Chiplet Trends in High-Fidelity Audio Processing Equipment

JUL 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chiplet Audio Evolution

The evolution of chiplet technology in high-fidelity audio processing equipment represents a significant shift in the design and manufacturing of audio systems. This trend has emerged as a response to the increasing demand for more powerful and efficient audio processing capabilities in a wide range of devices, from professional studio equipment to consumer-grade audio products.

Historically, audio processing chips were monolithic designs, integrating all functions onto a single die. However, as the complexity of audio processing requirements grew, this approach began to face limitations in terms of scalability, power efficiency, and cost-effectiveness. The introduction of chiplet technology in the audio domain marks a departure from this traditional paradigm.

Chiplets allow for the disaggregation of complex audio processing systems into smaller, more specialized components. These components can be manufactured using different process nodes, optimized for specific functions, and then integrated onto a single package. This modular approach enables audio equipment manufacturers to achieve higher performance, improved power efficiency, and greater flexibility in system design.

The evolution of chiplet technology in audio processing can be traced through several key stages. Initially, the focus was on separating digital and analog components to minimize interference and improve signal quality. This led to the development of multi-chip modules (MCMs) that housed separate dies for digital signal processing and analog-to-digital or digital-to-analog conversion.

As chiplet technology matured, we saw the emergence of more granular disaggregation. Audio processing functions such as signal routing, effects processing, and audio codec operations could be implemented on separate chiplets, each optimized for its specific task. This allowed for more efficient use of silicon area and enabled manufacturers to mix and match components to create customized solutions for different market segments.

Recent advancements in chiplet interconnect technologies, such as advanced packaging techniques and high-speed die-to-die interfaces, have further accelerated the adoption of chiplets in audio equipment. These innovations have reduced the performance penalties associated with inter-chip communication, making chiplet-based designs increasingly competitive with monolithic solutions.

Looking forward, the chiplet trend in high-fidelity audio processing is expected to continue evolving. We anticipate seeing greater integration of AI and machine learning capabilities into audio chiplets, enabling more sophisticated real-time audio processing and adaptive sound optimization. Additionally, the development of standardized chiplet interfaces for audio applications could foster a more diverse ecosystem of specialized audio processing components, potentially revolutionizing the way high-fidelity audio equipment is designed and manufactured.

Historically, audio processing chips were monolithic designs, integrating all functions onto a single die. However, as the complexity of audio processing requirements grew, this approach began to face limitations in terms of scalability, power efficiency, and cost-effectiveness. The introduction of chiplet technology in the audio domain marks a departure from this traditional paradigm.

Chiplets allow for the disaggregation of complex audio processing systems into smaller, more specialized components. These components can be manufactured using different process nodes, optimized for specific functions, and then integrated onto a single package. This modular approach enables audio equipment manufacturers to achieve higher performance, improved power efficiency, and greater flexibility in system design.

The evolution of chiplet technology in audio processing can be traced through several key stages. Initially, the focus was on separating digital and analog components to minimize interference and improve signal quality. This led to the development of multi-chip modules (MCMs) that housed separate dies for digital signal processing and analog-to-digital or digital-to-analog conversion.

As chiplet technology matured, we saw the emergence of more granular disaggregation. Audio processing functions such as signal routing, effects processing, and audio codec operations could be implemented on separate chiplets, each optimized for its specific task. This allowed for more efficient use of silicon area and enabled manufacturers to mix and match components to create customized solutions for different market segments.

Recent advancements in chiplet interconnect technologies, such as advanced packaging techniques and high-speed die-to-die interfaces, have further accelerated the adoption of chiplets in audio equipment. These innovations have reduced the performance penalties associated with inter-chip communication, making chiplet-based designs increasingly competitive with monolithic solutions.

Looking forward, the chiplet trend in high-fidelity audio processing is expected to continue evolving. We anticipate seeing greater integration of AI and machine learning capabilities into audio chiplets, enabling more sophisticated real-time audio processing and adaptive sound optimization. Additionally, the development of standardized chiplet interfaces for audio applications could foster a more diverse ecosystem of specialized audio processing components, potentially revolutionizing the way high-fidelity audio equipment is designed and manufactured.

Hi-Fi Market Analysis

The high-fidelity audio market has experienced significant growth and transformation in recent years, driven by technological advancements and changing consumer preferences. The global Hi-Fi market size was valued at approximately $14 billion in 2020 and is projected to reach $20 billion by 2027, growing at a CAGR of around 5% during the forecast period.

The demand for high-quality audio experiences has been fueled by the increasing popularity of streaming services, the resurgence of vinyl records, and the growing audiophile community. Consumers are increasingly seeking immersive and authentic sound reproduction, leading to a surge in demand for premium audio equipment.

The market is segmented into various product categories, including speakers, amplifiers, players, and headphones. Among these, speakers and headphones have shown the most robust growth, with wireless and smart speaker technologies gaining significant traction. The integration of voice assistants and multi-room audio capabilities has further expanded the appeal of Hi-Fi systems to a broader consumer base.

Geographically, North America and Europe remain the largest markets for Hi-Fi audio equipment, accounting for over 60% of the global market share. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by rising disposable incomes and a growing middle-class population in countries like China and India.

The competitive landscape of the Hi-Fi market is characterized by a mix of established players and innovative startups. Traditional audio equipment manufacturers like Bose, Sony, and Harman International continue to dominate the market, while newer entrants such as Sonos and Devialet have disrupted the industry with their innovative product offerings.

The adoption of advanced technologies, including artificial intelligence, machine learning, and digital signal processing, is reshaping the Hi-Fi audio landscape. These technologies are enabling more sophisticated audio processing capabilities, improved noise cancellation, and personalized listening experiences.

The trend towards miniaturization and modular design in audio processing equipment, exemplified by the adoption of chiplet technology, is expected to drive innovation in the Hi-Fi market. This approach allows for more efficient and flexible audio processing solutions, potentially leading to improved performance and cost-effectiveness in high-end audio equipment.

As consumers increasingly prioritize sustainability, there is a growing demand for eco-friendly audio products. Manufacturers are responding by incorporating recycled materials, implementing energy-efficient designs, and adopting more sustainable production practices.

The demand for high-quality audio experiences has been fueled by the increasing popularity of streaming services, the resurgence of vinyl records, and the growing audiophile community. Consumers are increasingly seeking immersive and authentic sound reproduction, leading to a surge in demand for premium audio equipment.

The market is segmented into various product categories, including speakers, amplifiers, players, and headphones. Among these, speakers and headphones have shown the most robust growth, with wireless and smart speaker technologies gaining significant traction. The integration of voice assistants and multi-room audio capabilities has further expanded the appeal of Hi-Fi systems to a broader consumer base.

Geographically, North America and Europe remain the largest markets for Hi-Fi audio equipment, accounting for over 60% of the global market share. However, the Asia-Pacific region is emerging as the fastest-growing market, driven by rising disposable incomes and a growing middle-class population in countries like China and India.

The competitive landscape of the Hi-Fi market is characterized by a mix of established players and innovative startups. Traditional audio equipment manufacturers like Bose, Sony, and Harman International continue to dominate the market, while newer entrants such as Sonos and Devialet have disrupted the industry with their innovative product offerings.

The adoption of advanced technologies, including artificial intelligence, machine learning, and digital signal processing, is reshaping the Hi-Fi audio landscape. These technologies are enabling more sophisticated audio processing capabilities, improved noise cancellation, and personalized listening experiences.

The trend towards miniaturization and modular design in audio processing equipment, exemplified by the adoption of chiplet technology, is expected to drive innovation in the Hi-Fi market. This approach allows for more efficient and flexible audio processing solutions, potentially leading to improved performance and cost-effectiveness in high-end audio equipment.

As consumers increasingly prioritize sustainability, there is a growing demand for eco-friendly audio products. Manufacturers are responding by incorporating recycled materials, implementing energy-efficient designs, and adopting more sustainable production practices.

Chiplet Challenges

The implementation of chiplet technology in high-fidelity audio processing equipment faces several significant challenges. One of the primary obstacles is the integration of heterogeneous components, which requires precise coordination between different chiplets to maintain signal integrity and minimize latency. This is particularly crucial in audio applications where even minor discrepancies can result in noticeable distortions or degradation of sound quality.

Thermal management presents another substantial hurdle. As chiplets allow for higher component density, heat dissipation becomes more complex, especially in compact audio devices. Efficient cooling solutions must be developed to prevent thermal throttling and ensure consistent performance across all chiplets, which is essential for maintaining audio fidelity during extended use.

Power distribution and management across multiple chiplets pose additional challenges. Ensuring stable and clean power delivery to each component is critical for minimizing noise and interference in audio signals. This requires sophisticated power management systems and careful PCB design to isolate sensitive analog components from digital noise sources.

Interconnect technology between chiplets is a critical area that demands continuous innovation. Current solutions may introduce latency or bandwidth limitations that could impact real-time audio processing capabilities. Developing high-speed, low-latency interconnects that can handle the massive data throughput required for high-resolution audio is essential for the success of chiplet-based audio equipment.

Testing and validation of chiplet-based audio systems present unique challenges. Traditional testing methodologies may not be sufficient to assess the performance of integrated heterogeneous components. New testing protocols and equipment need to be developed to ensure the reliability and quality of chiplet-based audio processing systems.

Cost considerations also play a significant role in the adoption of chiplet technology in audio equipment. While chiplets offer potential cost savings in manufacturing and yield improvement, the initial investment in design and tooling can be substantial. Balancing these costs against performance gains is crucial for market viability.

Standardization remains an ongoing challenge in the chiplet ecosystem. The lack of universal standards for chiplet interfaces and packaging can hinder interoperability and limit the potential for mix-and-match solutions in audio equipment design. Industry-wide collaboration is necessary to establish common standards that will facilitate broader adoption and innovation in chiplet-based audio processing.

Thermal management presents another substantial hurdle. As chiplets allow for higher component density, heat dissipation becomes more complex, especially in compact audio devices. Efficient cooling solutions must be developed to prevent thermal throttling and ensure consistent performance across all chiplets, which is essential for maintaining audio fidelity during extended use.

Power distribution and management across multiple chiplets pose additional challenges. Ensuring stable and clean power delivery to each component is critical for minimizing noise and interference in audio signals. This requires sophisticated power management systems and careful PCB design to isolate sensitive analog components from digital noise sources.

Interconnect technology between chiplets is a critical area that demands continuous innovation. Current solutions may introduce latency or bandwidth limitations that could impact real-time audio processing capabilities. Developing high-speed, low-latency interconnects that can handle the massive data throughput required for high-resolution audio is essential for the success of chiplet-based audio equipment.

Testing and validation of chiplet-based audio systems present unique challenges. Traditional testing methodologies may not be sufficient to assess the performance of integrated heterogeneous components. New testing protocols and equipment need to be developed to ensure the reliability and quality of chiplet-based audio processing systems.

Cost considerations also play a significant role in the adoption of chiplet technology in audio equipment. While chiplets offer potential cost savings in manufacturing and yield improvement, the initial investment in design and tooling can be substantial. Balancing these costs against performance gains is crucial for market viability.

Standardization remains an ongoing challenge in the chiplet ecosystem. The lack of universal standards for chiplet interfaces and packaging can hinder interoperability and limit the potential for mix-and-match solutions in audio equipment design. Industry-wide collaboration is necessary to establish common standards that will facilitate broader adoption and innovation in chiplet-based audio processing.

Current Chiplet Solutions

01 Chiplet integration and packaging technologies

Advanced packaging technologies for integrating multiple chiplets into a single package. This includes methods for interconnecting chiplets, thermal management, and optimizing signal integrity between different chiplets. These technologies enable the creation of more complex and powerful systems while potentially reducing costs and improving yield.- Chiplet integration and packaging: Chiplets are integrated circuit dies that can be combined in a single package to create more complex systems. This approach allows for modular design, improved yield, and cost-effective manufacturing of high-performance computing systems. Advanced packaging technologies are used to interconnect these chiplets, enabling high-bandwidth and low-latency communication between different functional blocks.

- Interconnect technologies for chiplets: Various interconnect technologies are employed to facilitate communication between chiplets. These may include through-silicon vias (TSVs), micro-bumps, and advanced interposers. The choice of interconnect technology impacts the overall performance, power efficiency, and thermal management of the chiplet-based system.

- Chiplet-based system-on-chip (SoC) design: Chiplet technology enables the creation of complex system-on-chip designs by combining different functional blocks as separate chiplets. This approach allows for mixing and matching of IP blocks from different process nodes, optimizing performance and cost. It also facilitates the reuse of proven designs across multiple products.

- Thermal management in chiplet designs: Effective thermal management is crucial in chiplet-based systems due to the high power density and potential hotspots. Advanced cooling solutions, such as integrated liquid cooling or novel heat spreader designs, are developed to address thermal challenges in these densely packed multi-chip modules.

- Testing and yield improvement for chiplets: Chiplet technology introduces new challenges in testing and yield management. Novel testing methodologies are developed to ensure the functionality and performance of individual chiplets as well as the integrated system. This includes advanced probe technologies, built-in self-test features, and adaptive testing strategies to improve overall yield and reliability.

02 Chiplet-based system-on-chip (SoC) designs

Approaches for designing and implementing SoCs using chiplet architecture. This involves partitioning complex systems into smaller, reusable chiplets that can be mixed and matched to create customized solutions. The focus is on modular design principles, standardized interfaces, and efficient communication between chiplets.Expand Specific Solutions03 Chiplet manufacturing and testing techniques

Specialized manufacturing processes and testing methodologies for chiplets. This includes techniques for ensuring individual chiplet quality, optimizing yield, and developing efficient testing procedures for chiplet-based systems. The goal is to improve overall system reliability and reduce production costs.Expand Specific Solutions04 Chiplet-based memory solutions

Innovative memory architectures using chiplet technology. This involves designing high-bandwidth, low-latency memory subsystems using multiple memory chiplets. The focus is on improving memory capacity, performance, and energy efficiency in complex computing systems.Expand Specific Solutions05 Chiplet interconnect and communication protocols

Development of specialized interconnect technologies and communication protocols for chiplet-based systems. This includes high-speed serial links, optical interconnects, and standardized interfaces to enable seamless integration of chiplets from different vendors. The aim is to optimize data transfer between chiplets while minimizing power consumption and latency.Expand Specific Solutions

Audio Chiplet Players

The chiplet trend in high-fidelity audio processing equipment is gaining momentum, reflecting the industry's transition towards more modular and efficient design approaches. The market is in a growth phase, with increasing demand for high-performance audio solutions in various applications. The global market size for audio processing chips is expanding, driven by advancements in consumer electronics and professional audio equipment. Technologically, the field is rapidly evolving, with companies like Analog Devices, Qualcomm, and Sony leading innovation. These firms are developing sophisticated chiplet-based solutions that offer improved performance, power efficiency, and scalability. Other players such as JVCKenwood and Alpine Electronics are also adapting to this trend, integrating chiplet technology into their audio product lines to enhance sound quality and functionality.

Sony Group Corp.

Technical Solution: Sony has been at the forefront of chiplet technology in high-fidelity audio processing equipment. Their approach involves developing modular audio processing chiplets that can be combined to create customized solutions for various audio applications. Sony's chiplets incorporate advanced digital signal processing (DSP) cores, high-precision analog-to-digital converters (ADCs), and dedicated neural processing units (NPUs) for AI-enhanced audio processing. These chiplets are designed with a focus on power efficiency and scalability, allowing for flexible integration in a wide range of audio devices, from portable players to high-end home theater systems[1][3]. Sony's chiplet design also includes specialized interconnects that minimize latency and maintain signal integrity between different functional blocks, crucial for high-fidelity audio processing[5].

Strengths: Modular design allows for customization and scalability; Integration of AI capabilities enhances audio processing; Expertise in both hardware and content creation provides a comprehensive audio ecosystem. Weaknesses: Potentially higher initial costs due to specialized design; May require proprietary interfaces for optimal performance.

Analog Devices, Inc.

Technical Solution: Analog Devices has developed a chiplet-based approach for high-fidelity audio processing that focuses on precision analog and mixed-signal technologies. Their chiplets include high-performance audio ADCs and DACs, ultra-low-noise amplifiers, and specialized DSP cores optimized for audio applications. ADI's chiplet strategy emphasizes the separation of analog and digital domains to minimize interference and maintain signal purity. They have implemented advanced packaging technologies, such as 2.5D and 3D integration, to enable high-density interconnects between chiplets while preserving audio quality[2]. ADI's chiplets also incorporate adaptive power management features that optimize energy consumption based on the audio processing workload, making them suitable for both portable and high-end stationary audio equipment[4].

Strengths: Expertise in high-precision analog and mixed-signal technologies; Advanced packaging solutions for optimal chiplet integration; Adaptive power management for diverse applications. Weaknesses: May have a steeper learning curve for system integrators; Potentially higher cost for ultra-high-end audio applications.

Key Chiplet Innovations

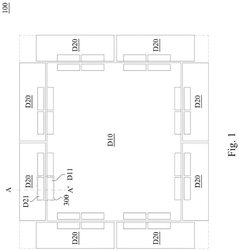

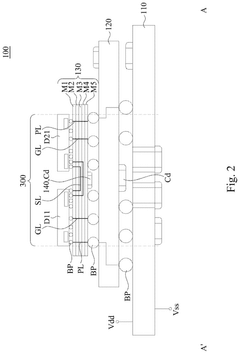

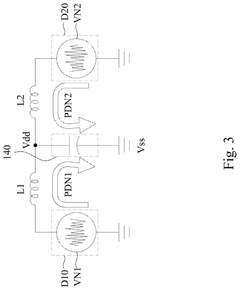

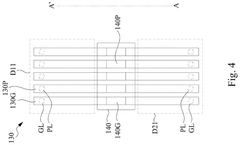

Semiconductor chiplet device and interposer

PatentPendingUS20250105163A1

Innovation

- A semiconductor chiplet device design incorporating a decoupling circuit and an interposer with staggered power and ground traces, reducing inductive impedance by shortening trace lengths and using decoupling capacitors to stabilize power supply, while maintaining a compact and cost-effective structure.

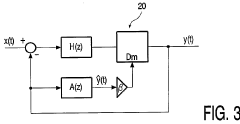

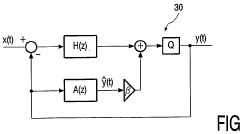

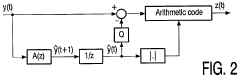

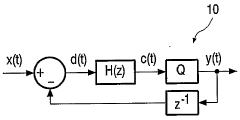

Noise-shaping device and method with improved lossless compression and good audio quality for high fidelity audio

PatentWO2005011126A1

Innovation

- The introduction of a noise-shaping device that utilizes a predictive filter and a weighting coefficient to produce an output signal based on both the input signal and a predictive signal, which represents future values of the output signal, allowing for a trade-off between bitstream compressibility and signal quality through a cost function that considers loopfilter and prediction filter outputs.

Thermal Management

Thermal management is a critical aspect of chiplet-based high-fidelity audio processing equipment design. As chiplets allow for more compact and powerful audio processing systems, they also introduce new challenges in heat dissipation. The increased power density of chiplet designs can lead to localized hotspots, potentially affecting the performance and longevity of audio processing equipment.

To address these thermal challenges, manufacturers are implementing advanced cooling solutions. Heat spreaders and thermal interface materials (TIMs) are being optimized to efficiently transfer heat from chiplets to the package substrate and heat sink. High-performance TIMs with improved thermal conductivity are being developed to minimize thermal resistance between chiplets and cooling components.

Active cooling solutions, such as miniaturized fans and liquid cooling systems, are being adapted for use in high-end audio equipment. These solutions provide more effective heat removal, enabling chiplets to operate at higher frequencies without thermal throttling. Some manufacturers are exploring the use of phase-change materials and microfluidic cooling channels integrated into the chiplet package to enhance thermal management.

Thermal-aware chiplet placement and routing strategies are becoming increasingly important. By optimizing the layout of chiplets within the package, designers can minimize thermal coupling between hot components and sensitive analog circuits. This approach helps maintain the high signal integrity required for premium audio performance.

Advanced thermal simulation tools are being employed to predict and mitigate thermal issues during the design phase. These tools allow engineers to model complex thermal interactions between chiplets, package components, and cooling systems, enabling more efficient and reliable designs.

Power management techniques are also playing a crucial role in thermal management. Dynamic voltage and frequency scaling (DVFS) algorithms are being refined to balance performance and power consumption, reducing overall heat generation. Additionally, chiplet-specific power gating techniques are being developed to selectively power down unused portions of the audio processing system, further minimizing heat output.

As the demand for more powerful and compact high-fidelity audio equipment grows, thermal management will continue to be a key focus area for chiplet-based designs. Innovations in materials science, cooling technologies, and thermal-aware design methodologies will be essential to push the boundaries of audio processing performance while maintaining optimal thermal conditions.

To address these thermal challenges, manufacturers are implementing advanced cooling solutions. Heat spreaders and thermal interface materials (TIMs) are being optimized to efficiently transfer heat from chiplets to the package substrate and heat sink. High-performance TIMs with improved thermal conductivity are being developed to minimize thermal resistance between chiplets and cooling components.

Active cooling solutions, such as miniaturized fans and liquid cooling systems, are being adapted for use in high-end audio equipment. These solutions provide more effective heat removal, enabling chiplets to operate at higher frequencies without thermal throttling. Some manufacturers are exploring the use of phase-change materials and microfluidic cooling channels integrated into the chiplet package to enhance thermal management.

Thermal-aware chiplet placement and routing strategies are becoming increasingly important. By optimizing the layout of chiplets within the package, designers can minimize thermal coupling between hot components and sensitive analog circuits. This approach helps maintain the high signal integrity required for premium audio performance.

Advanced thermal simulation tools are being employed to predict and mitigate thermal issues during the design phase. These tools allow engineers to model complex thermal interactions between chiplets, package components, and cooling systems, enabling more efficient and reliable designs.

Power management techniques are also playing a crucial role in thermal management. Dynamic voltage and frequency scaling (DVFS) algorithms are being refined to balance performance and power consumption, reducing overall heat generation. Additionally, chiplet-specific power gating techniques are being developed to selectively power down unused portions of the audio processing system, further minimizing heat output.

As the demand for more powerful and compact high-fidelity audio equipment grows, thermal management will continue to be a key focus area for chiplet-based designs. Innovations in materials science, cooling technologies, and thermal-aware design methodologies will be essential to push the boundaries of audio processing performance while maintaining optimal thermal conditions.

Standardization Efforts

Standardization efforts in the realm of chiplet technology for high-fidelity audio processing equipment have gained significant momentum in recent years. These initiatives aim to establish common protocols, interfaces, and design methodologies to facilitate interoperability and accelerate innovation in the audio industry.

One of the primary standardization efforts is the development of universal chiplet interconnect standards. Organizations such as the Open Compute Project (OCP) and the CHIPS Alliance are working on specifications that define standardized interfaces for chiplet-to-chiplet communication. These standards are crucial for enabling seamless integration of audio processing chiplets from different manufacturers, fostering a more diverse and competitive ecosystem.

Another key area of standardization focuses on power management and thermal considerations specific to audio processing chiplets. Industry consortia are collaborating to define guidelines for efficient power distribution and heat dissipation, ensuring optimal performance and reliability in high-fidelity audio equipment.

Standardization efforts also extend to the software domain, with initiatives to create common APIs and middleware layers for chiplet-based audio systems. These efforts aim to simplify the development process for audio equipment manufacturers and software developers, allowing them to leverage chiplet technology more effectively.

Data protocols for high-bandwidth, low-latency audio signal transmission between chiplets are also being standardized. These protocols are essential for maintaining the integrity of audio signals in multi-chiplet configurations, ensuring that the benefits of chiplet technology can be fully realized in high-fidelity audio applications.

Efforts are underway to standardize testing and validation methodologies for chiplet-based audio processing systems. These standards will help ensure consistent quality and performance across different implementations, building confidence in the technology among manufacturers and consumers alike.

Packaging and integration standards for audio processing chiplets are also being developed. These standards address challenges related to chip stacking, thermal management, and signal integrity in compact audio equipment designs, enabling more efficient and reliable products.

As the chiplet ecosystem for audio processing continues to evolve, ongoing standardization efforts will play a crucial role in driving adoption and innovation. By establishing common ground for manufacturers, designers, and developers, these initiatives are paving the way for more advanced, flexible, and cost-effective high-fidelity audio processing solutions.

One of the primary standardization efforts is the development of universal chiplet interconnect standards. Organizations such as the Open Compute Project (OCP) and the CHIPS Alliance are working on specifications that define standardized interfaces for chiplet-to-chiplet communication. These standards are crucial for enabling seamless integration of audio processing chiplets from different manufacturers, fostering a more diverse and competitive ecosystem.

Another key area of standardization focuses on power management and thermal considerations specific to audio processing chiplets. Industry consortia are collaborating to define guidelines for efficient power distribution and heat dissipation, ensuring optimal performance and reliability in high-fidelity audio equipment.

Standardization efforts also extend to the software domain, with initiatives to create common APIs and middleware layers for chiplet-based audio systems. These efforts aim to simplify the development process for audio equipment manufacturers and software developers, allowing them to leverage chiplet technology more effectively.

Data protocols for high-bandwidth, low-latency audio signal transmission between chiplets are also being standardized. These protocols are essential for maintaining the integrity of audio signals in multi-chiplet configurations, ensuring that the benefits of chiplet technology can be fully realized in high-fidelity audio applications.

Efforts are underway to standardize testing and validation methodologies for chiplet-based audio processing systems. These standards will help ensure consistent quality and performance across different implementations, building confidence in the technology among manufacturers and consumers alike.

Packaging and integration standards for audio processing chiplets are also being developed. These standards address challenges related to chip stacking, thermal management, and signal integrity in compact audio equipment designs, enabling more efficient and reliable products.

As the chiplet ecosystem for audio processing continues to evolve, ongoing standardization efforts will play a crucial role in driving adoption and innovation. By establishing common ground for manufacturers, designers, and developers, these initiatives are paving the way for more advanced, flexible, and cost-effective high-fidelity audio processing solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!