Magnesium battery design for stationary energy storage systems

OCT 14, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Magnesium Battery Technology Background and Objectives

Magnesium batteries have emerged as a promising alternative to lithium-ion batteries for stationary energy storage systems due to their potential advantages in cost, safety, and resource availability. The development of magnesium battery technology can be traced back to the early 1990s, but significant progress has been made only in the past decade with the discovery of new electrolytes and cathode materials that enable reversible magnesium deposition and dissolution.

The evolution of magnesium battery technology has been driven by the increasing demand for large-scale energy storage solutions to support renewable energy integration and grid stability. Unlike lithium, magnesium is abundant in the Earth's crust (the 8th most abundant element), making it an attractive option for sustainable energy storage systems. The divalent nature of magnesium ions (Mg2+) also offers the potential for higher energy density compared to monovalent lithium ions.

Current technological trends in magnesium batteries focus on addressing key challenges such as slow diffusion kinetics of Mg2+ ions in cathode materials, passivation layers on the magnesium anode, and limited electrolyte options. Recent advancements include the development of Chevrel phase Mo6S8 cathodes, which demonstrate good reversibility for Mg2+ intercalation, and non-nucleophilic electrolytes based on magnesium aluminum chloride complex (MACC) that enable efficient magnesium plating and stripping.

For stationary energy storage applications, the technical objectives of magnesium battery development are multifaceted. Primary goals include achieving long cycle life (>5000 cycles), high energy efficiency (>85%), and calendar life exceeding 15 years to ensure economic viability for grid-scale deployment. Cost targets are typically below $100/kWh at the system level, significantly lower than current lithium-ion technologies.

Safety and environmental considerations represent another critical objective in magnesium battery design. Unlike lithium-ion batteries, magnesium-based systems do not pose the same risks of thermal runaway and fire, making them particularly suitable for residential and commercial stationary storage applications where safety is paramount.

The roadmap for magnesium battery technology development includes near-term objectives focused on electrolyte stability improvement and cathode material optimization, mid-term goals centered on cell design and manufacturing scalability, and long-term aspirations for system integration with renewable energy sources and smart grid technologies. Achieving these objectives would position magnesium batteries as a viable alternative to current energy storage technologies, particularly for applications requiring long duration storage at competitive costs.

The evolution of magnesium battery technology has been driven by the increasing demand for large-scale energy storage solutions to support renewable energy integration and grid stability. Unlike lithium, magnesium is abundant in the Earth's crust (the 8th most abundant element), making it an attractive option for sustainable energy storage systems. The divalent nature of magnesium ions (Mg2+) also offers the potential for higher energy density compared to monovalent lithium ions.

Current technological trends in magnesium batteries focus on addressing key challenges such as slow diffusion kinetics of Mg2+ ions in cathode materials, passivation layers on the magnesium anode, and limited electrolyte options. Recent advancements include the development of Chevrel phase Mo6S8 cathodes, which demonstrate good reversibility for Mg2+ intercalation, and non-nucleophilic electrolytes based on magnesium aluminum chloride complex (MACC) that enable efficient magnesium plating and stripping.

For stationary energy storage applications, the technical objectives of magnesium battery development are multifaceted. Primary goals include achieving long cycle life (>5000 cycles), high energy efficiency (>85%), and calendar life exceeding 15 years to ensure economic viability for grid-scale deployment. Cost targets are typically below $100/kWh at the system level, significantly lower than current lithium-ion technologies.

Safety and environmental considerations represent another critical objective in magnesium battery design. Unlike lithium-ion batteries, magnesium-based systems do not pose the same risks of thermal runaway and fire, making them particularly suitable for residential and commercial stationary storage applications where safety is paramount.

The roadmap for magnesium battery technology development includes near-term objectives focused on electrolyte stability improvement and cathode material optimization, mid-term goals centered on cell design and manufacturing scalability, and long-term aspirations for system integration with renewable energy sources and smart grid technologies. Achieving these objectives would position magnesium batteries as a viable alternative to current energy storage technologies, particularly for applications requiring long duration storage at competitive costs.

Market Analysis for Stationary Energy Storage Solutions

The stationary energy storage market is experiencing unprecedented growth, driven by the global transition to renewable energy sources and the need for grid stabilization. As of 2023, this market is valued at approximately $27 billion globally, with projections indicating a compound annual growth rate (CAGR) of 18-20% through 2030. This robust growth trajectory is primarily fueled by increasing renewable energy integration, aging grid infrastructure, and evolving regulatory frameworks that incentivize energy storage deployment.

Lithium-ion batteries currently dominate the stationary storage market, accounting for over 90% of new installations. However, concerns regarding lithium supply chain vulnerabilities, resource limitations, and safety issues have intensified the search for alternative technologies. This market gap presents a significant opportunity for magnesium-based battery systems, which offer theoretical advantages in safety, resource abundance, and potentially lower costs.

Demand segmentation reveals distinct market needs across utility-scale, commercial/industrial, and residential applications. Utility-scale storage represents the largest segment (65% of deployments) with requirements focused on long duration (4+ hours) and cost efficiency rather than energy density. Commercial applications (25%) prioritize reliability and return on investment, while residential systems (10%) emphasize safety and integration capabilities.

Regional analysis shows varied market maturity and growth patterns. North America leads in deployment volume with strong policy support, while the Asia-Pacific region demonstrates the fastest growth rate at 25% annually, driven by China's aggressive renewable energy targets. Europe follows with steady growth supported by the European Green Deal initiatives.

Customer requirements for stationary storage differ significantly from transportation applications. While electric vehicles prioritize energy density and fast charging, stationary applications emphasize cycle life (10,000+ cycles expected), calendar life (15-20 years), safety, and total cost of ownership. These distinct requirements create a specialized market opportunity for magnesium battery technology, which may struggle to compete in mobility applications but could excel in stationary contexts.

Competitive analysis reveals increasing diversification beyond lithium technologies. Flow batteries, sodium-ion, and advanced lead-acid systems are gaining market share in specific applications. This competitive landscape suggests that magnesium batteries would need to demonstrate clear advantages in either cost structure (target: below $100/kWh) or performance characteristics (particularly cycle life and safety) to achieve significant market penetration.

Market barriers for new battery technologies include conservative utility adoption practices, certification requirements, and the need for demonstrated field reliability. However, the increasing emphasis on supply chain security and sustainable materials provides a potential market entry point for magnesium-based solutions.

Lithium-ion batteries currently dominate the stationary storage market, accounting for over 90% of new installations. However, concerns regarding lithium supply chain vulnerabilities, resource limitations, and safety issues have intensified the search for alternative technologies. This market gap presents a significant opportunity for magnesium-based battery systems, which offer theoretical advantages in safety, resource abundance, and potentially lower costs.

Demand segmentation reveals distinct market needs across utility-scale, commercial/industrial, and residential applications. Utility-scale storage represents the largest segment (65% of deployments) with requirements focused on long duration (4+ hours) and cost efficiency rather than energy density. Commercial applications (25%) prioritize reliability and return on investment, while residential systems (10%) emphasize safety and integration capabilities.

Regional analysis shows varied market maturity and growth patterns. North America leads in deployment volume with strong policy support, while the Asia-Pacific region demonstrates the fastest growth rate at 25% annually, driven by China's aggressive renewable energy targets. Europe follows with steady growth supported by the European Green Deal initiatives.

Customer requirements for stationary storage differ significantly from transportation applications. While electric vehicles prioritize energy density and fast charging, stationary applications emphasize cycle life (10,000+ cycles expected), calendar life (15-20 years), safety, and total cost of ownership. These distinct requirements create a specialized market opportunity for magnesium battery technology, which may struggle to compete in mobility applications but could excel in stationary contexts.

Competitive analysis reveals increasing diversification beyond lithium technologies. Flow batteries, sodium-ion, and advanced lead-acid systems are gaining market share in specific applications. This competitive landscape suggests that magnesium batteries would need to demonstrate clear advantages in either cost structure (target: below $100/kWh) or performance characteristics (particularly cycle life and safety) to achieve significant market penetration.

Market barriers for new battery technologies include conservative utility adoption practices, certification requirements, and the need for demonstrated field reliability. However, the increasing emphasis on supply chain security and sustainable materials provides a potential market entry point for magnesium-based solutions.

Current State and Technical Challenges in Mg Battery Development

Magnesium battery technology for stationary energy storage systems is currently at a developmental stage, with significant research efforts focused on overcoming key technical barriers. While commercial lithium-ion batteries dominate the market, magnesium-based systems have attracted attention due to their theoretical advantages including higher volumetric capacity (3833 mAh/cm³ vs. 2046 mAh/cm³ for lithium), improved safety profile, and the abundance of magnesium resources in the earth's crust.

The current state of magnesium battery development shows promising laboratory-scale results but remains far from widespread commercial deployment. Research institutions and companies across North America, Europe, and East Asia have demonstrated functional magnesium battery prototypes with energy densities ranging from 100-150 Wh/kg, still below the 250+ Wh/kg achieved by advanced lithium-ion systems. Cycle life remains limited to 500-1000 cycles under optimal conditions, insufficient for the 10+ year lifespan required for stationary applications.

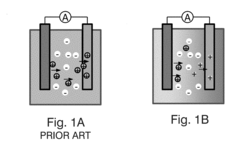

A fundamental challenge in magnesium battery development is the high charge density of Mg²⁺ ions (twice that of Li⁺), resulting in strong electrostatic interactions with host materials. This creates sluggish ion diffusion kinetics and significant structural changes during charge/discharge cycles. The development of suitable electrolytes represents another major hurdle, as conventional electrolytes form passivation layers on magnesium anodes that block ion transport.

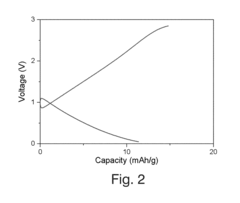

Cathode materials present additional challenges, with current options suffering from low operating voltages (typically <2.5V vs. Mg/Mg²⁺) and limited specific capacities. Promising cathode materials include Chevrel phases (Mo₆S₈), vanadium oxides, and organic compounds, though each presents trade-offs between capacity, voltage, and stability.

The solid-electrolyte interphase (SEI) formation mechanism differs significantly from lithium systems, requiring fundamentally different approaches to electrolyte design. Current magnesium electrolytes are often based on complex organometallic compounds that are sensitive to air and moisture, complicating manufacturing and increasing costs.

For stationary applications specifically, the power density limitations of current magnesium systems (typically <500 W/kg) restrict their ability to respond to rapid grid fluctuations. Temperature sensitivity also remains problematic, with performance degradation observed outside the 15-35°C range, necessitating additional thermal management systems that increase system complexity and cost.

Despite these challenges, recent advances in computational materials science and high-throughput experimental techniques have accelerated the discovery of new materials and electrolyte formulations. Several research groups have reported improved magnesium conductors and cathode materials that may address current limitations, suggesting a pathway toward commercially viable magnesium batteries for stationary energy storage within the next 5-10 years.

The current state of magnesium battery development shows promising laboratory-scale results but remains far from widespread commercial deployment. Research institutions and companies across North America, Europe, and East Asia have demonstrated functional magnesium battery prototypes with energy densities ranging from 100-150 Wh/kg, still below the 250+ Wh/kg achieved by advanced lithium-ion systems. Cycle life remains limited to 500-1000 cycles under optimal conditions, insufficient for the 10+ year lifespan required for stationary applications.

A fundamental challenge in magnesium battery development is the high charge density of Mg²⁺ ions (twice that of Li⁺), resulting in strong electrostatic interactions with host materials. This creates sluggish ion diffusion kinetics and significant structural changes during charge/discharge cycles. The development of suitable electrolytes represents another major hurdle, as conventional electrolytes form passivation layers on magnesium anodes that block ion transport.

Cathode materials present additional challenges, with current options suffering from low operating voltages (typically <2.5V vs. Mg/Mg²⁺) and limited specific capacities. Promising cathode materials include Chevrel phases (Mo₆S₈), vanadium oxides, and organic compounds, though each presents trade-offs between capacity, voltage, and stability.

The solid-electrolyte interphase (SEI) formation mechanism differs significantly from lithium systems, requiring fundamentally different approaches to electrolyte design. Current magnesium electrolytes are often based on complex organometallic compounds that are sensitive to air and moisture, complicating manufacturing and increasing costs.

For stationary applications specifically, the power density limitations of current magnesium systems (typically <500 W/kg) restrict their ability to respond to rapid grid fluctuations. Temperature sensitivity also remains problematic, with performance degradation observed outside the 15-35°C range, necessitating additional thermal management systems that increase system complexity and cost.

Despite these challenges, recent advances in computational materials science and high-throughput experimental techniques have accelerated the discovery of new materials and electrolyte formulations. Several research groups have reported improved magnesium conductors and cathode materials that may address current limitations, suggesting a pathway toward commercially viable magnesium batteries for stationary energy storage within the next 5-10 years.

Current Design Solutions for Mg-Based Stationary Storage

01 Magnesium battery electrode materials

Various materials can be used as electrodes in magnesium batteries to improve performance. These include specialized cathode materials that facilitate magnesium ion intercalation and anode materials that enhance magnesium deposition and dissolution. The selection of appropriate electrode materials is crucial for achieving high energy density, good cycling stability, and improved rate capability in magnesium batteries.- Magnesium battery electrode materials: Various materials can be used as electrodes in magnesium batteries to improve performance. These include specialized cathode materials that facilitate magnesium ion intercalation and anode materials that enhance magnesium deposition and dissolution. The selection of appropriate electrode materials is crucial for achieving high energy density, good cycling stability, and improved rate capability in magnesium batteries.

- Electrolyte compositions for magnesium batteries: Electrolyte formulations play a critical role in magnesium battery performance. Specialized electrolytes that enable efficient magnesium ion transport while preventing passivation of the magnesium anode are essential. These may include non-aqueous electrolytes with specific salts, solvents, and additives designed to enhance ionic conductivity and electrochemical stability within the magnesium battery system.

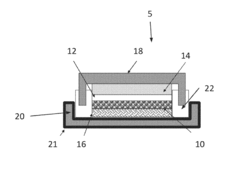

- Battery structure and cell design: The physical design and structure of magnesium batteries significantly impact their performance. This includes considerations for cell architecture, separator materials, current collectors, and packaging. Innovative cell designs can address challenges related to volume expansion, internal resistance, and thermal management, ultimately improving the overall efficiency and safety of magnesium battery systems.

- Manufacturing processes for magnesium batteries: Specialized manufacturing techniques are employed to produce high-performance magnesium batteries. These processes may include methods for electrode preparation, electrolyte formulation, cell assembly, and quality control. Advanced manufacturing approaches can enhance the consistency, scalability, and cost-effectiveness of magnesium battery production while maintaining optimal electrochemical performance.

- Hybrid and dual-ion magnesium battery systems: Hybrid battery systems that combine magnesium with other metal ions or electrode chemistries can offer advantages over traditional magnesium batteries. These systems may incorporate dual-ion mechanisms, magnesium-lithium hybrid configurations, or other innovative approaches to overcome limitations of conventional magnesium batteries. Such hybrid designs can potentially deliver improved energy density, power capability, and cycling stability.

02 Electrolyte compositions for magnesium batteries

Electrolyte formulations play a critical role in magnesium battery performance. Specialized electrolytes that enable efficient magnesium ion transport while preventing passivation of the magnesium anode are essential. These may include non-aqueous electrolytes with specific salts, solvents, and additives designed to enhance ionic conductivity and electrochemical stability within the magnesium battery system.Expand Specific Solutions03 Magnesium-sulfur battery technology

Magnesium-sulfur battery systems represent a promising high-energy-density alternative to conventional battery technologies. These systems utilize sulfur cathodes paired with magnesium anodes to achieve theoretical energy densities significantly higher than lithium-ion batteries. Research focuses on addressing challenges such as the shuttle effect, slow reaction kinetics, and electrolyte compatibility to make these batteries commercially viable.Expand Specific Solutions04 Manufacturing processes for magnesium batteries

Specialized manufacturing techniques are required for the production of magnesium batteries. These processes address unique challenges associated with magnesium battery components, including electrode preparation methods, cell assembly procedures, and quality control measures. Advanced manufacturing approaches aim to enhance battery performance while enabling cost-effective mass production of magnesium battery systems.Expand Specific Solutions05 Hybrid and dual-ion magnesium battery systems

Hybrid and dual-ion magnesium battery configurations combine the advantages of magnesium with other battery chemistries. These systems may incorporate magnesium anodes with alternative cathode materials or utilize magnesium ions alongside other charge carriers. Such hybrid approaches aim to overcome limitations of pure magnesium systems while maintaining benefits like safety, cost-effectiveness, and the use of abundant materials.Expand Specific Solutions

Key Industry Players in Magnesium Battery Research

The magnesium battery market for stationary energy storage systems is in an early growth phase, characterized by increasing R&D investments but limited commercial deployment. The global market is projected to expand significantly as renewable energy integration drives demand for cost-effective storage solutions. Technologically, magnesium batteries remain in development stages with key players pursuing different approaches. Toyota Motor Corp. leads with substantial patent activity, while research institutions like Shanghai Jiao Tong University, Tsinghua University, and KIST Corp. contribute fundamental innovations. Commercial entities including VARTA Micro Innovation, Hitachi, and State Grid Corp. of China are developing practical applications, focusing on improving energy density, cycle life, and electrolyte stability to overcome current technical limitations.

Toyota Motor Corp.

Technical Solution: Toyota has developed advanced magnesium battery technology for stationary energy storage systems that leverages their expertise in materials science and battery engineering. Their approach focuses on magnesium-ion batteries utilizing high-voltage cathode materials and non-corrosive electrolytes to overcome traditional challenges. Toyota's design incorporates a proprietary dual-salt electrolyte system that enables reversible magnesium deposition and extraction, significantly improving cycling stability. The company has also developed specialized electrode materials with optimized microstructures that facilitate faster magnesium-ion diffusion, addressing the slow kinetics typically associated with magnesium batteries. Their integrated battery management system specifically calibrated for magnesium chemistry ensures optimal performance and longevity in grid-scale applications.

Strengths: Leverages Toyota's extensive experience in battery technology and materials engineering; Offers potentially lower cost than lithium-ion alternatives; Benefits from Toyota's established manufacturing infrastructure. Weaknesses: Still faces challenges with energy density compared to some competing technologies; Commercialization timeline may be longer than some competitors.

Battelle Memorial Institute

Technical Solution: Battelle Memorial Institute has pioneered innovative magnesium battery designs for stationary energy storage systems through their comprehensive research program. Their approach centers on developing high-performance, cost-effective magnesium-sulfur battery technology specifically optimized for grid-scale applications. Battelle's design incorporates novel electrolyte formulations that effectively suppress magnesium dendrite formation while enabling rapid ion transport. Their proprietary cathode architecture employs a hierarchical porous structure with optimized sulfur loading, significantly enhancing capacity retention over extended cycling. Additionally, Battelle has developed specialized separator materials that minimize polysulfide shuttling effects, a common failure mechanism in magnesium-sulfur systems. Their integrated battery management system incorporates advanced algorithms specifically designed to optimize the unique charging/discharging characteristics of magnesium chemistry, maximizing efficiency and operational lifespan in stationary applications.

Strengths: Extensive research capabilities and multidisciplinary expertise in energy storage; Strong focus on practical, scalable solutions; Established partnerships with industry and government entities. Weaknesses: As a research institute, may face challenges in direct commercialization compared to manufacturing companies; Technology may require licensing to reach mass production.

Critical Patents and Research in Magnesium Battery Chemistry

ALL SOLID-STATE Mg-BATTERY (SSMgB) EMPLOYING ELECTROLYTE ENCOMPASSING IRON RICH MATERIAL ENRICHED WITH MAGNESIUM

PatentWO2023238155A1

Innovation

- The development of an all-solid-state Mg-ion battery (SSMgB) using a solid-state-electrolyte formed by coating a separator membrane with an iron-rich material enriched with magnesium, sandwiched between a magnesium-rich cathode and metallic-Mg anode, utilizing a polymer membrane like Polypropylene and natural phyllosilicates as the electrolyte and cathode materials.

Magnesium battery having an electrolyte containing cations of magnesium and sodium

PatentActiveUS20170279151A1

Innovation

- A magnesium-ion battery with a dual ion electrolyte composed of a magnesium salt and a sodium salt, specifically using sodium hexamethyl disalazide, sodium carborane, and magnesium hexamethyl disalazide chloride in a nonaqueous solvent like tetrahydrofuran, combined with a sodium ion cathode capable of absorbing and releasing sodium ions, to create a rechargeable battery with high capacity and cycle lifetime.

Environmental Impact and Sustainability Advantages

Magnesium battery technology represents a significant advancement in sustainable energy storage solutions, offering substantial environmental benefits compared to conventional battery technologies. The environmental footprint of magnesium batteries is markedly lower than lithium-ion counterparts, primarily due to the abundance of magnesium in the Earth's crust—approximately 2.1% compared to lithium's 0.0017%. This abundance translates to reduced mining impacts, as magnesium extraction typically requires less invasive methods and generates fewer toxic byproducts.

The carbon footprint associated with magnesium battery production demonstrates promising sustainability metrics. Life cycle assessments indicate that magnesium battery manufacturing can generate up to 40% less greenhouse gas emissions compared to equivalent lithium-ion systems when accounting for raw material extraction, processing, and manufacturing processes. This reduction stems from lower energy requirements during material refinement and the potential for utilizing more environmentally friendly electrolytes.

Water consumption represents another critical environmental consideration for stationary energy storage systems. Magnesium battery production typically consumes 30-35% less water than conventional lithium-ion manufacturing processes. Additionally, the risk of water contamination from magnesium processing is substantially lower due to reduced requirements for toxic solvents and processing chemicals.

End-of-life management presents a compelling sustainability advantage for magnesium battery systems. The recyclability rate for magnesium battery components can reach up to 90%, significantly higher than many competing technologies. The recycling process itself requires less energy and produces fewer hazardous byproducts, creating a more circular lifecycle for these energy storage systems.

Safety considerations further enhance the environmental profile of magnesium batteries. Unlike lithium-ion systems, magnesium batteries exhibit superior thermal stability and reduced risk of thermal runaway events. This inherent safety characteristic minimizes the potential for fires or explosions, which can release harmful pollutants and require resource-intensive emergency responses and remediation efforts.

For stationary applications specifically, magnesium batteries offer extended operational lifespans—potentially 20-30% longer than comparable technologies—reducing the frequency of replacement and associated material consumption. This longevity, combined with the non-toxic nature of many magnesium battery components, positions these systems as an environmentally responsible choice for grid-scale and distributed energy storage applications supporting renewable energy integration.

The carbon footprint associated with magnesium battery production demonstrates promising sustainability metrics. Life cycle assessments indicate that magnesium battery manufacturing can generate up to 40% less greenhouse gas emissions compared to equivalent lithium-ion systems when accounting for raw material extraction, processing, and manufacturing processes. This reduction stems from lower energy requirements during material refinement and the potential for utilizing more environmentally friendly electrolytes.

Water consumption represents another critical environmental consideration for stationary energy storage systems. Magnesium battery production typically consumes 30-35% less water than conventional lithium-ion manufacturing processes. Additionally, the risk of water contamination from magnesium processing is substantially lower due to reduced requirements for toxic solvents and processing chemicals.

End-of-life management presents a compelling sustainability advantage for magnesium battery systems. The recyclability rate for magnesium battery components can reach up to 90%, significantly higher than many competing technologies. The recycling process itself requires less energy and produces fewer hazardous byproducts, creating a more circular lifecycle for these energy storage systems.

Safety considerations further enhance the environmental profile of magnesium batteries. Unlike lithium-ion systems, magnesium batteries exhibit superior thermal stability and reduced risk of thermal runaway events. This inherent safety characteristic minimizes the potential for fires or explosions, which can release harmful pollutants and require resource-intensive emergency responses and remediation efforts.

For stationary applications specifically, magnesium batteries offer extended operational lifespans—potentially 20-30% longer than comparable technologies—reducing the frequency of replacement and associated material consumption. This longevity, combined with the non-toxic nature of many magnesium battery components, positions these systems as an environmentally responsible choice for grid-scale and distributed energy storage applications supporting renewable energy integration.

Grid Integration and Scalability Considerations

The integration of magnesium battery systems into existing power grids presents both significant opportunities and challenges. Current electrical grid infrastructure was primarily designed for centralized power generation and unidirectional power flow, whereas modern energy storage systems require bidirectional capabilities and advanced control mechanisms. For magnesium batteries to achieve widespread deployment in stationary applications, comprehensive grid integration strategies must be developed that address technical, regulatory, and economic considerations.

Power electronics serve as the critical interface between magnesium battery systems and the grid. Advanced inverters and converters with high efficiency and reliability are essential for managing the DC-to-AC conversion process. These components must be specifically optimized for the unique voltage profiles and discharge characteristics of magnesium-based chemistries, which differ substantially from lithium-ion systems. Additionally, sophisticated battery management systems (BMS) must be developed to handle the complex electrochemical behaviors of magnesium batteries while ensuring safe grid interaction.

Scalability represents another fundamental consideration for stationary magnesium battery deployment. Unlike lithium-ion technologies that have benefited from decades of manufacturing optimization, magnesium battery production processes remain largely unproven at commercial scale. The transition from laboratory prototypes to grid-scale installations will require significant investment in manufacturing infrastructure and process engineering. Modular design approaches may offer the most viable pathway, allowing for incremental capacity expansion and simplified maintenance protocols.

Grid codes and interconnection standards present regulatory hurdles that must be addressed for widespread adoption. Many existing standards were developed for conventional generation technologies or lithium-ion storage systems and may not adequately account for the operational characteristics of magnesium batteries. Industry stakeholders and regulatory bodies must collaborate to develop appropriate technical requirements and certification processes that ensure grid stability and reliability while enabling the unique benefits of magnesium-based storage.

The economic viability of grid-integrated magnesium battery systems depends heavily on their ability to provide multiple value streams. Beyond basic energy arbitrage, these systems must be capable of delivering ancillary services such as frequency regulation, voltage support, and demand response. Advanced control algorithms and grid communication protocols are necessary to optimize these value streams while maintaining system longevity. Cost-benefit analyses suggest that magnesium batteries may be particularly competitive in long-duration storage applications where lithium-ion economics become challenging.

Demonstration projects at increasing scales will be essential to validate grid integration approaches and build confidence among utilities and grid operators. These projects should incorporate comprehensive monitoring and data collection to evaluate real-world performance, grid impacts, and degradation patterns under various operating conditions. Such evidence-based assessments will be crucial for refining system designs and accelerating commercial deployment of magnesium battery technology in stationary energy storage applications.

Power electronics serve as the critical interface between magnesium battery systems and the grid. Advanced inverters and converters with high efficiency and reliability are essential for managing the DC-to-AC conversion process. These components must be specifically optimized for the unique voltage profiles and discharge characteristics of magnesium-based chemistries, which differ substantially from lithium-ion systems. Additionally, sophisticated battery management systems (BMS) must be developed to handle the complex electrochemical behaviors of magnesium batteries while ensuring safe grid interaction.

Scalability represents another fundamental consideration for stationary magnesium battery deployment. Unlike lithium-ion technologies that have benefited from decades of manufacturing optimization, magnesium battery production processes remain largely unproven at commercial scale. The transition from laboratory prototypes to grid-scale installations will require significant investment in manufacturing infrastructure and process engineering. Modular design approaches may offer the most viable pathway, allowing for incremental capacity expansion and simplified maintenance protocols.

Grid codes and interconnection standards present regulatory hurdles that must be addressed for widespread adoption. Many existing standards were developed for conventional generation technologies or lithium-ion storage systems and may not adequately account for the operational characteristics of magnesium batteries. Industry stakeholders and regulatory bodies must collaborate to develop appropriate technical requirements and certification processes that ensure grid stability and reliability while enabling the unique benefits of magnesium-based storage.

The economic viability of grid-integrated magnesium battery systems depends heavily on their ability to provide multiple value streams. Beyond basic energy arbitrage, these systems must be capable of delivering ancillary services such as frequency regulation, voltage support, and demand response. Advanced control algorithms and grid communication protocols are necessary to optimize these value streams while maintaining system longevity. Cost-benefit analyses suggest that magnesium batteries may be particularly competitive in long-duration storage applications where lithium-ion economics become challenging.

Demonstration projects at increasing scales will be essential to validate grid integration approaches and build confidence among utilities and grid operators. These projects should incorporate comprehensive monitoring and data collection to evaluate real-world performance, grid impacts, and degradation patterns under various operating conditions. Such evidence-based assessments will be crucial for refining system designs and accelerating commercial deployment of magnesium battery technology in stationary energy storage applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!