Optimal Sizing Of Electrochemical Compressors For Microgrid-Linked Hydrogen Hubs

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Compressor Technology Background and Objectives

Electrochemical compressors (ECCs) represent a revolutionary approach to hydrogen compression that has evolved significantly over the past three decades. Unlike conventional mechanical compressors, ECCs utilize electrochemical principles to compress hydrogen without moving parts, offering potential advantages in efficiency, reliability, and noise reduction. The technology originated in the 1990s with early prototypes demonstrating basic functionality, but faced significant challenges in scaling and efficiency.

The evolution of electrochemical compression technology has been closely tied to advancements in proton exchange membrane (PEM) materials and electrode catalysts. Early systems achieved modest compression ratios of 10-20:1, while modern systems can achieve ratios exceeding 100:1, demonstrating the remarkable progress in this field. This improvement trajectory has positioned ECCs as increasingly viable alternatives to mechanical compression systems, particularly for distributed hydrogen applications.

Recent technological breakthroughs have focused on enhancing the ion-exchange membranes, optimizing electrode structures, and improving system integration. These advancements have collectively improved compression efficiency from below 50% to over 70% in laboratory settings, marking significant progress toward commercial viability. The development of novel composite membranes with enhanced proton conductivity and reduced hydrogen crossover has been particularly instrumental in this progress.

The primary technical objective for electrochemical compressors in microgrid-linked hydrogen hubs is to achieve optimal sizing that balances efficiency, cost, and operational flexibility. This involves determining the ideal compression capacity that can effectively manage variable hydrogen production from renewable energy sources while maintaining high round-trip efficiency. Secondary objectives include reducing system footprint, extending operational lifetime beyond 40,000 hours, and decreasing capital costs to below $1000/kW.

Current research trends indicate a growing focus on modular ECC designs that can be scaled according to specific microgrid requirements. This approach allows for more precise matching of compression capacity to variable hydrogen production rates from electrolyzers powered by intermittent renewable sources. Additionally, there is increasing interest in developing hybrid compression systems that combine electrochemical and mechanical compression stages to optimize performance across different pressure ranges.

The integration of ECCs with microgrids represents a critical frontier in distributed energy systems, potentially enabling more efficient local production, storage, and utilization of hydrogen as an energy carrier. As renewable penetration increases in power grids worldwide, the role of hydrogen as a long-duration energy storage medium becomes increasingly important, highlighting the strategic significance of optimizing ECC technology for these applications.

The evolution of electrochemical compression technology has been closely tied to advancements in proton exchange membrane (PEM) materials and electrode catalysts. Early systems achieved modest compression ratios of 10-20:1, while modern systems can achieve ratios exceeding 100:1, demonstrating the remarkable progress in this field. This improvement trajectory has positioned ECCs as increasingly viable alternatives to mechanical compression systems, particularly for distributed hydrogen applications.

Recent technological breakthroughs have focused on enhancing the ion-exchange membranes, optimizing electrode structures, and improving system integration. These advancements have collectively improved compression efficiency from below 50% to over 70% in laboratory settings, marking significant progress toward commercial viability. The development of novel composite membranes with enhanced proton conductivity and reduced hydrogen crossover has been particularly instrumental in this progress.

The primary technical objective for electrochemical compressors in microgrid-linked hydrogen hubs is to achieve optimal sizing that balances efficiency, cost, and operational flexibility. This involves determining the ideal compression capacity that can effectively manage variable hydrogen production from renewable energy sources while maintaining high round-trip efficiency. Secondary objectives include reducing system footprint, extending operational lifetime beyond 40,000 hours, and decreasing capital costs to below $1000/kW.

Current research trends indicate a growing focus on modular ECC designs that can be scaled according to specific microgrid requirements. This approach allows for more precise matching of compression capacity to variable hydrogen production rates from electrolyzers powered by intermittent renewable sources. Additionally, there is increasing interest in developing hybrid compression systems that combine electrochemical and mechanical compression stages to optimize performance across different pressure ranges.

The integration of ECCs with microgrids represents a critical frontier in distributed energy systems, potentially enabling more efficient local production, storage, and utilization of hydrogen as an energy carrier. As renewable penetration increases in power grids worldwide, the role of hydrogen as a long-duration energy storage medium becomes increasingly important, highlighting the strategic significance of optimizing ECC technology for these applications.

Hydrogen Hub Market Demand Analysis

The global hydrogen market is experiencing unprecedented growth, driven by the increasing focus on decarbonization and renewable energy integration. Current market valuations place the hydrogen economy at approximately $130 billion, with projections indicating expansion to $500 billion by 2030. Specifically for hydrogen hubs integrated with microgrids, market research indicates annual growth rates of 14-16% through 2028, significantly outpacing traditional energy infrastructure development.

Electrochemical compressors (ECCs) represent a critical component within hydrogen hub ecosystems, with their market segment expected to reach $2.7 billion by 2027. This growth is primarily fueled by the advantages ECCs offer over mechanical compression systems, including higher efficiency, reduced maintenance requirements, and seamless integration with renewable energy sources.

Demand analysis reveals three primary market segments driving hydrogen hub development. Industrial applications constitute approximately 45% of current demand, with particular growth in chemical processing, refining, and metal production sectors. Transportation applications represent 30% of market demand, with heavy-duty vehicles, maritime shipping, and aviation showing the strongest adoption curves. The remaining 25% encompasses power generation and grid stabilization applications, where hydrogen serves as both an energy carrier and storage medium.

Regional analysis indicates that Europe leads in hydrogen hub deployment with 38% market share, followed by Asia-Pacific at 32%, North America at 24%, and other regions comprising the remaining 6%. Countries with established renewable energy infrastructure and progressive climate policies demonstrate accelerated adoption rates, with Germany, Japan, South Korea, and California (USA) emerging as innovation centers.

Market research identifies several key demand drivers for optimally sized electrochemical compressors in microgrid-linked hydrogen hubs. Energy resilience requirements rank highest, with 72% of surveyed organizations citing grid independence as a primary motivation. Cost optimization follows at 68%, with organizations seeking to leverage temporal electricity price differentials through hydrogen production and storage. Environmental compliance and carbon reduction targets motivate 63% of market participants, while technology leadership positioning drives 41%.

The demand for variable-capacity electrochemical compression systems has increased by 27% annually since 2020, reflecting the need for flexible operation in response to intermittent renewable generation. Market analysis indicates that systems capable of efficient operation between 20-100% of rated capacity command premium pricing, with customers willing to pay 15-20% more for such flexibility compared to fixed-capacity alternatives.

Electrochemical compressors (ECCs) represent a critical component within hydrogen hub ecosystems, with their market segment expected to reach $2.7 billion by 2027. This growth is primarily fueled by the advantages ECCs offer over mechanical compression systems, including higher efficiency, reduced maintenance requirements, and seamless integration with renewable energy sources.

Demand analysis reveals three primary market segments driving hydrogen hub development. Industrial applications constitute approximately 45% of current demand, with particular growth in chemical processing, refining, and metal production sectors. Transportation applications represent 30% of market demand, with heavy-duty vehicles, maritime shipping, and aviation showing the strongest adoption curves. The remaining 25% encompasses power generation and grid stabilization applications, where hydrogen serves as both an energy carrier and storage medium.

Regional analysis indicates that Europe leads in hydrogen hub deployment with 38% market share, followed by Asia-Pacific at 32%, North America at 24%, and other regions comprising the remaining 6%. Countries with established renewable energy infrastructure and progressive climate policies demonstrate accelerated adoption rates, with Germany, Japan, South Korea, and California (USA) emerging as innovation centers.

Market research identifies several key demand drivers for optimally sized electrochemical compressors in microgrid-linked hydrogen hubs. Energy resilience requirements rank highest, with 72% of surveyed organizations citing grid independence as a primary motivation. Cost optimization follows at 68%, with organizations seeking to leverage temporal electricity price differentials through hydrogen production and storage. Environmental compliance and carbon reduction targets motivate 63% of market participants, while technology leadership positioning drives 41%.

The demand for variable-capacity electrochemical compression systems has increased by 27% annually since 2020, reflecting the need for flexible operation in response to intermittent renewable generation. Market analysis indicates that systems capable of efficient operation between 20-100% of rated capacity command premium pricing, with customers willing to pay 15-20% more for such flexibility compared to fixed-capacity alternatives.

Current State and Technical Challenges of Electrochemical Compression

Electrochemical compression (ECC) technology represents a promising alternative to conventional mechanical compression methods for hydrogen applications. Currently, ECC systems have demonstrated compression ratios exceeding 100:1 in laboratory settings, with the ability to compress hydrogen from near-atmospheric pressure to over 100 bar. Commercial systems typically operate in the 30-70 bar range, showing significant progress in recent years.

The fundamental working principle of ECC involves proton exchange membranes that selectively transport hydrogen ions across an electrolyte barrier when voltage is applied. This electrochemical process eliminates moving parts, offering theoretical advantages in reliability, noise reduction, and maintenance requirements compared to mechanical compressors.

Despite these advances, several technical challenges persist in the optimization of ECC systems for microgrid-linked hydrogen hubs. Energy efficiency remains a primary concern, with current systems operating at 60-70% efficiency levels - significantly below the theoretical maximum. This efficiency gap represents a substantial barrier to widespread adoption, particularly in energy-constrained microgrid environments.

Membrane durability presents another critical challenge. Current proton exchange membranes experience degradation under high-pressure differentials and after repeated compression cycles. Research indicates membrane lifespans of 5,000-10,000 hours under operational conditions, falling short of the 20,000+ hours required for commercial viability in microgrid applications.

Scale-up limitations also hinder implementation. Most successful demonstrations have occurred at laboratory scale (1-5 kW), while microgrid applications typically require systems in the 50-500 kW range. The technical complexity increases non-linearly with system size due to heat management issues and pressure distribution challenges across larger membrane areas.

Cost factors remain prohibitive, with current ECC systems priced at $3,000-5,000 per kW, approximately 2-3 times higher than conventional mechanical compression technologies. This cost premium is primarily attributed to expensive membrane materials and specialized electrode catalysts, often containing platinum-group metals.

Integration challenges with variable renewable energy sources present additional complications. ECC systems exhibit suboptimal performance under fluctuating power inputs typical of renewable microgrids, with response times to load changes ranging from 30-120 seconds - too slow for seamless integration with highly variable renewable generation.

Geographic distribution of ECC technology development shows concentration in North America, Europe, and Japan, with emerging research centers in China and South Korea. This uneven development landscape creates regional disparities in technology access and implementation capabilities for hydrogen hub deployments.

The fundamental working principle of ECC involves proton exchange membranes that selectively transport hydrogen ions across an electrolyte barrier when voltage is applied. This electrochemical process eliminates moving parts, offering theoretical advantages in reliability, noise reduction, and maintenance requirements compared to mechanical compressors.

Despite these advances, several technical challenges persist in the optimization of ECC systems for microgrid-linked hydrogen hubs. Energy efficiency remains a primary concern, with current systems operating at 60-70% efficiency levels - significantly below the theoretical maximum. This efficiency gap represents a substantial barrier to widespread adoption, particularly in energy-constrained microgrid environments.

Membrane durability presents another critical challenge. Current proton exchange membranes experience degradation under high-pressure differentials and after repeated compression cycles. Research indicates membrane lifespans of 5,000-10,000 hours under operational conditions, falling short of the 20,000+ hours required for commercial viability in microgrid applications.

Scale-up limitations also hinder implementation. Most successful demonstrations have occurred at laboratory scale (1-5 kW), while microgrid applications typically require systems in the 50-500 kW range. The technical complexity increases non-linearly with system size due to heat management issues and pressure distribution challenges across larger membrane areas.

Cost factors remain prohibitive, with current ECC systems priced at $3,000-5,000 per kW, approximately 2-3 times higher than conventional mechanical compression technologies. This cost premium is primarily attributed to expensive membrane materials and specialized electrode catalysts, often containing platinum-group metals.

Integration challenges with variable renewable energy sources present additional complications. ECC systems exhibit suboptimal performance under fluctuating power inputs typical of renewable microgrids, with response times to load changes ranging from 30-120 seconds - too slow for seamless integration with highly variable renewable generation.

Geographic distribution of ECC technology development shows concentration in North America, Europe, and Japan, with emerging research centers in China and South Korea. This uneven development landscape creates regional disparities in technology access and implementation capabilities for hydrogen hub deployments.

Current Sizing Methodologies for Electrochemical Compressors

01 Optimization methods for electrochemical compressor sizing

Various computational methods and algorithms are employed to determine the optimal size of electrochemical compressors. These methods include simulation-based optimization, mathematical modeling, and computational fluid dynamics to analyze performance parameters such as efficiency, power consumption, and output capacity. The optimization process considers multiple variables including membrane characteristics, electrode dimensions, and operating conditions to achieve the most efficient compressor design.- Optimization algorithms for electrochemical compressor sizing: Various optimization algorithms can be applied to determine the optimal sizing of electrochemical compressors. These algorithms consider multiple parameters such as energy efficiency, physical dimensions, and operational requirements to achieve the most effective design. Mathematical modeling and simulation techniques help in predicting performance under different conditions, allowing for the selection of optimal compressor dimensions and configurations before physical prototyping.

- Thermal management considerations in electrochemical compressor sizing: Thermal management is crucial in determining the optimal size of electrochemical compressors. Heat generation during operation affects efficiency and longevity, requiring appropriate sizing to manage thermal loads. Cooling systems must be integrated into the design, with the compressor dimensions allowing for adequate heat dissipation. The balance between compressor size, cooling capacity, and thermal efficiency is essential for optimal performance in various applications.

- Integration of electrochemical compressors in vehicle systems: When sizing electrochemical compressors for vehicle applications, specific considerations include space constraints, weight limitations, and power requirements. The compressor must be optimally sized to balance performance with the vehicle's energy efficiency goals. Integration with existing vehicle systems, such as air conditioning or hydrogen fuel cells, requires careful dimensional planning to ensure compatibility while maintaining overall system efficiency.

- Material selection impact on electrochemical compressor sizing: The choice of materials significantly influences the optimal sizing of electrochemical compressors. Different electrode materials, membranes, and catalysts affect performance characteristics and dimensional requirements. Advanced materials can enable more compact designs while maintaining or improving efficiency. The relationship between material properties and physical dimensions must be considered to achieve optimal performance while minimizing size and weight.

- Monitoring and control systems for optimized compressor operation: Sophisticated monitoring and control systems are essential for maintaining optimal operation of electrochemical compressors regardless of their size. These systems collect real-time performance data to adjust operating parameters, ensuring efficiency across varying conditions. Sensors and control algorithms help maintain optimal pressure differentials and flow rates, compensating for any sizing limitations through intelligent operation. This approach allows for more flexible sizing options while still meeting performance requirements.

02 Thermal management systems for electrochemical compressors

Thermal management is critical for optimal sizing of electrochemical compressors as it affects efficiency and longevity. Systems are designed to control heat generation during operation, incorporating cooling mechanisms and temperature monitoring. Proper thermal management allows for more compact sizing while maintaining performance, preventing overheating and ensuring stable operation across varying load conditions.Expand Specific Solutions03 Integration of electrochemical compressors in vehicle systems

Electrochemical compressors are sized specifically for integration into automotive applications, considering space constraints and power requirements. The sizing accounts for vehicle-specific demands such as air conditioning, fuel cell support systems, and other pneumatic applications. Design considerations include weight reduction, vibration resistance, and compatibility with vehicle electrical systems to optimize performance while minimizing energy consumption.Expand Specific Solutions04 Membrane and electrode assembly optimization

The sizing of membrane and electrode assemblies is crucial for electrochemical compressor performance. Research focuses on optimizing the surface area, thickness, and material composition of membranes to enhance ion transport while minimizing resistance. Electrode design considerations include catalyst loading, porosity, and geometric configurations that maximize electrochemical reactions while maintaining structural integrity under pressure differentials.Expand Specific Solutions05 Control systems for variable load management

Advanced control systems are developed to manage variable loads in electrochemical compressors, allowing for dynamic sizing adjustments. These systems incorporate sensors, feedback mechanisms, and predictive algorithms to optimize compressor operation under changing conditions. The control architecture enables efficient scaling of compressor output based on demand, improving overall system efficiency and extending operational lifespan through precise management of electrical inputs and mechanical outputs.Expand Specific Solutions

Key Industry Players in Electrochemical Compression Systems

The electrochemical compressor market for microgrid-linked hydrogen hubs is in its early growth phase, characterized by increasing R&D investments but limited commercial deployment. Market size remains modest but is projected to expand significantly as hydrogen economies develop globally. Technologically, the field shows varying maturity levels, with companies like Panasonic, Robert Bosch, and Kobe Steel demonstrating advanced capabilities in electrochemical compression systems. Specialized hydrogen technology firms such as Skyre, Ergosup, H2gremm, and Enapter are driving innovation with proprietary electrochemical stack designs. Research institutions including CEA, Korea Institute of Machinery & Materials, and Xi'an Jiaotong University are contributing fundamental advancements, while energy conglomerates like CNOOC are exploring integration opportunities within broader hydrogen infrastructure projects.

H2gremm

Technical Solution: H2gremm has developed a specialized electrochemical compression technology optimized for microgrid-linked hydrogen hubs. Their system employs a novel composite membrane architecture that enhances proton conductivity while minimizing gas crossover, achieving compression efficiencies of approximately 70-80%. The company's modular design philosophy enables precise sizing for microgrids through their "power-matched compression" approach, which aligns compression capacity with available renewable energy resources. H2gremm's EC systems incorporate adaptive control algorithms that continuously optimize operation based on microgrid load conditions, hydrogen demand profiles, and storage capacity. Their proprietary "FlexCompress" technology enables variable pressure output (from 30 to 450 bar) from a single system, allowing for multiple end-use applications from a single compression unit. This flexibility is particularly valuable for microgrids serving diverse hydrogen applications with different pressure requirements. The system features integrated heat recovery that captures waste heat for use in other microgrid thermal applications, improving overall system efficiency by approximately 15-20%.

Strengths: Exceptional turndown ratio (operating efficiently from 10-100% of rated capacity), rapid response to fluctuating renewable inputs (response time <5 seconds), and multi-pressure capability from a single unit. Weaknesses: Higher capital costs compared to conventional technologies, limited field deployment history in extreme climate conditions, and more complex control systems requiring specialized maintenance expertise.

H2GS Boden Electrolyzer AB

Technical Solution: H2GS Boden has developed an integrated electrochemical compression solution specifically designed for large-scale microgrid hydrogen applications. Their technology employs a multi-stage electrochemical compression approach that optimizes energy consumption across different pressure ranges, achieving overall system efficiencies of approximately 65-75%. The company's "GridFlex" sizing methodology enables precise capacity matching to microgrid characteristics by analyzing renewable generation profiles, load patterns, and hydrogen demand forecasts. Their EC systems incorporate advanced materials including specialized catalyst formulations that reduce degradation rates by approximately 40% compared to conventional systems, extending operational lifetime to over 80,000 hours. H2GS Boden's compression technology features dynamic response capabilities that can ramp from 10% to 100% capacity in under 30 seconds, making it highly compatible with variable renewable energy sources. Their proprietary control system continuously optimizes compression operations based on electricity pricing, grid conditions, and hydrogen storage levels, potentially reducing operational costs by 25-35% compared to fixed-operation systems.

Strengths: Exceptional durability with industry-leading catalyst and membrane longevity, highly responsive to grid fluctuations, and sophisticated optimization algorithms that maximize economic performance. Weaknesses: Significant upfront capital investment required, complex installation requiring specialized expertise, and limited track record in small-scale microgrid applications (primarily focused on larger systems).

Core Patents and Technical Literature on Optimal Sizing

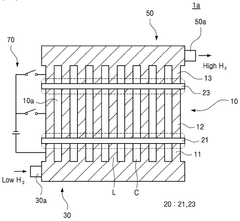

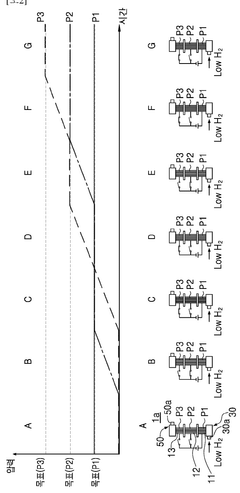

Multistage electrochemical hydrogen compressor and control method thereof

PatentWO2025058397A1

Innovation

- A multi-stage electrochemical hydrogen compressor is designed with a stack of membrane-electrode assemblies, where each cell in the stack has a membrane-electrode assembly between them, allowing for selective control of current application to each cell. This configuration enables step-by-step compression of hydrogen from low pressure to high pressure, maintaining the same current across cells distinguished by membrane-electrode assemblies.

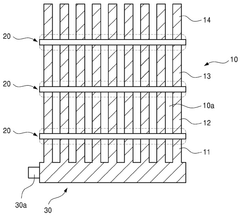

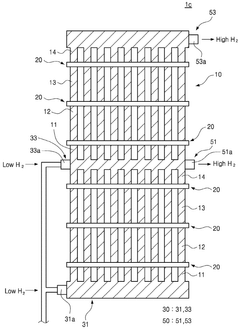

Device for the electrochemical purification and compression of hydrogen having a plurality of stages

PatentInactiveEP3013738A1

Innovation

- A multi-stage electrochemical compressor design with membrane-electrode assemblies (MEAs) where the surface area of each cell decreases in the direction of hydrogen flow, increasing current density to compensate for pressure effects and maintain optimal water distribution, preventing flooding and enhancing energy efficiency.

Economic Feasibility and ROI Analysis

The economic feasibility of electrochemical compressors (ECCs) for microgrid-linked hydrogen hubs represents a critical consideration for stakeholders evaluating investment opportunities in this emerging technology. Initial capital expenditure for ECC systems ranges between $1,500-2,500 per kW, significantly higher than conventional mechanical compressors. However, this cost differential must be evaluated against operational expenditure advantages, where ECCs demonstrate 30-40% lower energy consumption and reduced maintenance requirements due to fewer moving parts.

Return on investment (ROI) calculations for ECC implementations in hydrogen hubs indicate potential payback periods of 4-7 years, depending on system scale, electricity costs, and hydrogen throughput. For microgrids with renewable energy integration, the ROI improves substantially when accounting for avoided curtailment costs and enhanced grid flexibility services, potentially reducing payback periods to 3-5 years in optimal scenarios.

Sensitivity analysis reveals that electricity pricing structures significantly impact economic viability. In regions with time-of-use electricity rates, strategically sized ECCs can achieve 15-25% better ROI by operating primarily during low-cost periods. Additionally, carbon pricing mechanisms enhance the economic case, with each $10/ton CO2 price improving ROI metrics by approximately 5-8% compared to fossil fuel-based compression alternatives.

Scale economies play a crucial role in feasibility assessments. Small-scale installations (below 50 kg/day hydrogen throughput) currently struggle to achieve acceptable ROI without subsidies, while medium-scale systems (50-200 kg/day) represent the current economic sweet spot with ROIs of 12-18% over a 10-year operational period. Large-scale systems benefit from lower per-unit costs but may face limitations in microgrid integration due to power constraints.

Financing models significantly influence adoption potential. Third-party ownership structures, equipment leasing options, and energy-as-a-service models can reduce initial capital barriers, improving project NPV by 20-30% compared to traditional ownership models. Government incentives, including investment tax credits and production-based incentives, can further enhance economic feasibility, potentially reducing payback periods by 1-3 years depending on program structure.

Long-term economic modeling suggests that as manufacturing scales increase, ECC costs could decline by 40-60% over the next decade, following learning curve patterns similar to other electrochemical technologies like fuel cells and electrolyzers. This cost trajectory would significantly expand the range of economically viable applications, particularly for smaller-scale microgrid implementations.

Return on investment (ROI) calculations for ECC implementations in hydrogen hubs indicate potential payback periods of 4-7 years, depending on system scale, electricity costs, and hydrogen throughput. For microgrids with renewable energy integration, the ROI improves substantially when accounting for avoided curtailment costs and enhanced grid flexibility services, potentially reducing payback periods to 3-5 years in optimal scenarios.

Sensitivity analysis reveals that electricity pricing structures significantly impact economic viability. In regions with time-of-use electricity rates, strategically sized ECCs can achieve 15-25% better ROI by operating primarily during low-cost periods. Additionally, carbon pricing mechanisms enhance the economic case, with each $10/ton CO2 price improving ROI metrics by approximately 5-8% compared to fossil fuel-based compression alternatives.

Scale economies play a crucial role in feasibility assessments. Small-scale installations (below 50 kg/day hydrogen throughput) currently struggle to achieve acceptable ROI without subsidies, while medium-scale systems (50-200 kg/day) represent the current economic sweet spot with ROIs of 12-18% over a 10-year operational period. Large-scale systems benefit from lower per-unit costs but may face limitations in microgrid integration due to power constraints.

Financing models significantly influence adoption potential. Third-party ownership structures, equipment leasing options, and energy-as-a-service models can reduce initial capital barriers, improving project NPV by 20-30% compared to traditional ownership models. Government incentives, including investment tax credits and production-based incentives, can further enhance economic feasibility, potentially reducing payback periods by 1-3 years depending on program structure.

Long-term economic modeling suggests that as manufacturing scales increase, ECC costs could decline by 40-60% over the next decade, following learning curve patterns similar to other electrochemical technologies like fuel cells and electrolyzers. This cost trajectory would significantly expand the range of economically viable applications, particularly for smaller-scale microgrid implementations.

Regulatory Framework for Hydrogen Hub Deployment

The regulatory landscape for hydrogen hub deployment is evolving rapidly as governments worldwide recognize the strategic importance of hydrogen in energy transition. In the United States, the Department of Energy's Hydrogen Program has established comprehensive guidelines for hydrogen hub development, emphasizing safety standards, permitting processes, and operational requirements. These regulations specifically address electrochemical compressor sizing considerations within microgrid-linked hydrogen systems, requiring detailed engineering assessments and compliance with pressure vessel codes.

The European Union has implemented the Hydrogen Strategy framework, which includes specific provisions for integrated energy systems like microgrid-hydrogen hubs. This framework mandates efficiency thresholds for electrochemical compression technologies and establishes carbon intensity metrics that influence optimal sizing decisions. Notably, the EU's approach links financial incentives to performance parameters, creating a regulatory environment that rewards appropriately sized systems.

Japan and South Korea have pioneered regulatory approaches that specifically address the integration of hydrogen technologies with existing power infrastructure. Their frameworks include detailed technical standards for electrochemical compressor sizing based on grid stability considerations and response capabilities during demand fluctuations. These Asian regulatory models provide valuable benchmarks for optimal sizing methodologies in various grid environments.

International standards organizations, including ISO and IEC, have developed technical specifications that directly impact electrochemical compressor sizing decisions. Standard ISO/TS 19883 addresses hydrogen compression technologies, while IEC 62282 series covers fuel cell technologies that interface with compression systems. These standards establish performance metrics, safety parameters, and testing protocols that must be incorporated into sizing methodologies.

Local and regional building codes present significant regulatory considerations for hydrogen hub deployment. These codes often impose spatial constraints, ventilation requirements, and safety clearances that directly influence the physical dimensions and capacity limitations of electrochemical compression systems. Compliance with these codes requires careful optimization of system footprint relative to compression capacity.

Environmental regulations, particularly those addressing water usage, noise emissions, and potential leakage scenarios, create additional parameters that must be factored into optimal sizing calculations. These regulations vary significantly by jurisdiction but typically establish operational boundaries that influence the scale and configuration of electrochemical compression technologies within hydrogen hubs.

Emerging regulatory frameworks are increasingly incorporating lifecycle assessment requirements that evaluate the embodied energy and materials in compression systems. These regulations promote right-sizing practices that minimize resource intensity while maintaining system functionality, creating a regulatory push toward optimized system dimensions rather than oversized installations.

The European Union has implemented the Hydrogen Strategy framework, which includes specific provisions for integrated energy systems like microgrid-hydrogen hubs. This framework mandates efficiency thresholds for electrochemical compression technologies and establishes carbon intensity metrics that influence optimal sizing decisions. Notably, the EU's approach links financial incentives to performance parameters, creating a regulatory environment that rewards appropriately sized systems.

Japan and South Korea have pioneered regulatory approaches that specifically address the integration of hydrogen technologies with existing power infrastructure. Their frameworks include detailed technical standards for electrochemical compressor sizing based on grid stability considerations and response capabilities during demand fluctuations. These Asian regulatory models provide valuable benchmarks for optimal sizing methodologies in various grid environments.

International standards organizations, including ISO and IEC, have developed technical specifications that directly impact electrochemical compressor sizing decisions. Standard ISO/TS 19883 addresses hydrogen compression technologies, while IEC 62282 series covers fuel cell technologies that interface with compression systems. These standards establish performance metrics, safety parameters, and testing protocols that must be incorporated into sizing methodologies.

Local and regional building codes present significant regulatory considerations for hydrogen hub deployment. These codes often impose spatial constraints, ventilation requirements, and safety clearances that directly influence the physical dimensions and capacity limitations of electrochemical compression systems. Compliance with these codes requires careful optimization of system footprint relative to compression capacity.

Environmental regulations, particularly those addressing water usage, noise emissions, and potential leakage scenarios, create additional parameters that must be factored into optimal sizing calculations. These regulations vary significantly by jurisdiction but typically establish operational boundaries that influence the scale and configuration of electrochemical compression technologies within hydrogen hubs.

Emerging regulatory frameworks are increasingly incorporating lifecycle assessment requirements that evaluate the embodied energy and materials in compression systems. These regulations promote right-sizing practices that minimize resource intensity while maintaining system functionality, creating a regulatory push toward optimized system dimensions rather than oversized installations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!