Comparative Analysis Of Electrochemical Versus Mechanical Hydrogen Compression

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Compression Technology Background and Objectives

Hydrogen compression technology has evolved significantly over the past century, with mechanical compression methods dominating the industrial landscape since the early 1900s. Initially developed for industrial gas applications, hydrogen compression technologies have gained renewed importance with the global shift toward clean energy solutions. The historical trajectory shows a clear evolution from simple reciprocating compressors to sophisticated multi-stage systems capable of achieving pressures exceeding 900 bar.

The hydrogen economy presents unique challenges for compression technologies due to hydrogen's low molecular weight, high diffusivity, and potential for material embrittlement. Traditional mechanical compression methods, while well-established, face efficiency limitations particularly at higher compression ratios. This has driven research into alternative technologies, with electrochemical compression emerging as a promising contender in the last two decades.

Current technological objectives in hydrogen compression focus on addressing several critical parameters: energy efficiency, reliability, scalability, and cost-effectiveness. The industry aims to reduce the significant energy consumption associated with hydrogen compression, which currently accounts for approximately 10-15% of the total energy content of the hydrogen being processed. Additionally, minimizing hydrogen losses during compression and reducing system footprint represent key goals for next-generation compression technologies.

Electrochemical compression, utilizing principles similar to fuel cells and electrolyzers, offers theoretical advantages in energy efficiency and operational simplicity compared to mechanical alternatives. The technology leverages proton exchange membranes to transport hydrogen ions across an electrolyte under an applied voltage, achieving compression without moving parts. This approach potentially addresses several limitations of mechanical systems, particularly for distributed and small-scale applications.

The comparative analysis of these technologies must be contextualized within broader hydrogen infrastructure development goals. With projections indicating hydrogen could meet up to 24% of global energy demand by 2050, compression technology advancements are critical enablers for hydrogen storage, transportation, and end-use applications. Particularly for mobility applications requiring 350-700 bar pressures and stationary storage systems, compression technology selection significantly impacts overall system economics and performance.

Research objectives in this field aim to quantify performance differences between electrochemical and mechanical compression across various operational parameters, including energy efficiency, capital costs, maintenance requirements, and scalability. Additionally, identifying optimal application scenarios for each technology based on pressure requirements, throughput needs, and deployment contexts represents a key goal for technology developers and potential adopters.

The hydrogen economy presents unique challenges for compression technologies due to hydrogen's low molecular weight, high diffusivity, and potential for material embrittlement. Traditional mechanical compression methods, while well-established, face efficiency limitations particularly at higher compression ratios. This has driven research into alternative technologies, with electrochemical compression emerging as a promising contender in the last two decades.

Current technological objectives in hydrogen compression focus on addressing several critical parameters: energy efficiency, reliability, scalability, and cost-effectiveness. The industry aims to reduce the significant energy consumption associated with hydrogen compression, which currently accounts for approximately 10-15% of the total energy content of the hydrogen being processed. Additionally, minimizing hydrogen losses during compression and reducing system footprint represent key goals for next-generation compression technologies.

Electrochemical compression, utilizing principles similar to fuel cells and electrolyzers, offers theoretical advantages in energy efficiency and operational simplicity compared to mechanical alternatives. The technology leverages proton exchange membranes to transport hydrogen ions across an electrolyte under an applied voltage, achieving compression without moving parts. This approach potentially addresses several limitations of mechanical systems, particularly for distributed and small-scale applications.

The comparative analysis of these technologies must be contextualized within broader hydrogen infrastructure development goals. With projections indicating hydrogen could meet up to 24% of global energy demand by 2050, compression technology advancements are critical enablers for hydrogen storage, transportation, and end-use applications. Particularly for mobility applications requiring 350-700 bar pressures and stationary storage systems, compression technology selection significantly impacts overall system economics and performance.

Research objectives in this field aim to quantify performance differences between electrochemical and mechanical compression across various operational parameters, including energy efficiency, capital costs, maintenance requirements, and scalability. Additionally, identifying optimal application scenarios for each technology based on pressure requirements, throughput needs, and deployment contexts represents a key goal for technology developers and potential adopters.

Market Demand Analysis for Hydrogen Compression Solutions

The global hydrogen compression market is experiencing significant growth, driven primarily by the expanding hydrogen economy and the transition towards cleaner energy sources. Current market valuations indicate that the hydrogen compression market is expected to grow at a compound annual growth rate of 5.8% between 2023 and 2030, reaching approximately 2.7 billion USD by the end of the forecast period. This growth trajectory is underpinned by increasing investments in hydrogen infrastructure and the rising adoption of hydrogen as an energy carrier across various industries.

The demand for hydrogen compression solutions is segmented across several key application areas. Industrial applications, particularly in petroleum refining and ammonia production, continue to dominate the market share, accounting for over 60% of current demand. However, the fastest-growing segment is emerging in the transportation sector, where hydrogen fuel cell vehicles require efficient compression technologies for refueling stations. This segment is projected to grow at nearly 9% annually through 2030.

Geographically, Asia-Pacific represents the largest market for hydrogen compression technologies, led by significant investments in hydrogen infrastructure in countries like Japan, South Korea, and increasingly China. Europe follows closely, driven by ambitious decarbonization targets and supportive regulatory frameworks. North America, particularly the United States, is showing renewed interest with recent policy initiatives supporting hydrogen development.

When examining customer requirements, several key demand drivers emerge for hydrogen compression solutions. Energy efficiency ranks as the primary concern, with end-users seeking technologies that minimize the substantial energy input traditionally required for hydrogen compression. Reliability and maintenance requirements follow closely, as downtime in hydrogen systems can result in significant operational disruptions. Capital expenditure considerations remain important, though many industrial users increasingly evaluate total cost of ownership rather than initial investment alone.

The comparative analysis between electrochemical and mechanical compression technologies reveals shifting market preferences. While mechanical compression systems currently dominate with approximately 85% market share, electrochemical compression is gaining traction due to its potential advantages in efficiency, reliability, and scalability. Market research indicates that early adopters are willing to pay a premium of 15-20% for electrochemical systems if they can demonstrate superior efficiency and lower maintenance requirements.

Regulatory factors are increasingly influencing market demand, with stricter emissions standards and carbon pricing mechanisms favoring more efficient compression technologies. Additionally, government subsidies and incentives for hydrogen infrastructure development are creating market opportunities, particularly for innovative compression solutions that can overcome traditional efficiency limitations.

The demand for hydrogen compression solutions is segmented across several key application areas. Industrial applications, particularly in petroleum refining and ammonia production, continue to dominate the market share, accounting for over 60% of current demand. However, the fastest-growing segment is emerging in the transportation sector, where hydrogen fuel cell vehicles require efficient compression technologies for refueling stations. This segment is projected to grow at nearly 9% annually through 2030.

Geographically, Asia-Pacific represents the largest market for hydrogen compression technologies, led by significant investments in hydrogen infrastructure in countries like Japan, South Korea, and increasingly China. Europe follows closely, driven by ambitious decarbonization targets and supportive regulatory frameworks. North America, particularly the United States, is showing renewed interest with recent policy initiatives supporting hydrogen development.

When examining customer requirements, several key demand drivers emerge for hydrogen compression solutions. Energy efficiency ranks as the primary concern, with end-users seeking technologies that minimize the substantial energy input traditionally required for hydrogen compression. Reliability and maintenance requirements follow closely, as downtime in hydrogen systems can result in significant operational disruptions. Capital expenditure considerations remain important, though many industrial users increasingly evaluate total cost of ownership rather than initial investment alone.

The comparative analysis between electrochemical and mechanical compression technologies reveals shifting market preferences. While mechanical compression systems currently dominate with approximately 85% market share, electrochemical compression is gaining traction due to its potential advantages in efficiency, reliability, and scalability. Market research indicates that early adopters are willing to pay a premium of 15-20% for electrochemical systems if they can demonstrate superior efficiency and lower maintenance requirements.

Regulatory factors are increasingly influencing market demand, with stricter emissions standards and carbon pricing mechanisms favoring more efficient compression technologies. Additionally, government subsidies and incentives for hydrogen infrastructure development are creating market opportunities, particularly for innovative compression solutions that can overcome traditional efficiency limitations.

Current State and Challenges in Hydrogen Compression Technologies

Hydrogen compression technologies have evolved significantly over the past decades, with mechanical compression dominating the industrial landscape. Currently, conventional mechanical compressors, including reciprocating, diaphragm, and centrifugal types, represent approximately 90% of the hydrogen compression market. These systems typically achieve compression ratios of 100:1 to 1000:1, enabling pressures up to 700-900 bar for various applications including refueling stations and industrial processes.

Electrochemical hydrogen compression (EHC) has emerged as a promising alternative, though it currently holds less than 5% market share. EHC systems leverage proton exchange membranes to transport hydrogen ions across an electrolyte, achieving theoretical compression ratios exceeding 10,000:1 without moving parts. Laboratory demonstrations have shown successful compression from atmospheric pressure to 700 bar with energy efficiencies ranging from 60-85%, compared to 45-70% for mechanical systems.

The hydrogen compression technology landscape faces several critical challenges. Mechanical compressors suffer from significant energy inefficiency, with compression accounting for 10-15% of the total energy content of hydrogen. These systems also experience substantial maintenance requirements due to hydrogen embrittlement of metal components and seal degradation, resulting in average downtimes of 10-15% annually for high-pressure applications.

Contamination represents another major challenge, as oil lubrication in mechanical compressors can introduce impurities into hydrogen streams, necessitating additional purification steps that increase system complexity and cost. Leakage rates in mechanical systems typically range from 0.5-3% of compressed volume, presenting both safety and efficiency concerns.

For electrochemical compression, durability remains a primary obstacle. Current membrane systems demonstrate degradation rates of 10-15% per 1000 operating hours under high differential pressure conditions. Material costs also present barriers to widespread adoption, with platinum catalyst loadings of 0.5-1.0 mg/cm² contributing significantly to system expenses.

Scale-up challenges persist for both technologies. Mechanical compressors face diminishing efficiency at higher capacities, while electrochemical systems struggle with uniform current distribution across large-area membranes. The geographical distribution of technological development shows concentration in North America, Europe, and Japan, with emerging research centers in China and South Korea focusing particularly on electrochemical approaches.

Recent technological advancements include the development of oil-free mechanical compressors and ionic liquid-based systems that address contamination issues, alongside novel composite membranes for electrochemical compression that demonstrate improved durability under high-pressure differentials.

Electrochemical hydrogen compression (EHC) has emerged as a promising alternative, though it currently holds less than 5% market share. EHC systems leverage proton exchange membranes to transport hydrogen ions across an electrolyte, achieving theoretical compression ratios exceeding 10,000:1 without moving parts. Laboratory demonstrations have shown successful compression from atmospheric pressure to 700 bar with energy efficiencies ranging from 60-85%, compared to 45-70% for mechanical systems.

The hydrogen compression technology landscape faces several critical challenges. Mechanical compressors suffer from significant energy inefficiency, with compression accounting for 10-15% of the total energy content of hydrogen. These systems also experience substantial maintenance requirements due to hydrogen embrittlement of metal components and seal degradation, resulting in average downtimes of 10-15% annually for high-pressure applications.

Contamination represents another major challenge, as oil lubrication in mechanical compressors can introduce impurities into hydrogen streams, necessitating additional purification steps that increase system complexity and cost. Leakage rates in mechanical systems typically range from 0.5-3% of compressed volume, presenting both safety and efficiency concerns.

For electrochemical compression, durability remains a primary obstacle. Current membrane systems demonstrate degradation rates of 10-15% per 1000 operating hours under high differential pressure conditions. Material costs also present barriers to widespread adoption, with platinum catalyst loadings of 0.5-1.0 mg/cm² contributing significantly to system expenses.

Scale-up challenges persist for both technologies. Mechanical compressors face diminishing efficiency at higher capacities, while electrochemical systems struggle with uniform current distribution across large-area membranes. The geographical distribution of technological development shows concentration in North America, Europe, and Japan, with emerging research centers in China and South Korea focusing particularly on electrochemical approaches.

Recent technological advancements include the development of oil-free mechanical compressors and ionic liquid-based systems that address contamination issues, alongside novel composite membranes for electrochemical compression that demonstrate improved durability under high-pressure differentials.

Technical Comparison of Electrochemical and Mechanical Compression Solutions

01 Electrochemical hydrogen compression systems

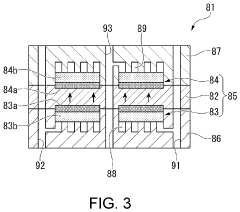

Electrochemical hydrogen compression systems utilize electrochemical cells to compress hydrogen without mechanical moving parts. These systems typically employ proton exchange membranes or solid oxide electrolysis cells to transport hydrogen ions across a membrane, effectively compressing the hydrogen gas. This approach offers advantages such as high efficiency, silent operation, and the ability to achieve high compression ratios with fewer stages compared to mechanical compressors.- Electrochemical hydrogen compression systems: Electrochemical hydrogen compression systems utilize electrochemical cells to compress hydrogen without mechanical moving parts. These systems typically employ proton exchange membranes (PEM) to transport hydrogen ions across an electrolyte barrier, allowing for compression through electrochemical potential rather than mechanical force. This approach offers advantages including higher efficiency at certain operating conditions, reduced maintenance requirements, and the ability to achieve high compression ratios with lower energy input compared to conventional mechanical systems.

- Mechanical hydrogen compression technologies: Mechanical hydrogen compression technologies encompass various systems that use mechanical force to increase hydrogen pressure. These include reciprocating piston compressors, diaphragm compressors, and centrifugal compressors specifically designed for hydrogen gas. These systems typically employ multiple compression stages to achieve high pressure ratios while managing the heat generated during compression. Advanced mechanical compression systems incorporate specialized materials and sealing technologies to address hydrogen's unique properties, including its small molecular size and potential for embrittlement of certain metals.

- Hybrid compression systems combining electrochemical and mechanical methods: Hybrid hydrogen compression systems integrate both electrochemical and mechanical compression technologies to optimize efficiency across different operating conditions. These systems typically use electrochemical compression for initial pressure buildup and mechanical compression for achieving final high pressures. The hybrid approach leverages the advantages of each technology: electrochemical compression's higher efficiency at lower pressure differentials and mechanical compression's effectiveness at higher pressures. This combination can result in overall system efficiency improvements while reducing energy consumption compared to single-technology approaches.

- Efficiency optimization techniques for hydrogen compression: Various techniques have been developed to optimize the efficiency of hydrogen compression systems. These include multi-stage compression with intercooling to manage heat generation, advanced control systems that adjust operation based on demand and input conditions, and energy recovery systems that capture and reuse compression heat. Other approaches focus on optimizing membrane materials in electrochemical systems to reduce internal resistance, developing specialized lubricants for mechanical compressors that minimize hydrogen interaction, and implementing variable speed drives to match compression power to actual demand requirements.

- Novel hydrogen storage and compression integration: Innovative approaches integrate hydrogen compression directly with storage systems to improve overall efficiency. These technologies include metal hydride compression systems that use thermally-driven hydrogen absorption and desorption processes, liquid organic hydrogen carrier systems that chemically bind and release hydrogen, and advanced composite pressure vessels designed to optimize the compression-storage interface. By closely integrating compression and storage functions, these systems reduce energy losses associated with intermediate steps and can achieve higher overall system efficiency while potentially reducing infrastructure complexity and cost.

02 Mechanical hydrogen compression technologies

Mechanical hydrogen compression technologies include various types of compressors such as reciprocating, diaphragm, and centrifugal designs specifically optimized for hydrogen gas. These systems use mechanical energy to reduce the volume of hydrogen gas, thereby increasing its pressure. Key innovations focus on specialized materials and sealing technologies to prevent hydrogen embrittlement and leakage, as well as multi-stage compression designs to achieve high pressure ratios while managing temperature increases during compression.Expand Specific Solutions03 Hybrid compression systems combining electrochemical and mechanical methods

Hybrid hydrogen compression systems integrate both electrochemical and mechanical compression technologies to maximize efficiency and overcome limitations of individual approaches. These systems typically use electrochemical compression for initial stages to efficiently achieve moderate pressure levels, followed by mechanical compression for final high-pressure stages. This combination leverages the high efficiency of electrochemical compression at lower pressures while utilizing mechanical compression's strengths at higher pressures, resulting in overall improved system efficiency and reliability.Expand Specific Solutions04 Efficiency enhancement techniques for hydrogen compression

Various techniques have been developed to enhance the efficiency of hydrogen compression processes. These include advanced heat management systems that recover compression heat, optimized compression staging with intercooling, improved membrane materials for electrochemical compression, and specialized lubricants and sealing technologies for mechanical compressors. Additional innovations focus on pressure swing adsorption integration, energy recovery systems, and smart control algorithms that optimize compression parameters based on operating conditions to maximize overall efficiency.Expand Specific Solutions05 Novel hydrogen storage and compression integration

Innovative approaches integrate hydrogen compression directly with storage systems to improve overall efficiency and reduce energy losses. These technologies include metal hydride compression systems that use thermally-driven absorption and desorption processes, liquid organic hydrogen carrier systems with integrated compression functionality, and advanced composite pressure vessels with built-in compression mechanisms. By combining compression and storage functions, these systems reduce energy requirements, minimize hydrogen losses, and improve the volumetric and gravimetric efficiency of the entire hydrogen handling process.Expand Specific Solutions

Key Industry Players in Hydrogen Compression Market

The hydrogen compression technology landscape is evolving rapidly, with electrochemical and mechanical compression methods competing in a market currently transitioning from early adoption to growth phase. The global hydrogen compression market is projected to expand significantly as hydrogen gains importance in clean energy transitions. Technologically, companies demonstrate varying maturity levels: established industrial players like Bosch, Panasonic, and Hyundai are advancing mechanical compression, while specialized firms such as Plug Power, GRZ Technologies, and Skyre lead electrochemical innovation. Automotive manufacturers (Honda, Hyundai, Kia) are increasingly investing in hydrogen compression technologies to support fuel cell vehicle ecosystems, while research institutions like CEA and academic partners contribute fundamental advancements that bridge current technical limitations in both compression approaches.

Ergosup SA

Technical Solution: Ergosup has developed an innovative electrochemical hydrogen compression technology based on a zinc-based redox process. Their unique approach utilizes a two-step electrochemical cycle: first, hydrogen is absorbed during the charging phase through zinc reduction in an alkaline electrolyte; subsequently, hydrogen is released at elevated pressure during the discharge phase. This process enables compression ratios exceeding 200:1 without mechanical components. Ergosup's system can deliver hydrogen at pressures up to 350 bar directly from the electrochemical cell, with energy efficiency approximately 20-30% higher than conventional mechanical compression methods at equivalent pressure outputs. The technology incorporates proprietary electrode materials and cell designs that optimize the zinc-hydrogen interaction while minimizing degradation mechanisms. Their systems are particularly effective for distributed hydrogen production and storage applications, where the integrated compression capability eliminates the need for separate mechanical compression equipment.

Strengths: Exceptionally high compression ratios achievable in a single electrochemical stage; integrated storage functionality provides buffer capacity; elimination of mechanical components reduces maintenance requirements; system operates with minimal noise and vibration. Weaknesses: Cyclical batch process rather than continuous flow operation; zinc electrode degradation over extended cycling requires periodic maintenance; limited maximum throughput capacity compared to industrial-scale mechanical compressors.

Plug Power, Inc.

Technical Solution: Plug Power has developed advanced electrochemical hydrogen compression (EHC) systems that utilize proton exchange membrane (PEM) technology. Their approach integrates electrochemical compression directly with fuel cell systems, creating a more efficient hydrogen delivery pathway. The technology operates by applying voltage across a PEM, causing hydrogen protons to migrate through the membrane while electrons flow through an external circuit. This process effectively compresses hydrogen without mechanical moving parts. Plug Power's systems achieve compression ratios exceeding 100:1 while maintaining high purity levels (>99.999%). Their integrated systems can compress hydrogen from near-atmospheric pressure to over 700 bar for vehicle refueling applications, with energy consumption approximately 30-40% lower than conventional mechanical compressors when operating at equivalent throughput rates.

Strengths: Zero mechanical wear components significantly reduce maintenance requirements and increase system reliability; operates silently with minimal vibration; delivers ultra-high purity hydrogen without oil contamination risks; scalable design allows for modular deployment. Weaknesses: Higher upfront capital costs compared to mechanical systems; membrane degradation over time can impact efficiency; limited maximum throughput capacity compared to large industrial mechanical compressors.

Core Patents and Innovations in Hydrogen Compression

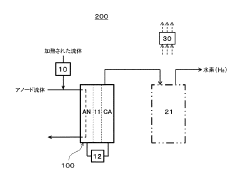

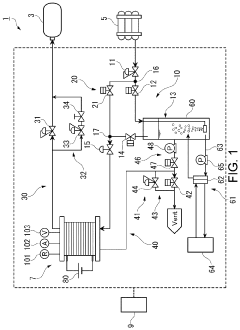

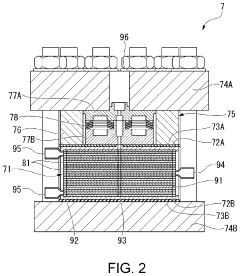

Electrochemical hydrogen compression system

PatentInactiveJP2020090695A

Innovation

- An electrochemical hydrogen compression system that includes a proton conductive electrolyte membrane with a cathode and anode, a voltage applicer, a feeder to supply heated fluid to the anode, and a controller to manage the fluid supply, optimizing cell heating during start-up and hydrogen boosting operations.

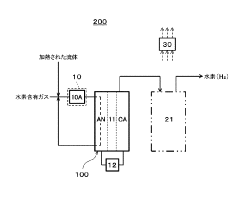

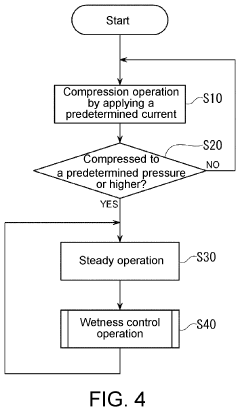

Electrochemical hydrogen compression system

PatentActiveUS11872526B2

Innovation

- An electrochemical hydrogen compression system that includes a control device to regulate the discharge of hydrogen based on the wet state of the electrolyte film, using a humidifier and distribution pipelines to maintain a uniform wet state across unit cells, ensuring optimal proton conductivity and energy efficiency.

Energy Efficiency Analysis of Compression Technologies

Energy efficiency represents a critical metric in evaluating hydrogen compression technologies, particularly when comparing electrochemical and mechanical approaches. Mechanical compression systems, which have dominated industrial applications for decades, typically operate with efficiency ranges of 65-75% for multi-stage compressors. These systems experience significant energy losses primarily through heat generation during the compression process, mechanical friction in moving parts, and gas leakage through seals.

In contrast, electrochemical hydrogen compression (EHC) demonstrates theoretical efficiency advantages, with laboratory-scale systems achieving efficiencies of 80-90% under optimal conditions. This superior performance stems from the fundamentally different compression mechanism that eliminates many mechanical losses. EHC systems convert electrical energy directly into compression work through electrochemical reactions, bypassing the thermodynamic limitations inherent in mechanical compression cycles.

The energy consumption profile across different pressure ranges reveals notable distinctions between these technologies. Mechanical compressors exhibit declining efficiency as compression ratios increase, requiring disproportionately more energy to achieve higher pressures. For instance, compression from 30 bar to 700 bar typically demands 3-4 kWh/kg H₂ in optimized mechanical systems. EHC systems maintain more consistent efficiency across pressure ranges, with energy requirements scaling more linearly with pressure increases.

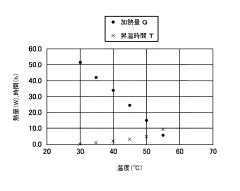

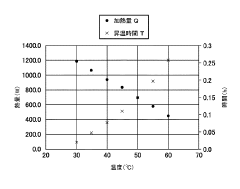

Temperature dependency further differentiates these technologies. Mechanical compressors generate significant heat during operation, necessitating intercooling systems that add complexity and energy overhead. EHC systems operate at lower temperatures and exhibit better isothermal characteristics, reducing cooling requirements and associated energy expenditures. However, this advantage diminishes at very high throughput rates where heat management becomes challenging even for electrochemical systems.

Scale effects significantly impact relative efficiency. Mechanical compression benefits from economies of scale, with large industrial compressors achieving better efficiency than smaller units. EHC technology currently demonstrates optimal efficiency at smaller scales but faces challenges in maintaining performance advantages when scaled to industrial capacities exceeding 100 kg/day.

Recent advancements in materials science have improved both technologies' efficiency profiles. Advanced polymer membranes with enhanced proton conductivity have boosted EHC efficiency by 15-20% over the past decade. Similarly, computational fluid dynamics optimization and advanced materials in mechanical compressors have yielded 8-12% efficiency improvements through reduced friction and better thermal management.

In contrast, electrochemical hydrogen compression (EHC) demonstrates theoretical efficiency advantages, with laboratory-scale systems achieving efficiencies of 80-90% under optimal conditions. This superior performance stems from the fundamentally different compression mechanism that eliminates many mechanical losses. EHC systems convert electrical energy directly into compression work through electrochemical reactions, bypassing the thermodynamic limitations inherent in mechanical compression cycles.

The energy consumption profile across different pressure ranges reveals notable distinctions between these technologies. Mechanical compressors exhibit declining efficiency as compression ratios increase, requiring disproportionately more energy to achieve higher pressures. For instance, compression from 30 bar to 700 bar typically demands 3-4 kWh/kg H₂ in optimized mechanical systems. EHC systems maintain more consistent efficiency across pressure ranges, with energy requirements scaling more linearly with pressure increases.

Temperature dependency further differentiates these technologies. Mechanical compressors generate significant heat during operation, necessitating intercooling systems that add complexity and energy overhead. EHC systems operate at lower temperatures and exhibit better isothermal characteristics, reducing cooling requirements and associated energy expenditures. However, this advantage diminishes at very high throughput rates where heat management becomes challenging even for electrochemical systems.

Scale effects significantly impact relative efficiency. Mechanical compression benefits from economies of scale, with large industrial compressors achieving better efficiency than smaller units. EHC technology currently demonstrates optimal efficiency at smaller scales but faces challenges in maintaining performance advantages when scaled to industrial capacities exceeding 100 kg/day.

Recent advancements in materials science have improved both technologies' efficiency profiles. Advanced polymer membranes with enhanced proton conductivity have boosted EHC efficiency by 15-20% over the past decade. Similarly, computational fluid dynamics optimization and advanced materials in mechanical compressors have yielded 8-12% efficiency improvements through reduced friction and better thermal management.

Safety and Regulatory Framework for Hydrogen Systems

The safety and regulatory framework for hydrogen systems represents a critical aspect when evaluating hydrogen compression technologies, particularly when comparing electrochemical and mechanical methods. Hydrogen's unique properties—including its wide flammability range, low ignition energy, and high diffusivity—necessitate comprehensive safety protocols and regulatory compliance measures across the hydrogen value chain.

International standards organizations have developed specific guidelines for hydrogen systems, with ISO/TC 197 and IEC/TC 105 providing foundational frameworks for safety requirements. These standards address design specifications, material compatibility, risk assessment methodologies, and operational procedures for hydrogen compression technologies. Notably, mechanical compression systems fall under more established regulatory frameworks due to their longer history in industrial applications.

Electrochemical compression introduces distinct safety considerations compared to mechanical alternatives. The absence of moving parts in electrochemical systems significantly reduces mechanical failure risks and potential leak points, offering inherent safety advantages. However, these systems present unique challenges related to membrane degradation, electrical safety, and potential hydrogen embrittlement of materials, requiring specialized regulatory approaches not fully addressed in existing frameworks.

Regulatory bodies worldwide have established varying requirements for hydrogen compression technologies. The European Union's Pressure Equipment Directive (PED) and ATEX Directive govern mechanical compression systems, while electrochemical systems must additionally comply with electrical safety standards. In the United States, the Department of Energy and OSHA have established guidelines for hydrogen systems, with NFPA 2 (Hydrogen Technologies Code) providing comprehensive safety provisions for both compression methodologies.

Risk assessment methodologies differ significantly between the two compression technologies. Mechanical systems require thorough evaluation of vibration, noise, lubrication contamination, and high-pressure containment risks. Electrochemical systems demand assessment of electrical hazards, membrane integrity, and potential chemical interactions. Both technologies must address common concerns including hydrogen leakage detection, ventilation requirements, and emergency shutdown protocols.

Certification processes for hydrogen compression equipment involve rigorous testing and validation. While mechanical compression systems benefit from established certification pathways, electrochemical compression technologies often face regulatory gaps requiring case-by-case assessment. This regulatory uncertainty represents a significant barrier to widespread commercial adoption of electrochemical compression, despite its potential safety advantages in certain applications.

Future regulatory developments are likely to evolve toward performance-based standards rather than prescriptive requirements, potentially benefiting innovative technologies like electrochemical compression. Harmonization efforts across international jurisdictions aim to establish consistent safety frameworks that accommodate both established and emerging hydrogen compression technologies while maintaining rigorous safety standards.

International standards organizations have developed specific guidelines for hydrogen systems, with ISO/TC 197 and IEC/TC 105 providing foundational frameworks for safety requirements. These standards address design specifications, material compatibility, risk assessment methodologies, and operational procedures for hydrogen compression technologies. Notably, mechanical compression systems fall under more established regulatory frameworks due to their longer history in industrial applications.

Electrochemical compression introduces distinct safety considerations compared to mechanical alternatives. The absence of moving parts in electrochemical systems significantly reduces mechanical failure risks and potential leak points, offering inherent safety advantages. However, these systems present unique challenges related to membrane degradation, electrical safety, and potential hydrogen embrittlement of materials, requiring specialized regulatory approaches not fully addressed in existing frameworks.

Regulatory bodies worldwide have established varying requirements for hydrogen compression technologies. The European Union's Pressure Equipment Directive (PED) and ATEX Directive govern mechanical compression systems, while electrochemical systems must additionally comply with electrical safety standards. In the United States, the Department of Energy and OSHA have established guidelines for hydrogen systems, with NFPA 2 (Hydrogen Technologies Code) providing comprehensive safety provisions for both compression methodologies.

Risk assessment methodologies differ significantly between the two compression technologies. Mechanical systems require thorough evaluation of vibration, noise, lubrication contamination, and high-pressure containment risks. Electrochemical systems demand assessment of electrical hazards, membrane integrity, and potential chemical interactions. Both technologies must address common concerns including hydrogen leakage detection, ventilation requirements, and emergency shutdown protocols.

Certification processes for hydrogen compression equipment involve rigorous testing and validation. While mechanical compression systems benefit from established certification pathways, electrochemical compression technologies often face regulatory gaps requiring case-by-case assessment. This regulatory uncertainty represents a significant barrier to widespread commercial adoption of electrochemical compression, despite its potential safety advantages in certain applications.

Future regulatory developments are likely to evolve toward performance-based standards rather than prescriptive requirements, potentially benefiting innovative technologies like electrochemical compression. Harmonization efforts across international jurisdictions aim to establish consistent safety frameworks that accommodate both established and emerging hydrogen compression technologies while maintaining rigorous safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!