Electrochemical Hydrogen Compressor Performance Metrics And Benchmarks

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EHC Technology Background and Objectives

Electrochemical hydrogen compression (EHC) technology represents a paradigm shift in hydrogen processing, offering a solid-state alternative to conventional mechanical compression methods. The evolution of this technology can be traced back to the early 1990s, when researchers began exploring proton exchange membrane (PEM) systems for hydrogen compression applications. Over the subsequent decades, significant advancements in materials science, electrochemistry, and system integration have propelled EHC from laboratory curiosity to commercial viability.

The fundamental principle of EHC leverages electrochemical potential to drive hydrogen across a membrane, eliminating the need for moving parts and mechanical compression stages. This approach offers inherent advantages in reliability, noise reduction, and potential efficiency gains, particularly at higher compression ratios. The technology shares core principles with PEM fuel cells and electrolyzers, benefiting from cross-pollination of research advances in these adjacent fields.

Current technological trends in EHC development focus on several key areas: membrane material optimization to enhance proton conductivity while reducing gas crossover; catalyst development to improve electrochemical efficiency and reduce precious metal loading; and system architecture innovations to address thermal management and pressure differential challenges. The convergence of these research streams has accelerated in the past five years, with notable breakthroughs in composite membrane structures and non-platinum catalyst formulations.

The primary technical objectives for advancing EHC technology center on performance metrics that define commercial viability. These include achieving compression ratios exceeding 700:1 (from atmospheric to 700+ bar), energy efficiency improvements to below 3 kWh/kg H₂ at high compression ratios, durability extending beyond 20,000 operating hours, and significant cost reductions to compete with conventional mechanical compression systems. Secondary objectives include miniaturization for distributed applications and integration capabilities with renewable energy sources.

From an industrial perspective, EHC technology aims to address critical bottlenecks in the hydrogen value chain, particularly in the context of the emerging hydrogen economy. The ability to efficiently compress hydrogen at the point of use or production represents a key enabler for applications ranging from hydrogen refueling stations to industrial processes and energy storage systems.

The trajectory of EHC development is increasingly aligned with global decarbonization initiatives, with particular emphasis on enabling cost-effective green hydrogen infrastructure. As such, the technology's evolution is now being shaped not only by technical considerations but also by policy frameworks, investment patterns, and emerging market demands across the clean energy landscape.

The fundamental principle of EHC leverages electrochemical potential to drive hydrogen across a membrane, eliminating the need for moving parts and mechanical compression stages. This approach offers inherent advantages in reliability, noise reduction, and potential efficiency gains, particularly at higher compression ratios. The technology shares core principles with PEM fuel cells and electrolyzers, benefiting from cross-pollination of research advances in these adjacent fields.

Current technological trends in EHC development focus on several key areas: membrane material optimization to enhance proton conductivity while reducing gas crossover; catalyst development to improve electrochemical efficiency and reduce precious metal loading; and system architecture innovations to address thermal management and pressure differential challenges. The convergence of these research streams has accelerated in the past five years, with notable breakthroughs in composite membrane structures and non-platinum catalyst formulations.

The primary technical objectives for advancing EHC technology center on performance metrics that define commercial viability. These include achieving compression ratios exceeding 700:1 (from atmospheric to 700+ bar), energy efficiency improvements to below 3 kWh/kg H₂ at high compression ratios, durability extending beyond 20,000 operating hours, and significant cost reductions to compete with conventional mechanical compression systems. Secondary objectives include miniaturization for distributed applications and integration capabilities with renewable energy sources.

From an industrial perspective, EHC technology aims to address critical bottlenecks in the hydrogen value chain, particularly in the context of the emerging hydrogen economy. The ability to efficiently compress hydrogen at the point of use or production represents a key enabler for applications ranging from hydrogen refueling stations to industrial processes and energy storage systems.

The trajectory of EHC development is increasingly aligned with global decarbonization initiatives, with particular emphasis on enabling cost-effective green hydrogen infrastructure. As such, the technology's evolution is now being shaped not only by technical considerations but also by policy frameworks, investment patterns, and emerging market demands across the clean energy landscape.

Hydrogen Compression Market Analysis

The global hydrogen compression market is experiencing significant growth, driven by the increasing adoption of hydrogen as a clean energy carrier across various industries. As of 2023, the market is valued at approximately 2.1 billion USD, with projections indicating a compound annual growth rate (CAGR) of 5.8% through 2030. This growth trajectory is primarily fueled by the expanding hydrogen infrastructure development worldwide, particularly in regions committed to decarbonization targets.

The market segmentation reveals distinct application sectors, with industrial processes currently dominating at 45% market share, followed by refining (30%), transportation (15%), and emerging applications (10%). Geographically, Asia-Pacific leads with 38% market share, followed by Europe (32%), North America (22%), and rest of the world (8%). Europe's position is strengthening rapidly due to aggressive hydrogen strategy implementation across the EU.

Traditional mechanical compression technologies currently dominate the market with approximately 85% share, while electrochemical hydrogen compression (EHC) represents a growing segment at 8%, with the remainder comprised of other emerging technologies. The EHC segment is projected to grow at a significantly higher rate of 12.3% annually, outpacing conventional technologies due to its superior efficiency and operational advantages.

Key market drivers include the global push for decarbonization, increasing hydrogen fueling infrastructure development, and growing industrial demand for high-purity compressed hydrogen. Government initiatives worldwide are providing substantial funding for hydrogen infrastructure, with the EU's Hydrogen Strategy allocating 430 billion EUR through 2030 and the US Department of Energy committing 8 billion USD for hydrogen hubs.

Market challenges include high capital costs for compression equipment, with EHC systems currently commanding a 30-40% premium over mechanical alternatives. Infrastructure limitations and technological maturity issues also present barriers to widespread adoption. The cost of hydrogen compression represents approximately 10-15% of the total hydrogen production and distribution cost chain.

Customer requirements are evolving toward higher efficiency, reduced energy consumption, and improved reliability. End-users increasingly demand compression solutions with lower maintenance requirements, smaller footprints, and the ability to handle variable hydrogen flow rates – all areas where EHC technology demonstrates competitive advantages over conventional mechanical compression methods.

The market segmentation reveals distinct application sectors, with industrial processes currently dominating at 45% market share, followed by refining (30%), transportation (15%), and emerging applications (10%). Geographically, Asia-Pacific leads with 38% market share, followed by Europe (32%), North America (22%), and rest of the world (8%). Europe's position is strengthening rapidly due to aggressive hydrogen strategy implementation across the EU.

Traditional mechanical compression technologies currently dominate the market with approximately 85% share, while electrochemical hydrogen compression (EHC) represents a growing segment at 8%, with the remainder comprised of other emerging technologies. The EHC segment is projected to grow at a significantly higher rate of 12.3% annually, outpacing conventional technologies due to its superior efficiency and operational advantages.

Key market drivers include the global push for decarbonization, increasing hydrogen fueling infrastructure development, and growing industrial demand for high-purity compressed hydrogen. Government initiatives worldwide are providing substantial funding for hydrogen infrastructure, with the EU's Hydrogen Strategy allocating 430 billion EUR through 2030 and the US Department of Energy committing 8 billion USD for hydrogen hubs.

Market challenges include high capital costs for compression equipment, with EHC systems currently commanding a 30-40% premium over mechanical alternatives. Infrastructure limitations and technological maturity issues also present barriers to widespread adoption. The cost of hydrogen compression represents approximately 10-15% of the total hydrogen production and distribution cost chain.

Customer requirements are evolving toward higher efficiency, reduced energy consumption, and improved reliability. End-users increasingly demand compression solutions with lower maintenance requirements, smaller footprints, and the ability to handle variable hydrogen flow rates – all areas where EHC technology demonstrates competitive advantages over conventional mechanical compression methods.

Global EHC Development Status and Challenges

Electrochemical Hydrogen Compressors (EHCs) have gained significant attention globally as a promising alternative to mechanical compression technologies. Currently, the global development of EHCs is concentrated in North America, Europe, and parts of Asia, with varying degrees of technological maturity and commercial readiness.

In North America, companies like HyET Hydrogen and Skyre (formerly Sustainable Innovations) have made substantial progress in EHC technology development. The United States Department of Energy has been actively supporting research initiatives through programs like H2@Scale, focusing on improving efficiency and reducing costs of hydrogen compression technologies.

European countries, particularly Germany and the Netherlands, have established themselves as leaders in EHC research and development. Companies such as Hysilabs and research institutions like Fraunhofer Institute have been pioneering advanced membrane materials and system designs that demonstrate improved performance metrics compared to conventional technologies.

In Asia, Japan and South Korea are making significant investments in hydrogen infrastructure, including compression technologies, as part of their national hydrogen strategies. China has also recently increased its focus on hydrogen technologies, though their EHC development remains at an earlier stage compared to Western counterparts.

Despite these advancements, several critical challenges persist in the global EHC landscape. The most significant technical barrier remains the durability of membrane electrode assemblies (MEAs) under high-pressure differential conditions. Current systems typically experience performance degradation after 5,000-10,000 hours of operation, falling short of the 50,000+ hours required for commercial viability in industrial applications.

Energy efficiency represents another major challenge, with most current EHC systems operating at 60-70% efficiency, compared to the theoretical maximum of approximately 85-90%. This efficiency gap translates directly to higher operational costs and reduced economic competitiveness against conventional technologies.

Cost remains a substantial barrier to widespread adoption. Current EHC systems typically cost between $1,000-2,000/kW, significantly higher than the U.S. Department of Energy's target of $300/kW for hydrogen compression technologies. This cost premium is largely attributed to expensive materials, particularly platinum-based catalysts and specialized polymer membranes.

Scalability presents another challenge, as most successful demonstrations have been limited to small or medium-scale applications. Few systems have demonstrated the ability to compress hydrogen at the multi-ton daily capacity required for industrial applications while maintaining performance metrics.

In North America, companies like HyET Hydrogen and Skyre (formerly Sustainable Innovations) have made substantial progress in EHC technology development. The United States Department of Energy has been actively supporting research initiatives through programs like H2@Scale, focusing on improving efficiency and reducing costs of hydrogen compression technologies.

European countries, particularly Germany and the Netherlands, have established themselves as leaders in EHC research and development. Companies such as Hysilabs and research institutions like Fraunhofer Institute have been pioneering advanced membrane materials and system designs that demonstrate improved performance metrics compared to conventional technologies.

In Asia, Japan and South Korea are making significant investments in hydrogen infrastructure, including compression technologies, as part of their national hydrogen strategies. China has also recently increased its focus on hydrogen technologies, though their EHC development remains at an earlier stage compared to Western counterparts.

Despite these advancements, several critical challenges persist in the global EHC landscape. The most significant technical barrier remains the durability of membrane electrode assemblies (MEAs) under high-pressure differential conditions. Current systems typically experience performance degradation after 5,000-10,000 hours of operation, falling short of the 50,000+ hours required for commercial viability in industrial applications.

Energy efficiency represents another major challenge, with most current EHC systems operating at 60-70% efficiency, compared to the theoretical maximum of approximately 85-90%. This efficiency gap translates directly to higher operational costs and reduced economic competitiveness against conventional technologies.

Cost remains a substantial barrier to widespread adoption. Current EHC systems typically cost between $1,000-2,000/kW, significantly higher than the U.S. Department of Energy's target of $300/kW for hydrogen compression technologies. This cost premium is largely attributed to expensive materials, particularly platinum-based catalysts and specialized polymer membranes.

Scalability presents another challenge, as most successful demonstrations have been limited to small or medium-scale applications. Few systems have demonstrated the ability to compress hydrogen at the multi-ton daily capacity required for industrial applications while maintaining performance metrics.

Current EHC Performance Solutions and Metrics

01 Efficiency and energy consumption metrics

Electrochemical hydrogen compressors are evaluated based on their energy efficiency and consumption patterns. Key performance metrics include the ratio of energy input to compression output, power density, and specific energy consumption. These metrics help in assessing the operational costs and environmental impact of the compression process. Advanced monitoring systems can track real-time energy usage and identify optimization opportunities to improve overall efficiency.- Efficiency and energy consumption metrics: Electrochemical hydrogen compressors are evaluated based on their energy efficiency and consumption patterns. Key performance metrics include the energy required per unit of hydrogen compressed, conversion efficiency rates, and power density. These metrics help in comparing different compressor designs and optimizing operational parameters to reduce energy losses during the compression process.

- Pressure differential and compression ratio analysis: Performance of electrochemical hydrogen compressors is measured by their ability to achieve specific pressure differentials and compression ratios. Metrics include maximum achievable pressure, pressure ramp rates, and stability at various operating conditions. The compression ratio capabilities directly impact the applicability of these systems in various hydrogen storage and distribution applications.

- Durability and operational lifetime assessment: Longevity metrics for electrochemical hydrogen compressors include membrane degradation rates, electrode stability, and system component lifetime. Performance is evaluated through accelerated stress testing, cycle life assessment, and long-term operational stability under various conditions. These metrics help predict maintenance requirements and total cost of ownership for hydrogen compression systems.

- Hydrogen purity and cross-contamination metrics: The quality of compressed hydrogen is a critical performance parameter for electrochemical compressors. Metrics include hydrogen purity levels, cross-contamination rates, and impurity filtering capabilities. These measurements are essential for applications requiring high-purity hydrogen, such as fuel cells and certain industrial processes, where contaminants can significantly impact downstream system performance.

- System response and control performance: Operational responsiveness metrics evaluate how quickly and accurately electrochemical hydrogen compressors can adjust to changing demands. Parameters include start-up time, load-following capabilities, transient response characteristics, and control system precision. These metrics are particularly important for applications requiring dynamic operation or integration with intermittent renewable energy sources.

02 Pressure ratio and throughput performance

The pressure ratio (output pressure to input pressure) and hydrogen throughput are critical performance metrics for electrochemical hydrogen compressors. These parameters determine the compressor's ability to deliver hydrogen at required pressures for various applications. Measurement techniques include flow rate monitoring, pressure differential analysis, and compression cycle efficiency. Higher pressure ratios with maintained throughput indicate superior compressor performance.Expand Specific Solutions03 Membrane and electrode durability assessment

The longevity and reliability of electrochemical hydrogen compressors depend significantly on membrane and electrode durability. Performance metrics in this category include degradation rates, operational lifetime under various conditions, resistance to contaminants, and mechanical stability. Testing protocols involve accelerated stress tests, impedance spectroscopy, and post-operation analysis to evaluate material integrity and performance consistency over time.Expand Specific Solutions04 System response and control dynamics

The dynamic response characteristics of electrochemical hydrogen compressors are essential performance metrics, particularly for applications requiring variable output. These metrics include start-up time, response to load changes, control precision, and operational stability. Advanced control systems utilize real-time monitoring and predictive algorithms to optimize performance across varying conditions, ensuring consistent hydrogen delivery while maintaining efficiency.Expand Specific Solutions05 Purity and contamination metrics

The quality of compressed hydrogen is measured through purity levels and contamination metrics. Electrochemical hydrogen compressors must maintain high hydrogen purity while preventing cross-contamination. Performance indicators include impurity concentration measurements, filtration efficiency, and cross-over rates. Monitoring systems analyze gas composition at various stages of compression to ensure the final product meets application-specific purity requirements.Expand Specific Solutions

Leading EHC Technology Companies and Competitors

Electrochemical hydrogen compressor technology is currently in the early growth phase, with a global market estimated at $300-500 million and projected to expand significantly as hydrogen economies develop. The competitive landscape features established industrial players like Panasonic, Robert Bosch, and China Petroleum & Chemical Corp focusing on performance optimization, alongside specialized innovators such as Plug Power, H2gremm, and Skyre developing proprietary electrochemical compression technologies. Technical maturity varies considerably, with companies like DuPont contributing membrane materials expertise while research institutions including Xi'an Jiaotong University and Commissariat à l'énergie atomique are advancing fundamental electrochemical processes to improve efficiency, durability, and cost-effectiveness for commercial applications.

Commissariat à l´énergie atomique et aux énergies Alternatives

Technical Solution: The French Alternative Energies and Atomic Energy Commission (CEA) has developed advanced electrochemical hydrogen compression technology as part of their broader hydrogen energy research portfolio. Their approach utilizes sophisticated composite membranes with optimized ionic conductivity and mechanical properties to enable efficient hydrogen compression across a wide pressure range. The CEA's EHC system employs a multi-cell architecture with specialized flow field designs that minimize concentration polarization and enhance mass transport. Performance metrics demonstrate compression capabilities from atmospheric pressure to 700+ bar with energy consumption of approximately 2.4-3.0 kWh/kg H₂ compressed. Their technology features proprietary catalyst formulations that maintain high activity while resisting degradation under high differential pressure conditions. The system achieves faradaic efficiencies exceeding 95% across most operating conditions, with demonstrated durability exceeding 15,000 hours of operation under variable load profiles. CEA's research has particularly focused on optimizing the balance between compression efficiency and system durability through advanced materials development and precise control strategies.

Strengths: Exceptional materials science foundation resulting in highly durable components; sophisticated control systems enabling precise pressure regulation; integration capability with various hydrogen production methods; and extensive performance validation through rigorous laboratory and field testing protocols. Weaknesses: Higher system complexity requiring specialized maintenance expertise; relatively high manufacturing costs for advanced membrane materials; and more limited commercial deployment compared to established mechanical compression technologies.

H2gremm

Technical Solution: H2gremm has developed a specialized electrochemical hydrogen compression technology focused on small to medium-scale applications. Their system employs a proprietary membrane electrode assembly (MEA) design that optimizes the balance between proton conductivity, mechanical strength, and gas permeability. The H2gremm EHC technology operates on a multi-stage compression principle, where hydrogen is progressively compressed through a series of electrochemical cells, each contributing to the overall pressure increase. This staged approach allows for more efficient energy utilization across the compression range. Performance metrics indicate their system achieves compression ratios up to 500:1 with discharge pressures reaching 500 bar while maintaining specific energy consumption between 2.3-3.0 kWh/kg H₂. The technology demonstrates particularly strong performance in variable load applications, with rapid response times to changing input conditions and the ability to maintain high efficiency across a wide operating range (20-100% of rated capacity).

Strengths: Exceptional turndown ratio allowing efficient operation even at partial loads; compact form factor suitable for distributed hydrogen infrastructure; integrated thermal management system that recovers waste heat; and compatibility with various hydrogen sources including electrolyzers and reformers. Weaknesses: Limited maximum throughput capacity compared to industrial-scale mechanical compressors; higher sensitivity to input gas purity requiring additional upstream filtration; and relatively limited field deployment history affecting reliability data availability.

Critical Patents and Technical Literature on EHC

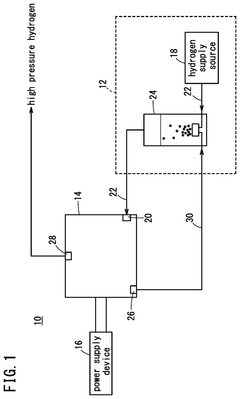

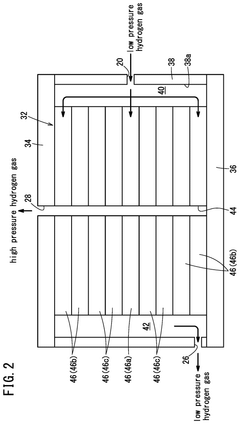

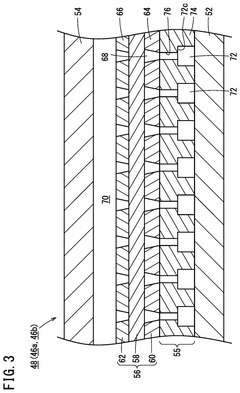

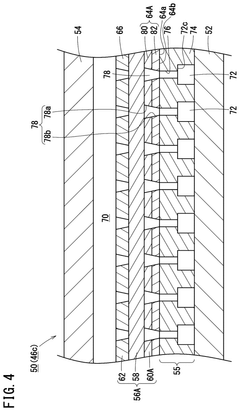

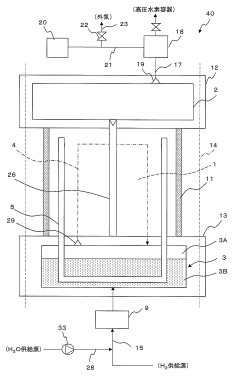

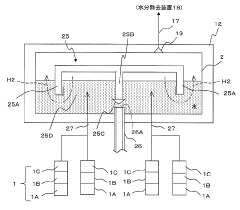

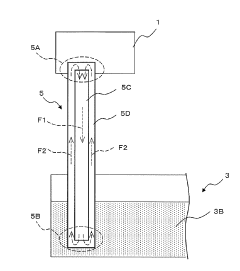

Electrochemical hydrogen compressor

PatentActiveUS12305305B2

Innovation

- The electrochemical hydrogen compressor incorporates an anode current collector made of hydrophilic conductive material with vent holes, where the surface facing the support member is subjected to water-repellent treatment, allowing for effective water retention and prevention of vent hole blockage.

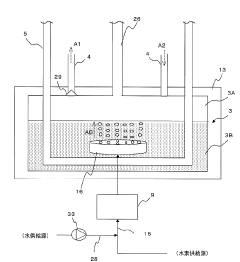

Electrochemical hydrogen compressor

PatentActiveJP2023022865A

Innovation

- The electrochemical hydrogen compressor integrates cell, bubbler, and water separator casings, eliminates external circulation systems, and uses a heat tube for self-cooling, reducing the need for pressure vessel standards and chillers, while allowing for compact cell stacking.

Energy Efficiency Benchmarking Methodologies

Establishing standardized energy efficiency benchmarking methodologies for Electrochemical Hydrogen Compressors (EHCs) is critical for meaningful performance comparisons across different technologies and manufacturers. The primary metric for EHC energy efficiency is typically expressed as kWh/kg H₂, representing the electrical energy consumed per kilogram of hydrogen compressed.

Current benchmarking approaches incorporate multiple testing conditions to ensure comprehensive evaluation. These include variable input pressures (typically 1-30 bar), output pressures (ranging from 350-700 bar for mobility applications), compression rates, and operating temperatures. Standard testing protocols require stabilized operation for minimum periods (typically 100-500 hours) to account for performance degradation over time.

The U.S. Department of Energy (DOE) has established target benchmarks for hydrogen compression efficiency, with current targets set at <1.6 kWh/kg H₂ for 350 bar compression and <2.0 kWh/kg H₂ for 700 bar compression. These targets serve as industry reference points against which new EHC technologies are evaluated.

Round-robin testing methodologies involving multiple independent laboratories have emerged as best practice for validating performance claims. This approach minimizes systematic errors and ensures reproducibility of results across different testing facilities, thereby increasing confidence in reported metrics.

Comparative benchmarking against mechanical compression technologies provides valuable context. While mechanical compressors typically achieve 2.5-3.5 kWh/kg H₂ for similar compression ratios, EHCs theoretically offer superior efficiency due to their isothermal compression characteristics. However, real-world EHC performance is often compromised by ohmic losses, membrane crossover, and other inefficiencies.

Life-cycle efficiency benchmarking has gained prominence, incorporating not only operational energy consumption but also manufacturing energy inputs and end-of-life considerations. This holistic approach provides a more comprehensive efficiency assessment, particularly relevant for emerging technologies with potentially high embodied energy costs.

Standardized testing conditions must account for hydrogen purity requirements, as impurities significantly impact EHC performance. Most benchmarking protocols now specify minimum inlet hydrogen purity (typically 99.97%) and measure outlet purity to ensure compression does not compromise gas quality for downstream applications.

Dynamic response benchmarking has recently been incorporated into evaluation frameworks, assessing how efficiently EHCs respond to variable loads and intermittent operation—critical factors for integration with renewable energy sources and demand-responsive hydrogen infrastructure.

Current benchmarking approaches incorporate multiple testing conditions to ensure comprehensive evaluation. These include variable input pressures (typically 1-30 bar), output pressures (ranging from 350-700 bar for mobility applications), compression rates, and operating temperatures. Standard testing protocols require stabilized operation for minimum periods (typically 100-500 hours) to account for performance degradation over time.

The U.S. Department of Energy (DOE) has established target benchmarks for hydrogen compression efficiency, with current targets set at <1.6 kWh/kg H₂ for 350 bar compression and <2.0 kWh/kg H₂ for 700 bar compression. These targets serve as industry reference points against which new EHC technologies are evaluated.

Round-robin testing methodologies involving multiple independent laboratories have emerged as best practice for validating performance claims. This approach minimizes systematic errors and ensures reproducibility of results across different testing facilities, thereby increasing confidence in reported metrics.

Comparative benchmarking against mechanical compression technologies provides valuable context. While mechanical compressors typically achieve 2.5-3.5 kWh/kg H₂ for similar compression ratios, EHCs theoretically offer superior efficiency due to their isothermal compression characteristics. However, real-world EHC performance is often compromised by ohmic losses, membrane crossover, and other inefficiencies.

Life-cycle efficiency benchmarking has gained prominence, incorporating not only operational energy consumption but also manufacturing energy inputs and end-of-life considerations. This holistic approach provides a more comprehensive efficiency assessment, particularly relevant for emerging technologies with potentially high embodied energy costs.

Standardized testing conditions must account for hydrogen purity requirements, as impurities significantly impact EHC performance. Most benchmarking protocols now specify minimum inlet hydrogen purity (typically 99.97%) and measure outlet purity to ensure compression does not compromise gas quality for downstream applications.

Dynamic response benchmarking has recently been incorporated into evaluation frameworks, assessing how efficiently EHCs respond to variable loads and intermittent operation—critical factors for integration with renewable energy sources and demand-responsive hydrogen infrastructure.

Regulatory Framework for Hydrogen Infrastructure

The regulatory landscape for hydrogen infrastructure is rapidly evolving as governments worldwide recognize hydrogen's potential in decarbonization strategies. In the United States, the Department of Energy (DOE) has established comprehensive guidelines for electrochemical hydrogen compressors (EHCs), mandating specific performance metrics including compression efficiency (minimum 65%), durability (>20,000 operating hours), and hydrogen purity (99.97% or higher). These standards are critical for ensuring EHC technologies meet industrial requirements while maintaining safety protocols.

The European Union has implemented more stringent regulatory frameworks through the European Hydrogen Strategy, which outlines performance benchmarks for hydrogen compression technologies. The EU mandates energy consumption metrics not exceeding 3 kWh/kg H₂ for low-pressure applications and 8 kWh/kg H₂ for high-pressure compression. Additionally, EU regulations require comprehensive lifecycle assessments for hydrogen infrastructure components, including EHCs, to ensure environmental sustainability across the value chain.

Safety standards represent a critical component of the regulatory framework, with organizations such as the International Organization for Standardization (ISO) developing specific protocols for hydrogen compression equipment. ISO 19880 series provides detailed guidelines for hydrogen fueling stations, including compression systems, while IEC 62282 addresses fuel cell technologies that interface with EHC systems. These standards establish minimum safety requirements, testing methodologies, and certification processes essential for commercial deployment.

Permitting processes for hydrogen infrastructure vary significantly across jurisdictions, creating challenges for widespread EHC implementation. Local authorities often require detailed performance data demonstrating compliance with noise limitations (typically <85 dB), emissions standards, and safety protocols. The fragmented nature of these requirements necessitates standardized testing methodologies for EHC performance metrics to facilitate regulatory approval processes.

Financial incentives and carbon pricing mechanisms increasingly influence the regulatory landscape for hydrogen technologies. Several countries have implemented subsidies for hydrogen infrastructure development contingent upon meeting specific performance benchmarks. For instance, Japan's hydrogen strategy offers financial support for compression technologies achieving energy efficiency improvements of at least 20% compared to conventional mechanical compressors, while maintaining comparable reliability metrics.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing greater flexibility in technological approaches while maintaining rigorous outcome metrics. This evolution supports innovation in EHC design while ensuring that fundamental performance benchmarks for efficiency, reliability, and safety remain central to regulatory compliance frameworks.

The European Union has implemented more stringent regulatory frameworks through the European Hydrogen Strategy, which outlines performance benchmarks for hydrogen compression technologies. The EU mandates energy consumption metrics not exceeding 3 kWh/kg H₂ for low-pressure applications and 8 kWh/kg H₂ for high-pressure compression. Additionally, EU regulations require comprehensive lifecycle assessments for hydrogen infrastructure components, including EHCs, to ensure environmental sustainability across the value chain.

Safety standards represent a critical component of the regulatory framework, with organizations such as the International Organization for Standardization (ISO) developing specific protocols for hydrogen compression equipment. ISO 19880 series provides detailed guidelines for hydrogen fueling stations, including compression systems, while IEC 62282 addresses fuel cell technologies that interface with EHC systems. These standards establish minimum safety requirements, testing methodologies, and certification processes essential for commercial deployment.

Permitting processes for hydrogen infrastructure vary significantly across jurisdictions, creating challenges for widespread EHC implementation. Local authorities often require detailed performance data demonstrating compliance with noise limitations (typically <85 dB), emissions standards, and safety protocols. The fragmented nature of these requirements necessitates standardized testing methodologies for EHC performance metrics to facilitate regulatory approval processes.

Financial incentives and carbon pricing mechanisms increasingly influence the regulatory landscape for hydrogen technologies. Several countries have implemented subsidies for hydrogen infrastructure development contingent upon meeting specific performance benchmarks. For instance, Japan's hydrogen strategy offers financial support for compression technologies achieving energy efficiency improvements of at least 20% compared to conventional mechanical compressors, while maintaining comparable reliability metrics.

Emerging regulatory trends indicate a shift toward performance-based standards rather than prescriptive requirements, allowing greater flexibility in technological approaches while maintaining rigorous outcome metrics. This evolution supports innovation in EHC design while ensuring that fundamental performance benchmarks for efficiency, reliability, and safety remain central to regulatory compliance frameworks.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!