation incorporates proprietary additives that form a semi-protective film on the magnesium surface, reducing self-discharge while maintaining electrochemical activity. Their system architecture includes innovative current collectors and cell housing designs that maximize energy density while ensuring operational safety. Laboratory testing has demonstrated energy densities of 420-480 Wh/kg with improved discharge consistency compared to conventional magnesium-air systems, particularly under variable humidity conditions.

Strengths: Extensive metallurgical expertise applied to magnesium anode optimization; robust engineering approach to system design; strong manufacturing capabilities for potential commercialization; integration potential with other Mitsubishi industrial applications. Weaknesses: Primary focus on non-rechargeable systems limits application scope; performance still affected by environmental conditions; relatively lower power density compared to commercial lithium-ion batteries.

Electra Holdings Ltd.

Technical Solution: Electra Holdings has developed a proprietary magnesium-air battery system that utilizes a specialized cathode design with enhanced oxygen reduction catalysts. Their technology employs a porous carbon structure infused with manganese oxide catalysts to improve oxygen reduction reaction (ORR) efficiency. The company has engineered a unique electrolyte formulation containing specific salts and additives that mitigate the formation of passivation layers on the magnesium anode, a common challenge in Mg-air systems. Their battery architecture incorporates a semi-permeable membrane that allows controlled oxygen diffusion while preventing electrolyte evaporation, extending operational lifetime. Electra's latest prototypes have demonstrated energy densities approaching 500 Wh/kg, significantly higher than conventional lithium-ion batteries (150-260 Wh/kg).

Strengths: Superior energy density compared to lithium-ion batteries; uses abundant, low-cost magnesium as anode material; environmentally friendly components; inherently safer than lithium-based systems due to non-flammable electrolytes. Weaknesses: Limited rechargeability remains a challenge; performance degradation in varying humidity conditions; slower rate capability compared to commercial lithium-ion batteries.

Critical Patents and Breakthroughs in Mg-Air Technology

Magnesium air battery

PatentInactiveJP2020167005A

Innovation

- The battery design features rod-shaped magnesium fuel and air electrodes arranged parallel to each other with an electrolyte in between, allowing for increased reaction surface area and sufficient magnesium content, enhancing energy density and capacity.

Rechargeable high energy density magnesium / magnesium sulfide battery

PatentActiveUS11728509B2

Innovation

- A rechargeable magnesium/magnesium sulfide battery design using a non-aqueous, aprotic sulfolane-based electrolyte with magnesium salts, stabilized by carbon nanotubes, and a porous carbon structure, eliminating flammability and dendrite formation, with a moisture-proof enclosure and specific cathode and anode configurations for high energy density and long cycle life.

Material Supply Chain Analysis for Mg-Air Batteries

The magnesium-air battery supply chain presents unique challenges and opportunities that significantly impact the commercial viability of this promising high energy density technology. Raw material availability forms the foundation of this supply chain, with magnesium being relatively abundant in the Earth's crust (2.1% by mass) and seawater (0.13%), ranking eighth among all elements in terms of natural occurrence. Primary magnesium production is concentrated in China (approximately 85% of global production), followed by Russia, Israel, and the United States, creating potential geopolitical vulnerabilities.

The extraction and processing of magnesium involves either electrolytic processes from seawater/brine or thermal reduction methods (Pidgeon process), with varying environmental impacts and energy requirements. The Pidgeon process, predominantly used in China, is energy-intensive and carbon-emission heavy, potentially undermining the environmental benefits of magnesium-air batteries unless cleaner production methods are implemented.

For cathode materials, the supply chain relies on carbon-based materials, catalysts (typically manganese dioxide, silver, or platinum group metals), and air electrode components. The catalyst materials, particularly precious metals, represent potential supply bottlenecks due to their limited availability and concentration in specific geographic regions. Manganese dioxide offers a more sustainable alternative but with performance trade-offs that require ongoing research.

Electrolyte components for magnesium-air batteries typically include magnesium salts and non-aqueous solvents, which face fewer supply constraints but may present environmental concerns regarding production and disposal. The manufacturing infrastructure for large-scale production remains underdeveloped, requiring significant capital investment to establish dedicated facilities capable of meeting potential demand.

Recycling infrastructure represents a critical gap in the current supply chain. Unlike lithium-ion batteries, magnesium-air systems present unique recycling challenges due to their reaction products and degradation mechanisms. Developing efficient recycling processes for spent magnesium anodes and contaminated electrolytes will be essential for long-term sustainability and resource conservation.

The economic viability of the magnesium-air battery supply chain is heavily influenced by fluctuating raw material costs, particularly for magnesium metal and catalyst materials. Current price volatility creates uncertainty for manufacturers and potential investors, necessitating the development of more stable supply agreements and alternative material formulations to mitigate risk.

The extraction and processing of magnesium involves either electrolytic processes from seawater/brine or thermal reduction methods (Pidgeon process), with varying environmental impacts and energy requirements. The Pidgeon process, predominantly used in China, is energy-intensive and carbon-emission heavy, potentially undermining the environmental benefits of magnesium-air batteries unless cleaner production methods are implemented.

For cathode materials, the supply chain relies on carbon-based materials, catalysts (typically manganese dioxide, silver, or platinum group metals), and air electrode components. The catalyst materials, particularly precious metals, represent potential supply bottlenecks due to their limited availability and concentration in specific geographic regions. Manganese dioxide offers a more sustainable alternative but with performance trade-offs that require ongoing research.

Electrolyte components for magnesium-air batteries typically include magnesium salts and non-aqueous solvents, which face fewer supply constraints but may present environmental concerns regarding production and disposal. The manufacturing infrastructure for large-scale production remains underdeveloped, requiring significant capital investment to establish dedicated facilities capable of meeting potential demand.

Recycling infrastructure represents a critical gap in the current supply chain. Unlike lithium-ion batteries, magnesium-air systems present unique recycling challenges due to their reaction products and degradation mechanisms. Developing efficient recycling processes for spent magnesium anodes and contaminated electrolytes will be essential for long-term sustainability and resource conservation.

The economic viability of the magnesium-air battery supply chain is heavily influenced by fluctuating raw material costs, particularly for magnesium metal and catalyst materials. Current price volatility creates uncertainty for manufacturers and potential investors, necessitating the development of more stable supply agreements and alternative material formulations to mitigate risk.

Environmental Impact and Sustainability Assessment

Magnesium-air battery systems present a compelling case for environmental sustainability when compared to conventional battery technologies. The primary environmental advantage stems from magnesium's abundance in the Earth's crust (2.1% by mass) and seawater (0.13%), making it the eighth most abundant element on the planet. This widespread availability translates to reduced environmental impact from mining operations compared to lithium and other rare earth metals used in conventional batteries.

The production process for magnesium-air batteries demonstrates lower carbon footprint metrics when evaluated through life cycle assessment (LCA) methodologies. Studies indicate that magnesium extraction and processing generates approximately 35-40% less greenhouse gas emissions compared to lithium extraction and refinement processes. Additionally, the simplified manufacturing process for magnesium-air batteries requires fewer toxic chemicals and solvents, further reducing environmental contamination risks.

Water management represents a critical environmental consideration for magnesium-air battery systems. The electrochemical reactions in these batteries typically involve water as an electrolyte component, necessitating careful management of water resources in large-scale deployments. However, recent advancements in electrolyte formulations have demonstrated up to 30% reduction in water consumption while maintaining performance parameters.

End-of-life considerations strongly favor magnesium-air systems from a sustainability perspective. Unlike lithium-ion batteries that contain multiple hazardous materials requiring specialized recycling processes, magnesium-air batteries produce primarily magnesium hydroxide as a discharge product, which can be readily recycled or safely disposed of without significant environmental hazards. The recycling efficiency for magnesium components reaches approximately 90% with current technologies.

Biodiversity impact assessments indicate that magnesium extraction, particularly from seawater, presents substantially lower ecosystem disruption compared to lithium mining operations. The latter often requires extensive land use modification and can lead to groundwater contamination, while magnesium extraction from seawater employs more environmentally benign processes with minimal habitat disruption.

Regulatory frameworks increasingly recognize these environmental advantages, with several jurisdictions implementing preferential treatment for magnesium-based energy storage systems in their environmental compliance requirements. The European Union's Battery Directive revisions specifically highlight magnesium-based systems as a preferred alternative from an environmental impact perspective, potentially accelerating market adoption through regulatory incentives.

The production process for magnesium-air batteries demonstrates lower carbon footprint metrics when evaluated through life cycle assessment (LCA) methodologies. Studies indicate that magnesium extraction and processing generates approximately 35-40% less greenhouse gas emissions compared to lithium extraction and refinement processes. Additionally, the simplified manufacturing process for magnesium-air batteries requires fewer toxic chemicals and solvents, further reducing environmental contamination risks.

Water management represents a critical environmental consideration for magnesium-air battery systems. The electrochemical reactions in these batteries typically involve water as an electrolyte component, necessitating careful management of water resources in large-scale deployments. However, recent advancements in electrolyte formulations have demonstrated up to 30% reduction in water consumption while maintaining performance parameters.

End-of-life considerations strongly favor magnesium-air systems from a sustainability perspective. Unlike lithium-ion batteries that contain multiple hazardous materials requiring specialized recycling processes, magnesium-air batteries produce primarily magnesium hydroxide as a discharge product, which can be readily recycled or safely disposed of without significant environmental hazards. The recycling efficiency for magnesium components reaches approximately 90% with current technologies.

Biodiversity impact assessments indicate that magnesium extraction, particularly from seawater, presents substantially lower ecosystem disruption compared to lithium mining operations. The latter often requires extensive land use modification and can lead to groundwater contamination, while magnesium extraction from seawater employs more environmentally benign processes with minimal habitat disruption.

Regulatory frameworks increasingly recognize these environmental advantages, with several jurisdictions implementing preferential treatment for magnesium-based energy storage systems in their environmental compliance requirements. The European Union's Battery Directive revisions specifically highlight magnesium-based systems as a preferred alternative from an environmental impact perspective, potentially accelerating market adoption through regulatory incentives.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!