Design Guidelines For Scalable Electrochemical Hydrogen Compressor Stacks

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Hydrogen Compression Technology Background and Objectives

Electrochemical hydrogen compression (EHC) technology represents a paradigm shift in hydrogen processing methods, offering a compelling alternative to conventional mechanical compression systems. The evolution of this technology can be traced back to the early 1990s when researchers began exploring proton exchange membrane (PEM) electrolyzers' potential for hydrogen compression. Over the subsequent decades, significant advancements in materials science, electrochemistry, and system engineering have propelled EHC from laboratory curiosity to commercial viability.

The fundamental principle behind EHC leverages electrochemical potential to drive hydrogen across a membrane, eliminating the need for moving parts and mechanical compression. This approach offers inherent advantages including isothermal operation, higher efficiency, reduced maintenance requirements, and the ability to achieve high compression ratios in a single stage. The technology's development trajectory has been characterized by progressive improvements in membrane materials, catalyst performance, and stack design optimization.

Current technological trends indicate a growing focus on scalability, efficiency enhancement, and cost reduction. Research efforts are increasingly directed toward novel membrane materials with improved conductivity and mechanical stability, advanced catalyst formulations with reduced precious metal loading, and innovative stack architectures that optimize flow distribution and minimize electrical resistance. These developments align with the broader hydrogen economy's evolution, where compression technology represents a critical link in the value chain.

The primary technical objectives for scalable EHC stack design encompass several dimensions. First, achieving higher compression ratios (>700 bar) while maintaining efficiency is essential for applications in hydrogen refueling stations and industrial processes. Second, improving durability and operational lifetime under variable load conditions remains crucial for commercial viability. Third, reducing system complexity and component count aims to enhance reliability while decreasing manufacturing costs.

Additionally, the technology seeks to address specific performance metrics including higher hydrogen throughput per active area, reduced electrical power consumption, improved tolerance to impurities, and enhanced thermal management capabilities. These objectives are driven by market requirements for more compact, efficient, and cost-effective hydrogen compression solutions across various applications from mobility to industrial processes.

The convergence of renewable energy integration, hydrogen mobility advancement, and industrial decarbonization efforts has created a favorable environment for EHC technology development. As hydrogen assumes a more central role in the global energy transition, the demand for efficient compression technologies continues to grow, establishing clear technical targets for next-generation EHC systems that balance performance, durability, and economic considerations.

The fundamental principle behind EHC leverages electrochemical potential to drive hydrogen across a membrane, eliminating the need for moving parts and mechanical compression. This approach offers inherent advantages including isothermal operation, higher efficiency, reduced maintenance requirements, and the ability to achieve high compression ratios in a single stage. The technology's development trajectory has been characterized by progressive improvements in membrane materials, catalyst performance, and stack design optimization.

Current technological trends indicate a growing focus on scalability, efficiency enhancement, and cost reduction. Research efforts are increasingly directed toward novel membrane materials with improved conductivity and mechanical stability, advanced catalyst formulations with reduced precious metal loading, and innovative stack architectures that optimize flow distribution and minimize electrical resistance. These developments align with the broader hydrogen economy's evolution, where compression technology represents a critical link in the value chain.

The primary technical objectives for scalable EHC stack design encompass several dimensions. First, achieving higher compression ratios (>700 bar) while maintaining efficiency is essential for applications in hydrogen refueling stations and industrial processes. Second, improving durability and operational lifetime under variable load conditions remains crucial for commercial viability. Third, reducing system complexity and component count aims to enhance reliability while decreasing manufacturing costs.

Additionally, the technology seeks to address specific performance metrics including higher hydrogen throughput per active area, reduced electrical power consumption, improved tolerance to impurities, and enhanced thermal management capabilities. These objectives are driven by market requirements for more compact, efficient, and cost-effective hydrogen compression solutions across various applications from mobility to industrial processes.

The convergence of renewable energy integration, hydrogen mobility advancement, and industrial decarbonization efforts has created a favorable environment for EHC technology development. As hydrogen assumes a more central role in the global energy transition, the demand for efficient compression technologies continues to grow, establishing clear technical targets for next-generation EHC systems that balance performance, durability, and economic considerations.

Market Analysis for Hydrogen Compression Solutions

The global hydrogen compression market is experiencing significant growth, driven primarily by the expanding hydrogen economy and the transition towards cleaner energy solutions. Current market valuations indicate that the hydrogen compression sector reached approximately 1.5 billion USD in 2022, with projections suggesting a compound annual growth rate of 5.8% through 2030. Electrochemical hydrogen compressors (EHCs) represent an emerging segment within this market, currently accounting for less than 10% of the total market share but demonstrating accelerated growth potential.

Traditional mechanical compression technologies dominate the current market landscape, with reciprocating compressors holding approximately 45% market share, followed by diaphragm compressors at 30% and centrifugal compressors at 15%. However, these conventional technologies face significant challenges in efficiency, maintenance requirements, and contamination risks that create market opportunities for alternative solutions like EHCs.

Market demand for hydrogen compression solutions spans multiple sectors, with industrial applications currently representing the largest segment at 60% of total demand. The transportation sector, particularly hydrogen refueling stations, constitutes approximately 25% of the market and is expected to grow substantially as hydrogen fuel cell vehicles gain wider adoption. Energy storage applications account for the remaining 15%, with significant growth potential as renewable energy integration accelerates.

Regional analysis reveals that Asia-Pacific currently leads the hydrogen compression market with 40% share, driven by substantial investments in hydrogen infrastructure in Japan, South Korea, and increasingly China. North America and Europe each represent approximately 30% of the market, with Europe demonstrating the fastest growth rate due to aggressive decarbonization policies and hydrogen strategy initiatives.

Customer requirements are evolving rapidly, with increasing emphasis on compression solutions that offer higher efficiency, reduced energy consumption, minimal maintenance, and elimination of lubricants that could contaminate hydrogen streams. EHC technology addresses these pain points directly, positioning it favorably against traditional compression methods despite current cost premiums.

Price sensitivity varies significantly by application segment. Industrial users prioritize reliability and total cost of ownership, while emerging applications like refueling stations demonstrate greater willingness to adopt innovative technologies that offer operational advantages despite higher initial investments. Current EHC solutions command a 30-40% price premium over traditional technologies, presenting both a market challenge and opportunity for cost optimization through scalable stack designs.

Traditional mechanical compression technologies dominate the current market landscape, with reciprocating compressors holding approximately 45% market share, followed by diaphragm compressors at 30% and centrifugal compressors at 15%. However, these conventional technologies face significant challenges in efficiency, maintenance requirements, and contamination risks that create market opportunities for alternative solutions like EHCs.

Market demand for hydrogen compression solutions spans multiple sectors, with industrial applications currently representing the largest segment at 60% of total demand. The transportation sector, particularly hydrogen refueling stations, constitutes approximately 25% of the market and is expected to grow substantially as hydrogen fuel cell vehicles gain wider adoption. Energy storage applications account for the remaining 15%, with significant growth potential as renewable energy integration accelerates.

Regional analysis reveals that Asia-Pacific currently leads the hydrogen compression market with 40% share, driven by substantial investments in hydrogen infrastructure in Japan, South Korea, and increasingly China. North America and Europe each represent approximately 30% of the market, with Europe demonstrating the fastest growth rate due to aggressive decarbonization policies and hydrogen strategy initiatives.

Customer requirements are evolving rapidly, with increasing emphasis on compression solutions that offer higher efficiency, reduced energy consumption, minimal maintenance, and elimination of lubricants that could contaminate hydrogen streams. EHC technology addresses these pain points directly, positioning it favorably against traditional compression methods despite current cost premiums.

Price sensitivity varies significantly by application segment. Industrial users prioritize reliability and total cost of ownership, while emerging applications like refueling stations demonstrate greater willingness to adopt innovative technologies that offer operational advantages despite higher initial investments. Current EHC solutions command a 30-40% price premium over traditional technologies, presenting both a market challenge and opportunity for cost optimization through scalable stack designs.

Current Challenges in Electrochemical Hydrogen Compressor Development

Despite significant advancements in electrochemical hydrogen compressor (EHC) technology, several critical challenges continue to impede the development of commercially viable, large-scale systems. The primary obstacle remains the limited current density capability, typically restricted to 1-2 A/cm², which necessitates larger active areas to achieve desired compression rates. This limitation directly impacts system footprint and capital costs, making EHCs less competitive against mechanical alternatives.

Material degradation presents another significant hurdle, particularly in membrane electrode assemblies (MEAs). The combination of high pressure differentials, fluctuating humidity conditions, and potential hydrogen embrittlement accelerates component deterioration. Nafion membranes, while standard in the industry, exhibit concerning mechanical failure rates when subjected to prolonged operation at compression ratios exceeding 100:1.

Thermal management challenges become increasingly pronounced in stack configurations. The inherent inefficiencies in the electrochemical compression process generate substantial waste heat that must be effectively dissipated to prevent membrane dehydration and catalyst degradation. Current cooling strategies prove inadequate for maintaining uniform temperature profiles across larger stacks, resulting in performance inconsistencies and reduced operational lifetimes.

Hydrogen crossover represents a persistent efficiency concern, with rates typically increasing at higher pressure differentials. This phenomenon not only reduces faradaic efficiency but also creates potential safety hazards in pressurized systems. Current membrane technologies struggle to maintain acceptable crossover rates below 1% when operating at pressure differentials above 350 bar.

Scaling challenges manifest in the form of pressure distribution inconsistencies across cells within larger stacks. Cells positioned at different locations experience varying mechanical stresses, leading to non-uniform compression and performance degradation. Engineering solutions to ensure homogeneous pressure distribution remain underdeveloped for systems exceeding 50 cells.

Cost factors continue to limit commercial viability, with current EHC systems requiring approximately $1,000-1,500/kW, significantly higher than the DOE target of $300/kW for hydrogen compression technologies. The high-cost components include platinum-based catalysts, specialized membranes, and precision-engineered bipolar plates capable of withstanding extreme pressure differentials.

System integration challenges persist, particularly regarding balance-of-plant components rated for high-pressure hydrogen service. Specialized sensors, valves, and control systems capable of reliable operation in these demanding conditions remain limited in availability and prohibitively expensive for large-scale deployment.

Material degradation presents another significant hurdle, particularly in membrane electrode assemblies (MEAs). The combination of high pressure differentials, fluctuating humidity conditions, and potential hydrogen embrittlement accelerates component deterioration. Nafion membranes, while standard in the industry, exhibit concerning mechanical failure rates when subjected to prolonged operation at compression ratios exceeding 100:1.

Thermal management challenges become increasingly pronounced in stack configurations. The inherent inefficiencies in the electrochemical compression process generate substantial waste heat that must be effectively dissipated to prevent membrane dehydration and catalyst degradation. Current cooling strategies prove inadequate for maintaining uniform temperature profiles across larger stacks, resulting in performance inconsistencies and reduced operational lifetimes.

Hydrogen crossover represents a persistent efficiency concern, with rates typically increasing at higher pressure differentials. This phenomenon not only reduces faradaic efficiency but also creates potential safety hazards in pressurized systems. Current membrane technologies struggle to maintain acceptable crossover rates below 1% when operating at pressure differentials above 350 bar.

Scaling challenges manifest in the form of pressure distribution inconsistencies across cells within larger stacks. Cells positioned at different locations experience varying mechanical stresses, leading to non-uniform compression and performance degradation. Engineering solutions to ensure homogeneous pressure distribution remain underdeveloped for systems exceeding 50 cells.

Cost factors continue to limit commercial viability, with current EHC systems requiring approximately $1,000-1,500/kW, significantly higher than the DOE target of $300/kW for hydrogen compression technologies. The high-cost components include platinum-based catalysts, specialized membranes, and precision-engineered bipolar plates capable of withstanding extreme pressure differentials.

System integration challenges persist, particularly regarding balance-of-plant components rated for high-pressure hydrogen service. Specialized sensors, valves, and control systems capable of reliable operation in these demanding conditions remain limited in availability and prohibitively expensive for large-scale deployment.

State-of-the-Art EHC Stack Design Approaches

01 Stack design and configuration for scalability

Electrochemical hydrogen compressor stacks can be designed with specific configurations to enhance scalability. These designs include modular architectures that allow for easy addition of cells, bipolar plate arrangements that optimize electrical connections, and innovative flow field patterns that maintain performance at larger scales. The stack configuration directly impacts the ability to scale up hydrogen compression capacity while maintaining efficiency and reliability.- Stack design and configuration for scalability: Electrochemical hydrogen compressor stacks can be designed with specific configurations to enhance scalability. These designs include modular architectures that allow for easy addition or removal of cells, bipolar plate arrangements that optimize electrical connections, and innovative flow field patterns that improve gas distribution across larger stacks. Such configurations enable the scaling of hydrogen compression capacity while maintaining efficiency and performance across different operational scales.

- Membrane and electrode assembly optimization: The scalability of electrochemical hydrogen compressor stacks depends significantly on the optimization of membrane electrode assemblies (MEAs). Advanced membrane materials with enhanced proton conductivity, improved electrode catalysts with higher activity, and optimized interface structures between components can maintain performance efficiency when scaling up. These improvements help overcome resistance increases and non-uniform current distribution issues that typically arise in larger stack configurations.

- Thermal management systems for large-scale stacks: Effective thermal management is crucial for the scalability of electrochemical hydrogen compressor stacks. As stack size increases, heat generation and distribution become more challenging to control. Advanced cooling systems, including liquid cooling channels, heat exchangers, and thermal interface materials, help maintain optimal operating temperatures across larger stacks. Uniform temperature distribution prevents localized hotspots and degradation, ensuring consistent performance and longevity in scaled-up systems.

- Pressure management and sealing solutions: Scaling up electrochemical hydrogen compressor stacks requires advanced pressure management and sealing solutions. Larger stacks face greater challenges in maintaining uniform pressure distribution and preventing gas leakage. Innovative sealing materials, compression systems, and pressure equalization techniques ensure gas-tight operation across expanded stack dimensions. These solutions address the mechanical stresses that increase with stack size while maintaining compression efficiency at higher throughput rates.

- System integration and control strategies: Successful scaling of electrochemical hydrogen compressor stacks depends on sophisticated system integration and control strategies. Advanced power management systems that handle increased electrical loads, intelligent control algorithms that optimize operation across larger cell arrays, and integrated monitoring systems that detect performance variations are essential for large-scale deployment. These strategies enable efficient operation of scaled-up stacks while adapting to varying hydrogen throughput demands and maintaining system reliability.

02 Membrane and electrode assembly optimization

The membrane electrode assembly (MEA) is a critical component affecting the scalability of electrochemical hydrogen compressor stacks. Optimized MEAs feature enhanced proton conductivity, improved mechanical stability under pressure differentials, and reduced crossover rates. Advanced membrane materials and electrode compositions enable consistent performance across larger active areas, which is essential for scaling up compressor stacks while maintaining efficiency.Expand Specific Solutions03 Thermal management systems for large-scale stacks

Effective thermal management is crucial for scaling up electrochemical hydrogen compressor stacks. As stack size increases, heat generation and distribution become more challenging to control. Advanced cooling systems, including liquid cooling channels, heat exchangers, and thermal interface materials, help maintain uniform temperature profiles across larger stacks. Proper thermal management prevents hotspots and ensures consistent performance and longevity in scaled-up systems.Expand Specific Solutions04 Pressure balancing and sealing technologies

Maintaining pressure integrity becomes increasingly challenging as electrochemical hydrogen compressor stacks scale up. Advanced sealing technologies, including composite gaskets, dynamic sealing mechanisms, and pressure-resistant cell frames, are essential for preventing leakage in larger stacks. Pressure balancing systems ensure uniform compression across all cells, preventing mechanical stress and maintaining consistent performance throughout scaled-up stack assemblies.Expand Specific Solutions05 System integration and control strategies

Successful scaling of electrochemical hydrogen compressor stacks requires sophisticated system integration and control strategies. This includes advanced power management systems that distribute current evenly across larger stacks, intelligent control algorithms that optimize operation based on demand, and integrated sensors for real-time monitoring. Modular system architectures allow for parallel operation of multiple stacks, providing a pathway to industrial-scale hydrogen compression while maintaining reliability and efficiency.Expand Specific Solutions

Leading Companies and Research Institutions in EHC Technology

The electrochemical hydrogen compressor (EHC) stack market is in its early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market is projected to expand significantly as hydrogen gains importance in clean energy transitions, with current estimates in the hundreds of millions and potential to reach billions as hydrogen infrastructure develops. Technologically, EHC stacks are advancing rapidly with key players at different maturity levels. Industry leaders like Robert Bosch, Air Products & Chemicals, and Toshiba Energy Systems have established commercial-scale solutions, while innovative companies such as Electric Hydrogen Co., Plug Power, and Fusion Fuel are developing next-generation technologies. Academic institutions including Zhejiang University and Universität Stuttgart are contributing fundamental research to improve efficiency and scalability of these systems.

Electric Hydrogen Co.

Technical Solution: Electric Hydrogen has pioneered a novel approach to electrochemical hydrogen compression with their high-pressure stack architecture designed specifically for green hydrogen applications. Their technology employs reinforced composite end plates and precision-engineered compression systems that maintain uniform pressure distribution across large-area cells (>1000 cm²). The company's proprietary stack design incorporates advanced sealing technologies that enable operation at differential pressures exceeding 50 MPa while minimizing gas crossover. Electric Hydrogen's stacks feature specialized catalyst layers and membrane formulations that resist hydrogen embrittlement and maintain performance under high-pressure gradients. Their modular compression units are designed for direct integration with electrolyzers, creating a seamless hydrogen production and compression system that eliminates intermediate storage requirements and reduces overall system complexity.

Strengths: Purpose-built design for renewable hydrogen applications; advanced materials science approach to high-pressure operation; vertical integration with electrolysis systems for optimized efficiency. Weaknesses: Limited commercial deployment history compared to established players; higher upfront costs; specialized maintenance requirements for high-pressure components.

Hoeller Electrolyzer GmbH

Technical Solution: Hoeller Electrolyzer has adapted their expertise in PEM electrolysis to develop specialized electrochemical hydrogen compressor stacks. Their "Prometheus" compression technology utilizes advanced titanium-based bipolar plates with proprietary coating technologies that resist hydrogen embrittlement while maintaining excellent electrical conductivity. The company's stack design features a gradient approach to cell compression, with varying clamping pressures optimized for different sections of the stack to counterbalance internal pressure differentials. Hoeller's EHC systems incorporate specialized membrane formulations with reinforced support structures that maintain mechanical integrity under high differential pressures while minimizing gas crossover. Their modular stack architecture allows for scalable deployment, with individual modules capable of achieving compression ratios of 50:1, and multiple modules configurable for higher pressure outputs. The company's integrated control system continuously monitors cell voltage distribution and adjusts operating parameters to prevent localized hotspots and membrane degradation.

Strengths: Direct technology transfer from advanced electrolysis expertise; specialized materials science approach to component design; European manufacturing capabilities with high quality standards. Weaknesses: Smaller scale operations compared to major industrial gas companies; limited deployment history specifically for compression applications; higher capital costs during early commercialization phase.

Critical Patents and Technical Literature on Scalable EHC Stacks

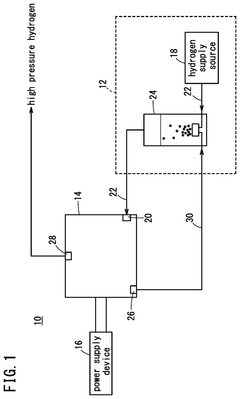

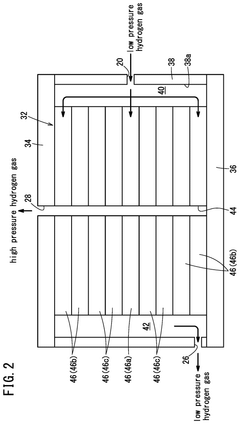

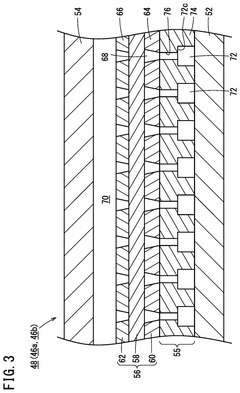

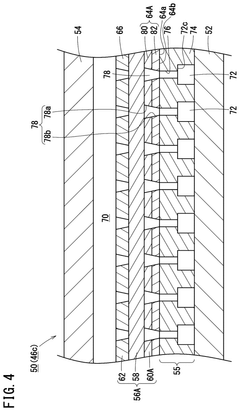

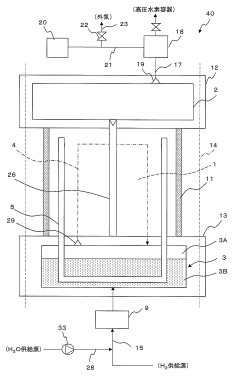

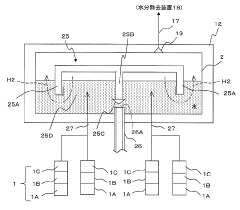

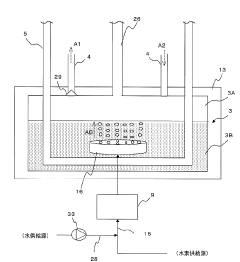

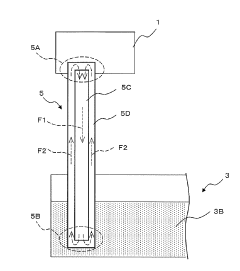

Electrochemical hydrogen compressor

PatentActiveUS12305305B2

Innovation

- The electrochemical hydrogen compressor incorporates an anode current collector made of hydrophilic conductive material with vent holes, where the surface facing the support member is subjected to water-repellent treatment, allowing for effective water retention and prevention of vent hole blockage.

Electrochemical hydrogen compressor

PatentActiveJP2023022865A

Innovation

- The electrochemical hydrogen compressor integrates cell, bubbler, and water separator casings, eliminates external circulation systems, and uses a heat tube for self-cooling, reducing the need for pressure vessel standards and chillers, while allowing for compact cell stacking.

Materials Science Advancements for EHC Stack Components

Recent advancements in materials science have significantly enhanced the performance and durability of Electrochemical Hydrogen Compressor (EHC) stack components. The membrane electrode assembly (MEA), a critical component in EHC stacks, has seen substantial improvements through the development of perfluorosulfonic acid (PFSA) membranes with enhanced proton conductivity and reduced gas crossover. These membranes, typically 25-175 μm thick, now demonstrate superior mechanical stability under high-pressure differentials exceeding 100 bar.

Catalyst layer innovations have focused on platinum-based materials with optimized particle size distribution (2-5 nm) and loading (0.1-0.5 mg/cm²), resulting in improved hydrogen oxidation and evolution reaction kinetics. Novel carbon support structures with increased corrosion resistance have extended catalyst lifetime under the demanding operational conditions of EHC systems.

Gas diffusion layers (GDLs) have evolved to incorporate hydrophobic treatments using polytetrafluoroethylene (PTFE) at concentrations of 5-30 wt%, effectively managing water content within the stack. Advanced microporous layers with controlled porosity (40-60%) and thickness (30-50 μm) now facilitate optimal gas transport while maintaining electrical conductivity above 200 S/cm.

Bipolar plate materials have transitioned from traditional graphite to coated metallic substrates, including titanium and stainless steel with noble metal or conductive polymer coatings. These materials offer superior electrical conductivity (>100 S/cm) and corrosion resistance while enabling thinner plate designs (0.5-3 mm), thereby increasing volumetric efficiency of EHC stacks.

Sealing technologies have progressed from conventional gaskets to composite materials combining silicone elastomers with PTFE reinforcement, capable of withstanding pressure differentials up to 700 bar while maintaining gas-tight integrity over thousands of operational hours. These advanced sealing solutions demonstrate compression set values below 15% after 1000 hours at elevated temperatures.

Interface materials between stack components have been engineered to minimize contact resistance while accommodating thermal expansion differentials. Conductive interface materials with thermal conductivity values exceeding 10 W/m·K ensure efficient heat dissipation during operation, preventing localized hotspots that could compromise membrane integrity.

The integration of these material advancements has collectively enabled EHC stacks to achieve compression ratios exceeding 1:700 with energy efficiencies approaching 60-70% of theoretical limits. Future research directions include exploration of non-PGM catalysts, hydrocarbon-based proton exchange membranes with enhanced mechanical properties, and composite bipolar plates with integrated cooling channels for improved thermal management in high-pressure applications.

Catalyst layer innovations have focused on platinum-based materials with optimized particle size distribution (2-5 nm) and loading (0.1-0.5 mg/cm²), resulting in improved hydrogen oxidation and evolution reaction kinetics. Novel carbon support structures with increased corrosion resistance have extended catalyst lifetime under the demanding operational conditions of EHC systems.

Gas diffusion layers (GDLs) have evolved to incorporate hydrophobic treatments using polytetrafluoroethylene (PTFE) at concentrations of 5-30 wt%, effectively managing water content within the stack. Advanced microporous layers with controlled porosity (40-60%) and thickness (30-50 μm) now facilitate optimal gas transport while maintaining electrical conductivity above 200 S/cm.

Bipolar plate materials have transitioned from traditional graphite to coated metallic substrates, including titanium and stainless steel with noble metal or conductive polymer coatings. These materials offer superior electrical conductivity (>100 S/cm) and corrosion resistance while enabling thinner plate designs (0.5-3 mm), thereby increasing volumetric efficiency of EHC stacks.

Sealing technologies have progressed from conventional gaskets to composite materials combining silicone elastomers with PTFE reinforcement, capable of withstanding pressure differentials up to 700 bar while maintaining gas-tight integrity over thousands of operational hours. These advanced sealing solutions demonstrate compression set values below 15% after 1000 hours at elevated temperatures.

Interface materials between stack components have been engineered to minimize contact resistance while accommodating thermal expansion differentials. Conductive interface materials with thermal conductivity values exceeding 10 W/m·K ensure efficient heat dissipation during operation, preventing localized hotspots that could compromise membrane integrity.

The integration of these material advancements has collectively enabled EHC stacks to achieve compression ratios exceeding 1:700 with energy efficiencies approaching 60-70% of theoretical limits. Future research directions include exploration of non-PGM catalysts, hydrocarbon-based proton exchange membranes with enhanced mechanical properties, and composite bipolar plates with integrated cooling channels for improved thermal management in high-pressure applications.

Safety and Regulatory Framework for Hydrogen Compression Systems

The safety and regulatory landscape for hydrogen compression systems, particularly for Electrochemical Hydrogen Compressor (EHC) stacks, is complex and evolving rapidly as hydrogen gains prominence in the global energy transition. Current regulatory frameworks vary significantly across regions, with the European Union's Hydrogen Strategy and the United States' Department of Energy Hydrogen Program Plan representing leading comprehensive approaches.

International standards organizations, including ISO (International Organization for Standardization) and IEC (International Electrotechnical Commission), have developed specific standards addressing hydrogen technologies. Notable among these are ISO 22734 for hydrogen generators using water electrolysis and IEC 62282 series for fuel cell technologies, which provide baseline safety requirements applicable to EHC systems.

Risk assessment methodologies for EHC stacks must address unique hazards including hydrogen embrittlement, potential for leakage, and electrical safety concerns specific to electrochemical processes. HAZOP (Hazard and Operability) studies and FMEA (Failure Mode and Effects Analysis) are increasingly being adapted specifically for hydrogen compression technologies to identify potential failure points and mitigation strategies.

Material compatibility represents a critical safety consideration in EHC design. Regulatory frameworks increasingly mandate specific material selection protocols to prevent hydrogen-induced degradation. This includes requirements for hydrogen-compatible polymers for membranes and seals, as well as metals resistant to hydrogen embrittlement for structural components and piping systems.

Pressure equipment directives, such as the European Pressure Equipment Directive (PED) and ASME Boiler and Pressure Vessel Code in the US, establish essential safety requirements for equipment operating under pressure. For scalable EHC stacks, compliance with these regulations becomes increasingly complex as system size and operating pressures increase.

Explosion protection regulations, including ATEX in Europe and Class I Division 1 requirements in North America, establish zoning requirements and equipment specifications for areas where explosive hydrogen-air mixtures may form. These regulations directly impact the design of EHC stack enclosures, ventilation systems, and monitoring equipment.

Emerging regulatory trends indicate movement toward performance-based rather than prescriptive requirements, allowing greater flexibility in innovative EHC designs while maintaining safety standards. Additionally, harmonization efforts between major regulatory bodies are underway to facilitate global deployment of hydrogen technologies, though significant regional differences remain in certification processes and compliance requirements.

International standards organizations, including ISO (International Organization for Standardization) and IEC (International Electrotechnical Commission), have developed specific standards addressing hydrogen technologies. Notable among these are ISO 22734 for hydrogen generators using water electrolysis and IEC 62282 series for fuel cell technologies, which provide baseline safety requirements applicable to EHC systems.

Risk assessment methodologies for EHC stacks must address unique hazards including hydrogen embrittlement, potential for leakage, and electrical safety concerns specific to electrochemical processes. HAZOP (Hazard and Operability) studies and FMEA (Failure Mode and Effects Analysis) are increasingly being adapted specifically for hydrogen compression technologies to identify potential failure points and mitigation strategies.

Material compatibility represents a critical safety consideration in EHC design. Regulatory frameworks increasingly mandate specific material selection protocols to prevent hydrogen-induced degradation. This includes requirements for hydrogen-compatible polymers for membranes and seals, as well as metals resistant to hydrogen embrittlement for structural components and piping systems.

Pressure equipment directives, such as the European Pressure Equipment Directive (PED) and ASME Boiler and Pressure Vessel Code in the US, establish essential safety requirements for equipment operating under pressure. For scalable EHC stacks, compliance with these regulations becomes increasingly complex as system size and operating pressures increase.

Explosion protection regulations, including ATEX in Europe and Class I Division 1 requirements in North America, establish zoning requirements and equipment specifications for areas where explosive hydrogen-air mixtures may form. These regulations directly impact the design of EHC stack enclosures, ventilation systems, and monitoring equipment.

Emerging regulatory trends indicate movement toward performance-based rather than prescriptive requirements, allowing greater flexibility in innovative EHC designs while maintaining safety standards. Additionally, harmonization efforts between major regulatory bodies are underway to facilitate global deployment of hydrogen technologies, though significant regional differences remain in certification processes and compliance requirements.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!