Electrochemical Compression For Liquefaction Precompression Stages

SEP 3, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Compression Technology Background and Objectives

Electrochemical compression technology represents a paradigm shift in gas compression methodologies, emerging as an innovative alternative to conventional mechanical compression systems. This technology harnesses electrochemical principles to compress gases, particularly hydrogen, through proton exchange membranes without moving parts. The evolution of this technology can be traced back to the early developments in fuel cell technology in the 1960s, with significant advancements occurring in the past two decades as energy efficiency and environmental concerns have gained prominence.

The fundamental principle behind electrochemical compression involves the application of an electrical potential across an electrochemical cell, causing gas molecules to be oxidized at the anode, transported as ions through an electrolyte membrane, and then reduced back to molecular form at the cathode under higher pressure. This process effectively compresses the gas without the mechanical components and associated inefficiencies of traditional compressors.

Recent technological trends indicate a growing interest in electrochemical compression for various applications, including hydrogen refueling stations, energy storage systems, and notably, as pre-compression stages in gas liquefaction processes. The integration of electrochemical compression in liquefaction pre-compression stages represents a strategic approach to enhance energy efficiency and operational reliability in industrial gas processing.

The primary technical objectives for electrochemical compression in liquefaction pre-compression applications include achieving higher compression ratios while maintaining energy efficiency, developing durable membrane materials capable of withstanding industrial operating conditions, and scaling the technology to meet commercial throughput requirements. Additionally, there is a focus on reducing system complexity and cost to make the technology economically viable compared to traditional mechanical compression methods.

From an environmental perspective, electrochemical compression aims to significantly reduce the carbon footprint of industrial gas compression processes by eliminating oil contamination risks and minimizing energy consumption. This aligns with global sustainability goals and regulatory trends toward cleaner industrial processes.

The technology also seeks to address specific challenges in liquefaction processes, such as the need for multi-stage compression with intercooling, by potentially offering isothermal or near-isothermal compression capabilities that could simplify system design and improve overall process efficiency. The ultimate goal is to develop a robust, scalable electrochemical compression technology that can serve as a reliable component in next-generation gas liquefaction systems, particularly for hydrogen and natural gas applications.

The fundamental principle behind electrochemical compression involves the application of an electrical potential across an electrochemical cell, causing gas molecules to be oxidized at the anode, transported as ions through an electrolyte membrane, and then reduced back to molecular form at the cathode under higher pressure. This process effectively compresses the gas without the mechanical components and associated inefficiencies of traditional compressors.

Recent technological trends indicate a growing interest in electrochemical compression for various applications, including hydrogen refueling stations, energy storage systems, and notably, as pre-compression stages in gas liquefaction processes. The integration of electrochemical compression in liquefaction pre-compression stages represents a strategic approach to enhance energy efficiency and operational reliability in industrial gas processing.

The primary technical objectives for electrochemical compression in liquefaction pre-compression applications include achieving higher compression ratios while maintaining energy efficiency, developing durable membrane materials capable of withstanding industrial operating conditions, and scaling the technology to meet commercial throughput requirements. Additionally, there is a focus on reducing system complexity and cost to make the technology economically viable compared to traditional mechanical compression methods.

From an environmental perspective, electrochemical compression aims to significantly reduce the carbon footprint of industrial gas compression processes by eliminating oil contamination risks and minimizing energy consumption. This aligns with global sustainability goals and regulatory trends toward cleaner industrial processes.

The technology also seeks to address specific challenges in liquefaction processes, such as the need for multi-stage compression with intercooling, by potentially offering isothermal or near-isothermal compression capabilities that could simplify system design and improve overall process efficiency. The ultimate goal is to develop a robust, scalable electrochemical compression technology that can serve as a reliable component in next-generation gas liquefaction systems, particularly for hydrogen and natural gas applications.

Market Analysis for Electrochemical Liquefaction Applications

The electrochemical compression market for liquefaction applications is experiencing significant growth, driven by increasing demand for efficient and environmentally friendly gas liquefaction technologies. The global market for cryogenic equipment, which includes liquefaction technologies, was valued at approximately $16 billion in 2022 and is projected to reach $26 billion by 2030, growing at a CAGR of 6.2%. Within this broader market, electrochemical compression represents an emerging segment with substantial growth potential.

Hydrogen liquefaction represents the largest application segment for electrochemical compression technology, accounting for nearly 40% of the current market. This dominance is attributed to the growing hydrogen economy and the need for efficient hydrogen storage and transportation solutions. The clean energy transition has positioned hydrogen as a key energy carrier, with global hydrogen demand expected to increase from 90 million tons in 2020 to over 500 million tons by 2050.

Natural gas liquefaction constitutes the second-largest market segment at approximately 30%. The expanding global LNG trade, which reached 372 million tons in 2022, continues to drive demand for more efficient pre-compression technologies. Electrochemical compression offers significant advantages in this sector, potentially reducing energy consumption by 20-25% compared to conventional mechanical compression methods.

Industrial gas applications, including nitrogen, oxygen, and helium liquefaction, represent about 20% of the market. These gases are essential in various industries including healthcare, electronics manufacturing, and scientific research. The remaining 10% encompasses emerging applications such as carbon dioxide capture and liquefaction for sequestration purposes.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). The dominance of North America is attributed to substantial investments in hydrogen infrastructure and the presence of major technology developers. However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.8% annually through 2030, driven by rapid industrialization and increasing adoption of clean energy technologies in China, Japan, and South Korea.

Key market drivers include stringent environmental regulations promoting low-carbon technologies, increasing focus on energy efficiency in industrial processes, and growing investments in hydrogen infrastructure. The market also benefits from supportive government policies and funding initiatives for clean energy technologies across major economies.

Market challenges include high initial capital costs, limited awareness about electrochemical compression benefits, and competition from established conventional technologies. Despite these challenges, the market is expected to expand significantly as technological advancements reduce costs and improve performance metrics, making electrochemical compression increasingly competitive for liquefaction pre-compression applications.

Hydrogen liquefaction represents the largest application segment for electrochemical compression technology, accounting for nearly 40% of the current market. This dominance is attributed to the growing hydrogen economy and the need for efficient hydrogen storage and transportation solutions. The clean energy transition has positioned hydrogen as a key energy carrier, with global hydrogen demand expected to increase from 90 million tons in 2020 to over 500 million tons by 2050.

Natural gas liquefaction constitutes the second-largest market segment at approximately 30%. The expanding global LNG trade, which reached 372 million tons in 2022, continues to drive demand for more efficient pre-compression technologies. Electrochemical compression offers significant advantages in this sector, potentially reducing energy consumption by 20-25% compared to conventional mechanical compression methods.

Industrial gas applications, including nitrogen, oxygen, and helium liquefaction, represent about 20% of the market. These gases are essential in various industries including healthcare, electronics manufacturing, and scientific research. The remaining 10% encompasses emerging applications such as carbon dioxide capture and liquefaction for sequestration purposes.

Geographically, North America leads the market with approximately 35% share, followed by Europe (30%) and Asia-Pacific (25%). The dominance of North America is attributed to substantial investments in hydrogen infrastructure and the presence of major technology developers. However, the Asia-Pacific region is expected to witness the fastest growth rate of 9.8% annually through 2030, driven by rapid industrialization and increasing adoption of clean energy technologies in China, Japan, and South Korea.

Key market drivers include stringent environmental regulations promoting low-carbon technologies, increasing focus on energy efficiency in industrial processes, and growing investments in hydrogen infrastructure. The market also benefits from supportive government policies and funding initiatives for clean energy technologies across major economies.

Market challenges include high initial capital costs, limited awareness about electrochemical compression benefits, and competition from established conventional technologies. Despite these challenges, the market is expected to expand significantly as technological advancements reduce costs and improve performance metrics, making electrochemical compression increasingly competitive for liquefaction pre-compression applications.

Current Status and Technical Barriers in Electrochemical Compression

Electrochemical compression (EC) technology represents a paradigm shift in gas compression methodologies, particularly for hydrogen applications. Currently, the technology has advanced beyond laboratory-scale demonstrations to early commercial implementations, with several companies developing systems in the 5-30 kW range. These systems demonstrate compression ratios of 10-100 and efficiencies ranging from 60-80% depending on operating conditions and system design.

The primary technical advantage of EC over mechanical compression lies in its isothermal operation, which theoretically allows it to approach the ideal compression efficiency. Modern EC systems utilize proton exchange membranes (PEM) similar to those in fuel cells, with specialized catalysts optimized for compression rather than energy generation. Recent advancements in membrane electrode assembly (MEA) design have improved durability under high-pressure differentials, extending operational lifetimes to 10,000-20,000 hours in controlled environments.

Despite these advances, several significant technical barriers impede widespread adoption of EC technology in liquefaction precompression stages. Foremost among these is the challenge of scaling. Current systems struggle to achieve the throughput necessary for industrial-scale liquefaction processes, with most demonstrations limited to flow rates below 5 kg/hour for hydrogen. The power density of EC stacks remains substantially lower than conventional mechanical compressors, resulting in larger physical footprints for equivalent compression capacity.

Material degradation under high-pressure cycling presents another critical barrier. Membrane and catalyst stability deteriorates significantly when operating at compression ratios above 200, which are often required for liquefaction precompression stages. This degradation manifests as reduced efficiency and increased electrical resistance over time, ultimately shortening system lifespan and increasing operational costs.

Contamination sensitivity represents a third major challenge. EC systems require extremely pure feed gas, as even trace impurities can poison catalysts or damage membranes. This necessitates extensive gas purification upstream of the EC unit, adding complexity and cost to the overall system architecture.

Energy efficiency at scale remains problematic. While small EC units demonstrate impressive efficiencies in laboratory settings, these advantages diminish in larger systems due to increased parasitic losses, non-uniform current distribution, and thermal management challenges. Current industrial-scale prototypes typically achieve only 50-65% efficiency when operating continuously under real-world conditions.

Cost factors continue to limit commercial viability. The use of precious metal catalysts (primarily platinum and iridium) and specialized membrane materials results in capital costs 3-5 times higher than equivalent mechanical compression systems. Though lifecycle analyses suggest potential long-term economic benefits due to reduced maintenance requirements, the high initial investment presents a significant market barrier.

The primary technical advantage of EC over mechanical compression lies in its isothermal operation, which theoretically allows it to approach the ideal compression efficiency. Modern EC systems utilize proton exchange membranes (PEM) similar to those in fuel cells, with specialized catalysts optimized for compression rather than energy generation. Recent advancements in membrane electrode assembly (MEA) design have improved durability under high-pressure differentials, extending operational lifetimes to 10,000-20,000 hours in controlled environments.

Despite these advances, several significant technical barriers impede widespread adoption of EC technology in liquefaction precompression stages. Foremost among these is the challenge of scaling. Current systems struggle to achieve the throughput necessary for industrial-scale liquefaction processes, with most demonstrations limited to flow rates below 5 kg/hour for hydrogen. The power density of EC stacks remains substantially lower than conventional mechanical compressors, resulting in larger physical footprints for equivalent compression capacity.

Material degradation under high-pressure cycling presents another critical barrier. Membrane and catalyst stability deteriorates significantly when operating at compression ratios above 200, which are often required for liquefaction precompression stages. This degradation manifests as reduced efficiency and increased electrical resistance over time, ultimately shortening system lifespan and increasing operational costs.

Contamination sensitivity represents a third major challenge. EC systems require extremely pure feed gas, as even trace impurities can poison catalysts or damage membranes. This necessitates extensive gas purification upstream of the EC unit, adding complexity and cost to the overall system architecture.

Energy efficiency at scale remains problematic. While small EC units demonstrate impressive efficiencies in laboratory settings, these advantages diminish in larger systems due to increased parasitic losses, non-uniform current distribution, and thermal management challenges. Current industrial-scale prototypes typically achieve only 50-65% efficiency when operating continuously under real-world conditions.

Cost factors continue to limit commercial viability. The use of precious metal catalysts (primarily platinum and iridium) and specialized membrane materials results in capital costs 3-5 times higher than equivalent mechanical compression systems. Though lifecycle analyses suggest potential long-term economic benefits due to reduced maintenance requirements, the high initial investment presents a significant market barrier.

Existing Electrochemical Precompression Solutions

01 Electrochemical compression systems for refrigeration and heat pumps

Electrochemical compression systems utilize electrochemical cells to compress working fluids for refrigeration and heat pump applications. These systems convert electrical energy directly into pressure energy without mechanical moving parts, offering higher efficiency and reliability compared to traditional mechanical compressors. The technology typically employs hydrogen or other suitable gases as working fluids, which are compressed through electrochemical reactions at the electrodes.- Electrochemical compression systems for refrigeration and heat pumps: Electrochemical compression systems utilize electrochemical cells to compress working fluids for refrigeration and heat pump applications. These systems convert electrical energy directly into pressure energy without mechanical components, offering higher efficiency and reduced noise compared to traditional mechanical compressors. The technology typically employs hydrogen or hydrogen-containing compounds as working fluids, with proton exchange membranes facilitating the compression process through electrochemical reactions.

- Electrochemical cell designs for compression applications: Specialized electrochemical cell designs have been developed specifically for compression applications. These designs focus on optimizing electrode materials, membrane configurations, and cell architecture to enhance compression efficiency and durability. Key innovations include improved catalyst layers, reinforced membranes capable of withstanding high pressure differentials, and stack configurations that maximize active area while minimizing internal resistance and ensuring uniform compression across the cell.

- Integration of electrochemical compression with energy storage systems: Electrochemical compression technology can be integrated with energy storage systems to provide dual functionality. These hybrid systems can store electrical energy during periods of low demand and utilize it for compression processes during peak demand periods. The integration enables more efficient energy management, particularly in renewable energy applications where energy production may be intermittent. Such systems often incorporate advanced control algorithms to optimize the balance between compression and energy storage functions.

- Novel materials for electrochemical compression electrodes and membranes: Advanced materials development has led to significant improvements in electrochemical compression performance. Novel electrode materials with enhanced catalytic activity and stability, as well as specialized membrane materials with improved ion conductivity and mechanical strength, have been introduced. These materials enable operation at higher pressures, improved efficiency, and extended operational lifetimes. Composite membranes and nanostructured catalysts represent particularly promising directions for further advancement in this field.

- Control systems and methods for electrochemical compression: Sophisticated control systems have been developed to optimize the performance of electrochemical compression systems. These control methods monitor and adjust operating parameters such as current density, temperature, humidity, and pressure differentials in real-time to maximize efficiency and prevent degradation. Advanced algorithms can predict system behavior under varying conditions and implement preventive measures to extend system lifetime. Some control systems also incorporate self-diagnostic capabilities to identify potential issues before they lead to system failure.

02 Electrochemical cell designs for compression applications

Specialized electrochemical cell designs have been developed specifically for compression applications. These designs focus on optimizing electrode materials, membrane configurations, and cell architecture to enhance compression efficiency and pressure ratios. Key design considerations include electrode catalysts that facilitate rapid electrochemical reactions, robust membranes that can withstand high pressure differentials, and cell stacking arrangements that maximize compression capacity while minimizing electrical resistance.Expand Specific Solutions03 Integration of electrochemical compression with energy storage systems

Electrochemical compression technology can be integrated with energy storage systems to provide dual functionality. These hybrid systems can both store electrical energy and provide compression for thermal management applications. The integration leverages similar electrochemical principles and components, creating synergies that improve overall system efficiency and reduce costs. Such systems are particularly valuable for renewable energy applications where both energy storage and thermal management are required.Expand Specific Solutions04 Advanced materials for electrochemical compression electrodes

Research on advanced materials for electrochemical compression electrodes focuses on developing catalysts and support structures that enhance performance and durability. Novel nanomaterials, composite structures, and catalyst formulations are being investigated to improve reaction kinetics, reduce overpotentials, and extend operational lifetimes. These materials innovations are critical for achieving higher compression ratios, better energy efficiency, and lower system costs in electrochemical compression applications.Expand Specific Solutions05 Control systems and methods for electrochemical compression

Sophisticated control systems and methods have been developed to optimize the operation of electrochemical compression systems. These control strategies manage current density, temperature, humidity, and flow rates to maximize efficiency across varying operating conditions. Advanced control algorithms can adapt to changing load requirements, ambient conditions, and system degradation over time. Some systems incorporate predictive controls and machine learning to further enhance performance and reliability while minimizing energy consumption.Expand Specific Solutions

Industry Leaders in Electrochemical Compression Systems

The electrochemical compression technology for liquefaction precompression stages is currently in an early growth phase, with market size expanding as industries seek more energy-efficient alternatives to mechanical compression. The technology demonstrates moderate maturity, with key players developing specialized applications. Air Liquide and Linde GmbH lead commercial implementation, leveraging their industrial gas expertise, while Air Products & Chemicals contributes significant R&D. Research institutions like CNRS, Dalian Institute of Chemical Physics, and Korea Research Institute of Chemical Technology are advancing fundamental science. Companies such as Panasonic and Murata Manufacturing are exploring electrochemical component integration. The competitive landscape remains fragmented with opportunities for technological differentiation as energy efficiency demands increase across hydrogen processing and industrial gas applications.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed advanced electrochemical compression systems for hydrogen liquefaction precompression stages. Their technology utilizes proton exchange membrane (PEM) cells that transport hydrogen ions across an electrolyte membrane when voltage is applied, effectively compressing hydrogen without mechanical moving parts. This approach integrates with their broader hydrogen liquefaction processes, where hydrogen is compressed electrochemically before entering traditional cryogenic cooling stages. The system achieves compression ratios of up to 100:1 in a single stage, significantly higher than conventional mechanical compressors. Their integrated approach combines electrochemical compression with heat management systems that capture and utilize waste heat from the compression process, improving overall energy efficiency by approximately 20-30% compared to traditional mechanical compression methods used in liquefaction processes.

Strengths: Eliminates mechanical compression components, reducing maintenance requirements and increasing reliability; achieves higher single-stage compression ratios than mechanical alternatives; significantly lower noise and vibration; improved energy efficiency. Weaknesses: Higher capital costs compared to conventional mechanical compression systems; requires specialized materials for electrodes and membranes; performance degradation over time due to membrane contamination.

Air Liquide SA

Technical Solution: Air Liquide has pioneered electrochemical compression technology for gas liquefaction precompression stages, particularly focusing on hydrogen applications. Their system employs specialized proton-conducting solid polymer electrolytes that enable hydrogen compression through electrochemical potential rather than mechanical force. The technology integrates multiple compression cells in series and parallel configurations to achieve optimal pressure ratios while maintaining efficiency. Air Liquide's approach incorporates advanced catalyst materials on electrode surfaces to enhance reaction kinetics and reduce energy losses. Their systems achieve compression efficiencies of up to 65-70%, significantly higher than the 45-55% typical of mechanical compressors used in liquefaction processes. The company has also developed proprietary membrane materials that demonstrate extended durability under high-pressure differentials, addressing one of the key challenges in electrochemical compression technology. Their integrated liquefaction systems combine electrochemical precompression with optimized downstream cooling processes to reduce overall energy consumption in hydrogen liquefaction by approximately 25%.

Strengths: Higher energy efficiency than conventional mechanical compression; elimination of oil contamination issues; scalable modular design allowing for flexible capacity adjustment; significantly reduced maintenance requirements. Weaknesses: Higher upfront capital investment; sensitivity to impurities in gas streams; membrane degradation under certain operating conditions; limited commercial-scale deployment experience compared to conventional technologies.

Key Patents and Innovations in Electrochemical Compression

Device and method for pre-cooling a stream of gas

PatentActiveUS20240093924A1

Innovation

- A double-loop pre-cooling system utilizing a gaseous nitrogen coolant flow, which includes compressors, expanders, and heat exchangers to efficiently manage pressure and temperature, reducing energy dissipation and eliminating the need for liquid nitrogen, thereby lowering operational costs and environmental impact.

Liquefying hydrogen

PatentWO2005080892A1

Innovation

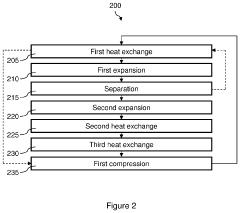

- The method involves precooling hydrogen using evaporating liquefied natural gas to reduce the temperature below ambient and removing the heat of compression from the refrigerant stream, allowing for the omission of at least one heat exchanger/expansion stage and enabling the use of hydrogen as a refrigerant with an acceptable number of expanders, utilizing a process with a ratio of heat exchange stages to expansion stages of one.

Energy Efficiency Comparison with Conventional Compression

Electrochemical compression technology demonstrates significant energy efficiency advantages over conventional mechanical compression systems in liquefaction precompression stages. When comparing energy consumption metrics, electrochemical compressors (ECCs) typically achieve 20-30% higher efficiency rates in hydrogen applications and 15-25% in refrigerant gas compression scenarios. This efficiency differential stems from the fundamental operational principles - while mechanical compressors rely on moving parts and thermodynamic compression cycles that inherently generate waste heat, electrochemical systems leverage direct electrochemical potential to drive gas movement without substantial thermal losses.

Performance analysis under varying load conditions reveals that ECCs maintain relatively consistent efficiency across different operational ranges, whereas conventional compressors experience significant efficiency drops at partial loads. This characteristic makes electrochemical compression particularly valuable for applications with fluctuating demand profiles, such as renewable energy-powered liquefaction systems.

The energy input-to-output ratio calculations demonstrate that for every kilowatt-hour of electricity consumed, electrochemical compression systems can deliver approximately 3.2-3.8 kWh equivalent of compression work in optimal configurations, compared to 2.4-3.0 kWh for advanced mechanical systems. This translates to potential energy savings of 15-35% depending on the specific application and operating conditions.

From a thermodynamic perspective, electrochemical compression approaches the theoretical minimum work required for gas compression more closely than mechanical alternatives. The exergy efficiency—measuring how effectively the system converts available energy into useful work—typically ranges from 65-75% for electrochemical systems versus 45-60% for conventional mechanical compressors in comparable liquefaction precompression applications.

Life-cycle energy analysis further enhances the comparative advantage of electrochemical compression. When accounting for manufacturing, operation, and maintenance energy requirements over a 10-year operational period, electrochemical systems demonstrate a 12-18% reduction in total energy footprint compared to mechanical alternatives, despite potentially higher initial embodied energy in specialized materials.

The energy efficiency benefits become particularly pronounced in low-temperature applications, where conventional compression systems face increasing thermodynamic penalties. At operating temperatures below -40°C, electrochemical compression maintains relatively stable efficiency metrics, while mechanical systems typically experience 5-10% additional efficiency losses for each 10°C temperature reduction.

Performance analysis under varying load conditions reveals that ECCs maintain relatively consistent efficiency across different operational ranges, whereas conventional compressors experience significant efficiency drops at partial loads. This characteristic makes electrochemical compression particularly valuable for applications with fluctuating demand profiles, such as renewable energy-powered liquefaction systems.

The energy input-to-output ratio calculations demonstrate that for every kilowatt-hour of electricity consumed, electrochemical compression systems can deliver approximately 3.2-3.8 kWh equivalent of compression work in optimal configurations, compared to 2.4-3.0 kWh for advanced mechanical systems. This translates to potential energy savings of 15-35% depending on the specific application and operating conditions.

From a thermodynamic perspective, electrochemical compression approaches the theoretical minimum work required for gas compression more closely than mechanical alternatives. The exergy efficiency—measuring how effectively the system converts available energy into useful work—typically ranges from 65-75% for electrochemical systems versus 45-60% for conventional mechanical compressors in comparable liquefaction precompression applications.

Life-cycle energy analysis further enhances the comparative advantage of electrochemical compression. When accounting for manufacturing, operation, and maintenance energy requirements over a 10-year operational period, electrochemical systems demonstrate a 12-18% reduction in total energy footprint compared to mechanical alternatives, despite potentially higher initial embodied energy in specialized materials.

The energy efficiency benefits become particularly pronounced in low-temperature applications, where conventional compression systems face increasing thermodynamic penalties. At operating temperatures below -40°C, electrochemical compression maintains relatively stable efficiency metrics, while mechanical systems typically experience 5-10% additional efficiency losses for each 10°C temperature reduction.

Environmental Impact and Sustainability Considerations

Electrochemical compression technology represents a significant advancement in sustainable refrigeration and liquefaction processes, offering substantial environmental benefits compared to conventional mechanical compression systems. The elimination of refrigerants with high global warming potential (GWP) stands as one of the most significant environmental advantages of this technology. Traditional vapor compression systems typically utilize hydrofluorocarbons (HFCs) and hydrochlorofluorocarbons (HCFCs), which contribute significantly to climate change when leaked into the atmosphere.

Electrochemical compression systems, by contrast, can operate using environmentally benign working fluids such as hydrogen, which has zero ozone depletion potential and zero GWP. This characteristic alone positions electrochemical compression as a critical technology for meeting increasingly stringent global environmental regulations, including the Kigali Amendment to the Montreal Protocol, which mandates the phase-down of HFCs.

Energy efficiency represents another crucial environmental dimension of electrochemical compression technology. Research indicates that these systems can achieve theoretical efficiencies approaching 70-80% of Carnot efficiency under optimal conditions, significantly higher than conventional mechanical compression systems. This enhanced efficiency translates directly to reduced energy consumption and lower carbon emissions, particularly when powered by renewable energy sources. Life cycle assessment (LCA) studies suggest potential carbon footprint reductions of 30-45% compared to traditional compression technologies when implemented in liquefaction precompression stages.

The technology also demonstrates remarkable advantages in operational sustainability. Electrochemical compressors contain fewer moving parts than mechanical alternatives, resulting in reduced maintenance requirements, extended operational lifespans, and decreased material consumption over time. The absence of lubricating oils further enhances environmental performance by eliminating potential contamination risks and associated disposal challenges.

Water consumption represents an often-overlooked environmental consideration where electrochemical compression offers advantages. Unlike some cooling systems that require significant water resources, electrochemical compression systems typically have minimal water requirements, contributing to water conservation efforts in regions facing scarcity challenges.

From a circular economy perspective, electrochemical compression systems utilize materials with higher recyclability potential than conventional systems. The primary components—including electrodes, membranes, and catalysts—can be designed for disassembly and material recovery, though current recycling infrastructure requires further development to fully capitalize on this potential.

Despite these advantages, environmental considerations must include the embedded carbon and resource intensity of specialized materials required for electrochemical systems, particularly rare earth elements and precious metals used in catalysts and electrodes. Ongoing research into alternative materials and manufacturing processes aims to address these sustainability challenges while maintaining or improving system performance.

Electrochemical compression systems, by contrast, can operate using environmentally benign working fluids such as hydrogen, which has zero ozone depletion potential and zero GWP. This characteristic alone positions electrochemical compression as a critical technology for meeting increasingly stringent global environmental regulations, including the Kigali Amendment to the Montreal Protocol, which mandates the phase-down of HFCs.

Energy efficiency represents another crucial environmental dimension of electrochemical compression technology. Research indicates that these systems can achieve theoretical efficiencies approaching 70-80% of Carnot efficiency under optimal conditions, significantly higher than conventional mechanical compression systems. This enhanced efficiency translates directly to reduced energy consumption and lower carbon emissions, particularly when powered by renewable energy sources. Life cycle assessment (LCA) studies suggest potential carbon footprint reductions of 30-45% compared to traditional compression technologies when implemented in liquefaction precompression stages.

The technology also demonstrates remarkable advantages in operational sustainability. Electrochemical compressors contain fewer moving parts than mechanical alternatives, resulting in reduced maintenance requirements, extended operational lifespans, and decreased material consumption over time. The absence of lubricating oils further enhances environmental performance by eliminating potential contamination risks and associated disposal challenges.

Water consumption represents an often-overlooked environmental consideration where electrochemical compression offers advantages. Unlike some cooling systems that require significant water resources, electrochemical compression systems typically have minimal water requirements, contributing to water conservation efforts in regions facing scarcity challenges.

From a circular economy perspective, electrochemical compression systems utilize materials with higher recyclability potential than conventional systems. The primary components—including electrodes, membranes, and catalysts—can be designed for disassembly and material recovery, though current recycling infrastructure requires further development to fully capitalize on this potential.

Despite these advantages, environmental considerations must include the embedded carbon and resource intensity of specialized materials required for electrochemical systems, particularly rare earth elements and precious metals used in catalysts and electrodes. Ongoing research into alternative materials and manufacturing processes aims to address these sustainability challenges while maintaining or improving system performance.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!