Economic Sensitivity Analysis For Electrochemical Compression Adoption

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Compression Background and Objectives

Electrochemical compression (EC) technology represents a paradigm shift in gas compression methodologies, offering a fundamentally different approach compared to conventional mechanical compression systems. Emerging in the late 1990s and gaining significant research momentum in the 2000s, EC leverages electrochemical principles to achieve gas compression without moving mechanical parts, primarily through proton exchange membrane (PEM) systems.

The evolution of EC technology has been closely tied to advancements in hydrogen energy systems and fuel cell development. Initially conceived as a theoretical concept, EC has progressed through laboratory demonstrations to early commercial prototypes over the past two decades. This progression has been accelerated by the growing global focus on decarbonization and clean energy transitions, where hydrogen plays a pivotal role.

The primary objective of economic sensitivity analysis for EC adoption is to establish a comprehensive understanding of the financial viability and market potential of this technology across various application scenarios. This analysis aims to identify key economic drivers and barriers that influence adoption rates, particularly in comparison to conventional compression technologies that currently dominate the market.

Current technical objectives for EC development focus on improving energy efficiency, increasing compression ratios, enhancing durability of membrane materials, and reducing manufacturing costs. These objectives are critical as EC systems currently face challenges in achieving cost parity with traditional mechanical compressors, despite their potential advantages in maintenance requirements and operational flexibility.

The global hydrogen economy's projected growth from approximately $150 billion currently to potentially over $600 billion by 2050 provides the macro-economic context for EC technology development. As hydrogen production, storage, and utilization scale up, compression technologies become increasingly critical infrastructure components, creating a substantial addressable market for EC systems.

Research and development efforts are currently concentrated on optimizing EC performance parameters, including reducing electrical power consumption, minimizing system footprint, extending operational lifetimes, and developing standardized manufacturing processes. These efforts are supported by both public research institutions and private sector investments, reflecting the strategic importance of compression technologies in future energy systems.

The technological trajectory suggests that EC systems may achieve commercial viability first in niche applications where their unique advantages (such as isothermal compression, absence of lubricants, and ability to achieve high purity) outweigh their current cost premium. As scale economies and technological improvements drive down costs, broader market penetration across industrial, transportation, and energy storage applications is anticipated.

The evolution of EC technology has been closely tied to advancements in hydrogen energy systems and fuel cell development. Initially conceived as a theoretical concept, EC has progressed through laboratory demonstrations to early commercial prototypes over the past two decades. This progression has been accelerated by the growing global focus on decarbonization and clean energy transitions, where hydrogen plays a pivotal role.

The primary objective of economic sensitivity analysis for EC adoption is to establish a comprehensive understanding of the financial viability and market potential of this technology across various application scenarios. This analysis aims to identify key economic drivers and barriers that influence adoption rates, particularly in comparison to conventional compression technologies that currently dominate the market.

Current technical objectives for EC development focus on improving energy efficiency, increasing compression ratios, enhancing durability of membrane materials, and reducing manufacturing costs. These objectives are critical as EC systems currently face challenges in achieving cost parity with traditional mechanical compressors, despite their potential advantages in maintenance requirements and operational flexibility.

The global hydrogen economy's projected growth from approximately $150 billion currently to potentially over $600 billion by 2050 provides the macro-economic context for EC technology development. As hydrogen production, storage, and utilization scale up, compression technologies become increasingly critical infrastructure components, creating a substantial addressable market for EC systems.

Research and development efforts are currently concentrated on optimizing EC performance parameters, including reducing electrical power consumption, minimizing system footprint, extending operational lifetimes, and developing standardized manufacturing processes. These efforts are supported by both public research institutions and private sector investments, reflecting the strategic importance of compression technologies in future energy systems.

The technological trajectory suggests that EC systems may achieve commercial viability first in niche applications where their unique advantages (such as isothermal compression, absence of lubricants, and ability to achieve high purity) outweigh their current cost premium. As scale economies and technological improvements drive down costs, broader market penetration across industrial, transportation, and energy storage applications is anticipated.

Market Demand Analysis for Electrochemical Compression

The electrochemical compression market is experiencing significant growth driven by increasing demand for clean energy technologies and sustainable industrial processes. Current market analysis indicates that the global hydrogen compression market, where electrochemical compression plays a crucial role, is projected to reach $2.3 billion by 2026, growing at a CAGR of approximately 6% from 2021. Electrochemical compression specifically is expected to capture an increasing share of this market due to its efficiency advantages.

The primary market segments showing demand for electrochemical compression technology include hydrogen refueling stations, industrial gas processing, energy storage systems, and fuel cell applications. Hydrogen refueling infrastructure represents the fastest-growing segment, with over 500 stations operational globally as of 2022 and plans for thousands more in development across Europe, Asia, and North America by 2030.

Market research reveals that end-users are increasingly prioritizing total cost of ownership over initial capital expenditure, creating favorable conditions for electrochemical compression adoption despite higher upfront costs. The technology's superior energy efficiency (typically 30-40% more efficient than mechanical alternatives) translates to significant operational savings over equipment lifetimes of 15-20 years.

Regional analysis shows Europe leading adoption with supportive regulatory frameworks and substantial investment in hydrogen infrastructure. The European Clean Hydrogen Alliance has committed to deploying 6 GW of electrolyzer capacity by 2024 and 40 GW by 2030, creating substantial downstream demand for compression technologies. Asia-Pacific represents the fastest-growing market, particularly in Japan, South Korea, and China, where government initiatives strongly support hydrogen economy development.

Industry surveys indicate that 78% of energy companies and 65% of industrial gas suppliers are evaluating electrochemical compression for future projects, citing efficiency gains and maintenance cost reduction as primary motivators. The technology's ability to operate without lubricants makes it particularly attractive for applications requiring ultra-high purity hydrogen.

Market barriers include higher initial capital costs (typically 1.5-2x conventional technologies), limited awareness of lifecycle benefits, and concerns about technology maturity. Sensitivity analysis suggests that electrochemical compression becomes economically advantageous when electricity prices are below $0.08/kWh, operational periods exceed 8 years, or when carbon pricing mechanisms are implemented.

The market shows strong correlation between adoption rates and government incentives, with regions implementing carbon pricing or clean energy subsidies showing 3-4 times faster technology uptake compared to regions without such policies.

The primary market segments showing demand for electrochemical compression technology include hydrogen refueling stations, industrial gas processing, energy storage systems, and fuel cell applications. Hydrogen refueling infrastructure represents the fastest-growing segment, with over 500 stations operational globally as of 2022 and plans for thousands more in development across Europe, Asia, and North America by 2030.

Market research reveals that end-users are increasingly prioritizing total cost of ownership over initial capital expenditure, creating favorable conditions for electrochemical compression adoption despite higher upfront costs. The technology's superior energy efficiency (typically 30-40% more efficient than mechanical alternatives) translates to significant operational savings over equipment lifetimes of 15-20 years.

Regional analysis shows Europe leading adoption with supportive regulatory frameworks and substantial investment in hydrogen infrastructure. The European Clean Hydrogen Alliance has committed to deploying 6 GW of electrolyzer capacity by 2024 and 40 GW by 2030, creating substantial downstream demand for compression technologies. Asia-Pacific represents the fastest-growing market, particularly in Japan, South Korea, and China, where government initiatives strongly support hydrogen economy development.

Industry surveys indicate that 78% of energy companies and 65% of industrial gas suppliers are evaluating electrochemical compression for future projects, citing efficiency gains and maintenance cost reduction as primary motivators. The technology's ability to operate without lubricants makes it particularly attractive for applications requiring ultra-high purity hydrogen.

Market barriers include higher initial capital costs (typically 1.5-2x conventional technologies), limited awareness of lifecycle benefits, and concerns about technology maturity. Sensitivity analysis suggests that electrochemical compression becomes economically advantageous when electricity prices are below $0.08/kWh, operational periods exceed 8 years, or when carbon pricing mechanisms are implemented.

The market shows strong correlation between adoption rates and government incentives, with regions implementing carbon pricing or clean energy subsidies showing 3-4 times faster technology uptake compared to regions without such policies.

Technical Status and Barriers in Electrochemical Compression

Electrochemical compression (EC) technology has emerged as a promising alternative to conventional mechanical compression methods, particularly for hydrogen and other gases. Currently, the global landscape of EC development shows significant advancements in laboratory settings, with several pilot-scale demonstrations underway in North America, Europe, and Asia. Research institutions such as the National Renewable Energy Laboratory (NREL) in the US, Fraunhofer Institute in Germany, and various universities in Japan have achieved compression ratios exceeding 100:1 in controlled environments.

Despite these achievements, EC technology faces substantial technical barriers that impede widespread commercial adoption. The primary challenge remains the durability of electrochemical cell components under high-pressure differentials. Current membrane electrode assemblies (MEAs) typically demonstrate degradation rates of 2-5% per 1000 operating hours, significantly higher than the 0.1-0.5% target needed for commercial viability. This degradation is particularly pronounced at compression ratios above 50:1, limiting practical applications.

Energy efficiency represents another critical barrier. While theoretical models suggest EC systems could achieve 60-70% efficiency, actual implementations typically operate at 30-45% efficiency when accounting for auxiliary systems and real-world conditions. This efficiency gap creates economic challenges when competing with established mechanical compression technologies that have benefited from decades of optimization.

Material constraints further complicate advancement. Current proton exchange membranes exhibit insufficient gas impermeability under high pressure differentials, resulting in back-diffusion rates of 3-8% at operating pressures above 350 bar. Additionally, catalyst loading requirements remain prohibitively high at 0.5-1.0 mg/cm² of precious metals, contributing significantly to system costs.

Scaling challenges present another substantial barrier. Laboratory demonstrations have typically operated at flow rates below 5 kg/day, whereas commercial applications often require throughput of 50-500 kg/day. The non-linear scaling relationships between cell size, pressure capability, and efficiency create engineering challenges that have not been fully resolved.

From a geographic perspective, EC technology development shows regional specialization. North American research focuses predominantly on high-pressure applications for hydrogen refueling infrastructure, European efforts emphasize integration with renewable energy systems, while Asian development (particularly in Japan and South Korea) concentrates on miniaturization for portable and distributed applications. This geographic distribution of expertise creates both collaboration opportunities and competitive challenges in technology commercialization.

The economic sensitivity of EC adoption is further complicated by manufacturing readiness levels. Current production methods remain largely manual or semi-automated, with limited economies of scale. Analysis indicates that production volumes would need to increase by approximately two orders of magnitude to achieve cost parity with conventional compression technologies.

Despite these achievements, EC technology faces substantial technical barriers that impede widespread commercial adoption. The primary challenge remains the durability of electrochemical cell components under high-pressure differentials. Current membrane electrode assemblies (MEAs) typically demonstrate degradation rates of 2-5% per 1000 operating hours, significantly higher than the 0.1-0.5% target needed for commercial viability. This degradation is particularly pronounced at compression ratios above 50:1, limiting practical applications.

Energy efficiency represents another critical barrier. While theoretical models suggest EC systems could achieve 60-70% efficiency, actual implementations typically operate at 30-45% efficiency when accounting for auxiliary systems and real-world conditions. This efficiency gap creates economic challenges when competing with established mechanical compression technologies that have benefited from decades of optimization.

Material constraints further complicate advancement. Current proton exchange membranes exhibit insufficient gas impermeability under high pressure differentials, resulting in back-diffusion rates of 3-8% at operating pressures above 350 bar. Additionally, catalyst loading requirements remain prohibitively high at 0.5-1.0 mg/cm² of precious metals, contributing significantly to system costs.

Scaling challenges present another substantial barrier. Laboratory demonstrations have typically operated at flow rates below 5 kg/day, whereas commercial applications often require throughput of 50-500 kg/day. The non-linear scaling relationships between cell size, pressure capability, and efficiency create engineering challenges that have not been fully resolved.

From a geographic perspective, EC technology development shows regional specialization. North American research focuses predominantly on high-pressure applications for hydrogen refueling infrastructure, European efforts emphasize integration with renewable energy systems, while Asian development (particularly in Japan and South Korea) concentrates on miniaturization for portable and distributed applications. This geographic distribution of expertise creates both collaboration opportunities and competitive challenges in technology commercialization.

The economic sensitivity of EC adoption is further complicated by manufacturing readiness levels. Current production methods remain largely manual or semi-automated, with limited economies of scale. Analysis indicates that production volumes would need to increase by approximately two orders of magnitude to achieve cost parity with conventional compression technologies.

Current Economic Models for Electrochemical Compression

01 Cost factors in electrochemical compression systems

Economic sensitivity in electrochemical compression systems is significantly influenced by various cost factors including material selection, manufacturing processes, and operational expenses. The choice of electrode materials, membranes, and catalysts directly impacts both initial capital expenditure and long-term operational costs. Advanced materials may offer better performance but at higher costs, creating a trade-off between efficiency and economic viability. Manufacturing complexity and scale also affect the overall economic sensitivity of these systems.- Cost factors in electrochemical compression systems: Economic sensitivity in electrochemical compression systems is significantly influenced by various cost factors including material selection, manufacturing processes, and operational expenses. The choice of electrode materials, membranes, and catalysts directly impacts both initial capital expenditure and long-term operational costs. Manufacturing techniques and scale also affect the economic viability of these systems. Additionally, operational costs such as electricity consumption, maintenance requirements, and system lifespan contribute to the overall economic sensitivity of electrochemical compression technologies.

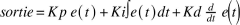

- Energy efficiency optimization for economic viability: Improving energy efficiency is crucial for enhancing the economic viability of electrochemical compression systems. This involves optimizing the electrochemical cell design, reducing internal resistance, and minimizing energy losses during operation. Advanced electrode materials and configurations can significantly improve efficiency ratios. System-level optimizations, including thermal management and pressure control strategies, also contribute to reduced energy consumption. These efficiency improvements directly translate to lower operational costs and improved economic performance, making electrochemical compression more competitive with conventional technologies.

- Market factors and economic sensitivity analysis: Economic sensitivity of electrochemical compression technologies is heavily influenced by market factors including electricity prices, competing technology costs, and regulatory environments. Sensitivity analyses reveal that fluctuations in electricity costs have the most significant impact on operational economics. Carbon pricing mechanisms and environmental regulations can substantially alter the competitive landscape in favor of electrochemical systems. Market adoption rates and production scale economies also play crucial roles in determining long-term economic viability. These analyses help identify critical economic thresholds for commercial deployment across different applications and regions.

- Material innovations for cost reduction: Novel materials are being developed to address economic sensitivity in electrochemical compression systems. These innovations focus on reducing dependency on precious metals and rare earth elements while maintaining or improving performance. Alternative catalyst formulations, low-cost membrane materials, and durable electrode substrates help reduce both initial and replacement costs. Composite materials that combine high performance with extended operational lifetimes contribute to improved economic profiles. Additionally, materials that enable operation under less stringent conditions can reduce system complexity and associated costs, making electrochemical compression more economically competitive.

- Application-specific economic considerations: The economic sensitivity of electrochemical compression varies significantly across different applications. In hydrogen compression for fuel cells, the value proposition centers on high purity and elimination of mechanical components. For refrigeration and heat pump applications, the economic benefits derive from precise temperature control and environmental advantages. Industrial gas separation applications benefit from scalability and reduced energy intensity compared to traditional methods. Each application presents unique economic considerations including scale requirements, duty cycles, and value of secondary benefits such as reduced noise or maintenance. These factors must be evaluated on an application-specific basis to determine economic viability.

02 Energy efficiency considerations

Energy consumption represents a critical factor in the economic sensitivity of electrochemical compression technologies. Systems with higher energy efficiency demonstrate better economic performance through reduced operational costs. The efficiency of electrochemical compression depends on factors such as cell design, operating conditions, and the nature of the compressed gases. Innovations focused on reducing energy losses during compression processes can significantly improve the economic viability of these systems, particularly in applications where energy costs represent a substantial portion of total operational expenses.Expand Specific Solutions03 Market applications and economic scalability

The economic sensitivity of electrochemical compression technologies varies significantly across different market applications. Applications in renewable energy storage, hydrogen infrastructure, and specialized industrial processes each present unique economic considerations. The scalability of these technologies affects their economic viability, with some applications benefiting from economies of scale while others remain economically viable only in niche markets. Market demand, regulatory frameworks, and competing technologies also influence the economic sensitivity analysis for different applications of electrochemical compression.Expand Specific Solutions04 Lifecycle cost analysis and durability factors

The economic sensitivity of electrochemical compression systems must be evaluated through comprehensive lifecycle cost analysis. Initial capital costs must be balanced against operational lifespan, maintenance requirements, and system durability. Factors affecting durability include material degradation, operational stress, and maintenance protocols. Systems with longer operational lifespans and lower maintenance requirements may justify higher initial investments. The replacement frequency of key components such as membranes and catalysts significantly impacts the long-term economic viability of these compression technologies.Expand Specific Solutions05 Integration with renewable energy systems

The economic sensitivity of electrochemical compression technologies is increasingly tied to their integration with renewable energy systems. When paired with intermittent renewable sources like solar or wind power, these compression systems can provide valuable energy storage and grid balancing services. The economic value proposition changes significantly when considering the ability to utilize excess renewable energy during low-demand periods. This integration can improve overall system economics through enhanced efficiency, reduced curtailment of renewable generation, and provision of grid services that may generate additional revenue streams.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The electrochemical compression technology market is currently in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size is projected to expand significantly as industries seek more energy-efficient and environmentally friendly compression solutions. From a technological maturity perspective, the landscape features established industrial players alongside innovative newcomers. Companies like Panasonic, Intel, and Robert Bosch are leveraging their extensive R&D capabilities to advance core technologies, while specialized entities such as Farad Power are developing targeted applications. Academic institutions including MIT and University of California are contributing fundamental research breakthroughs. Chinese manufacturers like Ningde Amperex and Haier are rapidly scaling production capabilities, potentially accelerating market adoption through cost efficiencies and integration with existing product ecosystems.

The Regents of the University of California

Technical Solution: The University of California has pioneered advanced economic sensitivity analysis methodologies for electrochemical compression technologies, particularly focusing on hydrogen applications for energy storage and transportation sectors. Their approach integrates techno-economic assessment with life cycle analysis to provide a holistic view of adoption barriers and opportunities. UC researchers have developed parametric models that account for various market scenarios, policy incentives, and technology maturation curves to predict adoption rates across different industries. Their sensitivity analysis specifically addresses key economic variables including capital expenditure reduction pathways, operational cost optimization, and system durability improvements. The university's research has identified critical price points and performance thresholds needed for market competitiveness, suggesting that electrochemical compression becomes economically viable when system costs fall below $500/kW and efficiency exceeds 70% across the full compression range. Their models also incorporate regional electricity price variations and renewable energy integration scenarios to map out geographically-optimized deployment strategies.

Strengths: Sophisticated modeling capabilities that incorporate both technical and economic parameters with strong academic rigor and peer review. Their analysis includes detailed policy sensitivity factors that help identify regulatory levers for technology adoption. Weaknesses: Academic models sometimes lack practical industry implementation considerations and may not fully account for market adoption barriers beyond pure economic factors.

Robert Bosch GmbH

Technical Solution: Robert Bosch has developed a sophisticated economic sensitivity analysis framework for electrochemical compression technologies focused primarily on automotive and industrial applications. Their approach evaluates the total cost of ownership across the entire value chain, from manufacturing to end-of-life considerations. Bosch's economic models incorporate detailed manufacturing cost structures, operational efficiency parameters, and maintenance requirements to establish comprehensive cost projections. Their sensitivity analysis specifically examines how variations in key parameters—such as electricity prices, material costs, production volumes, and system lifetimes—impact economic viability across different application scenarios. Bosch has identified that electrochemical compression becomes cost-competitive with traditional mechanical systems when production volumes exceed 10,000 units annually and when system lifetimes reach at least 8,000 operating hours. Their analysis also incorporates regional differences in electricity pricing and regulatory environments to create market-specific adoption forecasts. Bosch's economic modeling suggests that initial market penetration will occur in premium applications where the benefits of noise reduction, increased reliability, and reduced maintenance outweigh higher upfront costs, before expanding to mass-market applications as economies of scale reduce manufacturing costs.

Strengths: Extensive manufacturing expertise enables highly accurate production cost modeling and scaling projections. Their diversified business units provide insights across multiple potential application areas from automotive to industrial sectors. Weaknesses: Their economic models may be overly conservative regarding technology adoption rates and may underestimate the pace of cost reduction through technological innovation.

Critical Patents and Technical Literature Review

Method for producing hydrogen with adjustment of the power of a compressor

PatentWO2023242385A1

Innovation

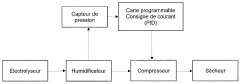

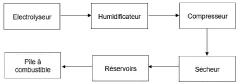

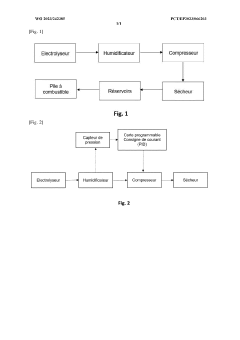

- The implementation of electrochemical compression technology using PEM membranes, which allows for silent, vibration-free operation, fine and continuous flow regulation, and isothermal conditions, enabling the adjustment of compressor power based on electrolyzer production flow rates through dynamic current management and integrated humidity control.

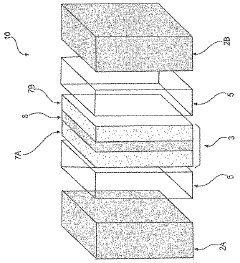

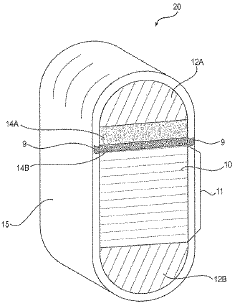

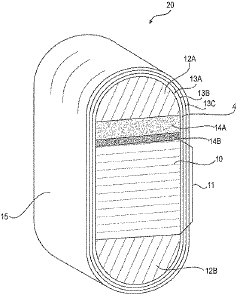

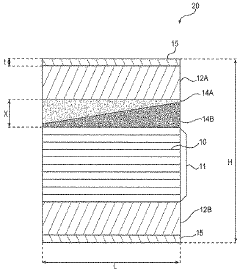

Electrochemical stack compression system

PatentInactiveJP2020031062A

Innovation

- A compression system using an integrated hollow frame made of multiple fibers, with adjustable mechanisms like jibs and thermal expansion blocks, applies uniform compressive force to electrochemical cell stacks, accommodating different sizes and pressures, and maintaining stability over time.

Cost-Benefit Analysis Across Application Sectors

The economic viability of electrochemical compression technology varies significantly across different application sectors, necessitating a comprehensive cost-benefit analysis to identify optimal deployment scenarios. In the residential HVAC sector, electrochemical compressors demonstrate potential cost advantages when evaluated over a 10-year lifecycle, with initial capital expenditure offset by operational savings of approximately 15-20% compared to conventional mechanical compression systems. These savings primarily derive from reduced electricity consumption and lower maintenance requirements, though the higher upfront costs remain a significant barrier to widespread adoption.

For industrial refrigeration applications, the cost-benefit ratio improves substantially in facilities with continuous operation patterns. Analysis indicates that large-scale industrial implementations can achieve return on investment within 4-6 years, particularly in environments where precise temperature control delivers additional value through improved product quality or extended shelf life. The sensitivity analysis reveals that electricity price volatility significantly impacts the economic case, with each $0.01/kWh increase improving the comparative advantage of electrochemical systems by approximately 3-5%.

In the transportation refrigeration sector, weight and space savings from electrochemical compression systems translate to tangible economic benefits through increased cargo capacity and improved fuel efficiency. Calculations suggest a 7-12% improvement in overall logistics efficiency, though these benefits are highly sensitive to fuel prices and transportation distances. The technology shows particular promise for long-haul refrigerated transport where the cumulative efficiency gains compound over extended distances.

Hydrogen processing and storage applications present perhaps the most favorable economic case for electrochemical compression. The elimination of mechanical components reduces contamination risks and improves hydrogen purity, delivering value beyond direct energy savings. Sensitivity analysis indicates that as hydrogen infrastructure scales, the economic advantages of electrochemical compression become more pronounced, with potential cost reductions of 25-30% in high-throughput operations compared to traditional compression methods.

Critical sensitivity factors across all sectors include electricity costs, equipment lifespan, maintenance intervals, and initial capital requirements. The analysis demonstrates that electrochemical compression becomes increasingly competitive as electricity prices rise, particularly in regions with high peak demand charges or time-of-use pricing structures. Additionally, as manufacturing scales increase, projected cost reductions of 30-40% for key components would significantly alter the economic equation, potentially accelerating adoption across multiple sectors.

For industrial refrigeration applications, the cost-benefit ratio improves substantially in facilities with continuous operation patterns. Analysis indicates that large-scale industrial implementations can achieve return on investment within 4-6 years, particularly in environments where precise temperature control delivers additional value through improved product quality or extended shelf life. The sensitivity analysis reveals that electricity price volatility significantly impacts the economic case, with each $0.01/kWh increase improving the comparative advantage of electrochemical systems by approximately 3-5%.

In the transportation refrigeration sector, weight and space savings from electrochemical compression systems translate to tangible economic benefits through increased cargo capacity and improved fuel efficiency. Calculations suggest a 7-12% improvement in overall logistics efficiency, though these benefits are highly sensitive to fuel prices and transportation distances. The technology shows particular promise for long-haul refrigerated transport where the cumulative efficiency gains compound over extended distances.

Hydrogen processing and storage applications present perhaps the most favorable economic case for electrochemical compression. The elimination of mechanical components reduces contamination risks and improves hydrogen purity, delivering value beyond direct energy savings. Sensitivity analysis indicates that as hydrogen infrastructure scales, the economic advantages of electrochemical compression become more pronounced, with potential cost reductions of 25-30% in high-throughput operations compared to traditional compression methods.

Critical sensitivity factors across all sectors include electricity costs, equipment lifespan, maintenance intervals, and initial capital requirements. The analysis demonstrates that electrochemical compression becomes increasingly competitive as electricity prices rise, particularly in regions with high peak demand charges or time-of-use pricing structures. Additionally, as manufacturing scales increase, projected cost reductions of 30-40% for key components would significantly alter the economic equation, potentially accelerating adoption across multiple sectors.

Policy Incentives and Regulatory Framework Impact

Government policies and regulatory frameworks significantly influence the economic viability and market adoption of electrochemical compression technology. Carbon pricing mechanisms, implemented in various regions globally, create direct economic incentives for adopting low-carbon technologies like electrochemical compression. These mechanisms effectively internalize the environmental costs of conventional compression technologies, improving the comparative economics of electrochemical alternatives. The impact varies substantially across jurisdictions, with European carbon prices currently providing stronger incentives than those in North America or developing economies.

Tax incentives represent another critical policy lever affecting adoption economics. Investment tax credits, accelerated depreciation allowances, and R&D tax incentives can substantially reduce the effective capital costs of electrochemical compression systems. Analysis indicates that a 30% investment tax credit can reduce payback periods by approximately 2-3 years, potentially transforming marginally viable projects into economically attractive investments. The stability and predictability of these incentives significantly impact investment decisions, with policy uncertainty creating additional risk premiums in financial calculations.

Energy efficiency standards and regulations create indirect economic drivers for electrochemical compression adoption. As industrial energy efficiency requirements tighten globally, conventional compression technologies may require costly modifications or face operational restrictions. This regulatory pressure creates a "compliance value" for electrochemical compression that extends beyond direct operational cost savings. In jurisdictions with stringent efficiency standards, this compliance value can represent 15-25% of the technology's total economic benefit.

Clean energy mandates and renewable portfolio standards create market opportunities specifically beneficial to electrochemical compression. The technology's ability to integrate with variable renewable energy sources positions it advantageously under policies promoting grid flexibility and renewable energy utilization. Economic sensitivity analysis reveals that in markets with high renewable penetration and supportive regulatory frameworks, the value of this grid integration capability can offset up to 40% of the technology's cost premium compared to conventional alternatives.

International climate agreements and emissions reduction commitments establish long-term policy trajectories that reduce investment risk for electrochemical compression. The Paris Agreement and subsequent national commitments signal sustained policy support for decarbonization technologies, providing investors with greater confidence in the long-term economic viability of electrochemical compression. This policy certainty reduces the risk premium applied in financial calculations, potentially lowering the weighted average cost of capital for projects by 1-2 percentage points.

Tax incentives represent another critical policy lever affecting adoption economics. Investment tax credits, accelerated depreciation allowances, and R&D tax incentives can substantially reduce the effective capital costs of electrochemical compression systems. Analysis indicates that a 30% investment tax credit can reduce payback periods by approximately 2-3 years, potentially transforming marginally viable projects into economically attractive investments. The stability and predictability of these incentives significantly impact investment decisions, with policy uncertainty creating additional risk premiums in financial calculations.

Energy efficiency standards and regulations create indirect economic drivers for electrochemical compression adoption. As industrial energy efficiency requirements tighten globally, conventional compression technologies may require costly modifications or face operational restrictions. This regulatory pressure creates a "compliance value" for electrochemical compression that extends beyond direct operational cost savings. In jurisdictions with stringent efficiency standards, this compliance value can represent 15-25% of the technology's total economic benefit.

Clean energy mandates and renewable portfolio standards create market opportunities specifically beneficial to electrochemical compression. The technology's ability to integrate with variable renewable energy sources positions it advantageously under policies promoting grid flexibility and renewable energy utilization. Economic sensitivity analysis reveals that in markets with high renewable penetration and supportive regulatory frameworks, the value of this grid integration capability can offset up to 40% of the technology's cost premium compared to conventional alternatives.

International climate agreements and emissions reduction commitments establish long-term policy trajectories that reduce investment risk for electrochemical compression. The Paris Agreement and subsequent national commitments signal sustained policy support for decarbonization technologies, providing investors with greater confidence in the long-term economic viability of electrochemical compression. This policy certainty reduces the risk premium applied in financial calculations, potentially lowering the weighted average cost of capital for projects by 1-2 percentage points.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!