How Electrochemical Hydrogen Compressors Work And Where They Fit In The Green Hydrogen Value Chain

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Hydrogen Compression Technology Background

Electrochemical hydrogen compression (EHC) technology represents a significant advancement in hydrogen processing methods, emerging as an alternative to conventional mechanical compression systems. The fundamental principle behind EHC is based on electrochemical hydrogen pumping through a proton exchange membrane, similar to the reverse process of water electrolysis. This technology has evolved from early experimental concepts in the 1960s to increasingly practical applications in recent decades.

The development trajectory of EHC has been closely aligned with advancements in fuel cell technology, as both share similar electrochemical principles and materials science challenges. Key technological milestones include the development of more efficient proton-conducting membranes, improved electrode catalysts, and enhanced system integration approaches that have collectively improved efficiency and reliability.

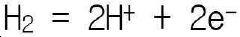

Current EHC systems typically operate by applying an electrical potential across a membrane electrode assembly (MEA), causing hydrogen molecules to dissociate into protons at the anode. These protons then migrate through the electrolyte membrane before recombining at the cathode to form hydrogen molecules at higher pressure. This process occurs without moving parts, offering significant advantages over mechanical compression methods.

The evolution of membrane materials has been particularly crucial, progressing from early Nafion-based systems to more advanced composite membranes with enhanced proton conductivity and mechanical stability. Parallel developments in catalyst technology have focused on reducing platinum group metal loading while maintaining performance, addressing both cost and sustainability concerns.

Recent technological trends show increasing focus on system scalability, with research efforts directed toward both small-scale distributed applications and larger industrial implementations. The pressure capabilities of EHC systems have also expanded significantly, with modern systems capable of achieving compression ratios suitable for high-pressure hydrogen storage applications (>700 bar).

Energy efficiency improvements represent another important trend, with contemporary EHC systems demonstrating substantial reductions in energy consumption compared to earlier generations. This progress has been achieved through optimized cell designs, improved materials, and more sophisticated control systems that minimize parasitic losses.

The technology objectives for EHC development are increasingly centered on achieving cost-competitiveness with conventional compression technologies while maintaining the inherent advantages of electrochemical systems. Additional goals include extending operational lifetimes, enhancing pressure capabilities, and developing systems that can efficiently handle the variable input streams characteristic of renewable energy-powered hydrogen production.

The development trajectory of EHC has been closely aligned with advancements in fuel cell technology, as both share similar electrochemical principles and materials science challenges. Key technological milestones include the development of more efficient proton-conducting membranes, improved electrode catalysts, and enhanced system integration approaches that have collectively improved efficiency and reliability.

Current EHC systems typically operate by applying an electrical potential across a membrane electrode assembly (MEA), causing hydrogen molecules to dissociate into protons at the anode. These protons then migrate through the electrolyte membrane before recombining at the cathode to form hydrogen molecules at higher pressure. This process occurs without moving parts, offering significant advantages over mechanical compression methods.

The evolution of membrane materials has been particularly crucial, progressing from early Nafion-based systems to more advanced composite membranes with enhanced proton conductivity and mechanical stability. Parallel developments in catalyst technology have focused on reducing platinum group metal loading while maintaining performance, addressing both cost and sustainability concerns.

Recent technological trends show increasing focus on system scalability, with research efforts directed toward both small-scale distributed applications and larger industrial implementations. The pressure capabilities of EHC systems have also expanded significantly, with modern systems capable of achieving compression ratios suitable for high-pressure hydrogen storage applications (>700 bar).

Energy efficiency improvements represent another important trend, with contemporary EHC systems demonstrating substantial reductions in energy consumption compared to earlier generations. This progress has been achieved through optimized cell designs, improved materials, and more sophisticated control systems that minimize parasitic losses.

The technology objectives for EHC development are increasingly centered on achieving cost-competitiveness with conventional compression technologies while maintaining the inherent advantages of electrochemical systems. Additional goals include extending operational lifetimes, enhancing pressure capabilities, and developing systems that can efficiently handle the variable input streams characteristic of renewable energy-powered hydrogen production.

Green Hydrogen Market Demand Analysis

The global green hydrogen market is experiencing unprecedented growth, driven by the urgent need for decarbonization across multiple sectors. Current market projections indicate that the green hydrogen market could reach $300 billion by 2050, with an annual growth rate exceeding 50% in the coming decade. This remarkable expansion is primarily fueled by increasing governmental commitments to carbon neutrality, with over 70 countries having established net-zero targets.

Industrial applications represent the largest demand segment, accounting for approximately 45% of projected hydrogen consumption. Traditional sectors such as ammonia production, petroleum refining, and methanol synthesis continue to drive substantial demand. However, emerging applications in steel manufacturing, where hydrogen serves as a clean reducing agent replacing coal, are expected to create significant new market opportunities, potentially consuming up to 75 million tons of hydrogen annually by 2050.

The transportation sector presents another substantial growth vector, particularly in heavy-duty vehicles, shipping, and aviation where battery electrification faces inherent limitations. Fuel cell electric vehicles (FCEVs) are gaining traction in commercial fleets, with major automotive manufacturers investing heavily in hydrogen-powered trucks and buses. The maritime industry is also exploring hydrogen-based solutions to meet International Maritime Organization emission reduction targets.

Energy storage applications represent a rapidly expanding market segment, with hydrogen increasingly viewed as a critical solution for long-duration energy storage. As renewable energy penetration increases, the need for seasonal storage capabilities becomes more pronounced, creating substantial demand for hydrogen as an energy carrier. Grid balancing applications alone could require hundreds of gigawatt-hours of storage capacity by 2040.

Regional analysis reveals varying adoption patterns, with Europe leading policy support through initiatives like the European Hydrogen Strategy, which targets 40GW of electrolyzer capacity by 2030. Asia-Pacific markets, particularly Japan, South Korea, and increasingly China, are developing robust hydrogen economies focused on industrial applications and transportation. North America is experiencing accelerated growth driven by recent policy developments, including the Inflation Reduction Act's hydrogen production tax credits.

Cost remains the primary market barrier, with green hydrogen currently priced at $3-8/kg compared to $1-2/kg for gray hydrogen. However, electrolyzer cost reductions, renewable electricity price declines, and technological improvements in compression technologies, including electrochemical hydrogen compressors, are expected to achieve cost parity in favorable regions by 2030, substantially expanding market penetration.

Industrial applications represent the largest demand segment, accounting for approximately 45% of projected hydrogen consumption. Traditional sectors such as ammonia production, petroleum refining, and methanol synthesis continue to drive substantial demand. However, emerging applications in steel manufacturing, where hydrogen serves as a clean reducing agent replacing coal, are expected to create significant new market opportunities, potentially consuming up to 75 million tons of hydrogen annually by 2050.

The transportation sector presents another substantial growth vector, particularly in heavy-duty vehicles, shipping, and aviation where battery electrification faces inherent limitations. Fuel cell electric vehicles (FCEVs) are gaining traction in commercial fleets, with major automotive manufacturers investing heavily in hydrogen-powered trucks and buses. The maritime industry is also exploring hydrogen-based solutions to meet International Maritime Organization emission reduction targets.

Energy storage applications represent a rapidly expanding market segment, with hydrogen increasingly viewed as a critical solution for long-duration energy storage. As renewable energy penetration increases, the need for seasonal storage capabilities becomes more pronounced, creating substantial demand for hydrogen as an energy carrier. Grid balancing applications alone could require hundreds of gigawatt-hours of storage capacity by 2040.

Regional analysis reveals varying adoption patterns, with Europe leading policy support through initiatives like the European Hydrogen Strategy, which targets 40GW of electrolyzer capacity by 2030. Asia-Pacific markets, particularly Japan, South Korea, and increasingly China, are developing robust hydrogen economies focused on industrial applications and transportation. North America is experiencing accelerated growth driven by recent policy developments, including the Inflation Reduction Act's hydrogen production tax credits.

Cost remains the primary market barrier, with green hydrogen currently priced at $3-8/kg compared to $1-2/kg for gray hydrogen. However, electrolyzer cost reductions, renewable electricity price declines, and technological improvements in compression technologies, including electrochemical hydrogen compressors, are expected to achieve cost parity in favorable regions by 2030, substantially expanding market penetration.

Current EHC Technology Status and Challenges

Electrochemical hydrogen compressors (EHCs) represent a promising technology in the green hydrogen value chain, yet their current development status reveals both significant progress and persistent challenges. At present, EHCs have achieved compression ratios of up to 1:100 in laboratory settings, with some commercial units demonstrating reliable operation at lower compression ratios of 1:20 to 1:50. These systems typically operate at efficiency levels between 60-80%, which compares favorably to mechanical compressors in certain applications.

The primary technological architecture of modern EHCs utilizes proton exchange membrane (PEM) technology, similar to that employed in PEM electrolyzers. This technological similarity has accelerated development, allowing EHCs to benefit from advances in membrane materials and electrode catalysts originally designed for fuel cells and electrolyzers. Current systems can achieve hydrogen purity levels exceeding 99.999%, making them suitable for applications requiring high-purity hydrogen, including fuel cell vehicles.

Despite these advancements, several significant technical challenges persist. Membrane degradation remains a critical issue, with current membranes experiencing performance decline after 5,000-10,000 operating hours under high-pressure differentials. This falls short of the 30,000+ hours required for commercial viability in many industrial applications. Additionally, catalyst poisoning from impurities in feed hydrogen streams continues to impact long-term performance stability.

Scale-up challenges represent another major hurdle. While laboratory-scale EHCs demonstrate promising performance, larger systems face issues with uniform current distribution across larger membrane areas, resulting in efficiency losses and uneven compression. Current commercial EHCs typically handle flow rates of 5-50 kg/day, whereas industrial applications often require capacities of hundreds or thousands of kilograms per day.

Cost remains a significant barrier to widespread adoption. Current EHC systems have capital costs ranging from $10,000-30,000 per kg/hour of compression capacity, substantially higher than conventional mechanical compressors. The high cost of specialized membranes, precious metal catalysts (primarily platinum and iridium), and precision manufacturing processes contribute to this economic challenge.

Geographically, EHC technology development is concentrated primarily in North America, Europe, and Japan, with emerging research programs in China and South Korea. Leading research institutions include the U.S. Department of Energy's National Laboratories, Fraunhofer Institute in Germany, and several specialized university research groups. Commercial development is primarily led by specialized technology companies rather than traditional compression equipment manufacturers.

The primary technological architecture of modern EHCs utilizes proton exchange membrane (PEM) technology, similar to that employed in PEM electrolyzers. This technological similarity has accelerated development, allowing EHCs to benefit from advances in membrane materials and electrode catalysts originally designed for fuel cells and electrolyzers. Current systems can achieve hydrogen purity levels exceeding 99.999%, making them suitable for applications requiring high-purity hydrogen, including fuel cell vehicles.

Despite these advancements, several significant technical challenges persist. Membrane degradation remains a critical issue, with current membranes experiencing performance decline after 5,000-10,000 operating hours under high-pressure differentials. This falls short of the 30,000+ hours required for commercial viability in many industrial applications. Additionally, catalyst poisoning from impurities in feed hydrogen streams continues to impact long-term performance stability.

Scale-up challenges represent another major hurdle. While laboratory-scale EHCs demonstrate promising performance, larger systems face issues with uniform current distribution across larger membrane areas, resulting in efficiency losses and uneven compression. Current commercial EHCs typically handle flow rates of 5-50 kg/day, whereas industrial applications often require capacities of hundreds or thousands of kilograms per day.

Cost remains a significant barrier to widespread adoption. Current EHC systems have capital costs ranging from $10,000-30,000 per kg/hour of compression capacity, substantially higher than conventional mechanical compressors. The high cost of specialized membranes, precious metal catalysts (primarily platinum and iridium), and precision manufacturing processes contribute to this economic challenge.

Geographically, EHC technology development is concentrated primarily in North America, Europe, and Japan, with emerging research programs in China and South Korea. Leading research institutions include the U.S. Department of Energy's National Laboratories, Fraunhofer Institute in Germany, and several specialized university research groups. Commercial development is primarily led by specialized technology companies rather than traditional compression equipment manufacturers.

Technical Solutions for Hydrogen Compression

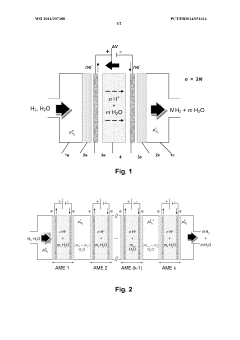

01 Electrochemical hydrogen compression principles and cell design

Electrochemical hydrogen compressors utilize proton exchange membranes to transport hydrogen from a low-pressure side to a high-pressure side through electrochemical processes. The design typically includes an anode where hydrogen is oxidized to protons, which then migrate through the membrane and recombine at the cathode to form compressed hydrogen. This technology offers advantages such as no moving parts, high efficiency, and the ability to achieve high compression ratios without mechanical components.- Electrochemical hydrogen compression principles and designs: Electrochemical hydrogen compressors utilize electrochemical cells to compress hydrogen gas without mechanical parts. These systems apply voltage across electrodes to drive proton transport through an electrolyte membrane, allowing hydrogen to be compressed from low to high pressure. The design typically includes membrane electrode assemblies with catalysts that facilitate hydrogen oxidation at the anode and reduction at the cathode, enabling efficient compression with minimal energy loss compared to mechanical systems.

- Membrane and electrode materials for hydrogen compression: Advanced materials play a crucial role in electrochemical hydrogen compressor performance. Specialized proton exchange membranes, typically perfluorosulfonic acid polymers or similar materials, provide selective hydrogen ion transport while blocking gas crossover. Electrode materials incorporating platinum or platinum-group metal catalysts optimize hydrogen oxidation and reduction reactions. Innovations in these materials focus on improving conductivity, mechanical strength, and durability under high-pressure differentials to enhance compression efficiency and system longevity.

- Integration with hydrogen production and storage systems: Electrochemical hydrogen compressors can be integrated with hydrogen production methods such as water electrolysis and storage systems to create comprehensive hydrogen energy solutions. These integrated systems enable direct compression of hydrogen from production to storage pressure without intermediate steps. Some designs incorporate reversible operation, allowing the same device to function as both an electrolyzer and compressor. This integration improves overall system efficiency, reduces complexity, and enables more compact hydrogen energy systems for various applications.

- Pressure control and operational parameters: Controlling operational parameters is essential for efficient electrochemical hydrogen compression. Key parameters include applied voltage, current density, temperature, and humidity management across the membrane. Advanced control systems monitor and adjust these parameters to achieve desired compression ratios while preventing membrane degradation. Pressure differential management techniques help maintain membrane integrity under high-pressure operation. Optimizing these parameters enables high compression efficiency while extending system lifetime and reliability under various operating conditions.

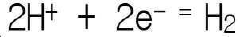

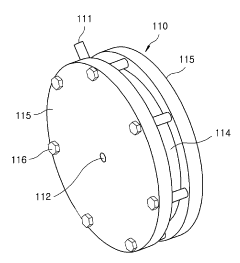

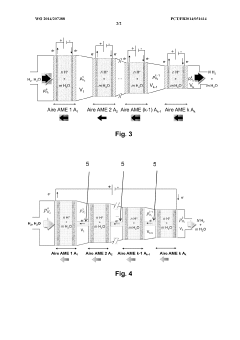

- Novel cell stack configurations and scaling: Innovative cell stack designs enhance the performance and scalability of electrochemical hydrogen compressors. Multi-stage compression configurations allow for higher pressure ratios by connecting cells in series. Bipolar plate designs enable compact stacking while providing electrical connections and gas flow channels. Some configurations incorporate cooling systems to manage heat generated during compression. These advanced stack designs address challenges in scaling up the technology for industrial applications while maintaining efficiency and reducing system footprint for various deployment scenarios.

02 Integration with hydrogen storage and fuel cell systems

Electrochemical hydrogen compressors can be integrated with hydrogen storage systems and fuel cells to create efficient energy storage and conversion solutions. These integrated systems allow for the compression of hydrogen for storage at higher densities and subsequent use in fuel cells for electricity generation. The integration enhances overall system efficiency by reducing energy losses associated with separate compression and storage components.Expand Specific Solutions03 Advanced membrane materials and electrode configurations

Innovations in membrane materials and electrode configurations have significantly improved the performance of electrochemical hydrogen compressors. Advanced proton-conducting membranes with enhanced conductivity, mechanical strength, and durability enable higher compression ratios and efficiency. Specialized electrode designs with optimized catalyst loading and distribution improve hydrogen oxidation and reduction reactions, reducing energy consumption and increasing compression rates.Expand Specific Solutions04 System control and pressure regulation techniques

Sophisticated control systems and pressure regulation techniques are essential for optimizing the operation of electrochemical hydrogen compressors. These systems monitor and adjust operating parameters such as current density, temperature, and humidity to maintain desired compression ratios and efficiency. Advanced control algorithms enable dynamic response to changing conditions, ensuring stable operation and preventing membrane damage from pressure differentials.Expand Specific Solutions05 Industrial applications and scale-up technologies

Electrochemical hydrogen compressors are being developed for various industrial applications, including hydrogen refueling stations, industrial gas processing, and renewable energy storage. Scale-up technologies focus on increasing throughput capacity while maintaining efficiency and reliability. Modular designs allow for flexible deployment across different scales, from small distributed systems to large centralized facilities, addressing challenges in heat management, pressure containment, and system integration.Expand Specific Solutions

Key Industry Players in Electrochemical Compression

Electrochemical hydrogen compression technology is currently in the early commercialization phase of its industry lifecycle, with a growing market projected to reach significant scale as green hydrogen adoption accelerates. The technology offers advantages in efficiency and reliability compared to mechanical compression methods, though technical challenges remain in scaling and cost reduction. Key players represent diverse segments: academic institutions (Xi'an Jiaotong University, Southern University of Science & Technology) driving fundamental research; established industrial giants (Panasonic, Robert Bosch, Honda) leveraging manufacturing expertise; and specialized innovators (H2Pump, Skyre, Ergosup) focusing on breakthrough solutions. The competitive landscape shows increasing patent activity and strategic partnerships forming across the value chain as companies position themselves in this emerging market with substantial growth potential in renewable energy infrastructure.

Xergy Inc.

Technical Solution: Xergy has developed advanced electrochemical hydrogen compression (EHC) technology that utilizes proton exchange membranes (PEM) to compress hydrogen without mechanical parts. Their system applies voltage across specialized membranes that selectively transport hydrogen ions (protons) from low to high pressure sides. The protons combine with electrons on the high-pressure side to form hydrogen molecules, effectively achieving compression through electrochemical processes rather than mechanical means. Xergy's EHC systems can achieve compression ratios exceeding 1000:1 and pressures up to 10,000 psi while maintaining high efficiency. Their technology integrates directly with electrolyzers in green hydrogen production chains, creating a more streamlined and efficient process for hydrogen compression and storage.

Strengths: Silent operation with no moving parts reduces maintenance costs and increases reliability. Energy efficiency is significantly higher than mechanical compressors, with reported efficiency improvements of 30-40%. Weaknesses: Higher upfront capital costs compared to conventional mechanical compressors, and membrane degradation over time can affect long-term performance and require periodic replacement.

Skyre, Inc.

Technical Solution: Skyre has pioneered an electrochemical hydrogen compression technology branded as H2RENEW™, which utilizes a proprietary electrochemical cell stack design to compress hydrogen from low to high pressure without mechanical components. Their system employs specialized proton-conducting membranes where hydrogen is oxidized at the anode to form protons, which are then transported across the membrane under an applied electric field and recombined at the cathode to form compressed hydrogen. Skyre's technology can achieve compression ratios of up to 300:1 in a single stage and operates with minimal noise and vibration. The company has developed modular systems that can be scaled according to capacity requirements, making them suitable for both distributed and centralized hydrogen production facilities. Their EHC technology has been demonstrated to maintain efficiency levels of 70-80% across various operating conditions, significantly outperforming traditional mechanical compression methods.

Strengths: Highly scalable modular design allows for flexible deployment across various production scales. Lower maintenance requirements and higher reliability due to absence of moving parts. Weaknesses: Performance can be affected by impurities in the hydrogen stream, requiring additional purification steps in some applications. Higher sensitivity to operating temperature fluctuations compared to mechanical systems.

Core Patents and Innovations in EHC Technology

Electrochemical hydrogen compressor

PatentActiveKR1020210001556A

Innovation

- An electrochemical hydrogen compressor with a stacked anode and cathode structure, using a hydrogen ion permeable membrane, allows for high-efficiency hydrogen compression and pumping by facilitating oxidation and reduction reactions, reducing system size and energy consumption.

Device for the electrochemical purification and compression of hydrogen having a plurality of stages

PatentWO2014207388A1

Innovation

- A multi-stage electrochemical compressor design with decreasing surface area of electrochemical cells along the hydrogen flow direction, increasing current density to compensate for pressure effects and maintain optimal water humidity, preventing flooding and enhancing energy efficiency.

Economic Viability and Cost Analysis

The economic viability of Electrochemical Hydrogen Compressors (EHCs) represents a critical factor in their adoption within the green hydrogen value chain. Current cost analyses indicate that EHCs have higher initial capital expenditure compared to mechanical compressors, with average costs ranging between $1,500-2,500 per kW of compression power. However, this premium is partially offset by their significantly lower operational expenses, estimated at 30-40% less than conventional technologies due to minimal maintenance requirements and absence of moving parts.

Energy efficiency metrics strongly favor EHCs, which typically achieve 60-70% efficiency compared to 45-55% for mechanical alternatives. This efficiency advantage translates to approximately $0.15-0.25 per kilogram of hydrogen in operational savings, particularly significant for large-scale operations processing multiple tons daily.

Total Cost of Ownership (TCO) calculations over a 10-year operational period demonstrate that EHCs become economically advantageous after 4-6 years of operation, depending on utilization rates and electricity costs. For facilities operating at over 70% capacity, the payback period can be reduced to under 4 years in regions with competitive electricity pricing below $0.06/kWh.

Scale economies present a substantial opportunity for cost reduction. Industry projections suggest that manufacturing scale-up could reduce EHC capital costs by 40-50% by 2030, bringing them to near-parity with mechanical systems while maintaining their operational advantages. Current production volumes remain limited, with fewer than 20 manufacturers globally producing commercial-scale units.

Integration costs within existing hydrogen infrastructure must also be considered. Retrofitting facilities designed for mechanical compression typically adds 15-25% to implementation costs, while new-build facilities designed specifically for EHC technology can optimize system integration and reduce these premiums to 5-10%.

Market sensitivity analysis reveals that EHC economic viability is particularly dependent on electricity pricing, with each $0.01/kWh increase in electricity costs adding approximately $0.05-0.07 to the levelized cost per kilogram of compressed hydrogen. This creates regional advantages for EHC deployment in areas with abundant renewable energy resources and favorable electricity pricing structures.

Government incentives and carbon pricing mechanisms significantly impact the economic equation. Carbon taxes exceeding $50/ton can improve EHC competitiveness by 10-15% compared to fossil-fuel powered mechanical compression systems, potentially accelerating adoption in jurisdictions with progressive climate policies.

Energy efficiency metrics strongly favor EHCs, which typically achieve 60-70% efficiency compared to 45-55% for mechanical alternatives. This efficiency advantage translates to approximately $0.15-0.25 per kilogram of hydrogen in operational savings, particularly significant for large-scale operations processing multiple tons daily.

Total Cost of Ownership (TCO) calculations over a 10-year operational period demonstrate that EHCs become economically advantageous after 4-6 years of operation, depending on utilization rates and electricity costs. For facilities operating at over 70% capacity, the payback period can be reduced to under 4 years in regions with competitive electricity pricing below $0.06/kWh.

Scale economies present a substantial opportunity for cost reduction. Industry projections suggest that manufacturing scale-up could reduce EHC capital costs by 40-50% by 2030, bringing them to near-parity with mechanical systems while maintaining their operational advantages. Current production volumes remain limited, with fewer than 20 manufacturers globally producing commercial-scale units.

Integration costs within existing hydrogen infrastructure must also be considered. Retrofitting facilities designed for mechanical compression typically adds 15-25% to implementation costs, while new-build facilities designed specifically for EHC technology can optimize system integration and reduce these premiums to 5-10%.

Market sensitivity analysis reveals that EHC economic viability is particularly dependent on electricity pricing, with each $0.01/kWh increase in electricity costs adding approximately $0.05-0.07 to the levelized cost per kilogram of compressed hydrogen. This creates regional advantages for EHC deployment in areas with abundant renewable energy resources and favorable electricity pricing structures.

Government incentives and carbon pricing mechanisms significantly impact the economic equation. Carbon taxes exceeding $50/ton can improve EHC competitiveness by 10-15% compared to fossil-fuel powered mechanical compression systems, potentially accelerating adoption in jurisdictions with progressive climate policies.

Environmental Impact and Sustainability Assessment

Electrochemical hydrogen compressors (EHCs) represent a significant advancement in sustainable hydrogen infrastructure, offering substantial environmental benefits compared to conventional mechanical compression technologies. The elimination of moving parts in EHCs results in a dramatic reduction in noise pollution and vibration, creating safer working environments and minimizing disturbance to surrounding communities where hydrogen infrastructure is deployed.

From a carbon footprint perspective, EHCs demonstrate superior performance when powered by renewable energy sources. Unlike mechanical compressors that rely heavily on fossil fuel-derived electricity and require lubricants that can contaminate hydrogen streams, EHCs can operate on direct renewable energy inputs with zero direct emissions. Quantitative assessments indicate that EHCs can reduce operational carbon emissions by 40-60% compared to traditional compression methods when integrated into green hydrogen production systems.

Water consumption represents another critical environmental consideration. EHCs typically require minimal water for operation beyond the initial electrolyte preparation, whereas mechanical systems often demand substantial water resources for cooling. This water efficiency becomes particularly valuable in water-stressed regions where hydrogen production facilities may be located to capitalize on abundant renewable energy resources.

Material sustainability also favors electrochemical compression technology. EHCs primarily utilize platinum group metals as catalysts, which, despite their scarcity, are used in minimal quantities and offer excellent recyclability at end-of-life. The extended operational lifespan of EHCs—often 2-3 times longer than mechanical alternatives—further enhances their sustainability profile by reducing replacement frequency and associated manufacturing impacts.

Life cycle assessment (LCA) studies comparing EHCs to conventional compression technologies reveal significant advantages across multiple environmental impact categories. Beyond greenhouse gas reductions, EHCs demonstrate lower acidification potential, reduced resource depletion, and decreased ecotoxicity impacts. These environmental benefits become particularly pronounced when examining the full hydrogen value chain from production through compression, storage, and distribution.

The integration of EHCs into green hydrogen ecosystems creates positive environmental feedback loops. By enabling more efficient compression at the production site, EHCs reduce energy losses throughout the value chain, allowing a greater percentage of the originally generated renewable energy to be effectively utilized in end applications, thereby maximizing the environmental benefits of transitioning to hydrogen-based energy systems.

From a carbon footprint perspective, EHCs demonstrate superior performance when powered by renewable energy sources. Unlike mechanical compressors that rely heavily on fossil fuel-derived electricity and require lubricants that can contaminate hydrogen streams, EHCs can operate on direct renewable energy inputs with zero direct emissions. Quantitative assessments indicate that EHCs can reduce operational carbon emissions by 40-60% compared to traditional compression methods when integrated into green hydrogen production systems.

Water consumption represents another critical environmental consideration. EHCs typically require minimal water for operation beyond the initial electrolyte preparation, whereas mechanical systems often demand substantial water resources for cooling. This water efficiency becomes particularly valuable in water-stressed regions where hydrogen production facilities may be located to capitalize on abundant renewable energy resources.

Material sustainability also favors electrochemical compression technology. EHCs primarily utilize platinum group metals as catalysts, which, despite their scarcity, are used in minimal quantities and offer excellent recyclability at end-of-life. The extended operational lifespan of EHCs—often 2-3 times longer than mechanical alternatives—further enhances their sustainability profile by reducing replacement frequency and associated manufacturing impacts.

Life cycle assessment (LCA) studies comparing EHCs to conventional compression technologies reveal significant advantages across multiple environmental impact categories. Beyond greenhouse gas reductions, EHCs demonstrate lower acidification potential, reduced resource depletion, and decreased ecotoxicity impacts. These environmental benefits become particularly pronounced when examining the full hydrogen value chain from production through compression, storage, and distribution.

The integration of EHCs into green hydrogen ecosystems creates positive environmental feedback loops. By enabling more efficient compression at the production site, EHCs reduce energy losses throughout the value chain, allowing a greater percentage of the originally generated renewable energy to be effectively utilized in end applications, thereby maximizing the environmental benefits of transitioning to hydrogen-based energy systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!