Digital Twin Approaches For Electrochemical Compressor Operation And Predictive Maintenance

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Compressor Digital Twin Background & Objectives

Electrochemical compressors (ECCs) represent a revolutionary advancement in compression technology, offering significant advantages over traditional mechanical compressors including higher efficiency, reduced noise, elimination of moving parts, and environmental friendliness. The concept of ECCs dates back to the 1970s, but substantial technological progress has only been achieved in the past decade with advancements in materials science and electrochemical engineering.

The evolution of ECCs has been marked by progressive improvements in membrane technology, electrode materials, and system integration capabilities. Initially limited by low efficiency and reliability issues, modern ECCs now demonstrate competitive performance metrics in specific applications, particularly in hydrogen compression and refrigeration cycles. This technological maturation coincides with the global push toward sustainable energy solutions and hydrogen economy development.

Digital twin technology, meanwhile, has emerged as a transformative approach to industrial asset management, providing real-time virtual representations of physical systems. The convergence of these two technological domains—electrochemical compression and digital twins—presents a compelling opportunity to address persistent challenges in ECC deployment, including performance optimization, reliability enhancement, and maintenance planning.

The primary objective of implementing digital twin approaches for electrochemical compressors is to create comprehensive virtual models that accurately simulate the complex electrochemical processes, thermal behaviors, and degradation mechanisms within these systems. These models aim to enable real-time monitoring, performance prediction, and optimization of operational parameters to maximize efficiency and extend service life.

Additionally, digital twin implementation seeks to establish predictive maintenance capabilities that can identify potential failure modes before they manifest, reducing downtime and maintenance costs. This proactive approach represents a significant advancement over traditional reactive or scheduled maintenance strategies, particularly for ECCs where internal conditions are difficult to monitor through conventional means.

The long-term technological goal is to develop self-optimizing ECC systems that leverage digital twin insights to autonomously adjust operational parameters based on changing conditions, performance history, and predicted future states. Such systems would represent a step change in compression technology, offering unprecedented levels of reliability, efficiency, and adaptability across various applications from refrigeration to hydrogen infrastructure.

As global energy systems transition toward greater electrification and hydrogen utilization, the development of sophisticated digital twin approaches for ECCs aligns with broader technological trends toward smart, connected industrial systems and sustainable energy technologies. The successful implementation of these approaches could significantly accelerate ECC adoption across multiple sectors, contributing to decarbonization efforts and energy efficiency improvements.

The evolution of ECCs has been marked by progressive improvements in membrane technology, electrode materials, and system integration capabilities. Initially limited by low efficiency and reliability issues, modern ECCs now demonstrate competitive performance metrics in specific applications, particularly in hydrogen compression and refrigeration cycles. This technological maturation coincides with the global push toward sustainable energy solutions and hydrogen economy development.

Digital twin technology, meanwhile, has emerged as a transformative approach to industrial asset management, providing real-time virtual representations of physical systems. The convergence of these two technological domains—electrochemical compression and digital twins—presents a compelling opportunity to address persistent challenges in ECC deployment, including performance optimization, reliability enhancement, and maintenance planning.

The primary objective of implementing digital twin approaches for electrochemical compressors is to create comprehensive virtual models that accurately simulate the complex electrochemical processes, thermal behaviors, and degradation mechanisms within these systems. These models aim to enable real-time monitoring, performance prediction, and optimization of operational parameters to maximize efficiency and extend service life.

Additionally, digital twin implementation seeks to establish predictive maintenance capabilities that can identify potential failure modes before they manifest, reducing downtime and maintenance costs. This proactive approach represents a significant advancement over traditional reactive or scheduled maintenance strategies, particularly for ECCs where internal conditions are difficult to monitor through conventional means.

The long-term technological goal is to develop self-optimizing ECC systems that leverage digital twin insights to autonomously adjust operational parameters based on changing conditions, performance history, and predicted future states. Such systems would represent a step change in compression technology, offering unprecedented levels of reliability, efficiency, and adaptability across various applications from refrigeration to hydrogen infrastructure.

As global energy systems transition toward greater electrification and hydrogen utilization, the development of sophisticated digital twin approaches for ECCs aligns with broader technological trends toward smart, connected industrial systems and sustainable energy technologies. The successful implementation of these approaches could significantly accelerate ECC adoption across multiple sectors, contributing to decarbonization efforts and energy efficiency improvements.

Market Demand Analysis for Digital Twin in Compressor Technology

The global market for digital twin technology in compressor systems is experiencing significant growth, driven by increasing demand for operational efficiency and predictive maintenance solutions. The electrochemical compressor sector, in particular, represents an emerging application area where digital twin implementation can deliver substantial value. Current market analysis indicates that industries including HVAC, refrigeration, and industrial gas processing are actively seeking advanced monitoring and optimization technologies to reduce operational costs and extend equipment lifespan.

Market research reveals that maintenance-related downtime costs industrial manufacturers approximately $50 million annually, creating a strong economic incentive for predictive maintenance solutions. Digital twin technology for electrochemical compressors addresses this need by enabling real-time performance monitoring and failure prediction, potentially reducing unplanned downtime by up to 30% according to recent industry studies.

Energy efficiency requirements are another significant market driver, with regulatory frameworks increasingly mandating reduced energy consumption in industrial processes. Electrochemical compressors offer inherent efficiency advantages over mechanical alternatives, and when paired with digital twin technology, can achieve further optimization. This combination positions the technology favorably in markets where energy costs represent a substantial operational expense.

The healthcare and pharmaceutical sectors demonstrate growing interest in electrochemical compression systems with digital twin capabilities, particularly for applications requiring precise gas handling and contamination-free operation. Market forecasts project this segment to grow at a compound annual rate exceeding 20% through 2028, outpacing traditional industrial applications.

Geographic market distribution shows North America and Europe leading adoption, with Asia-Pacific regions demonstrating the fastest growth trajectory. This regional variation correlates with industrial digitalization maturity and environmental regulatory frameworks. China's recent five-year plan specifically highlights digital twin technology as a priority area for industrial advancement, signaling potential market expansion.

Customer demand analysis indicates varying requirements across market segments. Large industrial operations prioritize integration capabilities with existing systems and demonstrable ROI metrics, while smaller operations seek scalable, lower-cost implementation options. This market segmentation necessitates flexible digital twin solutions that can adapt to different operational scales and technical requirements.

Market barriers include concerns about data security, implementation costs, and technical expertise requirements. However, the emergence of cloud-based digital twin platforms is addressing these concerns by reducing upfront investment requirements and simplifying deployment. This trend is expected to accelerate market penetration, particularly among mid-sized operations previously hesitant to adopt advanced monitoring technologies.

Market research reveals that maintenance-related downtime costs industrial manufacturers approximately $50 million annually, creating a strong economic incentive for predictive maintenance solutions. Digital twin technology for electrochemical compressors addresses this need by enabling real-time performance monitoring and failure prediction, potentially reducing unplanned downtime by up to 30% according to recent industry studies.

Energy efficiency requirements are another significant market driver, with regulatory frameworks increasingly mandating reduced energy consumption in industrial processes. Electrochemical compressors offer inherent efficiency advantages over mechanical alternatives, and when paired with digital twin technology, can achieve further optimization. This combination positions the technology favorably in markets where energy costs represent a substantial operational expense.

The healthcare and pharmaceutical sectors demonstrate growing interest in electrochemical compression systems with digital twin capabilities, particularly for applications requiring precise gas handling and contamination-free operation. Market forecasts project this segment to grow at a compound annual rate exceeding 20% through 2028, outpacing traditional industrial applications.

Geographic market distribution shows North America and Europe leading adoption, with Asia-Pacific regions demonstrating the fastest growth trajectory. This regional variation correlates with industrial digitalization maturity and environmental regulatory frameworks. China's recent five-year plan specifically highlights digital twin technology as a priority area for industrial advancement, signaling potential market expansion.

Customer demand analysis indicates varying requirements across market segments. Large industrial operations prioritize integration capabilities with existing systems and demonstrable ROI metrics, while smaller operations seek scalable, lower-cost implementation options. This market segmentation necessitates flexible digital twin solutions that can adapt to different operational scales and technical requirements.

Market barriers include concerns about data security, implementation costs, and technical expertise requirements. However, the emergence of cloud-based digital twin platforms is addressing these concerns by reducing upfront investment requirements and simplifying deployment. This trend is expected to accelerate market penetration, particularly among mid-sized operations previously hesitant to adopt advanced monitoring technologies.

Current State and Challenges in Electrochemical Compressor Monitoring

Electrochemical compressors (ECCs) represent a promising alternative to conventional mechanical compressors, offering advantages in energy efficiency, reduced environmental impact, and operational flexibility. However, current monitoring approaches for ECCs face significant limitations that hinder their widespread adoption and optimal performance. Traditional monitoring systems typically rely on basic sensor networks that capture only a limited set of operational parameters, providing an incomplete picture of system health and performance.

The global landscape of ECC monitoring technology reveals varying levels of advancement. Leading research institutions in North America and Europe have developed sophisticated monitoring frameworks incorporating multiple sensor types, while implementation in commercial settings remains largely rudimentary. Asian markets, particularly in Japan and South Korea, have made notable progress in integrating advanced monitoring systems with existing industrial infrastructure.

A primary technical challenge in ECC monitoring is the complex electrochemical processes occurring at the electrode-electrolyte interfaces. These processes are difficult to measure directly and exhibit nonlinear behaviors that conventional sensors struggle to capture accurately. The harsh operating environments of many ECC applications—including exposure to corrosive substances, high pressures, and temperature fluctuations—further complicate reliable data acquisition.

Data integration presents another significant hurdle. Current monitoring systems often operate in isolation, with limited capability to synthesize information across different operational parameters or to correlate electrochemical performance indicators with mechanical system metrics. This fragmentation impedes comprehensive system understanding and effective predictive maintenance strategies.

Existing sensor technologies face limitations in durability and accuracy when deployed in ECC environments. Electrode degradation sensors, critical for monitoring system health, frequently suffer from drift and calibration issues. Similarly, membrane condition monitoring—essential for predicting failure modes—lacks robust, long-term reliable solutions in industrial settings.

Communication protocols and data standardization remain underdeveloped in the ECC monitoring space. The absence of industry-wide standards creates interoperability challenges when integrating monitoring systems with broader plant management platforms or when attempting to benchmark performance across different installations.

Real-time processing capabilities are currently insufficient for the complex data streams generated by comprehensive ECC monitoring. Most systems operate with significant latency between data acquisition and analysis, limiting their utility for dynamic control adjustments or immediate fault detection. This gap becomes particularly problematic in applications requiring rapid response to changing conditions or early intervention to prevent cascading failures.

AI and machine learning implementation in ECC monitoring remains in its infancy, with most deployments limited to basic pattern recognition rather than sophisticated predictive analytics. The shortage of comprehensive historical datasets further hampers the development of robust predictive models for ECC behavior and maintenance needs.

The global landscape of ECC monitoring technology reveals varying levels of advancement. Leading research institutions in North America and Europe have developed sophisticated monitoring frameworks incorporating multiple sensor types, while implementation in commercial settings remains largely rudimentary. Asian markets, particularly in Japan and South Korea, have made notable progress in integrating advanced monitoring systems with existing industrial infrastructure.

A primary technical challenge in ECC monitoring is the complex electrochemical processes occurring at the electrode-electrolyte interfaces. These processes are difficult to measure directly and exhibit nonlinear behaviors that conventional sensors struggle to capture accurately. The harsh operating environments of many ECC applications—including exposure to corrosive substances, high pressures, and temperature fluctuations—further complicate reliable data acquisition.

Data integration presents another significant hurdle. Current monitoring systems often operate in isolation, with limited capability to synthesize information across different operational parameters or to correlate electrochemical performance indicators with mechanical system metrics. This fragmentation impedes comprehensive system understanding and effective predictive maintenance strategies.

Existing sensor technologies face limitations in durability and accuracy when deployed in ECC environments. Electrode degradation sensors, critical for monitoring system health, frequently suffer from drift and calibration issues. Similarly, membrane condition monitoring—essential for predicting failure modes—lacks robust, long-term reliable solutions in industrial settings.

Communication protocols and data standardization remain underdeveloped in the ECC monitoring space. The absence of industry-wide standards creates interoperability challenges when integrating monitoring systems with broader plant management platforms or when attempting to benchmark performance across different installations.

Real-time processing capabilities are currently insufficient for the complex data streams generated by comprehensive ECC monitoring. Most systems operate with significant latency between data acquisition and analysis, limiting their utility for dynamic control adjustments or immediate fault detection. This gap becomes particularly problematic in applications requiring rapid response to changing conditions or early intervention to prevent cascading failures.

AI and machine learning implementation in ECC monitoring remains in its infancy, with most deployments limited to basic pattern recognition rather than sophisticated predictive analytics. The shortage of comprehensive historical datasets further hampers the development of robust predictive models for ECC behavior and maintenance needs.

Current Digital Twin Implementation Approaches for Electrochemical Systems

01 Digital twin modeling for electrochemical compressor systems

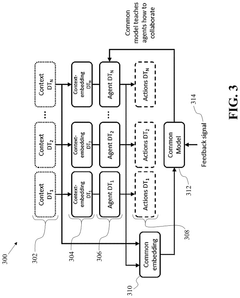

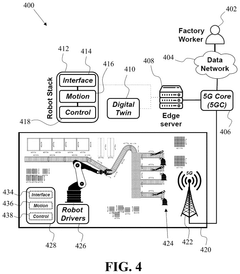

Digital twin technology can be applied to electrochemical compressor systems to create virtual replicas that simulate real-time operation. These models integrate physical parameters, electrochemical reactions, and operational conditions to accurately represent compressor behavior. The digital twin enables operators to visualize system performance, identify optimal operating parameters, and understand the complex interactions between electrochemical processes and mechanical components, ultimately improving system efficiency and reliability.- Digital twin modeling for electrochemical compressor systems: Digital twin technology can be applied to electrochemical compressor systems to create virtual replicas that simulate real-time operation. These models integrate physical parameters, electrochemical reactions, and operational data to provide accurate representations of compressor behavior. The digital twins enable operators to monitor performance metrics, visualize system states, and understand the complex interactions between components under various operating conditions.

- Predictive maintenance algorithms for electrochemical compressors: Advanced algorithms can analyze operational data from electrochemical compressors to predict potential failures before they occur. These predictive maintenance systems utilize machine learning techniques to identify patterns associated with component degradation, membrane fouling, or electrode deterioration. By continuously monitoring key parameters such as pressure differentials, current efficiency, and thermal profiles, the system can generate early warnings and recommend maintenance actions to prevent unplanned downtime.

- Real-time monitoring and anomaly detection systems: Real-time monitoring systems for electrochemical compressors collect and analyze operational data to detect anomalies and deviations from normal performance. These systems utilize sensors to measure critical parameters such as temperature, pressure, humidity, current density, and voltage across the electrochemical cells. Advanced signal processing and statistical methods help identify subtle changes in system behavior that may indicate developing issues, allowing for timely intervention before failures occur.

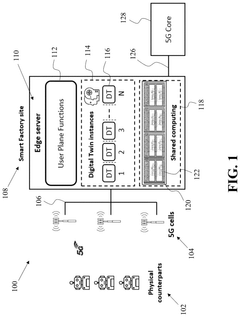

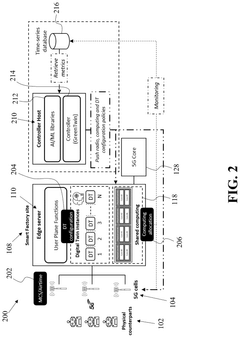

- Integration of IoT and cloud computing for compressor management: Internet of Things (IoT) devices and cloud computing platforms can be integrated with electrochemical compressor systems to enhance monitoring and maintenance capabilities. This architecture enables remote access to operational data, facilitates centralized management of distributed compressor units, and supports advanced analytics. The cloud-based digital twin can process large volumes of historical and real-time data to optimize performance, reduce energy consumption, and extend equipment lifespan through intelligent control strategies.

- Performance optimization through simulation-based control: Digital twin technology enables simulation-based control strategies for electrochemical compressors that optimize performance under varying operating conditions. These control systems use the digital model to predict system responses to different inputs and environmental factors, allowing for proactive adjustments to operating parameters. By continuously comparing actual performance with simulated predictions, the control system can adapt to changing conditions, compensate for component degradation, and maintain optimal efficiency throughout the compressor's operational life.

02 Predictive maintenance algorithms for electrochemical compressors

Advanced algorithms can analyze operational data from electrochemical compressors to predict potential failures before they occur. These predictive maintenance systems utilize machine learning techniques to identify patterns associated with component degradation, performance decline, or imminent failures. By continuously monitoring key parameters such as pressure differentials, current density, membrane conditions, and thermal profiles, the system can recommend maintenance interventions at optimal times, reducing downtime and extending equipment lifespan.Expand Specific Solutions03 Real-time monitoring and anomaly detection systems

Real-time monitoring systems for electrochemical compressors collect and analyze operational data to detect anomalies and deviations from normal performance. These systems employ sensors to measure critical parameters including temperature, pressure, flow rates, voltage, and current efficiency. Advanced signal processing and statistical methods are used to identify unusual patterns that may indicate developing issues. Early detection of anomalies allows for prompt intervention, preventing catastrophic failures and optimizing maintenance scheduling.Expand Specific Solutions04 Performance optimization through digital simulation

Digital twin technology enables performance optimization of electrochemical compressors through simulation-based analysis. By creating virtual testing environments, operators can experiment with different operational parameters, material configurations, and control strategies without risking actual equipment. These simulations help identify optimal operating conditions that maximize efficiency, minimize energy consumption, and extend component lifespan. The digital models can also be used to train operators and develop improved control algorithms for various operating scenarios.Expand Specific Solutions05 Integration of IoT and cloud computing for remote monitoring

Internet of Things (IoT) sensors and cloud computing platforms can be integrated with electrochemical compressor systems to enable remote monitoring and management. This architecture allows for continuous data collection, storage, and analysis regardless of geographical location. Cloud-based digital twins can process large volumes of operational data to generate insights, trigger automated responses to critical conditions, and provide accessible dashboards for maintenance teams. This approach facilitates centralized management of distributed compressor systems and enables expert remote diagnostics.Expand Specific Solutions

Key Industry Players in Electrochemical Compressor Digital Twin Solutions

The digital twin market for electrochemical compressor operation and predictive maintenance is in its early growth phase, characterized by increasing adoption across industrial applications. The market is projected to expand significantly as industries prioritize operational efficiency and equipment reliability. Leading technology providers like Siemens AG, IBM, and Applied Materials are developing sophisticated digital twin solutions that integrate real-time monitoring with predictive analytics. Academic institutions including Xi'an Jiaotong University and Shanghai Jiao Tong University are contributing fundamental research, while industrial players such as Bosch, ABB Group, and SK Innovation are implementing application-specific solutions. The technology is approaching early maturity in monitoring capabilities but still evolving in predictive maintenance algorithms and electrochemical process optimization.

Siemens AG

Technical Solution: Siemens has developed a comprehensive Digital Twin approach for electrochemical compressors that integrates multi-physics modeling with real-time operational data. Their solution combines thermodynamic models, electrochemical reaction kinetics, and fluid dynamics simulations to create high-fidelity virtual representations of compressor systems. Siemens' platform utilizes their Teamcenter software for lifecycle management and MindSphere IoT operating system to collect operational data from sensors embedded throughout the compressor system. The digital twin continuously analyzes performance parameters including membrane conductivity, electrode degradation, and system efficiency. For predictive maintenance, Siemens employs machine learning algorithms that identify anomalous behavior patterns before failures occur, with reported accuracy rates exceeding 85% for early fault detection. Their system can simulate various operational scenarios and aging processes, enabling operators to optimize maintenance schedules and extend component lifespans by an estimated 15-30%.

Strengths: Siemens offers a mature ecosystem of software tools that seamlessly integrate with their hardware solutions, providing end-to-end digital twin capabilities. Their extensive experience in industrial automation and process control enables highly accurate simulations. Weaknesses: The system requires significant computational resources and specialized expertise to implement and maintain, potentially limiting accessibility for smaller operations.

International Business Machines Corp.

Technical Solution: IBM has pioneered an advanced Digital Twin framework for electrochemical compressor systems that leverages their Watson IoT platform and hybrid cloud architecture. Their approach creates a dynamic virtual model that simulates both the electrochemical processes and mechanical components with high precision. IBM's solution incorporates multi-scale modeling techniques that bridge molecular-level electrochemical reactions with system-level performance metrics. The platform collects operational data through a network of smart sensors and employs sophisticated AI algorithms to analyze patterns and detect anomalies. For predictive maintenance, IBM utilizes their Maximo Asset Performance Management system enhanced with specialized electrochemical degradation models. The system continuously monitors critical parameters such as membrane hydration levels, catalyst activity, and electrical efficiency. Their predictive analytics can forecast component failures up to several weeks in advance with reported accuracy rates of over 90%, allowing for optimized maintenance scheduling and reduced downtime. IBM's solution also includes digital dashboards that provide real-time visualization of system health and performance metrics.

Strengths: IBM's solution excels in data integration capabilities, seamlessly combining operational technology (OT) and information technology (IT) data streams. Their advanced AI algorithms provide superior predictive capabilities compared to conventional approaches. Weaknesses: Implementation requires significant customization and integration work, potentially resulting in longer deployment timelines and higher initial costs.

Core Technologies for Electrochemical Process Simulation and Modeling

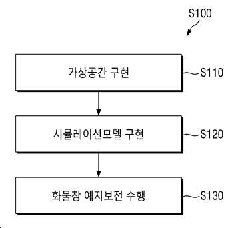

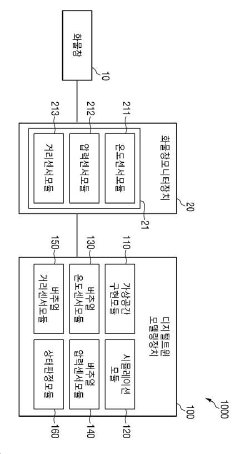

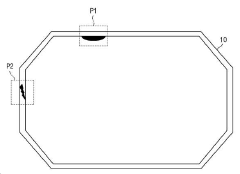

Predictive maintenance method and system based on digital twin model

PatentPendingKR1020230127674A

Innovation

- A digital twin model-based predictive maintenance system that includes virtual space implementation, simulation, and sensor modules to objectively assess cargo hold conditions, determining damage and hazardous areas, and perform proactive maintenance.

Energy consumption optimization in digital twin applications

PatentPendingUS20240319774A1

Innovation

- A computer-implemented method that receives input metrics from digital twins, determines updated configurations including radio, computing, and digital twin configurations to reduce power consumption, and provides these configurations through APIs, leveraging delay budgets to optimize energy use and resource allocation.

Data Security and Integration Challenges in Industrial Digital Twins

The integration of digital twin technology with electrochemical compressors introduces significant data security and integration challenges that must be addressed for successful implementation. Industrial environments generate massive volumes of sensitive operational data, including proprietary compression algorithms, performance metrics, and maintenance histories. This data requires robust protection against unauthorized access, particularly as digital twins often operate in networked environments where cybersecurity threats are prevalent.

Encryption protocols specifically designed for real-time electrochemical data streams represent a critical security requirement. Standard encryption methods may introduce latency that compromises the digital twin's ability to accurately model compressor behavior, necessitating specialized approaches that balance security with performance. Multi-factor authentication systems must be implemented to control access to digital twin interfaces, particularly for functions that can modify operational parameters of electrochemical compressors.

Data integration challenges are equally significant, as electrochemical compressor digital twins must synthesize information from disparate sources. Sensor networks monitoring electrochemical reactions, mechanical components, and environmental conditions often utilize different communication protocols and data formats. This heterogeneity creates integration bottlenecks that can undermine the digital twin's predictive maintenance capabilities if not properly addressed through standardized data exchange frameworks.

Legacy systems present particular difficulties, as many industrial facilities operate electrochemical equipment with outdated control systems that lack modern API capabilities. Retrofitting these systems to communicate with digital twin platforms requires careful engineering to avoid disrupting critical operations while ensuring data integrity. Custom middleware solutions are frequently necessary to translate between proprietary protocols and standardized digital twin interfaces.

Cloud-edge computing architectures offer promising solutions to these challenges by processing sensitive data locally while leveraging cloud resources for complex predictive analytics. This hybrid approach reduces security vulnerabilities associated with transmitting raw operational data while maintaining the computational power needed for sophisticated electrochemical modeling. However, implementing such architectures demands careful consideration of data synchronization mechanisms to ensure consistency between edge and cloud components.

Regulatory compliance adds another layer of complexity, particularly in industries where electrochemical compressors handle hazardous materials or support critical infrastructure. Digital twins must incorporate compliance frameworks that document data handling practices and security measures according to relevant standards such as IEC 62443 for industrial automation and control systems security.

Encryption protocols specifically designed for real-time electrochemical data streams represent a critical security requirement. Standard encryption methods may introduce latency that compromises the digital twin's ability to accurately model compressor behavior, necessitating specialized approaches that balance security with performance. Multi-factor authentication systems must be implemented to control access to digital twin interfaces, particularly for functions that can modify operational parameters of electrochemical compressors.

Data integration challenges are equally significant, as electrochemical compressor digital twins must synthesize information from disparate sources. Sensor networks monitoring electrochemical reactions, mechanical components, and environmental conditions often utilize different communication protocols and data formats. This heterogeneity creates integration bottlenecks that can undermine the digital twin's predictive maintenance capabilities if not properly addressed through standardized data exchange frameworks.

Legacy systems present particular difficulties, as many industrial facilities operate electrochemical equipment with outdated control systems that lack modern API capabilities. Retrofitting these systems to communicate with digital twin platforms requires careful engineering to avoid disrupting critical operations while ensuring data integrity. Custom middleware solutions are frequently necessary to translate between proprietary protocols and standardized digital twin interfaces.

Cloud-edge computing architectures offer promising solutions to these challenges by processing sensitive data locally while leveraging cloud resources for complex predictive analytics. This hybrid approach reduces security vulnerabilities associated with transmitting raw operational data while maintaining the computational power needed for sophisticated electrochemical modeling. However, implementing such architectures demands careful consideration of data synchronization mechanisms to ensure consistency between edge and cloud components.

Regulatory compliance adds another layer of complexity, particularly in industries where electrochemical compressors handle hazardous materials or support critical infrastructure. Digital twins must incorporate compliance frameworks that document data handling practices and security measures according to relevant standards such as IEC 62443 for industrial automation and control systems security.

ROI Assessment Framework for Digital Twin Implementation

Implementing a digital twin for electrochemical compressors requires a structured approach to evaluate return on investment. This framework provides organizations with a systematic methodology to assess the financial viability and business value of digital twin implementations specifically for electrochemical compressor operations and maintenance.

The ROI assessment begins with identifying key performance indicators directly impacted by digital twin implementation. For electrochemical compressors, these typically include reduction in unplanned downtime, extension of component lifespan, optimization of energy consumption, and decreased maintenance costs. Each KPI should be assigned a monetary value to establish baseline metrics for comparison.

Implementation costs must be thoroughly cataloged, including initial software development or licensing, hardware sensors and infrastructure, integration with existing systems, staff training, and ongoing maintenance of the digital twin platform. These costs should be projected over a 3-5 year period to account for the full implementation lifecycle and technology maturation.

Benefit quantification requires modeling several value streams. Direct benefits include reduced maintenance costs through condition-based maintenance rather than scheduled interventions, decreased energy consumption through optimized operation parameters, and extended equipment lifespan. Indirect benefits encompass improved operational efficiency, reduced safety incidents, and enhanced decision-making capabilities.

Risk factors must be incorporated into the assessment framework, including technology implementation delays, data quality issues, integration challenges with legacy systems, and potential cybersecurity vulnerabilities. Each risk should be assigned a probability and potential financial impact to create a weighted risk adjustment factor for the ROI calculation.

The timeframe for ROI realization varies significantly based on implementation complexity. For electrochemical compressors, pilot implementations typically show initial returns within 6-12 months through early fault detection, while comprehensive benefits from predictive maintenance capabilities may take 18-36 months to fully materialize as the digital twin accumulates sufficient operational data to refine its predictive algorithms.

Sensitivity analysis should be performed to understand how variations in key assumptions affect the overall ROI. This includes testing different scenarios for implementation timelines, varying degrees of performance improvement, and different cost structures to provide decision-makers with a comprehensive understanding of potential outcomes under different conditions.

The ROI assessment begins with identifying key performance indicators directly impacted by digital twin implementation. For electrochemical compressors, these typically include reduction in unplanned downtime, extension of component lifespan, optimization of energy consumption, and decreased maintenance costs. Each KPI should be assigned a monetary value to establish baseline metrics for comparison.

Implementation costs must be thoroughly cataloged, including initial software development or licensing, hardware sensors and infrastructure, integration with existing systems, staff training, and ongoing maintenance of the digital twin platform. These costs should be projected over a 3-5 year period to account for the full implementation lifecycle and technology maturation.

Benefit quantification requires modeling several value streams. Direct benefits include reduced maintenance costs through condition-based maintenance rather than scheduled interventions, decreased energy consumption through optimized operation parameters, and extended equipment lifespan. Indirect benefits encompass improved operational efficiency, reduced safety incidents, and enhanced decision-making capabilities.

Risk factors must be incorporated into the assessment framework, including technology implementation delays, data quality issues, integration challenges with legacy systems, and potential cybersecurity vulnerabilities. Each risk should be assigned a probability and potential financial impact to create a weighted risk adjustment factor for the ROI calculation.

The timeframe for ROI realization varies significantly based on implementation complexity. For electrochemical compressors, pilot implementations typically show initial returns within 6-12 months through early fault detection, while comprehensive benefits from predictive maintenance capabilities may take 18-36 months to fully materialize as the digital twin accumulates sufficient operational data to refine its predictive algorithms.

Sensitivity analysis should be performed to understand how variations in key assumptions affect the overall ROI. This includes testing different scenarios for implementation timelines, varying degrees of performance improvement, and different cost structures to provide decision-makers with a comprehensive understanding of potential outcomes under different conditions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!