Prototyping And Scale-Up Roadmap For Electrochemical Compressor Modules

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Compressor Technology Background and Objectives

Electrochemical compressors represent a revolutionary approach to gas compression technology that has evolved significantly over the past three decades. Unlike conventional mechanical compressors that rely on moving parts to compress gases, electrochemical compressors utilize electrochemical principles to achieve compression through ion transport across membranes. This technology originated in the 1980s with early conceptual designs, but significant advancements have only materialized in the last decade due to breakthroughs in materials science and electrochemistry.

The evolution of electrochemical compressor technology has been closely tied to developments in hydrogen fuel cells and electrolyzers, as they share similar fundamental principles and materials. Early prototypes demonstrated limited efficiency and compression ratios, but recent innovations in proton exchange membranes, electrode materials, and system integration have dramatically improved performance metrics.

Current electrochemical compressors can achieve compression ratios of 10:1 to 30:1 in single stages, with multi-stage systems capable of reaching much higher pressures. The technology shows particular promise for applications requiring oil-free, quiet, and vibration-free compression, especially for hydrogen and refrigerant gases.

The global push toward hydrogen economies and sustainable cooling solutions has accelerated interest in electrochemical compression technology. Market projections indicate substantial growth potential as industries seek more efficient and environmentally friendly compression solutions. The technology aligns with global decarbonization goals by enabling more efficient hydrogen infrastructure and reducing the environmental impact of cooling systems.

The primary technical objectives for electrochemical compressor development include improving energy efficiency, increasing compression ratios, enhancing durability and operational lifetime, and reducing manufacturing costs. Current research focuses on novel membrane materials with higher ion conductivity, advanced catalyst formulations to improve reaction kinetics, and innovative cell designs to optimize gas flow and reduce internal resistance.

Scale-up challenges represent a critical frontier in electrochemical compressor development. Laboratory prototypes must transition to commercially viable modules capable of meeting industrial demands for flow rates and pressure requirements. This necessitates addressing issues related to thermal management, uniform current distribution across larger active areas, and system integration with balance-of-plant components.

The roadmap for electrochemical compressor technology aims to achieve cost parity with conventional compression technologies by 2030, while offering superior environmental performance and operational benefits. This will require coordinated efforts across material science, manufacturing processes, and system engineering to overcome current limitations and realize the full potential of this promising technology.

The evolution of electrochemical compressor technology has been closely tied to developments in hydrogen fuel cells and electrolyzers, as they share similar fundamental principles and materials. Early prototypes demonstrated limited efficiency and compression ratios, but recent innovations in proton exchange membranes, electrode materials, and system integration have dramatically improved performance metrics.

Current electrochemical compressors can achieve compression ratios of 10:1 to 30:1 in single stages, with multi-stage systems capable of reaching much higher pressures. The technology shows particular promise for applications requiring oil-free, quiet, and vibration-free compression, especially for hydrogen and refrigerant gases.

The global push toward hydrogen economies and sustainable cooling solutions has accelerated interest in electrochemical compression technology. Market projections indicate substantial growth potential as industries seek more efficient and environmentally friendly compression solutions. The technology aligns with global decarbonization goals by enabling more efficient hydrogen infrastructure and reducing the environmental impact of cooling systems.

The primary technical objectives for electrochemical compressor development include improving energy efficiency, increasing compression ratios, enhancing durability and operational lifetime, and reducing manufacturing costs. Current research focuses on novel membrane materials with higher ion conductivity, advanced catalyst formulations to improve reaction kinetics, and innovative cell designs to optimize gas flow and reduce internal resistance.

Scale-up challenges represent a critical frontier in electrochemical compressor development. Laboratory prototypes must transition to commercially viable modules capable of meeting industrial demands for flow rates and pressure requirements. This necessitates addressing issues related to thermal management, uniform current distribution across larger active areas, and system integration with balance-of-plant components.

The roadmap for electrochemical compressor technology aims to achieve cost parity with conventional compression technologies by 2030, while offering superior environmental performance and operational benefits. This will require coordinated efforts across material science, manufacturing processes, and system engineering to overcome current limitations and realize the full potential of this promising technology.

Market Analysis for Electrochemical Compression Applications

The electrochemical compression market is experiencing significant growth driven by increasing demand for clean energy technologies and sustainable industrial processes. Current market assessments indicate that the global hydrogen compression market, where electrochemical compression holds substantial promise, is valued at approximately $1.5 billion with projections to reach $2.3 billion by 2027. Electrochemical compressors specifically are gaining traction within this broader market due to their unique advantages in efficiency and environmental performance.

Key market segments for electrochemical compression applications include hydrogen refueling stations, industrial gas processing, refrigeration systems, and energy storage solutions. The hydrogen refueling infrastructure segment shows particularly strong growth potential, with over 500 stations currently operational globally and plans for thousands more in development across Europe, Asia, and North America. This expansion directly drives demand for more efficient compression technologies.

The refrigeration and heat pump sector represents another substantial market opportunity, valued at approximately $120 billion globally. Electrochemical compression offers a promising alternative to conventional vapor compression systems, potentially capturing 5-10% of this market in specialized applications over the next decade. Early adopters include data centers seeking energy-efficient cooling solutions and pharmaceutical companies requiring precise temperature control.

Market penetration analysis reveals regional variations in adoption rates. Japan, Germany, and California lead in hydrogen infrastructure development, creating immediate market opportunities. China is rapidly expanding its hydrogen economy with substantial government backing, while South Korea focuses on residential fuel cell applications that require compression technologies.

Customer demand analysis indicates three primary drivers: energy efficiency improvements (20-40% potential gains over mechanical compression), elimination of lubricants and associated maintenance, and silent operation capabilities. These benefits are particularly valued in urban settings, medical facilities, and premium residential applications where noise and reliability are critical factors.

Competitive landscape assessment shows limited commercial-scale deployment of electrochemical compression technology to date, creating a significant first-mover advantage opportunity. Several startups have secured venture funding in the $10-50 million range to accelerate commercialization efforts, while established industrial gas companies are primarily pursuing strategic partnerships rather than internal development.

Market barriers include higher initial capital costs compared to conventional technologies, limited awareness among potential end-users, and the need for specialized integration expertise. However, total cost of ownership analyses demonstrate favorable economics over 5-10 year operational periods when accounting for energy savings and reduced maintenance requirements.

Key market segments for electrochemical compression applications include hydrogen refueling stations, industrial gas processing, refrigeration systems, and energy storage solutions. The hydrogen refueling infrastructure segment shows particularly strong growth potential, with over 500 stations currently operational globally and plans for thousands more in development across Europe, Asia, and North America. This expansion directly drives demand for more efficient compression technologies.

The refrigeration and heat pump sector represents another substantial market opportunity, valued at approximately $120 billion globally. Electrochemical compression offers a promising alternative to conventional vapor compression systems, potentially capturing 5-10% of this market in specialized applications over the next decade. Early adopters include data centers seeking energy-efficient cooling solutions and pharmaceutical companies requiring precise temperature control.

Market penetration analysis reveals regional variations in adoption rates. Japan, Germany, and California lead in hydrogen infrastructure development, creating immediate market opportunities. China is rapidly expanding its hydrogen economy with substantial government backing, while South Korea focuses on residential fuel cell applications that require compression technologies.

Customer demand analysis indicates three primary drivers: energy efficiency improvements (20-40% potential gains over mechanical compression), elimination of lubricants and associated maintenance, and silent operation capabilities. These benefits are particularly valued in urban settings, medical facilities, and premium residential applications where noise and reliability are critical factors.

Competitive landscape assessment shows limited commercial-scale deployment of electrochemical compression technology to date, creating a significant first-mover advantage opportunity. Several startups have secured venture funding in the $10-50 million range to accelerate commercialization efforts, while established industrial gas companies are primarily pursuing strategic partnerships rather than internal development.

Market barriers include higher initial capital costs compared to conventional technologies, limited awareness among potential end-users, and the need for specialized integration expertise. However, total cost of ownership analyses demonstrate favorable economics over 5-10 year operational periods when accounting for energy savings and reduced maintenance requirements.

Current Technical Challenges in Electrochemical Compressor Development

Electrochemical compressors (ECCs) represent a promising alternative to conventional mechanical compressors, offering potential advantages in energy efficiency, reliability, and environmental impact. However, the development of these systems faces several significant technical challenges that must be addressed before widespread commercial adoption can occur.

The primary challenge in ECC development is achieving commercially viable energy efficiency. Current prototypes demonstrate theoretical efficiency advantages over mechanical systems, but practical implementations often suffer from high electrical resistance, membrane degradation, and parasitic losses. These factors collectively reduce the coefficient of performance (COP) to levels that struggle to compete with established technologies, particularly at higher compression ratios.

Material limitations present another substantial hurdle. The proton exchange membranes (PEMs) used in ECCs must simultaneously provide high ionic conductivity, low gas permeability, and excellent mechanical stability under pressure differentials. Existing membrane materials like Nafion show promising performance but experience accelerated degradation under the operating conditions required for practical applications, limiting device lifespan and reliability.

Scaling production from laboratory prototypes to commercial modules introduces complex engineering challenges. The uniform distribution of reactants across larger active areas becomes increasingly difficult, leading to performance inconsistencies and reduced efficiency. Current cell stack designs struggle to maintain even compression and electrical contact across larger surface areas, resulting in localized hotspots and premature failure points.

Heat management represents a critical technical barrier, particularly for high-compression applications. The electrochemical reactions in ECCs generate significant heat that must be efficiently removed to prevent membrane dehydration and degradation. Existing thermal management solutions add considerable complexity, weight, and cost to the system, undermining the inherent advantages of the technology.

Control system development presents unique challenges for ECCs compared to mechanical compressors. The response characteristics of electrochemical systems differ fundamentally from mechanical systems, requiring sophisticated control algorithms to manage transient operations, load variations, and system protection. Current control strategies lack the robustness needed for reliable operation across diverse operating conditions.

Manufacturing processes for ECCs remain largely artisanal and laboratory-focused, with significant barriers to cost-effective mass production. The precise assembly requirements for cell stacks, the handling of sensitive membrane materials, and the integration of complex balance-of-plant components all contribute to high production costs that currently limit commercial viability.

Durability testing protocols and accelerated life testing methodologies for ECCs are still in early development stages. The lack of standardized testing procedures makes it difficult to accurately predict system lifetime and reliability, creating uncertainty for potential adopters and investors in the technology.

The primary challenge in ECC development is achieving commercially viable energy efficiency. Current prototypes demonstrate theoretical efficiency advantages over mechanical systems, but practical implementations often suffer from high electrical resistance, membrane degradation, and parasitic losses. These factors collectively reduce the coefficient of performance (COP) to levels that struggle to compete with established technologies, particularly at higher compression ratios.

Material limitations present another substantial hurdle. The proton exchange membranes (PEMs) used in ECCs must simultaneously provide high ionic conductivity, low gas permeability, and excellent mechanical stability under pressure differentials. Existing membrane materials like Nafion show promising performance but experience accelerated degradation under the operating conditions required for practical applications, limiting device lifespan and reliability.

Scaling production from laboratory prototypes to commercial modules introduces complex engineering challenges. The uniform distribution of reactants across larger active areas becomes increasingly difficult, leading to performance inconsistencies and reduced efficiency. Current cell stack designs struggle to maintain even compression and electrical contact across larger surface areas, resulting in localized hotspots and premature failure points.

Heat management represents a critical technical barrier, particularly for high-compression applications. The electrochemical reactions in ECCs generate significant heat that must be efficiently removed to prevent membrane dehydration and degradation. Existing thermal management solutions add considerable complexity, weight, and cost to the system, undermining the inherent advantages of the technology.

Control system development presents unique challenges for ECCs compared to mechanical compressors. The response characteristics of electrochemical systems differ fundamentally from mechanical systems, requiring sophisticated control algorithms to manage transient operations, load variations, and system protection. Current control strategies lack the robustness needed for reliable operation across diverse operating conditions.

Manufacturing processes for ECCs remain largely artisanal and laboratory-focused, with significant barriers to cost-effective mass production. The precise assembly requirements for cell stacks, the handling of sensitive membrane materials, and the integration of complex balance-of-plant components all contribute to high production costs that currently limit commercial viability.

Durability testing protocols and accelerated life testing methodologies for ECCs are still in early development stages. The lack of standardized testing procedures makes it difficult to accurately predict system lifetime and reliability, creating uncertainty for potential adopters and investors in the technology.

Current Prototyping Methodologies for Electrochemical Compressors

01 Electrochemical compressor design and components

Electrochemical compressors utilize electrochemical cells to compress gases through electrochemical reactions. The design includes key components such as electrodes, membranes, and electrolytes that facilitate ion transport and gas compression. These components are arranged in modules that can be scaled up for various applications. The design considerations focus on optimizing the electrochemical interfaces and ensuring efficient gas handling within the compressor system.- Electrochemical compressor design and fabrication: Electrochemical compressors utilize electrochemical reactions to compress gases without mechanical moving parts. The design involves electrode assemblies, membrane electrode assemblies (MEAs), and specialized cell stacks. Prototyping these compressors requires precise fabrication techniques for components like electrodes, membranes, and bipolar plates. The scale-up process involves optimizing these components for increased capacity while maintaining efficiency and reliability.

- Thermal management systems for electrochemical modules: Effective thermal management is crucial for electrochemical compressor modules during prototyping and scale-up. These systems include cooling channels, heat exchangers, and thermal interface materials to maintain optimal operating temperatures. Advanced thermal management solutions help prevent overheating, improve efficiency, and extend the lifespan of electrochemical compressor modules, particularly when scaling up to larger systems with higher power densities.

- Control systems and monitoring for electrochemical compressors: Sophisticated control systems are essential for electrochemical compressor modules during prototyping and scale-up. These systems include sensors for monitoring pressure, temperature, humidity, and electrical parameters. Advanced algorithms optimize performance and prevent system failures. The control architecture typically includes microcontrollers, power management systems, and communication interfaces that enable real-time monitoring and adjustment of operating parameters to maintain efficiency during scale-up.

- Materials selection and optimization for scale-up: The selection and optimization of materials is critical for successful prototyping and scale-up of electrochemical compressor modules. This includes developing advanced electrode materials, ion-exchange membranes, catalysts, and sealing components that can withstand the operating conditions while maintaining performance. Material optimization focuses on improving conductivity, durability, and chemical stability while reducing costs for commercial viability during scale-up.

- Manufacturing processes for large-scale production: Transitioning from prototype to large-scale production of electrochemical compressor modules requires specialized manufacturing processes. These include automated assembly techniques, quality control systems, and testing protocols to ensure consistency and reliability. Advanced manufacturing methods such as roll-to-roll processing, injection molding, and precision machining are employed to produce components at scale while maintaining tight tolerances and reducing production costs.

02 Prototyping methods for electrochemical modules

Various prototyping methods are employed for developing electrochemical compressor modules, including rapid prototyping techniques, 3D printing, and modular design approaches. These methods allow for iterative testing and refinement of compressor components before full-scale production. Prototyping focuses on validating the electrochemical performance, mechanical integrity, and thermal management of the compressor modules under various operating conditions.Expand Specific Solutions03 Scale-up strategies and manufacturing processes

Scaling up electrochemical compressor modules from prototype to commercial scale involves specific manufacturing processes and quality control measures. These include automated assembly techniques, precision fabrication methods, and standardized testing protocols. The scale-up strategies address challenges related to maintaining performance consistency across larger systems, optimizing material usage, and ensuring cost-effective production while preserving the electrochemical efficiency achieved in smaller prototypes.Expand Specific Solutions04 Thermal management and efficiency optimization

Effective thermal management is crucial for electrochemical compressor modules during both prototyping and scale-up phases. This involves designing cooling systems, heat exchangers, and thermal interfaces to maintain optimal operating temperatures. Efficiency optimization techniques include electrode surface modification, electrolyte composition adjustments, and operating parameter optimization to maximize compression ratios while minimizing energy consumption.Expand Specific Solutions05 Control systems and performance monitoring

Advanced control systems and performance monitoring technologies are integrated into electrochemical compressor modules to ensure reliable operation during prototyping and after scale-up. These systems include sensors for monitoring pressure, temperature, and electrochemical parameters, along with control algorithms for optimizing performance under varying conditions. Real-time monitoring capabilities allow for data collection during testing phases, which informs design improvements and operational adjustments for scaled-up systems.Expand Specific Solutions

Industry Leaders and Competitive Landscape Analysis

The electrochemical compressor module market is in an early growth phase, characterized by significant R&D activity and emerging commercial applications. The market size remains relatively modest but is expanding rapidly due to increasing demand for energy-efficient cooling and heating solutions. From a technological maturity perspective, the field is transitioning from laboratory research to commercial prototyping, with key players demonstrating varied levels of advancement. Companies like Toyota Industries and DENSO are leveraging their automotive compressor expertise to develop electrochemical alternatives, while research institutions such as University of Southern California, Zhejiang University, and North Carolina State University are driving fundamental innovation. Specialized firms including Microfabrica and Enapter are focusing on micro-fabrication techniques and hydrogen technologies respectively, essential for module miniaturization and efficiency improvements. Energy companies like Osaka Gas and Koninklijke Philips are exploring integration opportunities within broader energy systems.

Enapter Srl

Technical Solution: Enapter has developed a modular approach to electrochemical compression through their AEM (Anion Exchange Membrane) technology. Their electrochemical compressor modules utilize a patented stack design that enables hydrogen compression from atmospheric pressure to 35+ bar without mechanical components. The system integrates with their electrolyzers to create a complete hydrogen production and compression solution. Enapter's prototype development follows a standardized process beginning with lab-scale testing of membrane electrode assemblies, followed by single-cell testing, small stack validation, and finally full module integration. Their scale-up roadmap includes progressive capacity increases from 0.5 Nm³/h to 10+ Nm³/h systems with corresponding increases in compression capabilities. The company employs advanced manufacturing techniques including automated assembly lines to ensure consistent quality across production units.

Strengths: Highly modular design allows for flexible scaling; elimination of mechanical components reduces maintenance requirements and increases reliability; integrated approach with electrolysis systems creates end-to-end solutions. Weaknesses: Current technology limited to moderate pressure ranges compared to mechanical compressors; requires specialized materials that may face supply chain constraints; energy efficiency still being optimized at larger scales.

Shenzhen Senergy Fuel Cell Technology Co., Ltd.

Technical Solution: Shenzhen Senergy has pioneered electrochemical compression technology specifically designed for hydrogen fuel cell applications. Their compressor modules utilize proton exchange membrane (PEM) technology with proprietary catalyst formulations that enhance efficiency and durability. The company's prototyping process involves systematic testing of membrane electrode assemblies with various catalyst loadings and membrane thicknesses to optimize performance. Their scale-up roadmap includes three distinct phases: (1) laboratory prototype development (1-5 kW systems), (2) pilot production with semi-automated assembly (5-50 kW systems), and (3) full commercial production with fully automated manufacturing lines (50+ kW systems). Senergy has developed specialized bipolar plate designs that improve current distribution and heat management within the stack, allowing for more efficient compression at higher throughput rates. Their modules achieve compression ratios of up to 50:1 while maintaining high efficiency.

Strengths: Specialized expertise in hydrogen applications for fuel cell vehicles; advanced catalyst technology improves efficiency; integrated thermal management system extends operational lifetime. Weaknesses: Current designs primarily focused on automotive applications with limited adaptability to other industries; higher production costs compared to conventional technologies; requires specialized manufacturing capabilities.

Key Patents and Technical Innovations in Electrochemical Compression

Electrochemical compressor based heating element and hybrid hot water heater employing same

PatentInactiveUS20150114829A1

Innovation

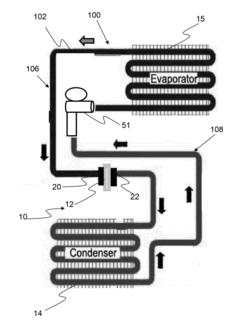

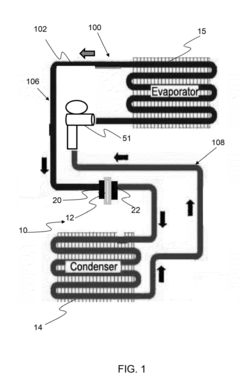

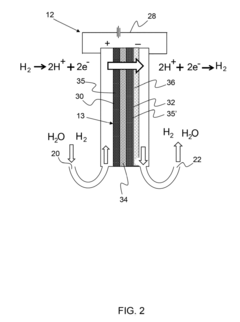

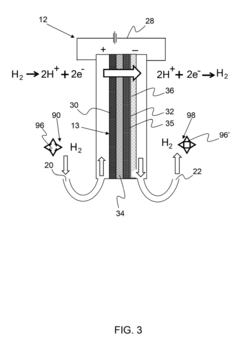

- An electrochemical compressor system utilizing a mixed gas refrigerant with hydrogen and a proton associable compound, such as water, within a membrane electrode assembly, which produces high-pressure gas through reversible redox reactions, integrated with a condenser, expansion valve, and evaporator to form a closed loop heat pump system.

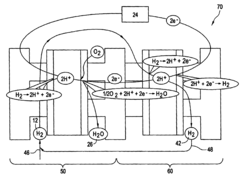

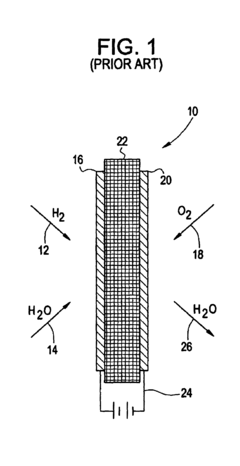

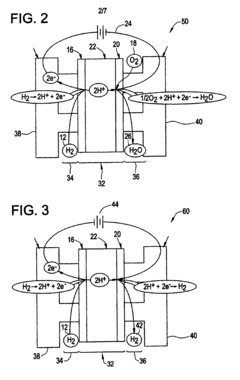

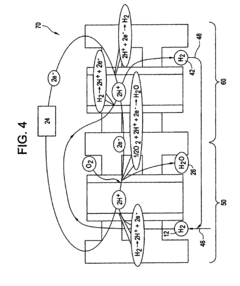

Electrochemical hydrogen compressor for electrochemical cell system and method for controlling

PatentInactiveUS6994929B2

Innovation

- An electrochemical hydrogen compressor is introduced, which uses electrodes in electrical communication with an electricity source to compress and recirculate excess hydrogen gas back into the fuel cell, eliminating the need for mechanical compressors and improving hydrogen utilization.

Manufacturing Scale-Up Strategies and Process Optimization

The transition from laboratory-scale prototypes to commercial-scale production of electrochemical compressor modules requires a systematic approach to manufacturing scale-up. Initial production typically begins with small batch processes that allow for quality control refinement and process validation. As production volumes increase, manufacturers must implement semi-automated assembly lines that maintain precision while improving throughput rates.

Material procurement strategies become increasingly critical during scale-up phases. Establishing reliable supply chains for specialized components such as membranes, electrodes, and catalysts helps prevent production bottlenecks. Strategic partnerships with material suppliers can secure preferential pricing and ensure consistent quality as production volumes increase.

Process optimization techniques, including Design of Experiments (DOE) and Statistical Process Control (SPC), should be implemented to identify critical manufacturing parameters. These methodologies help determine optimal operating conditions for key processes such as membrane electrode assembly (MEA) fabrication, cell stacking, and system integration. Continuous monitoring of these parameters ensures consistent product quality while minimizing waste and rework.

Modular manufacturing approaches offer significant advantages for electrochemical compressor production. By designing standardized sub-assemblies that can be manufactured independently and later integrated, companies can achieve greater production flexibility. This approach allows for parallel processing workflows and facilitates easier scaling of production capacity in response to market demand fluctuations.

Automation integration presents both opportunities and challenges during scale-up. While robotic assembly systems can dramatically improve consistency and throughput for repetitive tasks like cell stacking, the high precision requirements of electrochemical systems demand sophisticated vision systems and precision control. A phased automation approach, beginning with semi-automated workstations before progressing to fully automated lines, minimizes implementation risks.

Quality assurance protocols must evolve alongside production scaling. In-line testing stations should be strategically positioned throughout the manufacturing process to detect defects early. Non-destructive testing methods such as impedance spectroscopy and leak detection systems can verify product integrity without compromising production efficiency. Implementing statistical sampling plans balances thorough quality verification with production throughput requirements.

Material procurement strategies become increasingly critical during scale-up phases. Establishing reliable supply chains for specialized components such as membranes, electrodes, and catalysts helps prevent production bottlenecks. Strategic partnerships with material suppliers can secure preferential pricing and ensure consistent quality as production volumes increase.

Process optimization techniques, including Design of Experiments (DOE) and Statistical Process Control (SPC), should be implemented to identify critical manufacturing parameters. These methodologies help determine optimal operating conditions for key processes such as membrane electrode assembly (MEA) fabrication, cell stacking, and system integration. Continuous monitoring of these parameters ensures consistent product quality while minimizing waste and rework.

Modular manufacturing approaches offer significant advantages for electrochemical compressor production. By designing standardized sub-assemblies that can be manufactured independently and later integrated, companies can achieve greater production flexibility. This approach allows for parallel processing workflows and facilitates easier scaling of production capacity in response to market demand fluctuations.

Automation integration presents both opportunities and challenges during scale-up. While robotic assembly systems can dramatically improve consistency and throughput for repetitive tasks like cell stacking, the high precision requirements of electrochemical systems demand sophisticated vision systems and precision control. A phased automation approach, beginning with semi-automated workstations before progressing to fully automated lines, minimizes implementation risks.

Quality assurance protocols must evolve alongside production scaling. In-line testing stations should be strategically positioned throughout the manufacturing process to detect defects early. Non-destructive testing methods such as impedance spectroscopy and leak detection systems can verify product integrity without compromising production efficiency. Implementing statistical sampling plans balances thorough quality verification with production throughput requirements.

Sustainability and Energy Efficiency Considerations

Electrochemical compressors represent a significant advancement in sustainable compression technology, offering substantial environmental benefits compared to conventional mechanical systems. These devices operate without harmful refrigerants, utilizing proton exchange membranes to compress hydrogen or other gases through electrochemical processes rather than mechanical compression. This fundamental operational difference translates to zero direct greenhouse gas emissions during operation, positioning them as critical components in the global transition toward carbon neutrality.

Energy efficiency stands as a paramount advantage of electrochemical compressor modules. Traditional vapor compression systems typically achieve Coefficients of Performance (COP) ranging from 2.5 to 4.0, whereas electrochemical compressors have demonstrated potential COPs exceeding 6.0 under optimal conditions. This efficiency differential becomes particularly significant in large-scale industrial applications, where even marginal improvements in energy consumption can yield substantial operational cost reductions and environmental benefits over system lifetimes.

The lifecycle assessment of electrochemical compressor technology reveals additional sustainability advantages. Manufacturing processes for these systems generally require fewer raw materials and generate less waste compared to conventional compressors with numerous moving parts. The absence of lubricants and reduced maintenance requirements further enhance their environmental profile, minimizing both operational waste streams and resource consumption throughout the product lifecycle.

Water management represents a critical sustainability consideration in the scale-up roadmap. Electrochemical compression processes involve water transport across membranes, necessitating careful system design to optimize water balance and prevent membrane degradation. Advanced water recovery systems integrated into larger modules can significantly reduce freshwater requirements, addressing an increasingly important sustainability metric in water-stressed regions.

Material selection for scaled electrochemical compressor modules presents both challenges and opportunities for sustainability enhancement. Current systems rely on platinum-group catalysts that face supply constraints and environmental concerns related to mining practices. The roadmap must prioritize research into reduced-catalyst or catalyst-free designs, alongside the development of recycling protocols for critical materials to establish a more circular economic model for these systems.

Energy source integration constitutes another vital consideration, as the environmental benefits of electrochemical compressors are maximized when powered by renewable electricity. The scale-up roadmap should include strategies for direct coupling with renewable generation, potentially incorporating energy storage capabilities to optimize operation during periods of abundant renewable energy availability, thereby further enhancing the overall sustainability profile of these systems.

Energy efficiency stands as a paramount advantage of electrochemical compressor modules. Traditional vapor compression systems typically achieve Coefficients of Performance (COP) ranging from 2.5 to 4.0, whereas electrochemical compressors have demonstrated potential COPs exceeding 6.0 under optimal conditions. This efficiency differential becomes particularly significant in large-scale industrial applications, where even marginal improvements in energy consumption can yield substantial operational cost reductions and environmental benefits over system lifetimes.

The lifecycle assessment of electrochemical compressor technology reveals additional sustainability advantages. Manufacturing processes for these systems generally require fewer raw materials and generate less waste compared to conventional compressors with numerous moving parts. The absence of lubricants and reduced maintenance requirements further enhance their environmental profile, minimizing both operational waste streams and resource consumption throughout the product lifecycle.

Water management represents a critical sustainability consideration in the scale-up roadmap. Electrochemical compression processes involve water transport across membranes, necessitating careful system design to optimize water balance and prevent membrane degradation. Advanced water recovery systems integrated into larger modules can significantly reduce freshwater requirements, addressing an increasingly important sustainability metric in water-stressed regions.

Material selection for scaled electrochemical compressor modules presents both challenges and opportunities for sustainability enhancement. Current systems rely on platinum-group catalysts that face supply constraints and environmental concerns related to mining practices. The roadmap must prioritize research into reduced-catalyst or catalyst-free designs, alongside the development of recycling protocols for critical materials to establish a more circular economic model for these systems.

Energy source integration constitutes another vital consideration, as the environmental benefits of electrochemical compressors are maximized when powered by renewable electricity. The scale-up roadmap should include strategies for direct coupling with renewable generation, potentially incorporating energy storage capabilities to optimize operation during periods of abundant renewable energy availability, thereby further enhancing the overall sustainability profile of these systems.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!