Materials Corrosion And Durability In Electrochemical Hydrogen Compressors

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Hydrogen Compression Technology Background and Objectives

Electrochemical hydrogen compression (EHC) technology represents a significant advancement in hydrogen processing and storage systems, emerging as a promising alternative to conventional mechanical compression methods. The evolution of this technology can be traced back to the early 2000s when researchers began exploring electrochemical approaches to address the limitations of mechanical compression, particularly for high-purity applications and energy efficiency concerns.

The fundamental principle of EHC leverages proton exchange membranes (PEMs) to transport hydrogen ions across an electrolyte barrier, enabling compression without moving parts. This approach offers several inherent advantages, including isothermal operation, scalability, and the ability to achieve high compression ratios with relatively low energy input compared to traditional methods.

Over the past decade, EHC technology has progressed from laboratory-scale demonstrations to early commercial prototypes, with significant improvements in efficiency, durability, and operational pressure ranges. The technology has evolved from initial systems capable of modest compression ratios (10-100:1) to advanced designs achieving compression ratios exceeding 1000:1, with output pressures reaching 700 bar or higher in some experimental systems.

A critical aspect of this technological evolution has been the ongoing challenge of materials corrosion and durability. The harsh electrochemical environment within these compressors, characterized by high potentials, acidic conditions, and pressurized hydrogen, creates a particularly demanding setting for materials performance and longevity.

The primary technical objectives in this field focus on developing materials systems that can withstand these aggressive conditions while maintaining operational efficiency and service life. Specifically, research aims to address corrosion of metallic components, degradation of polymer membranes, and catalyst stability under high-pressure hydrogen environments.

Current development trajectories are focused on novel material compositions, protective coatings, and innovative cell designs that mitigate corrosion mechanisms while enhancing overall system performance. The field is witnessing a convergence of materials science, electrochemistry, and mechanical engineering to overcome these challenges.

The ultimate goal of EHC technology development is to achieve compression systems with operational lifetimes exceeding 50,000 hours, pressure capabilities compatible with hydrogen refueling standards (350-700 bar), and energy efficiencies surpassing 70% - all while maintaining material integrity against corrosion and degradation. These objectives align with broader hydrogen economy initiatives and the growing demand for efficient, reliable hydrogen infrastructure solutions.

The fundamental principle of EHC leverages proton exchange membranes (PEMs) to transport hydrogen ions across an electrolyte barrier, enabling compression without moving parts. This approach offers several inherent advantages, including isothermal operation, scalability, and the ability to achieve high compression ratios with relatively low energy input compared to traditional methods.

Over the past decade, EHC technology has progressed from laboratory-scale demonstrations to early commercial prototypes, with significant improvements in efficiency, durability, and operational pressure ranges. The technology has evolved from initial systems capable of modest compression ratios (10-100:1) to advanced designs achieving compression ratios exceeding 1000:1, with output pressures reaching 700 bar or higher in some experimental systems.

A critical aspect of this technological evolution has been the ongoing challenge of materials corrosion and durability. The harsh electrochemical environment within these compressors, characterized by high potentials, acidic conditions, and pressurized hydrogen, creates a particularly demanding setting for materials performance and longevity.

The primary technical objectives in this field focus on developing materials systems that can withstand these aggressive conditions while maintaining operational efficiency and service life. Specifically, research aims to address corrosion of metallic components, degradation of polymer membranes, and catalyst stability under high-pressure hydrogen environments.

Current development trajectories are focused on novel material compositions, protective coatings, and innovative cell designs that mitigate corrosion mechanisms while enhancing overall system performance. The field is witnessing a convergence of materials science, electrochemistry, and mechanical engineering to overcome these challenges.

The ultimate goal of EHC technology development is to achieve compression systems with operational lifetimes exceeding 50,000 hours, pressure capabilities compatible with hydrogen refueling standards (350-700 bar), and energy efficiencies surpassing 70% - all while maintaining material integrity against corrosion and degradation. These objectives align with broader hydrogen economy initiatives and the growing demand for efficient, reliable hydrogen infrastructure solutions.

Market Analysis for Hydrogen Compression Technologies

The global hydrogen compression market is experiencing significant growth, driven by the increasing adoption of hydrogen as a clean energy carrier. As of 2023, the market is valued at approximately 2.1 billion USD, with projections indicating a compound annual growth rate (CAGR) of 5.8% through 2030. This growth trajectory is primarily fueled by expanding applications in industrial processes, fuel cell vehicles, and energy storage systems.

Traditional mechanical compression technologies currently dominate the market, accounting for roughly 75% of installations worldwide. These systems, while well-established, face efficiency limitations and maintenance challenges that create market opportunities for alternative technologies. Electrochemical hydrogen compressors (EHCs) are emerging as a promising alternative, currently representing about 8% of the market but expected to reach 15% by 2027.

The market segmentation reveals distinct application sectors with varying requirements. Industrial applications constitute the largest segment (42%), followed by refueling infrastructure (28%), power-to-gas systems (18%), and laboratory/research applications (12%). Each segment presents unique material durability requirements, with industrial applications demanding the highest pressure ratings and longest operational lifespans.

Regional analysis shows Europe leading the EHC adoption with approximately 38% market share, followed by North America (32%), Asia-Pacific (24%), and other regions (6%). This distribution correlates strongly with regional hydrogen strategy implementations and clean energy transition policies.

Customer demand patterns indicate growing preference for compression systems with higher durability, lower maintenance requirements, and improved energy efficiency. Market surveys reveal that 67% of potential customers identify material durability as a "very important" or "critical" factor in purchasing decisions for hydrogen compression equipment.

Competitive landscape analysis shows increasing investment in advanced materials research by major players. Companies including Nel Hydrogen, Hydrogenics (Cummins), and emerging startups like Hystar and Enapter are actively developing proprietary materials and coatings to address corrosion challenges in electrochemical compression systems.

Economic factors affecting market growth include declining renewable electricity costs, which improve the economics of green hydrogen production, and increasing carbon pricing mechanisms that favor low-carbon hydrogen applications. The total cost of ownership analysis indicates that despite higher initial capital costs, EHC systems with advanced corrosion-resistant materials can achieve 22-30% lower lifetime costs compared to conventional mechanical compressors in certain applications.

Traditional mechanical compression technologies currently dominate the market, accounting for roughly 75% of installations worldwide. These systems, while well-established, face efficiency limitations and maintenance challenges that create market opportunities for alternative technologies. Electrochemical hydrogen compressors (EHCs) are emerging as a promising alternative, currently representing about 8% of the market but expected to reach 15% by 2027.

The market segmentation reveals distinct application sectors with varying requirements. Industrial applications constitute the largest segment (42%), followed by refueling infrastructure (28%), power-to-gas systems (18%), and laboratory/research applications (12%). Each segment presents unique material durability requirements, with industrial applications demanding the highest pressure ratings and longest operational lifespans.

Regional analysis shows Europe leading the EHC adoption with approximately 38% market share, followed by North America (32%), Asia-Pacific (24%), and other regions (6%). This distribution correlates strongly with regional hydrogen strategy implementations and clean energy transition policies.

Customer demand patterns indicate growing preference for compression systems with higher durability, lower maintenance requirements, and improved energy efficiency. Market surveys reveal that 67% of potential customers identify material durability as a "very important" or "critical" factor in purchasing decisions for hydrogen compression equipment.

Competitive landscape analysis shows increasing investment in advanced materials research by major players. Companies including Nel Hydrogen, Hydrogenics (Cummins), and emerging startups like Hystar and Enapter are actively developing proprietary materials and coatings to address corrosion challenges in electrochemical compression systems.

Economic factors affecting market growth include declining renewable electricity costs, which improve the economics of green hydrogen production, and increasing carbon pricing mechanisms that favor low-carbon hydrogen applications. The total cost of ownership analysis indicates that despite higher initial capital costs, EHC systems with advanced corrosion-resistant materials can achieve 22-30% lower lifetime costs compared to conventional mechanical compressors in certain applications.

Current Corrosion Challenges in EHC Materials

Electrochemical Hydrogen Compressors (EHCs) represent a promising technology for hydrogen compression without moving parts, offering potential advantages in efficiency, reliability, and maintenance requirements. However, material corrosion presents significant challenges that currently limit the widespread adoption and long-term durability of these systems.

The harsh operating environment within EHCs creates multiple corrosion mechanisms that affect critical components. The combination of high pressure differentials (often exceeding 700 bar), elevated temperatures, and the presence of highly reactive hydrogen species creates particularly aggressive conditions. Proton Exchange Membranes (PEMs), which serve as the core component in EHCs, suffer from chemical degradation through radical attack, particularly from hydroxyl and peroxyl radicals formed during operation.

Electrode materials face severe challenges related to hydrogen embrittlement, where atomic hydrogen diffuses into metal lattices, causing mechanical property deterioration and potential catastrophic failure. This is especially problematic for compression stages operating at higher pressures, where hydrogen concentration gradients are steepest.

Bipolar plates and current collectors, typically made from stainless steel or titanium alloys, experience localized corrosion at the interface with membrane electrode assemblies. The formation of passive oxide layers initially provides some protection, but these layers can break down under the electrochemical cycling conditions typical in EHC operation, leading to pitting corrosion and eventual component failure.

Catalyst degradation represents another critical corrosion challenge. Noble metal catalysts (primarily platinum and its alloys) undergo dissolution-redeposition cycles that lead to particle agglomeration and surface area reduction. This process accelerates in the presence of contaminants such as carbon monoxide, sulfur compounds, and ammonia, which are often present in hydrogen streams from reforming or industrial processes.

Sealing materials and interfaces between components suffer from chemical attack and mechanical stress-induced degradation. Fluoroelastomer gaskets commonly used in EHCs experience swelling and embrittlement when exposed to hydrogen under pressure, compromising seal integrity and leading to hydrogen leakage.

The presence of water, essential for proton conductivity in PEM-based systems, creates additional corrosion pathways. Water management issues can lead to localized drying or flooding, creating concentration cells that accelerate corrosion processes. Furthermore, impurities in water can concentrate during operation, forming highly corrosive microenvironments at material interfaces.

These corrosion challenges collectively contribute to performance degradation, reduced efficiency, and ultimately shortened operational lifetimes of EHC systems, presenting significant barriers to their commercial viability and widespread adoption in hydrogen infrastructure applications.

The harsh operating environment within EHCs creates multiple corrosion mechanisms that affect critical components. The combination of high pressure differentials (often exceeding 700 bar), elevated temperatures, and the presence of highly reactive hydrogen species creates particularly aggressive conditions. Proton Exchange Membranes (PEMs), which serve as the core component in EHCs, suffer from chemical degradation through radical attack, particularly from hydroxyl and peroxyl radicals formed during operation.

Electrode materials face severe challenges related to hydrogen embrittlement, where atomic hydrogen diffuses into metal lattices, causing mechanical property deterioration and potential catastrophic failure. This is especially problematic for compression stages operating at higher pressures, where hydrogen concentration gradients are steepest.

Bipolar plates and current collectors, typically made from stainless steel or titanium alloys, experience localized corrosion at the interface with membrane electrode assemblies. The formation of passive oxide layers initially provides some protection, but these layers can break down under the electrochemical cycling conditions typical in EHC operation, leading to pitting corrosion and eventual component failure.

Catalyst degradation represents another critical corrosion challenge. Noble metal catalysts (primarily platinum and its alloys) undergo dissolution-redeposition cycles that lead to particle agglomeration and surface area reduction. This process accelerates in the presence of contaminants such as carbon monoxide, sulfur compounds, and ammonia, which are often present in hydrogen streams from reforming or industrial processes.

Sealing materials and interfaces between components suffer from chemical attack and mechanical stress-induced degradation. Fluoroelastomer gaskets commonly used in EHCs experience swelling and embrittlement when exposed to hydrogen under pressure, compromising seal integrity and leading to hydrogen leakage.

The presence of water, essential for proton conductivity in PEM-based systems, creates additional corrosion pathways. Water management issues can lead to localized drying or flooding, creating concentration cells that accelerate corrosion processes. Furthermore, impurities in water can concentrate during operation, forming highly corrosive microenvironments at material interfaces.

These corrosion challenges collectively contribute to performance degradation, reduced efficiency, and ultimately shortened operational lifetimes of EHC systems, presenting significant barriers to their commercial viability and widespread adoption in hydrogen infrastructure applications.

Current Anti-Corrosion Solutions for EHC Components

01 Corrosion-resistant materials for electrochemical hydrogen compressors

Various corrosion-resistant materials can be used in electrochemical hydrogen compressors to enhance durability. These materials include specialized alloys, coatings, and composite structures that resist degradation in the highly corrosive environment of hydrogen compression systems. The selection of appropriate materials is crucial for extending the operational lifetime of these compressors and maintaining their efficiency over time.- Corrosion-resistant materials for electrochemical hydrogen compressors: Various corrosion-resistant materials can be used in electrochemical hydrogen compressors to enhance durability. These include specialized coatings, noble metals, and corrosion-resistant alloys that can withstand the harsh electrochemical environment. The selection of appropriate materials is crucial for preventing degradation of components such as electrodes, membranes, and bipolar plates, thereby extending the operational lifetime of the compressor system.

- Membrane and electrode assembly durability improvements: Enhancing the durability of membrane electrode assemblies (MEAs) is critical for electrochemical hydrogen compressors. Innovations include reinforced polymer electrolyte membranes, optimized catalyst layers with improved adhesion, and structural modifications that reduce mechanical stress during operation. These improvements help maintain performance over extended periods by minimizing degradation mechanisms such as membrane thinning, catalyst dissolution, and delamination under high-pressure differentials.

- Monitoring and control systems for corrosion prevention: Advanced monitoring and control systems can be implemented to detect and mitigate corrosion in electrochemical hydrogen compressors. These systems include sensors for measuring key parameters such as pH, potential, temperature, and humidity, which can indicate corrosion onset. Automated control mechanisms can adjust operating conditions to minimize corrosive environments, while predictive maintenance algorithms help identify potential failure points before catastrophic damage occurs.

- Electrolyte composition and management for enhanced durability: The composition and management of electrolytes significantly impact the durability of electrochemical hydrogen compressors. Optimized electrolyte formulations can include corrosion inhibitors, pH buffers, and stabilizing additives that reduce degradation of cell components. Proper water management systems prevent flooding or drying of membranes, while purification techniques remove contaminants that could accelerate corrosion processes or poison catalysts.

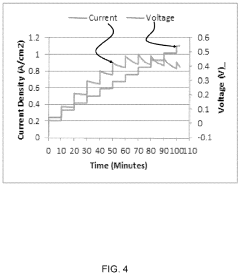

- System design and operating protocols to minimize degradation: Innovative system designs and operating protocols can significantly extend the service life of electrochemical hydrogen compressors. These include optimized flow field geometries that ensure uniform current distribution, pressure management systems that reduce mechanical stress, and thermal management solutions that prevent hotspots. Additionally, specialized start-up and shutdown procedures, along with controlled operating parameters such as current density and compression ratios, help minimize degradation mechanisms during both steady-state and transient operations.

02 Membrane and electrode assembly durability improvements

Enhancing the durability of membrane and electrode assemblies (MEAs) is critical for electrochemical hydrogen compressors. Innovations include reinforced membrane structures, optimized catalyst compositions, and improved electrode designs that can withstand high pressure differentials and acidic conditions. These improvements help prevent membrane degradation, catalyst poisoning, and electrode delamination, thereby extending the service life of the compressor system.Expand Specific Solutions03 Monitoring and control systems for corrosion prevention

Advanced monitoring and control systems can detect early signs of corrosion and implement preventive measures in electrochemical hydrogen compressors. These systems may include sensors for measuring pH levels, hydrogen concentration, temperature, and pressure, along with automated control mechanisms that adjust operating parameters to minimize corrosion risks. Real-time monitoring enables timely maintenance interventions before significant damage occurs.Expand Specific Solutions04 Electrolyte composition and management for extended durability

The composition and management of electrolytes play a crucial role in preventing corrosion in electrochemical hydrogen compressors. Optimized electrolyte formulations with corrosion inhibitors, pH buffers, and stabilizing agents can significantly reduce degradation of compressor components. Proper electrolyte circulation, purification, and replenishment strategies further enhance system durability by maintaining consistent chemical conditions within the compressor.Expand Specific Solutions05 Sealing and interface protection technologies

Effective sealing and interface protection technologies are essential for preventing leakage and localized corrosion in electrochemical hydrogen compressors. Advanced gasket materials, compression techniques, and interface treatments help maintain the integrity of cell stacks under high-pressure operation. These technologies focus on critical junctions between different materials and components where corrosion often initiates due to galvanic effects or concentration cells.Expand Specific Solutions

Leading Companies and Research Institutions in EHC Technology

The electrochemical hydrogen compression market is currently in an early growth phase, characterized by increasing adoption as hydrogen gains prominence in clean energy transitions. The global market size is projected to expand significantly, driven by decarbonization initiatives and hydrogen infrastructure development. Regarding technical maturity, materials corrosion and durability remain critical challenges. Leading companies addressing these issues include Siemens AG and GE Technology, who are developing advanced materials and coatings, while DuPont and LANXESS focus on polymer membrane innovations. Henkel and Dow Global Technologies are pioneering specialized sealants and protective coatings to combat electrochemical degradation. Research collaborations between industry leaders like ExxonMobil, Saudi Aramco, and academic institutions such as Portland State University are accelerating solutions for long-term durability in harsh operating environments.

General Electric Technology GmbH

Technical Solution: GE has developed a comprehensive materials solution for electrochemical hydrogen compressors focusing on long-term durability under high-pressure differential conditions. Their approach centers on advanced composite bipolar plates utilizing carbon-polymer composites with specialized coatings that resist both hydrogen embrittlement and oxidative degradation. GE's technology incorporates proprietary catalyst layer formulations with platinum-group metal catalysts supported on corrosion-resistant carbon structures, engineered to maintain electrochemical performance while minimizing degradation. The company has pioneered membrane technologies with reinforced perfluorosulfonic acid (PFSA) structures that maintain mechanical integrity under compression while preserving proton conductivity. Their systems employ advanced sealing solutions with fluoroelastomer materials specifically formulated to resist hydrogen permeation and maintain compression set resistance over thousands of operational hours. GE's integrated approach includes specialized surface treatments for metallic components that create passive oxide layers to prevent corrosion initiation.

Strengths: GE's solutions demonstrate excellent durability with reported operational lifetimes exceeding 25,000 hours under industrial conditions. Their integrated systems approach addresses multiple failure modes simultaneously. Weaknesses: The complex manufacturing processes required for their advanced materials increase production costs, and the specialized components have limited suppliers, creating potential supply chain vulnerabilities.

Saudi Arabian Oil Co.

Technical Solution: Saudi Aramco has developed innovative materials solutions for electrochemical hydrogen compressors focused on extreme durability in high-temperature and high-pressure applications. Their approach centers on advanced ceramic-metallic (cermet) composite materials for bipolar plates that resist both hydrogen embrittlement and oxidative degradation while maintaining electrical conductivity. Saudi Aramco's technology incorporates specialized membrane formulations with hydrocarbon-based polymer backbones modified with sulfonated side chains that demonstrate enhanced mechanical stability and chemical resistance compared to traditional perfluorinated membranes. The company has engineered catalyst layer compositions utilizing platinum-ruthenium alloy catalysts supported on titanium oxide-modified carbon structures that show exceptional resistance to carbon corrosion under potential cycling conditions. Their comprehensive materials solution includes advanced inorganic-organic composite sealing systems based on modified silicone chemistry with inorganic fillers that maintain compression set resistance and chemical stability at elevated temperatures. Saudi Aramco's approach also incorporates specialized surface treatments for metallic components using plasma nitriding techniques to create diffusion barrier layers against hydrogen permeation.

Strengths: Saudi Aramco's materials demonstrate exceptional thermal stability and maintain performance under extreme operating conditions typical in petrochemical applications. Their solutions offer cost advantages through the use of alternative non-fluorinated polymer systems. Weaknesses: Some of their advanced materials have limited commercial availability and require specialized manufacturing processes that challenge large-scale production.

Key Patents and Research on Corrosion-Resistant Materials

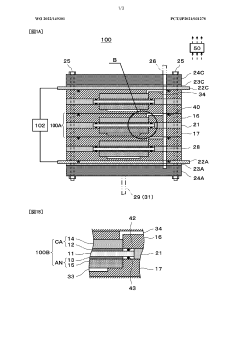

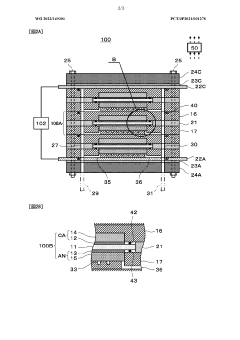

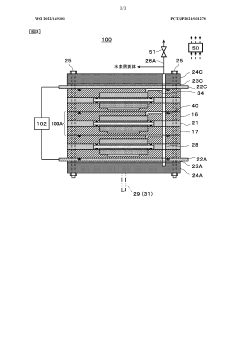

Compressor and method for controlling compressor

PatentWO2022149301A1

Innovation

- An electrochemical compressor design with a controller that applies a voltage between an anode and a cathode, ensuring the voltage remains below the corrosion potential of the metal anode separator, and includes a gas flow path with a valve to manage hydrogen purity and flow, using a solid polymer membrane and resistant metal separators like SUS316 or SUS316L to prevent membrane deterioration and maintain high hydrogen purity.

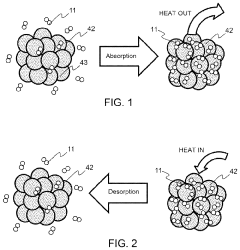

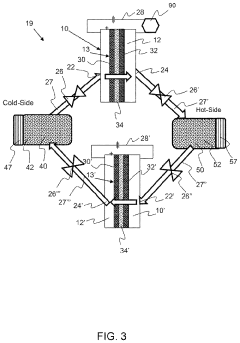

Advanced metal hydride heat transfer system utilizing an electrochemical hydrogen compressor

PatentActiveUS11994319B2

Innovation

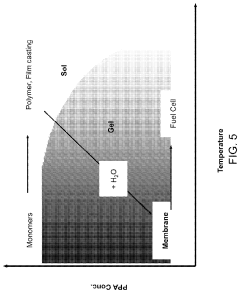

- An electrochemical compressor-driven metal hydride heat pump system using a dry hydrogen gas and a phosphoric acid-functionalized polybenzimidazole/polytetrafluoroethylene composite membrane that operates in a dry state, eliminating the need for desiccation and reducing parasitic loads, with a configuration that optimizes hydrogen transfer between metal hydride reservoirs and incorporates a regenerative unit for efficient operation.

Lifecycle Assessment and Sustainability Factors

Lifecycle assessment of electrochemical hydrogen compressors (EHCs) reveals significant sustainability advantages over mechanical alternatives, primarily due to their solid-state operation and absence of moving parts. However, material corrosion and degradation issues present substantial challenges to their long-term environmental viability. The lifecycle environmental impact of EHCs is heavily influenced by the durability of critical components, particularly membrane electrode assemblies and catalyst materials.

When examining the full lifecycle of EHCs, material selection emerges as a crucial factor affecting both performance and environmental footprint. Platinum group metals (PGMs) used as catalysts represent a sustainability concern due to their scarcity, energy-intensive mining processes, and significant carbon footprint. Research indicates that extending catalyst lifespan through corrosion resistance improvements could reduce lifecycle emissions by 30-45% compared to current designs requiring frequent replacement.

Water management systems within EHCs also present sustainability challenges, as corrosion-induced leakage can lead to increased maintenance requirements and premature system failure. Studies demonstrate that implementing advanced water management strategies and corrosion-resistant materials can extend operational lifespans by 2-3 times, substantially improving lifecycle assessment metrics.

Energy efficiency throughout the operational phase represents another critical sustainability factor. Corrosion-related performance degradation typically increases energy consumption by 15-25% over the system lifetime. This efficiency loss translates directly to increased carbon emissions in applications where grid electricity powers the compression process. Innovations in corrosion-resistant coatings and material treatments show potential to maintain efficiency parameters closer to initial specifications throughout the operational lifecycle.

End-of-life considerations for EHCs present both challenges and opportunities. The recovery and recycling of precious metals from degraded components can offset initial environmental impacts, but current recycling processes for composite materials and contaminated membranes remain inefficient. Designing for disassembly and material recovery represents a promising approach to improving overall sustainability metrics.

Comparative lifecycle assessments between traditional mechanical compressors and EHCs demonstrate that despite material durability challenges, electrochemical systems maintain a lower environmental impact when operational lifespans exceed 5-7 years. This advantage stems primarily from eliminated lubricant requirements, reduced maintenance interventions, and higher operational efficiency when corrosion is effectively managed.

When examining the full lifecycle of EHCs, material selection emerges as a crucial factor affecting both performance and environmental footprint. Platinum group metals (PGMs) used as catalysts represent a sustainability concern due to their scarcity, energy-intensive mining processes, and significant carbon footprint. Research indicates that extending catalyst lifespan through corrosion resistance improvements could reduce lifecycle emissions by 30-45% compared to current designs requiring frequent replacement.

Water management systems within EHCs also present sustainability challenges, as corrosion-induced leakage can lead to increased maintenance requirements and premature system failure. Studies demonstrate that implementing advanced water management strategies and corrosion-resistant materials can extend operational lifespans by 2-3 times, substantially improving lifecycle assessment metrics.

Energy efficiency throughout the operational phase represents another critical sustainability factor. Corrosion-related performance degradation typically increases energy consumption by 15-25% over the system lifetime. This efficiency loss translates directly to increased carbon emissions in applications where grid electricity powers the compression process. Innovations in corrosion-resistant coatings and material treatments show potential to maintain efficiency parameters closer to initial specifications throughout the operational lifecycle.

End-of-life considerations for EHCs present both challenges and opportunities. The recovery and recycling of precious metals from degraded components can offset initial environmental impacts, but current recycling processes for composite materials and contaminated membranes remain inefficient. Designing for disassembly and material recovery represents a promising approach to improving overall sustainability metrics.

Comparative lifecycle assessments between traditional mechanical compressors and EHCs demonstrate that despite material durability challenges, electrochemical systems maintain a lower environmental impact when operational lifespans exceed 5-7 years. This advantage stems primarily from eliminated lubricant requirements, reduced maintenance interventions, and higher operational efficiency when corrosion is effectively managed.

Safety Standards and Certification Requirements

The safety standards and certification requirements for electrochemical hydrogen compressors (EHCs) are critical due to the inherent risks associated with hydrogen handling and the corrosive environments present in these systems. International standards such as ISO 16111, which addresses hydrogen stored in reversible metal hydrides, provide foundational guidelines that partially apply to EHC systems. Additionally, the IEC 62282 series for fuel cell technologies offers relevant safety parameters that can be adapted for hydrogen compression applications.

Material-specific safety standards are particularly important when addressing corrosion and durability concerns. ASTM G5 and ASTM G61 establish protocols for conducting potentiostatic and potentiodynamic polarization measurements, which are essential for evaluating the corrosion resistance of materials used in EHCs. These standards help manufacturers assess material degradation under operational conditions and predict service lifetimes.

Pressure equipment directives, such as the European Pressure Equipment Directive (PED) 2014/68/EU, impose strict requirements on components operating under pressure. For EHCs, this necessitates rigorous testing of membrane materials and structural components to ensure they maintain integrity under cyclic loading and varying pressure conditions. The ASME Boiler and Pressure Vessel Code Section VIII provides additional guidelines for pressure-containing components that may be subject to hydrogen embrittlement.

Certification processes typically require extensive documentation of material properties, including corrosion rates in various electrolytes, hydrogen permeation characteristics, and mechanical stability after prolonged exposure to operational conditions. Third-party testing laboratories conduct accelerated aging tests according to standards like IEC 62282-2, which can be adapted to evaluate EHC materials' long-term performance.

Hazardous area classifications, as defined by IEC 60079 series, are particularly relevant for EHC installations due to the potential for hydrogen leakage. Materials used in these environments must not only resist corrosion but also meet specific requirements for preventing ignition sources, which adds another layer of complexity to material selection and certification.

Emerging standards specifically addressing electrochemical hydrogen technologies are being developed by organizations such as ISO TC 197 (Hydrogen Technologies) and IEC TC 105 (Fuel Cell Technologies). These standards aim to establish comprehensive frameworks for safety assessment, including material compatibility testing protocols and performance criteria tailored to the unique operating conditions of EHCs.

For commercial deployment, manufacturers must navigate a complex landscape of regional certifications, including CE marking in Europe, UL certification in North America, and equivalent standards in Asian markets. Each certification process evaluates materials' resistance to degradation mechanisms specific to electrochemical hydrogen compression, ensuring that durability and safety requirements are met across global markets.

Material-specific safety standards are particularly important when addressing corrosion and durability concerns. ASTM G5 and ASTM G61 establish protocols for conducting potentiostatic and potentiodynamic polarization measurements, which are essential for evaluating the corrosion resistance of materials used in EHCs. These standards help manufacturers assess material degradation under operational conditions and predict service lifetimes.

Pressure equipment directives, such as the European Pressure Equipment Directive (PED) 2014/68/EU, impose strict requirements on components operating under pressure. For EHCs, this necessitates rigorous testing of membrane materials and structural components to ensure they maintain integrity under cyclic loading and varying pressure conditions. The ASME Boiler and Pressure Vessel Code Section VIII provides additional guidelines for pressure-containing components that may be subject to hydrogen embrittlement.

Certification processes typically require extensive documentation of material properties, including corrosion rates in various electrolytes, hydrogen permeation characteristics, and mechanical stability after prolonged exposure to operational conditions. Third-party testing laboratories conduct accelerated aging tests according to standards like IEC 62282-2, which can be adapted to evaluate EHC materials' long-term performance.

Hazardous area classifications, as defined by IEC 60079 series, are particularly relevant for EHC installations due to the potential for hydrogen leakage. Materials used in these environments must not only resist corrosion but also meet specific requirements for preventing ignition sources, which adds another layer of complexity to material selection and certification.

Emerging standards specifically addressing electrochemical hydrogen technologies are being developed by organizations such as ISO TC 197 (Hydrogen Technologies) and IEC TC 105 (Fuel Cell Technologies). These standards aim to establish comprehensive frameworks for safety assessment, including material compatibility testing protocols and performance criteria tailored to the unique operating conditions of EHCs.

For commercial deployment, manufacturers must navigate a complex landscape of regional certifications, including CE marking in Europe, UL certification in North America, and equivalent standards in Asian markets. Each certification process evaluates materials' resistance to degradation mechanisms specific to electrochemical hydrogen compression, ensuring that durability and safety requirements are met across global markets.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!