Chiplet Use Cases in Medical Imaging Technology

JUL 16, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Chiplet Evolution in Medical Imaging

The evolution of chiplet technology in medical imaging represents a significant advancement in the field, offering improved performance, efficiency, and scalability for complex imaging systems. This technological progression can be traced through several key stages, each marked by notable innovations and breakthroughs.

In the early 2000s, medical imaging systems primarily relied on monolithic chip designs, which integrated all components onto a single die. While effective for their time, these designs faced limitations in terms of scalability and manufacturing yield, particularly as imaging resolution and processing requirements increased.

The mid-2010s saw the emergence of the first chiplet-based architectures in medical imaging. This shift was driven by the need for more powerful and efficient imaging systems, capable of handling the growing demands of advanced imaging modalities such as high-resolution CT and 3D ultrasound. Initial chiplet designs focused on separating core processing units from memory and I/O components, allowing for more optimized manufacturing processes and improved thermal management.

By the late 2010s, chiplet technology in medical imaging had matured significantly. Manufacturers began implementing more sophisticated chiplet designs, incorporating specialized accelerators for image reconstruction, machine learning algorithms, and real-time data processing. This modular approach allowed for greater flexibility in system design and enabled the rapid integration of new technologies without requiring a complete overhaul of the entire imaging system.

The early 2020s marked a turning point in chiplet adoption for medical imaging, with the technology becoming increasingly mainstream. Advanced packaging techniques, such as 2.5D and 3D integration, facilitated the development of highly compact and efficient imaging systems. These innovations led to the creation of portable, high-performance imaging devices that could be used in a wider range of clinical settings.

Current trends in chiplet evolution for medical imaging focus on further specialization and integration. Manufacturers are developing chiplets tailored for specific imaging modalities, such as dedicated neural network accelerators for AI-assisted diagnosis in radiology. Additionally, there is a growing emphasis on incorporating advanced communication interfaces between chiplets to minimize latency and maximize data throughput, critical for real-time imaging applications.

Looking ahead, the future of chiplet technology in medical imaging is poised for continued innovation. Emerging research areas include the development of chiplets with integrated photonics for ultra-fast data transfer, as well as the incorporation of novel materials and manufacturing processes to enhance energy efficiency and reduce form factors. These advancements are expected to enable the next generation of medical imaging systems, capable of providing unprecedented levels of detail, speed, and diagnostic accuracy.

In the early 2000s, medical imaging systems primarily relied on monolithic chip designs, which integrated all components onto a single die. While effective for their time, these designs faced limitations in terms of scalability and manufacturing yield, particularly as imaging resolution and processing requirements increased.

The mid-2010s saw the emergence of the first chiplet-based architectures in medical imaging. This shift was driven by the need for more powerful and efficient imaging systems, capable of handling the growing demands of advanced imaging modalities such as high-resolution CT and 3D ultrasound. Initial chiplet designs focused on separating core processing units from memory and I/O components, allowing for more optimized manufacturing processes and improved thermal management.

By the late 2010s, chiplet technology in medical imaging had matured significantly. Manufacturers began implementing more sophisticated chiplet designs, incorporating specialized accelerators for image reconstruction, machine learning algorithms, and real-time data processing. This modular approach allowed for greater flexibility in system design and enabled the rapid integration of new technologies without requiring a complete overhaul of the entire imaging system.

The early 2020s marked a turning point in chiplet adoption for medical imaging, with the technology becoming increasingly mainstream. Advanced packaging techniques, such as 2.5D and 3D integration, facilitated the development of highly compact and efficient imaging systems. These innovations led to the creation of portable, high-performance imaging devices that could be used in a wider range of clinical settings.

Current trends in chiplet evolution for medical imaging focus on further specialization and integration. Manufacturers are developing chiplets tailored for specific imaging modalities, such as dedicated neural network accelerators for AI-assisted diagnosis in radiology. Additionally, there is a growing emphasis on incorporating advanced communication interfaces between chiplets to minimize latency and maximize data throughput, critical for real-time imaging applications.

Looking ahead, the future of chiplet technology in medical imaging is poised for continued innovation. Emerging research areas include the development of chiplets with integrated photonics for ultra-fast data transfer, as well as the incorporation of novel materials and manufacturing processes to enhance energy efficiency and reduce form factors. These advancements are expected to enable the next generation of medical imaging systems, capable of providing unprecedented levels of detail, speed, and diagnostic accuracy.

Market Demand Analysis

The market demand for Chiplet technology in medical imaging is experiencing significant growth, driven by the increasing need for high-performance, energy-efficient, and cost-effective imaging solutions. Medical imaging technologies, such as Computed Tomography (CT), Magnetic Resonance Imaging (MRI), and Positron Emission Tomography (PET), require advanced computational capabilities to process and analyze large volumes of data quickly and accurately. Chiplet-based solutions offer a promising approach to meet these demands.

The global medical imaging market is projected to expand substantially in the coming years, with a particular emphasis on advanced imaging technologies. This growth is fueled by factors such as the rising prevalence of chronic diseases, an aging population, and the increasing adoption of preventive healthcare practices. As healthcare providers seek to improve diagnostic accuracy and treatment outcomes, there is a growing demand for more sophisticated imaging equipment that can deliver higher resolution images and faster processing times.

Chiplet technology addresses several key market needs in medical imaging. First, it enables the development of more powerful imaging systems by allowing the integration of specialized processing units optimized for specific imaging tasks. This modular approach enhances overall system performance while maintaining flexibility in design and manufacturing. Second, Chiplets offer improved energy efficiency, which is crucial in healthcare settings where power consumption and heat generation are significant concerns.

The market is also driven by the need for cost-effective solutions. Traditional monolithic chip designs face increasing challenges in terms of manufacturing costs and yield rates as they grow in complexity. Chiplet-based architectures provide a more economical alternative by allowing the use of smaller, more easily manufactured components that can be combined to create high-performance systems. This approach not only reduces production costs but also enables more frequent upgrades and customization of imaging equipment.

Another significant market driver is the growing trend towards AI-assisted medical imaging. Chiplet technology is well-suited to support the integration of AI accelerators and specialized processors required for advanced image analysis and machine learning algorithms. This capability is particularly valuable in applications such as automated lesion detection, image segmentation, and diagnostic support systems.

The demand for portable and point-of-care imaging devices is also contributing to the market potential for Chiplet technology. These devices require compact, power-efficient designs that can deliver high-performance imaging capabilities in smaller form factors. Chiplet-based solutions offer the flexibility to create modular, scalable designs that can be adapted to various imaging modalities and use cases.

As healthcare systems worldwide seek to improve efficiency and reduce costs, there is an increasing focus on interoperability and standardization of medical imaging equipment. Chiplet technology, with its modular approach, aligns well with these objectives by enabling the development of more standardized and upgradable imaging platforms. This trend is likely to drive further adoption of Chiplet-based solutions in the medical imaging market.

The global medical imaging market is projected to expand substantially in the coming years, with a particular emphasis on advanced imaging technologies. This growth is fueled by factors such as the rising prevalence of chronic diseases, an aging population, and the increasing adoption of preventive healthcare practices. As healthcare providers seek to improve diagnostic accuracy and treatment outcomes, there is a growing demand for more sophisticated imaging equipment that can deliver higher resolution images and faster processing times.

Chiplet technology addresses several key market needs in medical imaging. First, it enables the development of more powerful imaging systems by allowing the integration of specialized processing units optimized for specific imaging tasks. This modular approach enhances overall system performance while maintaining flexibility in design and manufacturing. Second, Chiplets offer improved energy efficiency, which is crucial in healthcare settings where power consumption and heat generation are significant concerns.

The market is also driven by the need for cost-effective solutions. Traditional monolithic chip designs face increasing challenges in terms of manufacturing costs and yield rates as they grow in complexity. Chiplet-based architectures provide a more economical alternative by allowing the use of smaller, more easily manufactured components that can be combined to create high-performance systems. This approach not only reduces production costs but also enables more frequent upgrades and customization of imaging equipment.

Another significant market driver is the growing trend towards AI-assisted medical imaging. Chiplet technology is well-suited to support the integration of AI accelerators and specialized processors required for advanced image analysis and machine learning algorithms. This capability is particularly valuable in applications such as automated lesion detection, image segmentation, and diagnostic support systems.

The demand for portable and point-of-care imaging devices is also contributing to the market potential for Chiplet technology. These devices require compact, power-efficient designs that can deliver high-performance imaging capabilities in smaller form factors. Chiplet-based solutions offer the flexibility to create modular, scalable designs that can be adapted to various imaging modalities and use cases.

As healthcare systems worldwide seek to improve efficiency and reduce costs, there is an increasing focus on interoperability and standardization of medical imaging equipment. Chiplet technology, with its modular approach, aligns well with these objectives by enabling the development of more standardized and upgradable imaging platforms. This trend is likely to drive further adoption of Chiplet-based solutions in the medical imaging market.

Technical Challenges

The integration of chiplet technology in medical imaging presents several significant technical challenges that need to be addressed for successful implementation. One of the primary hurdles is the high-speed interconnect between chiplets. Medical imaging systems require rapid data transfer and processing, necessitating ultra-fast and reliable communication between different chiplet components. Achieving this level of performance while maintaining signal integrity across chiplet boundaries is a complex task that demands innovative solutions in packaging and interconnect technologies.

Another critical challenge lies in the thermal management of chiplet-based medical imaging systems. As these systems often require high-performance computing capabilities, the heat generated by multiple chiplets in close proximity can be substantial. Effective heat dissipation is crucial to maintain system stability and prevent performance degradation, especially in sensitive medical environments where reliability is paramount.

Power management presents an additional layer of complexity in chiplet-based medical imaging technology. Balancing power consumption across multiple chiplets while optimizing overall system performance is a delicate task. This challenge is particularly pronounced in portable or battery-operated medical imaging devices, where energy efficiency is a key consideration.

The integration of heterogeneous chiplets, each potentially manufactured using different process nodes or even different materials, poses significant challenges in terms of design and manufacturing. Ensuring seamless functionality and compatibility between diverse chiplets, while maintaining the high precision required for medical imaging applications, demands sophisticated design methodologies and advanced manufacturing techniques.

Data synchronization and latency management across multiple chiplets is another critical technical hurdle. Medical imaging often requires real-time processing and analysis, making it essential to minimize latency and ensure perfect synchronization between different chiplet components. This challenge is further complicated by the need to handle large volumes of imaging data efficiently.

Reliability and fault tolerance are paramount in medical imaging applications, adding another layer of complexity to chiplet integration. Developing robust error detection and correction mechanisms that can operate across chiplet boundaries is crucial for ensuring the accuracy and dependability of medical imaging systems.

Lastly, the challenge of standardization and interoperability in chiplet-based medical imaging systems cannot be overlooked. As the technology evolves, establishing industry-wide standards for chiplet interfaces, protocols, and integration methodologies becomes increasingly important to foster innovation and ensure compatibility across different platforms and manufacturers in the medical imaging sector.

Another critical challenge lies in the thermal management of chiplet-based medical imaging systems. As these systems often require high-performance computing capabilities, the heat generated by multiple chiplets in close proximity can be substantial. Effective heat dissipation is crucial to maintain system stability and prevent performance degradation, especially in sensitive medical environments where reliability is paramount.

Power management presents an additional layer of complexity in chiplet-based medical imaging technology. Balancing power consumption across multiple chiplets while optimizing overall system performance is a delicate task. This challenge is particularly pronounced in portable or battery-operated medical imaging devices, where energy efficiency is a key consideration.

The integration of heterogeneous chiplets, each potentially manufactured using different process nodes or even different materials, poses significant challenges in terms of design and manufacturing. Ensuring seamless functionality and compatibility between diverse chiplets, while maintaining the high precision required for medical imaging applications, demands sophisticated design methodologies and advanced manufacturing techniques.

Data synchronization and latency management across multiple chiplets is another critical technical hurdle. Medical imaging often requires real-time processing and analysis, making it essential to minimize latency and ensure perfect synchronization between different chiplet components. This challenge is further complicated by the need to handle large volumes of imaging data efficiently.

Reliability and fault tolerance are paramount in medical imaging applications, adding another layer of complexity to chiplet integration. Developing robust error detection and correction mechanisms that can operate across chiplet boundaries is crucial for ensuring the accuracy and dependability of medical imaging systems.

Lastly, the challenge of standardization and interoperability in chiplet-based medical imaging systems cannot be overlooked. As the technology evolves, establishing industry-wide standards for chiplet interfaces, protocols, and integration methodologies becomes increasingly important to foster innovation and ensure compatibility across different platforms and manufacturers in the medical imaging sector.

Current Chiplet Solutions

01 Chiplet architecture and integration

Chiplets are modular components that can be integrated to form larger, more complex systems-on-chip. This approach allows for flexible design, improved yield, and cost-effective manufacturing. The architecture involves connecting multiple smaller dies or chiplets using advanced packaging technologies, enabling high-performance and scalable semiconductor solutions.- Chiplet architecture and integration: Chiplets are modular components that can be integrated to form larger, more complex systems-on-chip. This approach allows for flexible design, improved yield, and cost-effective manufacturing of advanced semiconductor devices. The integration of chiplets often involves advanced packaging technologies and interconnect solutions to ensure high-performance communication between the individual components.

- Interconnect technologies for chiplets: Various interconnect technologies are employed to facilitate high-bandwidth, low-latency communication between chiplets. These may include advanced packaging solutions, through-silicon vias (TSVs), and novel interface protocols. The choice of interconnect technology significantly impacts the overall performance, power efficiency, and thermal characteristics of the chiplet-based system.

- Power management in chiplet-based systems: Efficient power management is crucial in chiplet-based designs to optimize performance and reduce energy consumption. This involves implementing sophisticated power gating techniques, dynamic voltage and frequency scaling, and thermal management strategies across multiple chiplets. Advanced power delivery networks and on-chip voltage regulators may be employed to ensure stable power distribution to individual chiplets.

- Testing and validation of chiplet-based systems: Testing and validation of chiplet-based systems present unique challenges due to the modular nature of the components. Specialized test methodologies and infrastructure are developed to ensure the functionality and performance of individual chiplets as well as the integrated system. This may include built-in self-test (BIST) mechanisms, advanced probe technologies, and system-level validation techniques.

- Chiplet standardization and ecosystem development: Efforts are underway to establish industry standards for chiplet interfaces, packaging, and integration methodologies. This standardization aims to create a robust ecosystem that enables interoperability between chiplets from different vendors, fostering innovation and reducing time-to-market for complex semiconductor products. Collaborative initiatives and consortia are working towards defining common specifications and protocols for chiplet-based designs.

02 Interconnect technologies for chiplets

Various interconnect technologies are employed to facilitate communication between chiplets and ensure high-speed data transfer. These may include through-silicon vias (TSVs), interposers, and advanced packaging techniques. The interconnect design is crucial for maintaining performance and power efficiency in multi-chiplet systems.Expand Specific Solutions03 Power management in chiplet-based systems

Efficient power management is essential in chiplet-based designs to optimize performance and reduce energy consumption. This involves implementing advanced power gating techniques, voltage scaling, and thermal management strategies across multiple chiplets to ensure overall system efficiency and reliability.Expand Specific Solutions04 Testing and validation of chiplet systems

Developing comprehensive testing and validation methodologies for chiplet-based systems is crucial to ensure functionality, performance, and reliability. This includes pre-silicon verification, post-silicon validation, and system-level testing to address challenges associated with integrating multiple chiplets from potentially different vendors or process nodes.Expand Specific Solutions05 Chiplet standardization and ecosystem development

Efforts are underway to establish industry standards for chiplet interfaces, protocols, and packaging to facilitate interoperability and foster a robust ecosystem. This includes developing common specifications for chiplet-to-chiplet communication, physical interfaces, and design methodologies to enable a more diverse and competitive chiplet marketplace.Expand Specific Solutions

Key Industry Players

The chiplet use cases in medical imaging technology market is in a growth phase, driven by increasing demand for advanced diagnostic tools. The market size is expanding rapidly, with major players like Koninklijke Philips, Siemens Healthineers, and GE Precision Healthcare leading innovation. These companies are leveraging chiplet technology to enhance imaging resolution, processing speed, and energy efficiency. The technology's maturity is advancing, with established firms and research institutions like The Regents of the University of California collaborating to overcome integration challenges. Emerging players such as Shanghai United Imaging Healthcare are also contributing to the competitive landscape, focusing on specialized applications and regional markets.

Koninklijke Philips NV

Technical Solution: Philips has developed a chiplet-based architecture for medical imaging systems, particularly in their advanced CT scanners. Their approach involves disaggregating complex System-on-Chip (SoC) designs into smaller, reusable chiplets. This allows for more flexible and scalable imaging system designs, enabling the integration of heterogeneous technologies optimized for specific functions such as image processing, AI acceleration, and data acquisition. The company's chiplet strategy includes the use of advanced packaging technologies like 2.5D and 3D integration, allowing for high-bandwidth, low-latency interconnects between chiplets[1][3]. Philips has also implemented chiplet-based designs in their MRI systems, where they use specialized chiplets for RF signal processing and gradient control, improving image quality and reducing scan times[2].

Strengths: Increased flexibility in system design, improved performance through specialized chiplets, and potential for cost reduction through reuse of chiplet designs. Weaknesses: Complexity in system integration and potential challenges in thermal management of densely packed chiplets.

Siemens Healthineers AG

Technical Solution: Siemens Healthineers has embraced chiplet technology in their medical imaging equipment, particularly in their latest generation of CT and MRI scanners. Their approach focuses on creating modular imaging systems with chiplet-based components that can be easily upgraded or replaced. The company has developed custom chiplets for specific imaging functions, such as data acquisition and image reconstruction, which can be combined with general-purpose computing chiplets for AI-assisted diagnostics. Siemens' chiplet implementation includes advanced packaging techniques like silicon interposers and through-silicon vias (TSVs) to achieve high-performance interconnects between chiplets[4]. They have reported up to 30% improvement in image processing speed and a 20% reduction in power consumption compared to their previous monolithic chip designs[5].

Strengths: Modularity allowing for easier upgrades, improved energy efficiency, and enhanced performance in specific imaging tasks. Weaknesses: Potential increase in initial system complexity and higher upfront costs for chiplet development.

Core Chiplet Innovations

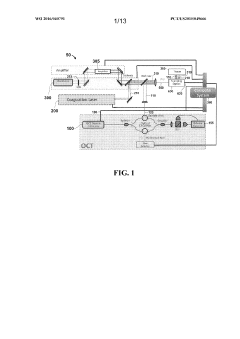

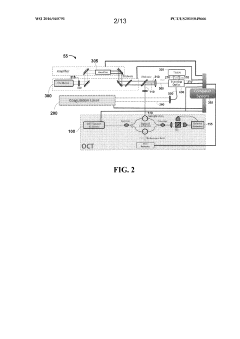

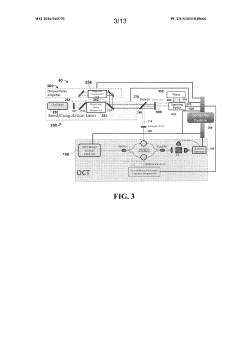

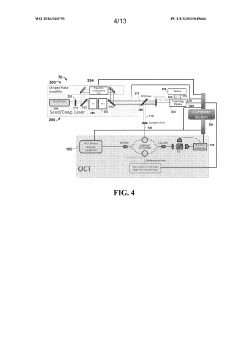

Systems and methods for imaging and manipulating tissue

PatentWO2016040791A2

Innovation

- The use of light-based systems that integrate optical coherence tomography (OCT) and multiphoton luminescence (MPL) with lasers to simultaneously image, coagulate, and cut tissue, allowing for precise and rapid tissue removal while sparing surrounding structures.

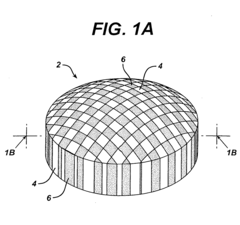

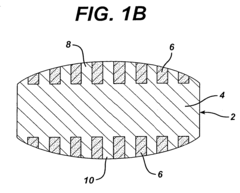

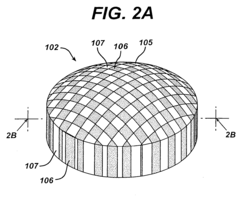

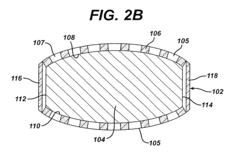

Composite dosage forms having an inlaid portion

PatentActiveUS20040156902A1

Innovation

- A composite dosage form comprising a first portion with cavities and indentations and a second molded portion made of solidified thermoplastic material, inlaid into the cavities, which can have different compositions and colors, providing enhanced versatility and stability.

Regulatory Considerations

The integration of chiplet technology in medical imaging devices necessitates careful consideration of regulatory requirements to ensure patient safety, data privacy, and device efficacy. In the United States, the Food and Drug Administration (FDA) plays a crucial role in overseeing medical devices, including those incorporating chiplet technology. The FDA's regulatory framework for medical imaging devices is primarily based on the level of risk associated with the device's intended use.

For chiplet-based medical imaging systems, manufacturers must navigate the premarket approval (PMA) or 510(k) clearance processes, depending on the device classification. Class II devices, which include many diagnostic imaging systems, typically require 510(k) clearance. However, novel chiplet implementations may necessitate more rigorous PMA if they introduce significant technological changes or pose higher risks.

Compliance with international standards is equally important for global market access. The International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) provide guidelines relevant to medical imaging devices. Standards such as IEC 60601-1 for medical electrical equipment safety and IEC 62304 for medical device software lifecycle processes are particularly pertinent to chiplet-based systems.

Data protection regulations, including the Health Insurance Portability and Accountability Act (HIPAA) in the United States and the General Data Protection Regulation (GDPR) in the European Union, must be addressed in the design and implementation of chiplet-based medical imaging technologies. These regulations mandate strict controls over patient data handling, storage, and transmission.

Electromagnetic compatibility (EMC) regulations are critical for chiplet-based medical imaging devices. Compliance with standards like IEC 60601-1-2 is essential to ensure that the device neither causes nor is susceptible to electromagnetic interference, which could compromise image quality or patient safety.

As chiplet technology evolves, regulatory bodies may need to adapt their frameworks to address new challenges. This could include developing specific guidance for chiplet-based medical devices, considering aspects such as interoperability, reliability, and long-term performance. Manufacturers should engage in early and frequent communication with regulatory agencies to navigate these evolving requirements effectively.

For chiplet-based medical imaging systems, manufacturers must navigate the premarket approval (PMA) or 510(k) clearance processes, depending on the device classification. Class II devices, which include many diagnostic imaging systems, typically require 510(k) clearance. However, novel chiplet implementations may necessitate more rigorous PMA if they introduce significant technological changes or pose higher risks.

Compliance with international standards is equally important for global market access. The International Electrotechnical Commission (IEC) and the International Organization for Standardization (ISO) provide guidelines relevant to medical imaging devices. Standards such as IEC 60601-1 for medical electrical equipment safety and IEC 62304 for medical device software lifecycle processes are particularly pertinent to chiplet-based systems.

Data protection regulations, including the Health Insurance Portability and Accountability Act (HIPAA) in the United States and the General Data Protection Regulation (GDPR) in the European Union, must be addressed in the design and implementation of chiplet-based medical imaging technologies. These regulations mandate strict controls over patient data handling, storage, and transmission.

Electromagnetic compatibility (EMC) regulations are critical for chiplet-based medical imaging devices. Compliance with standards like IEC 60601-1-2 is essential to ensure that the device neither causes nor is susceptible to electromagnetic interference, which could compromise image quality or patient safety.

As chiplet technology evolves, regulatory bodies may need to adapt their frameworks to address new challenges. This could include developing specific guidance for chiplet-based medical devices, considering aspects such as interoperability, reliability, and long-term performance. Manufacturers should engage in early and frequent communication with regulatory agencies to navigate these evolving requirements effectively.

Cost-Benefit Analysis

The adoption of chiplet technology in medical imaging devices presents a complex cost-benefit scenario that requires careful analysis. On the cost side, implementing chiplet architecture in medical imaging systems initially demands significant investment in research, development, and retooling of manufacturing processes. This upfront expenditure can be substantial, potentially increasing the short-term costs of medical imaging equipment.

However, the long-term benefits of chiplet technology in medical imaging are compelling. Chiplets allow for more efficient use of silicon, potentially reducing overall production costs once economies of scale are achieved. This could lead to more affordable medical imaging devices, making advanced diagnostic tools more accessible to healthcare providers and patients.

The modular nature of chiplets offers enhanced flexibility in system design, enabling manufacturers to customize imaging systems more easily for specific medical applications. This adaptability can result in reduced development time and costs for new imaging products, accelerating innovation in the field.

Chiplet technology also promises improved performance and energy efficiency in medical imaging devices. By optimizing each chiplet for its specific function, overall system performance can be enhanced, leading to higher resolution images, faster scan times, and improved diagnostic capabilities. The reduced power consumption of chiplet-based systems can result in lower operating costs for healthcare facilities.

From a maintenance perspective, chiplet-based medical imaging systems may offer advantages in terms of repairability and upgradability. Faulty components could potentially be replaced more easily, reducing downtime and extending the lifespan of expensive medical equipment.

However, it's important to consider potential drawbacks. The complexity of chiplet-based systems may require specialized training for maintenance personnel, potentially increasing ongoing support costs. Additionally, ensuring seamless integration and communication between multiple chiplets in a medical imaging context presents technical challenges that must be addressed.

In conclusion, while the initial costs of implementing chiplet technology in medical imaging devices are significant, the potential long-term benefits in terms of performance, efficiency, and flexibility appear to outweigh these costs. As the technology matures and becomes more widely adopted, the cost-benefit ratio is likely to improve further, making chiplet-based solutions increasingly attractive for medical imaging applications.

However, the long-term benefits of chiplet technology in medical imaging are compelling. Chiplets allow for more efficient use of silicon, potentially reducing overall production costs once economies of scale are achieved. This could lead to more affordable medical imaging devices, making advanced diagnostic tools more accessible to healthcare providers and patients.

The modular nature of chiplets offers enhanced flexibility in system design, enabling manufacturers to customize imaging systems more easily for specific medical applications. This adaptability can result in reduced development time and costs for new imaging products, accelerating innovation in the field.

Chiplet technology also promises improved performance and energy efficiency in medical imaging devices. By optimizing each chiplet for its specific function, overall system performance can be enhanced, leading to higher resolution images, faster scan times, and improved diagnostic capabilities. The reduced power consumption of chiplet-based systems can result in lower operating costs for healthcare facilities.

From a maintenance perspective, chiplet-based medical imaging systems may offer advantages in terms of repairability and upgradability. Faulty components could potentially be replaced more easily, reducing downtime and extending the lifespan of expensive medical equipment.

However, it's important to consider potential drawbacks. The complexity of chiplet-based systems may require specialized training for maintenance personnel, potentially increasing ongoing support costs. Additionally, ensuring seamless integration and communication between multiple chiplets in a medical imaging context presents technical challenges that must be addressed.

In conclusion, while the initial costs of implementing chiplet technology in medical imaging devices are significant, the potential long-term benefits in terms of performance, efficiency, and flexibility appear to outweigh these costs. As the technology matures and becomes more widely adopted, the cost-benefit ratio is likely to improve further, making chiplet-based solutions increasingly attractive for medical imaging applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!