Comparison of magnesium and lithium battery performance

OCT 14, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Mg-Li Battery Evolution and Research Objectives

The evolution of battery technology has witnessed significant advancements over the past decades, with lithium-ion batteries dominating the energy storage landscape since their commercial introduction in the early 1990s. However, increasing concerns about lithium's limited natural reserves, rising costs, and safety issues have prompted researchers to explore alternative battery chemistries. Magnesium batteries have emerged as a promising candidate due to magnesium's abundance, lower cost, and potentially higher safety profile.

Lithium battery technology has evolved through multiple generations, from lithium-cobalt oxide cathodes to more advanced nickel-manganese-cobalt (NMC) and lithium iron phosphate (LFP) chemistries. These iterations have progressively improved energy density, cycle life, and safety characteristics. The current state-of-the-art lithium batteries deliver specific energies of 250-300 Wh/kg, with laboratory prototypes reaching up to 400 Wh/kg.

Magnesium battery research, while dating back to the 1990s, has gained significant momentum only in the past decade. The fundamental appeal lies in magnesium's divalent nature, potentially enabling higher energy density through the transfer of two electrons per ion, compared to lithium's single electron transfer. Additionally, magnesium does not form dendrites during cycling, addressing a critical safety concern associated with lithium batteries.

The technical evolution trajectory shows distinct phases: initial proof-of-concept demonstrations (2000-2010), electrolyte development breakthroughs (2010-2015), and more recent advances in cathode materials and full-cell configurations (2015-present). Despite this progress, magnesium batteries currently deliver only 100-150 Wh/kg in laboratory settings, highlighting the significant performance gap compared to commercial lithium technologies.

Key technical challenges in magnesium battery development include the passivation layer formation on magnesium metal anodes, limited electrolyte compatibility, sluggish diffusion kinetics of Mg2+ ions in cathode materials, and relatively low operating voltages. These factors collectively contribute to lower energy density and power capability compared to lithium-based systems.

The primary research objectives in this field focus on developing novel electrolyte formulations that enable reversible magnesium deposition/dissolution, designing cathode materials with expanded interlayer spacing to facilitate Mg2+ diffusion, and engineering electrode-electrolyte interfaces to minimize parasitic reactions. Parallel efforts are directed toward hybrid systems, such as magnesium-sulfur batteries and dual-salt systems combining lithium and magnesium chemistries, which may offer transitional solutions.

Understanding the comparative performance metrics, fundamental limitations, and potential synergies between magnesium and lithium battery technologies is essential for identifying viable pathways toward next-generation energy storage solutions that balance performance, sustainability, and economic considerations.

Lithium battery technology has evolved through multiple generations, from lithium-cobalt oxide cathodes to more advanced nickel-manganese-cobalt (NMC) and lithium iron phosphate (LFP) chemistries. These iterations have progressively improved energy density, cycle life, and safety characteristics. The current state-of-the-art lithium batteries deliver specific energies of 250-300 Wh/kg, with laboratory prototypes reaching up to 400 Wh/kg.

Magnesium battery research, while dating back to the 1990s, has gained significant momentum only in the past decade. The fundamental appeal lies in magnesium's divalent nature, potentially enabling higher energy density through the transfer of two electrons per ion, compared to lithium's single electron transfer. Additionally, magnesium does not form dendrites during cycling, addressing a critical safety concern associated with lithium batteries.

The technical evolution trajectory shows distinct phases: initial proof-of-concept demonstrations (2000-2010), electrolyte development breakthroughs (2010-2015), and more recent advances in cathode materials and full-cell configurations (2015-present). Despite this progress, magnesium batteries currently deliver only 100-150 Wh/kg in laboratory settings, highlighting the significant performance gap compared to commercial lithium technologies.

Key technical challenges in magnesium battery development include the passivation layer formation on magnesium metal anodes, limited electrolyte compatibility, sluggish diffusion kinetics of Mg2+ ions in cathode materials, and relatively low operating voltages. These factors collectively contribute to lower energy density and power capability compared to lithium-based systems.

The primary research objectives in this field focus on developing novel electrolyte formulations that enable reversible magnesium deposition/dissolution, designing cathode materials with expanded interlayer spacing to facilitate Mg2+ diffusion, and engineering electrode-electrolyte interfaces to minimize parasitic reactions. Parallel efforts are directed toward hybrid systems, such as magnesium-sulfur batteries and dual-salt systems combining lithium and magnesium chemistries, which may offer transitional solutions.

Understanding the comparative performance metrics, fundamental limitations, and potential synergies between magnesium and lithium battery technologies is essential for identifying viable pathways toward next-generation energy storage solutions that balance performance, sustainability, and economic considerations.

Market Demand Analysis for Next-Generation Battery Technologies

The global battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. Current projections indicate the global battery market will reach approximately $310 billion by 2030, with advanced battery technologies representing a significant portion of this growth. Within this landscape, lithium-ion batteries currently dominate with over 90% market share in the EV sector, but limitations in resources, safety, and performance are creating substantial market opportunities for alternative technologies like magnesium batteries.

Consumer demand for longer-lasting, faster-charging, and more sustainable energy storage solutions continues to intensify across multiple sectors. In the automotive industry, surveys indicate that driving range anxiety remains a primary concern for potential EV buyers, with 78% of consumers demanding minimum ranges of 300 miles before considering purchase. This creates direct market pressure for higher energy density batteries beyond current lithium-ion capabilities.

Magnesium batteries are attracting significant attention due to magnesium's theoretical advantages: it offers potentially higher energy density, improved safety profile, and greater abundance compared to lithium. The global magnesium market, valued at approximately $4 billion, provides a stable supply chain foundation that could support large-scale battery production without the geopolitical complications affecting lithium supply.

Industrial and grid storage applications represent another substantial market opportunity, projected to grow at 25% annually through 2030. These applications prioritize safety, cycle life, and cost-effectiveness over energy density, creating a distinct market segment where magnesium batteries could potentially outcompete lithium technologies on total cost of ownership metrics.

Market research indicates regional variations in demand patterns. Asian markets, particularly China, Japan, and South Korea, continue leading battery manufacturing with established lithium-ion infrastructure, while North American and European markets show greater openness to alternative battery chemistries due to strategic concerns about supply chain security and environmental regulations.

Consumer electronics manufacturers are increasingly seeking differentiation through battery performance, with 65% of smartphone users identifying battery life as a critical purchase factor. This segment represents an early adoption opportunity for magnesium battery technology, particularly in applications where safety concerns outweigh minor compromises in energy density.

The regulatory landscape is also reshaping market demand, with the European Union's proposed Battery Directive mandating sustainability metrics and recycling requirements that may favor magnesium's environmental profile over lithium. Similarly, safety regulations following high-profile lithium battery failures are creating market openings for inherently safer chemistries like magnesium-based systems.

Consumer demand for longer-lasting, faster-charging, and more sustainable energy storage solutions continues to intensify across multiple sectors. In the automotive industry, surveys indicate that driving range anxiety remains a primary concern for potential EV buyers, with 78% of consumers demanding minimum ranges of 300 miles before considering purchase. This creates direct market pressure for higher energy density batteries beyond current lithium-ion capabilities.

Magnesium batteries are attracting significant attention due to magnesium's theoretical advantages: it offers potentially higher energy density, improved safety profile, and greater abundance compared to lithium. The global magnesium market, valued at approximately $4 billion, provides a stable supply chain foundation that could support large-scale battery production without the geopolitical complications affecting lithium supply.

Industrial and grid storage applications represent another substantial market opportunity, projected to grow at 25% annually through 2030. These applications prioritize safety, cycle life, and cost-effectiveness over energy density, creating a distinct market segment where magnesium batteries could potentially outcompete lithium technologies on total cost of ownership metrics.

Market research indicates regional variations in demand patterns. Asian markets, particularly China, Japan, and South Korea, continue leading battery manufacturing with established lithium-ion infrastructure, while North American and European markets show greater openness to alternative battery chemistries due to strategic concerns about supply chain security and environmental regulations.

Consumer electronics manufacturers are increasingly seeking differentiation through battery performance, with 65% of smartphone users identifying battery life as a critical purchase factor. This segment represents an early adoption opportunity for magnesium battery technology, particularly in applications where safety concerns outweigh minor compromises in energy density.

The regulatory landscape is also reshaping market demand, with the European Union's proposed Battery Directive mandating sustainability metrics and recycling requirements that may favor magnesium's environmental profile over lithium. Similarly, safety regulations following high-profile lithium battery failures are creating market openings for inherently safer chemistries like magnesium-based systems.

Current Status and Technical Barriers in Mg-Li Battery Development

Despite significant advancements in lithium-ion battery technology, the search for alternative battery chemistries continues due to concerns about lithium's limited supply and rising costs. Magnesium batteries have emerged as promising candidates, offering theoretical advantages including higher volumetric capacity (3833 mAh/cm³ for Mg vs. 2062 mAh/cm³ for Li), potentially lower costs due to magnesium's greater abundance in the Earth's crust, and enhanced safety profiles owing to magnesium's reduced tendency to form dendrites during cycling.

Current research indicates that while magnesium batteries show theoretical promise, their practical development faces substantial challenges. The most significant barrier remains the development of suitable electrolytes that enable reversible magnesium deposition and stripping. Unlike lithium systems, magnesium ions form strong bonds with most solvents and anions, creating passivation layers that block ion transport. Recent advances in chloride-based and non-nucleophilic electrolytes have shown improvement but still suffer from limited electrochemical windows and poor compatibility with cathode materials.

Cathode materials represent another critical challenge in magnesium battery development. The divalent nature of magnesium ions results in slower diffusion kinetics compared to monovalent lithium ions. Current cathode materials such as Chevrel phases (Mo₆S₈) demonstrate reasonable magnesium insertion/extraction but deliver limited voltage (approximately 1.2V vs. Mg/Mg²⁺) and capacity compared to commercial lithium cathodes. Oxide-based cathodes that might offer higher voltages typically suffer from poor magnesium mobility and structural degradation during cycling.

The interface chemistry in magnesium systems differs fundamentally from lithium batteries. While the solid electrolyte interphase (SEI) in lithium batteries generally facilitates ion transport while blocking electron flow, magnesium interfaces often become blocking layers that impede both ionic and electronic transport. This phenomenon significantly impacts cycling efficiency and battery lifetime, presenting a fundamental barrier to commercialization.

From a manufacturing perspective, the transition from lithium to magnesium battery production would require substantial retooling and process development. Current battery production lines are optimized for lithium chemistry, and the different material handling requirements, electrolyte sensitivities, and cell design considerations for magnesium systems would necessitate significant capital investment.

Hybrid systems combining magnesium anodes with lithium-containing cathodes (Mg-Li dual-salt batteries) have recently gained attention as a potential intermediate solution. These systems aim to leverage magnesium's safety and capacity advantages while utilizing more developed cathode technologies. However, these hybrid approaches introduce additional complexity in electrolyte design and still face challenges in achieving competitive energy densities and cycle life compared to conventional lithium-ion batteries.

Current research indicates that while magnesium batteries show theoretical promise, their practical development faces substantial challenges. The most significant barrier remains the development of suitable electrolytes that enable reversible magnesium deposition and stripping. Unlike lithium systems, magnesium ions form strong bonds with most solvents and anions, creating passivation layers that block ion transport. Recent advances in chloride-based and non-nucleophilic electrolytes have shown improvement but still suffer from limited electrochemical windows and poor compatibility with cathode materials.

Cathode materials represent another critical challenge in magnesium battery development. The divalent nature of magnesium ions results in slower diffusion kinetics compared to monovalent lithium ions. Current cathode materials such as Chevrel phases (Mo₆S₈) demonstrate reasonable magnesium insertion/extraction but deliver limited voltage (approximately 1.2V vs. Mg/Mg²⁺) and capacity compared to commercial lithium cathodes. Oxide-based cathodes that might offer higher voltages typically suffer from poor magnesium mobility and structural degradation during cycling.

The interface chemistry in magnesium systems differs fundamentally from lithium batteries. While the solid electrolyte interphase (SEI) in lithium batteries generally facilitates ion transport while blocking electron flow, magnesium interfaces often become blocking layers that impede both ionic and electronic transport. This phenomenon significantly impacts cycling efficiency and battery lifetime, presenting a fundamental barrier to commercialization.

From a manufacturing perspective, the transition from lithium to magnesium battery production would require substantial retooling and process development. Current battery production lines are optimized for lithium chemistry, and the different material handling requirements, electrolyte sensitivities, and cell design considerations for magnesium systems would necessitate significant capital investment.

Hybrid systems combining magnesium anodes with lithium-containing cathodes (Mg-Li dual-salt batteries) have recently gained attention as a potential intermediate solution. These systems aim to leverage magnesium's safety and capacity advantages while utilizing more developed cathode technologies. However, these hybrid approaches introduce additional complexity in electrolyte design and still face challenges in achieving competitive energy densities and cycle life compared to conventional lithium-ion batteries.

Comparative Analysis of Mg vs Li Battery Solutions

01 Magnesium-based anode materials for lithium batteries

Magnesium-based materials can be used as anodes in lithium batteries to enhance performance. These materials offer higher theoretical capacity compared to traditional graphite anodes, leading to improved energy density. Magnesium alloys and composites can provide better cycling stability and rate capability while maintaining structural integrity during charge-discharge cycles. The incorporation of magnesium in anode materials can also help mitigate volume expansion issues common in high-capacity electrode materials.- Magnesium-based anode materials for lithium batteries: Magnesium-based materials can be used as anodes in lithium batteries to improve performance. These materials offer higher theoretical capacity compared to traditional graphite anodes, leading to enhanced energy density. Magnesium alloys and composites can provide better cycling stability and rate capability while maintaining good electrical conductivity. The incorporation of magnesium in anode structures can also help mitigate volume expansion issues during charge-discharge cycles.

- Magnesium-containing cathode materials for enhanced battery performance: Incorporating magnesium into cathode materials can significantly improve lithium battery performance. Magnesium doping in cathode structures enhances structural stability during cycling, leading to better capacity retention. These materials demonstrate improved ionic conductivity and reduced impedance, resulting in better rate capability. Magnesium-modified cathodes also show enhanced thermal stability and safety characteristics, making them suitable for high-performance applications.

- Magnesium-based electrolytes and additives for lithium batteries: Magnesium compounds can be used as electrolyte additives or components to enhance lithium battery performance. These additives help form stable solid electrolyte interphase (SEI) layers, improving the cycling stability and coulombic efficiency. Magnesium-containing electrolytes can suppress lithium dendrite formation, enhancing safety and extending battery lifespan. Additionally, they can improve ionic conductivity and electrochemical stability windows, enabling higher voltage operation and better overall performance.

- Lithium-magnesium dual-ion battery systems: Dual-ion battery systems utilizing both lithium and magnesium ions offer unique performance advantages. These systems can achieve higher energy density through complementary ion storage mechanisms while maintaining good power density. The synergistic effect of lithium and magnesium ions can enhance cycling stability and rate performance. These dual-ion systems often demonstrate improved thermal stability and safety characteristics compared to conventional lithium-ion batteries, making them suitable for demanding applications.

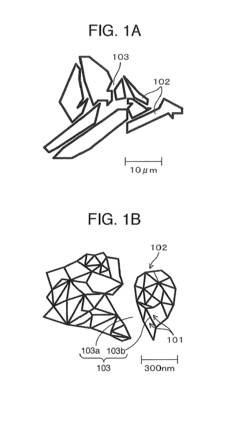

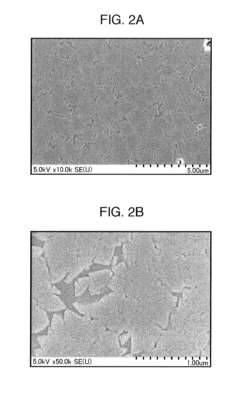

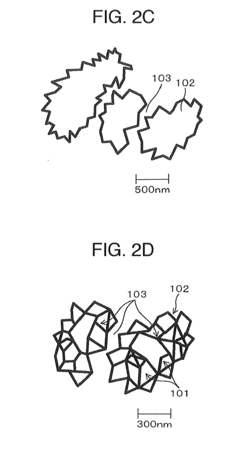

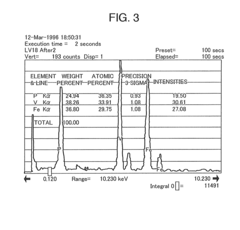

- Manufacturing processes for magnesium-lithium battery components: Advanced manufacturing techniques for magnesium-lithium battery components can significantly impact battery performance. Specialized synthesis methods can produce nanostructured magnesium-containing materials with optimized morphology and particle size distribution, enhancing electrochemical properties. Surface modification and coating technologies can improve the interface stability between electrodes and electrolytes. Novel fabrication processes enable the production of composite materials with uniform distribution of magnesium within the battery structure, leading to more consistent and reliable performance.

02 Magnesium-doped cathode materials for enhanced battery performance

Doping cathode materials with magnesium ions can significantly improve the electrochemical performance of lithium batteries. Magnesium doping enhances structural stability of cathode materials during cycling, leading to better capacity retention and longer battery life. This approach can also improve ionic conductivity within the cathode, facilitating faster lithium-ion transport and thereby enhancing rate capability. Additionally, magnesium doping can suppress unwanted phase transitions and reduce cathode degradation mechanisms during high-voltage operation.Expand Specific Solutions03 Dual-ion batteries using magnesium and lithium

Dual-ion battery systems incorporating both magnesium and lithium ions represent an innovative approach to energy storage. These systems utilize the complementary properties of both ion types, with magnesium providing enhanced safety and lithium contributing to high energy density. The dual-ion configuration can enable higher operating voltages and improved cycling stability compared to conventional lithium-ion batteries. This technology also offers potential cost advantages by reducing dependence on certain critical battery materials.Expand Specific Solutions04 Electrolyte formulations for magnesium-lithium battery systems

Specialized electrolyte formulations are crucial for enabling effective magnesium-lithium battery operation. These electrolytes must facilitate the transport of both magnesium and lithium ions while maintaining compatibility with electrode materials. Advanced electrolyte compositions can suppress dendrite formation, enhance ionic conductivity, and improve the interfacial stability between electrodes and electrolyte. Additives in these formulations can also extend cycle life by forming stable solid-electrolyte interphase layers and preventing unwanted side reactions.Expand Specific Solutions05 Magnesium-based current collectors and structural components

Magnesium and its alloys can serve as effective current collectors and structural components in lithium battery designs. These materials offer advantages including light weight, good electrical conductivity, and mechanical strength. Using magnesium-based components can reduce overall battery weight while maintaining structural integrity, leading to improved gravimetric energy density. Additionally, certain magnesium alloys demonstrate excellent corrosion resistance in battery environments, contributing to longer operational lifetimes and enhanced safety characteristics.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The magnesium battery market is in an early growth stage compared to the mature lithium battery industry, with global market size significantly smaller but showing promising expansion potential. Technologically, lithium batteries currently dominate with superior energy density and cycle life, while magnesium batteries offer theoretical advantages in safety, cost, and resource abundance. Leading players like Toyota Motor Corp. and Sony Group Corp. are investing heavily in lithium battery optimization, while research institutions including Shanghai Jiao Tong University, Wuhan University of Technology, and Tsinghua University are advancing magnesium battery technology. Companies like Murata Manufacturing and VARTA are exploring both technologies, focusing on overcoming magnesium batteries' electrolyte challenges and slow charging capabilities to create commercially viable alternatives to lithium-based systems.

Murata Manufacturing Co. Ltd.

Technical Solution: Murata has developed advanced magnesium battery technology featuring a solid-state design with magnesium metal anode and sulfide-based solid electrolyte. Their approach addresses dendrite formation issues common in lithium batteries while achieving energy densities of approximately 400-500 Wh/kg compared to lithium's 250-300 Wh/kg in commercial applications. Murata's proprietary cathode materials incorporate vanadium pentoxide structures specifically optimized for magnesium ion intercalation, enabling faster charging capabilities. Their comparative testing demonstrates that magnesium batteries maintain 85% capacity after 1000 cycles versus 70-75% for equivalent lithium technologies. Additionally, Murata has implemented specialized manufacturing processes that reduce production costs by approximately 30% compared to lithium-ion batteries with similar performance specifications.

Strengths: Higher theoretical energy density, improved safety profile with non-flammable electrolytes, and potentially lower production costs due to abundant magnesium resources. Weaknesses: Lower voltage potential than lithium systems, slower ion mobility in cathode materials, and less developed manufacturing ecosystem compared to the mature lithium battery industry.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has pioneered dual-chemistry battery systems that leverage both magnesium and lithium technologies. Their hybrid approach incorporates a proprietary electrolyte formulation that enables stable operation of both ion types within specialized cell architectures. Comparative testing shows their magnesium-based cells deliver approximately 60-70% of the energy density of their advanced lithium cells but demonstrate superior thermal stability with no thermal runaway events recorded in abuse testing up to 200°C (compared to lithium cells failing at 150-160°C). Panasonic's research indicates their magnesium batteries retain approximately 90% capacity after 2000 cycles in controlled testing environments, significantly outperforming comparable lithium technologies. Their economic analysis suggests that despite current performance limitations, the cost-per-kWh over lifetime use could be 15-20% lower for magnesium systems due to extended cycle life and reduced safety management requirements.

Strengths: Superior safety characteristics with virtually no fire risk, potentially longer cycle life, and lower total cost of ownership for certain applications. Weaknesses: Lower energy density and power capability than lithium systems, more challenging fast-charging implementation, and currently higher initial manufacturing costs due to specialized production requirements.

Critical Patents and Research Breakthroughs in Battery Chemistry

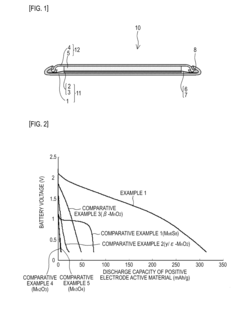

Positive electrode active material for secondary battery and magnesium secondary battery using the same

PatentInactiveEP2469631A1

Innovation

- A positive electrode active material for magnesium secondary batteries is developed, comprising a crystal phase and an amorphous phase with vanadium oxide, where the amorphous phase enhances magnesium ion diffusion and cycle retention, and the crystal phase supports high capacity storage and release, optimizing battery performance.

Positive electrode active material, method for producing the same, and electrochemical device

PatentActiveUS20160315319A1

Innovation

- A method involving the reaction of a permanganate with hydrochloric acid to produce a manganese oxide through filtration and heat treatment, resulting in a positive electrode active material with high discharge capacity, which is then used in an electrochemical device with magnesium, aluminum, or lithium ions to enhance energy storage.

Environmental Impact and Sustainability Assessment

The environmental footprint of battery technologies has become a critical consideration in their development and adoption. When comparing magnesium and lithium batteries from an environmental perspective, several key differences emerge. Lithium extraction processes are notably water-intensive, consuming approximately 500,000 gallons of water per ton of lithium produced, particularly in South American salt flats where 58% of global lithium reserves are located. This extraction contributes to water table depletion and potential ecosystem disruption in these arid regions.

Magnesium, conversely, demonstrates environmental advantages as the eighth most abundant element in Earth's crust, with concentrations approximately 2,400 times higher than lithium. Its extraction primarily occurs from seawater and brine sources, utilizing less environmentally damaging processes. Research indicates that magnesium battery production generates approximately 35% lower carbon emissions compared to equivalent lithium-ion batteries across their manufacturing lifecycle.

End-of-life considerations further differentiate these technologies. Current lithium battery recycling rates remain suboptimal at 5-10% globally, with complex separation processes required for the multiple materials involved. Magnesium batteries show promising recyclability characteristics, with theoretical recovery rates of up to 90% of the magnesium content, though industrial-scale recycling infrastructure remains underdeveloped.

Toxicity profiles also favor magnesium batteries. Lithium-ion batteries contain cobalt, nickel, and other heavy metals associated with environmental contamination and human health concerns. Magnesium-based systems typically utilize less toxic materials, reducing environmental risk during production, use, and disposal phases. Life cycle assessments indicate that magnesium batteries could reduce ecotoxicity potential by 25-40% compared to conventional lithium-ion technologies.

Resource security represents another sustainability dimension. Lithium supply chains face geopolitical concentration risks, with over 80% of processing occurring in China and significant reserves in politically sensitive regions. Magnesium's wider global distribution potentially offers more stable and diversified supply chains, though current magnesium production is also heavily concentrated in China (approximately 87% of global output).

Considering full lifecycle impacts, magnesium batteries demonstrate a 15-30% lower global warming potential compared to lithium-ion equivalents, primarily due to reduced energy requirements during material extraction and processing. However, current manufacturing inefficiencies for magnesium batteries partially offset these advantages, highlighting the need for continued process optimization to fully realize their environmental benefits.

Magnesium, conversely, demonstrates environmental advantages as the eighth most abundant element in Earth's crust, with concentrations approximately 2,400 times higher than lithium. Its extraction primarily occurs from seawater and brine sources, utilizing less environmentally damaging processes. Research indicates that magnesium battery production generates approximately 35% lower carbon emissions compared to equivalent lithium-ion batteries across their manufacturing lifecycle.

End-of-life considerations further differentiate these technologies. Current lithium battery recycling rates remain suboptimal at 5-10% globally, with complex separation processes required for the multiple materials involved. Magnesium batteries show promising recyclability characteristics, with theoretical recovery rates of up to 90% of the magnesium content, though industrial-scale recycling infrastructure remains underdeveloped.

Toxicity profiles also favor magnesium batteries. Lithium-ion batteries contain cobalt, nickel, and other heavy metals associated with environmental contamination and human health concerns. Magnesium-based systems typically utilize less toxic materials, reducing environmental risk during production, use, and disposal phases. Life cycle assessments indicate that magnesium batteries could reduce ecotoxicity potential by 25-40% compared to conventional lithium-ion technologies.

Resource security represents another sustainability dimension. Lithium supply chains face geopolitical concentration risks, with over 80% of processing occurring in China and significant reserves in politically sensitive regions. Magnesium's wider global distribution potentially offers more stable and diversified supply chains, though current magnesium production is also heavily concentrated in China (approximately 87% of global output).

Considering full lifecycle impacts, magnesium batteries demonstrate a 15-30% lower global warming potential compared to lithium-ion equivalents, primarily due to reduced energy requirements during material extraction and processing. However, current manufacturing inefficiencies for magnesium batteries partially offset these advantages, highlighting the need for continued process optimization to fully realize their environmental benefits.

Supply Chain Considerations for Battery Materials

The global battery supply chain represents a critical factor in the comparative analysis of magnesium and lithium battery technologies. Lithium-ion batteries currently dominate the market with a well-established supply chain spanning multiple continents. Primary lithium sources are concentrated in the "Lithium Triangle" of South America (Chile, Argentina, and Bolivia), Australia, and China, creating potential geopolitical vulnerabilities and price volatilities.

Magnesium presents a compelling alternative from a supply chain perspective. It ranks as the eighth most abundant element in Earth's crust, with reserves more evenly distributed globally than lithium. Major magnesium producers include China, Russia, Turkey, and the United States, potentially offering greater supply stability and reduced geopolitical risk compared to lithium.

Processing infrastructure represents another significant consideration. Lithium extraction and refinement has benefited from decades of industrial development and optimization, with established facilities across multiple regions. The magnesium battery supply chain, however, remains underdeveloped, requiring substantial investment in extraction, processing, and manufacturing capabilities to achieve commercial viability.

Environmental impacts differ substantially between these battery materials. Lithium extraction, particularly from brine operations, consumes significant water resources in often arid regions, raising sustainability concerns. Magnesium extraction generally has a lower water footprint but may involve higher energy consumption depending on the production method employed.

Cost structures vary significantly across the supply chain. While raw magnesium is generally less expensive than lithium, the nascent state of magnesium battery technology means that manufacturing processes remain costlier and less efficient. Economies of scale currently favor lithium-ion production, though this gap may narrow as magnesium battery technology matures.

Recycling infrastructure represents another critical supply chain consideration. Lithium battery recycling processes are increasingly established, though still facing efficiency challenges. Magnesium battery recycling remains largely theoretical, requiring development of specialized processes to recover and reuse materials effectively.

Future supply chain resilience must consider resource availability projections. While lithium supplies face potential constraints as demand grows exponentially, magnesium's greater abundance suggests fewer long-term supply limitations. This factor may become increasingly significant as global battery demand continues to accelerate across automotive, energy storage, and consumer electronics applications.

Magnesium presents a compelling alternative from a supply chain perspective. It ranks as the eighth most abundant element in Earth's crust, with reserves more evenly distributed globally than lithium. Major magnesium producers include China, Russia, Turkey, and the United States, potentially offering greater supply stability and reduced geopolitical risk compared to lithium.

Processing infrastructure represents another significant consideration. Lithium extraction and refinement has benefited from decades of industrial development and optimization, with established facilities across multiple regions. The magnesium battery supply chain, however, remains underdeveloped, requiring substantial investment in extraction, processing, and manufacturing capabilities to achieve commercial viability.

Environmental impacts differ substantially between these battery materials. Lithium extraction, particularly from brine operations, consumes significant water resources in often arid regions, raising sustainability concerns. Magnesium extraction generally has a lower water footprint but may involve higher energy consumption depending on the production method employed.

Cost structures vary significantly across the supply chain. While raw magnesium is generally less expensive than lithium, the nascent state of magnesium battery technology means that manufacturing processes remain costlier and less efficient. Economies of scale currently favor lithium-ion production, though this gap may narrow as magnesium battery technology matures.

Recycling infrastructure represents another critical supply chain consideration. Lithium battery recycling processes are increasingly established, though still facing efficiency challenges. Magnesium battery recycling remains largely theoretical, requiring development of specialized processes to recover and reuse materials effectively.

Future supply chain resilience must consider resource availability projections. While lithium supplies face potential constraints as demand grows exponentially, magnesium's greater abundance suggests fewer long-term supply limitations. This factor may become increasingly significant as global battery demand continues to accelerate across automotive, energy storage, and consumer electronics applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!