Electrochemical Compressor Retrofit Options For Existing Hydrogen Stations

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Compression Technology Background and Objectives

Electrochemical compression technology represents a paradigm shift in hydrogen compression methodologies, evolving from traditional mechanical compression systems that have dominated the industry for decades. This technology leverages electrochemical principles to compress hydrogen without moving parts, offering a potentially more efficient and reliable alternative for hydrogen infrastructure. The evolution of electrochemical compression can be traced back to early research in proton exchange membrane (PEM) technology in the 1960s, with significant advancements occurring in the early 2000s as interest in hydrogen energy systems intensified.

The fundamental principle behind electrochemical compression involves the transport of hydrogen across a membrane using an applied electrical potential, effectively "pumping" hydrogen from a low-pressure environment to a high-pressure one. This process eliminates the mechanical friction and wear associated with conventional compressors, potentially reducing maintenance requirements and increasing operational lifetimes.

Recent technological developments have focused on improving membrane materials, electrode catalysts, and system integration to enhance compression efficiency and pressure ratios. Notable milestones include the development of high-performance composite membranes with improved conductivity and mechanical stability, as well as advanced catalyst materials that reduce electrical resistance and improve hydrogen transport kinetics.

The primary objective of electrochemical compressor retrofit technology is to provide a viable pathway for upgrading existing hydrogen refueling stations without requiring complete infrastructure replacement. This approach aims to address several critical challenges in the hydrogen infrastructure sector, including reducing operational costs, improving energy efficiency, minimizing maintenance requirements, and extending equipment lifespan.

Additional technical goals include achieving compression ratios comparable to or exceeding those of mechanical systems (typically 700-900 bar for vehicle refueling applications), while maintaining or improving overall system efficiency. Current electrochemical compression systems demonstrate electrical efficiencies ranging from 60-80%, with research targeting improvements beyond 85% to make the technology economically competitive with traditional compression methods.

The technology trajectory suggests continued improvements in membrane durability, with current systems typically requiring replacement after 5,000-10,000 hours of operation. Research aims to extend this to 20,000+ hours to match the maintenance intervals of conventional systems. Parallel development efforts focus on modular designs that facilitate integration with existing station architecture, allowing for phased implementation and reducing capital expenditure barriers for station operators considering retrofits.

The fundamental principle behind electrochemical compression involves the transport of hydrogen across a membrane using an applied electrical potential, effectively "pumping" hydrogen from a low-pressure environment to a high-pressure one. This process eliminates the mechanical friction and wear associated with conventional compressors, potentially reducing maintenance requirements and increasing operational lifetimes.

Recent technological developments have focused on improving membrane materials, electrode catalysts, and system integration to enhance compression efficiency and pressure ratios. Notable milestones include the development of high-performance composite membranes with improved conductivity and mechanical stability, as well as advanced catalyst materials that reduce electrical resistance and improve hydrogen transport kinetics.

The primary objective of electrochemical compressor retrofit technology is to provide a viable pathway for upgrading existing hydrogen refueling stations without requiring complete infrastructure replacement. This approach aims to address several critical challenges in the hydrogen infrastructure sector, including reducing operational costs, improving energy efficiency, minimizing maintenance requirements, and extending equipment lifespan.

Additional technical goals include achieving compression ratios comparable to or exceeding those of mechanical systems (typically 700-900 bar for vehicle refueling applications), while maintaining or improving overall system efficiency. Current electrochemical compression systems demonstrate electrical efficiencies ranging from 60-80%, with research targeting improvements beyond 85% to make the technology economically competitive with traditional compression methods.

The technology trajectory suggests continued improvements in membrane durability, with current systems typically requiring replacement after 5,000-10,000 hours of operation. Research aims to extend this to 20,000+ hours to match the maintenance intervals of conventional systems. Parallel development efforts focus on modular designs that facilitate integration with existing station architecture, allowing for phased implementation and reducing capital expenditure barriers for station operators considering retrofits.

Hydrogen Station Market Demand Analysis

The global hydrogen station market is experiencing significant growth, driven by increasing adoption of hydrogen fuel cell vehicles (FCEVs) and governmental commitments to decarbonization. Current market analysis indicates that hydrogen refueling infrastructure is expanding at a compound annual growth rate of approximately 30% globally, with particularly strong development in Asia-Pacific, Europe, and North America.

Japan leads with over 160 operational hydrogen stations, followed by Germany with more than 90 stations and the United States with approximately 70 stations, primarily concentrated in California. China has ambitious plans to expand from its current base of about 120 stations to over 1,000 by 2030, representing the most aggressive growth trajectory globally.

Market demand for hydrogen stations is primarily segmented into light-duty vehicles, heavy-duty vehicles, and industrial applications. The heavy-duty segment, including buses and trucks, is showing the strongest growth potential due to the operational advantages of hydrogen over battery electric alternatives for long-haul transportation. This segment is projected to grow at 35-40% annually through 2030.

Existing hydrogen stations face significant operational challenges, including high compression costs which can represent 30-40% of station operating expenses. Traditional mechanical compressors are energy-intensive and maintenance-heavy, creating a substantial retrofit opportunity for electrochemical compression technology, which offers 15-25% greater energy efficiency and reduced maintenance requirements.

Consumer demand patterns indicate that hydrogen station utilization rates are critical for economic viability. Current stations often operate below optimal capacity, with utilization rates averaging 30-50% in most markets. Stations equipped with more efficient compression technology could reduce hydrogen dispensing costs by 10-15%, potentially accelerating adoption rates.

Regional market analysis reveals varying demand drivers. In Europe, policy frameworks like the European Green Deal and IPCEI Hydrogen are creating strong market pull. In Asia, particularly Japan and South Korea, automotive manufacturer commitments are driving infrastructure development. In North America, California's zero-emission vehicle mandates and the recent Inflation Reduction Act have significantly strengthened the business case for hydrogen infrastructure investment.

The retrofit market specifically represents a growing opportunity, with over 700 existing stations globally that could benefit from electrochemical compressor upgrades. Industry forecasts suggest that 40-50% of these stations will require significant equipment upgrades within the next five years, creating a defined market for retrofit solutions that can improve efficiency without requiring complete station redesigns.

Japan leads with over 160 operational hydrogen stations, followed by Germany with more than 90 stations and the United States with approximately 70 stations, primarily concentrated in California. China has ambitious plans to expand from its current base of about 120 stations to over 1,000 by 2030, representing the most aggressive growth trajectory globally.

Market demand for hydrogen stations is primarily segmented into light-duty vehicles, heavy-duty vehicles, and industrial applications. The heavy-duty segment, including buses and trucks, is showing the strongest growth potential due to the operational advantages of hydrogen over battery electric alternatives for long-haul transportation. This segment is projected to grow at 35-40% annually through 2030.

Existing hydrogen stations face significant operational challenges, including high compression costs which can represent 30-40% of station operating expenses. Traditional mechanical compressors are energy-intensive and maintenance-heavy, creating a substantial retrofit opportunity for electrochemical compression technology, which offers 15-25% greater energy efficiency and reduced maintenance requirements.

Consumer demand patterns indicate that hydrogen station utilization rates are critical for economic viability. Current stations often operate below optimal capacity, with utilization rates averaging 30-50% in most markets. Stations equipped with more efficient compression technology could reduce hydrogen dispensing costs by 10-15%, potentially accelerating adoption rates.

Regional market analysis reveals varying demand drivers. In Europe, policy frameworks like the European Green Deal and IPCEI Hydrogen are creating strong market pull. In Asia, particularly Japan and South Korea, automotive manufacturer commitments are driving infrastructure development. In North America, California's zero-emission vehicle mandates and the recent Inflation Reduction Act have significantly strengthened the business case for hydrogen infrastructure investment.

The retrofit market specifically represents a growing opportunity, with over 700 existing stations globally that could benefit from electrochemical compressor upgrades. Industry forecasts suggest that 40-50% of these stations will require significant equipment upgrades within the next five years, creating a defined market for retrofit solutions that can improve efficiency without requiring complete station redesigns.

Current State and Challenges of Electrochemical Compressors

Electrochemical compressors (ECCs) represent a promising alternative to mechanical compression technologies for hydrogen stations. Currently, ECCs operate on the principle of electrochemical hydrogen pumping through a proton exchange membrane, similar to fuel cell technology but in reverse operation. The technology has advanced significantly in recent years, with several commercial prototypes demonstrating compression ratios of up to 100:1 and delivery pressures reaching 700 bar, suitable for hydrogen refueling applications.

The current state of ECC technology shows notable advantages over conventional mechanical compressors, including no moving parts (except for peripheral components), lower noise levels, and potentially higher reliability. Laboratory-scale systems have demonstrated energy efficiencies between 60-70% under optimal conditions, which is competitive with mechanical alternatives. Several companies including HyET Hydrogen, Skyre, and Sustainable Innovations have developed commercial-scale units with capacities ranging from 5-50 kg/day.

Despite these advancements, ECCs face significant challenges that limit their widespread adoption in existing hydrogen stations. The primary technical limitation is the relatively low throughput compared to mechanical compressors, with most commercial units struggling to achieve the flow rates required for high-capacity refueling stations (>200 kg/day). This throughput limitation stems from current density constraints and membrane degradation issues at higher operating rates.

Durability remains another critical challenge, with membrane electrode assemblies (MEAs) showing performance degradation after 5,000-10,000 hours of operation, particularly under variable load conditions typical in refueling applications. This falls short of the 20,000+ hours expected for commercial hydrogen station equipment. The degradation mechanisms include membrane thinning, catalyst poisoning, and electrode delamination under high-pressure differentials.

Cost factors present additional barriers, with current ECC systems costing approximately $3,000-5,000 per kg/day of capacity, significantly higher than established mechanical compression technologies. This cost premium is largely attributed to expensive materials (platinum catalysts and specialized membranes) and limited production scale.

Integration challenges with existing hydrogen station infrastructure represent another significant hurdle. Most stations are designed around mechanical compression systems with different control parameters, footprints, and operational characteristics. Retrofitting requires substantial modifications to piping, control systems, and safety protocols, often necessitating station downtime and recertification.

Regulatory and standardization issues further complicate implementation, as many codes and standards for hydrogen stations were developed with mechanical compression technologies in mind. ECCs must demonstrate compliance with these standards or pursue alternative certification pathways, adding time and cost to deployment efforts.

The current state of ECC technology shows notable advantages over conventional mechanical compressors, including no moving parts (except for peripheral components), lower noise levels, and potentially higher reliability. Laboratory-scale systems have demonstrated energy efficiencies between 60-70% under optimal conditions, which is competitive with mechanical alternatives. Several companies including HyET Hydrogen, Skyre, and Sustainable Innovations have developed commercial-scale units with capacities ranging from 5-50 kg/day.

Despite these advancements, ECCs face significant challenges that limit their widespread adoption in existing hydrogen stations. The primary technical limitation is the relatively low throughput compared to mechanical compressors, with most commercial units struggling to achieve the flow rates required for high-capacity refueling stations (>200 kg/day). This throughput limitation stems from current density constraints and membrane degradation issues at higher operating rates.

Durability remains another critical challenge, with membrane electrode assemblies (MEAs) showing performance degradation after 5,000-10,000 hours of operation, particularly under variable load conditions typical in refueling applications. This falls short of the 20,000+ hours expected for commercial hydrogen station equipment. The degradation mechanisms include membrane thinning, catalyst poisoning, and electrode delamination under high-pressure differentials.

Cost factors present additional barriers, with current ECC systems costing approximately $3,000-5,000 per kg/day of capacity, significantly higher than established mechanical compression technologies. This cost premium is largely attributed to expensive materials (platinum catalysts and specialized membranes) and limited production scale.

Integration challenges with existing hydrogen station infrastructure represent another significant hurdle. Most stations are designed around mechanical compression systems with different control parameters, footprints, and operational characteristics. Retrofitting requires substantial modifications to piping, control systems, and safety protocols, often necessitating station downtime and recertification.

Regulatory and standardization issues further complicate implementation, as many codes and standards for hydrogen stations were developed with mechanical compression technologies in mind. ECCs must demonstrate compliance with these standards or pursue alternative certification pathways, adding time and cost to deployment efforts.

Retrofit Solutions for Existing Hydrogen Stations

01 Basic structure and operation principles of electrochemical compressors

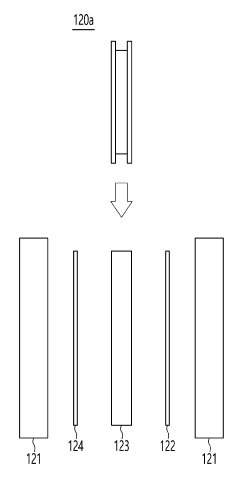

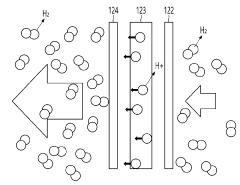

Electrochemical compressors utilize electrochemical cells to compress gases by converting electrical energy into pressure energy. These systems typically consist of electrodes, electrolytes, and membranes that facilitate the movement of ions and gases. The electrochemical process allows for compression without mechanical moving parts, resulting in potentially higher efficiency and reliability compared to traditional mechanical compressors.- Basic principles and designs of electrochemical compressors: Electrochemical compressors operate on the principle of electrochemical reactions to compress gases. These devices use electrochemical cells to transport gas molecules across a membrane when an electric current is applied. The basic design typically includes electrodes, an electrolyte membrane, and gas chambers. This technology offers advantages such as no moving parts, quiet operation, and high efficiency compared to traditional mechanical compressors.

- Hydrogen-based electrochemical compression systems: Hydrogen-based electrochemical compressors utilize proton exchange membranes to transport hydrogen ions across an electrolyte. When an electric potential is applied, hydrogen molecules are oxidized at the anode to form protons, which migrate through the membrane and recombine at the cathode to form compressed hydrogen gas. These systems are particularly valuable for hydrogen storage, fuel cell applications, and clean energy solutions where high-purity compressed hydrogen is required.

- Advanced materials and components for electrochemical compressors: Recent developments in electrochemical compressors focus on advanced materials for membranes, electrodes, and catalysts to improve efficiency and durability. Novel membrane materials with enhanced ion conductivity, electrode structures with optimized porosity, and high-performance catalysts that reduce activation energy are being incorporated. These material innovations help overcome challenges such as membrane degradation, electrode poisoning, and efficiency losses during operation.

- Integration of electrochemical compressors in cooling and heating systems: Electrochemical compressors are being integrated into innovative cooling and heating systems as alternatives to traditional vapor compression technology. These systems utilize electrochemically active working fluids that can be compressed without mechanical components. The integration enables more energy-efficient heat pumps, refrigeration units, and climate control systems with reduced environmental impact, lower noise levels, and potentially smaller form factors.

- Control systems and optimization for electrochemical compressors: Advanced control systems are being developed to optimize the performance of electrochemical compressors under varying operating conditions. These control strategies include adaptive algorithms that adjust current density, temperature, and pressure parameters in real-time. Optimization techniques focus on maximizing efficiency, extending operational lifetime, and ensuring stable performance across different load profiles, while minimizing energy consumption and degradation of components.

02 Advanced materials and components for electrochemical compression

The development of specialized materials and components enhances the performance of electrochemical compressors. These include novel electrode materials, improved ion-exchange membranes, and optimized electrolyte compositions. Advanced materials can increase compression efficiency, reduce energy consumption, and extend the operational lifetime of electrochemical compression systems.Expand Specific Solutions03 Integration of electrochemical compressors in cooling and heating systems

Electrochemical compressors can be integrated into various cooling and heating applications, including refrigeration systems, heat pumps, and air conditioning units. These systems leverage the electrochemical compression of refrigerants to achieve temperature control with potentially higher efficiency and lower environmental impact compared to conventional vapor compression systems.Expand Specific Solutions04 Control systems and operational optimization for electrochemical compressors

Advanced control systems and optimization strategies are essential for maximizing the performance of electrochemical compressors. These include electronic control units, sensors for monitoring operational parameters, and algorithms for adjusting compression rates based on demand. Proper control systems can enhance efficiency, ensure stable operation, and extend the service life of electrochemical compression systems.Expand Specific Solutions05 Novel applications and system configurations for electrochemical compression

Emerging applications and innovative system configurations expand the utility of electrochemical compressors beyond traditional uses. These include hydrogen compression for fuel cells, carbon capture systems, and hybrid compression arrangements that combine electrochemical and mechanical compression methods. Novel configurations can address specific industrial needs, improve overall system performance, and enable new technological capabilities.Expand Specific Solutions

Key Industry Players in Electrochemical Compression

The electrochemical compressor retrofit market for hydrogen stations is currently in an early growth phase, with market size expanding as hydrogen infrastructure develops globally. Technical maturity varies significantly among key players, with companies like Electric Hydrogen Co. and Plug Power leading commercial applications, while research institutions such as Xi'an Jiaotong University and CNRS advance fundamental technologies. Major industrial conglomerates including Siemens, Bosch, and Haier are leveraging their manufacturing expertise to scale solutions. The competitive landscape features diverse approaches: established energy companies (EDF, CHN Energy) focus on integration with existing infrastructure, while specialized firms like Xergy and H2gremm develop proprietary compression technologies. This fragmented market indicates significant innovation potential but requires further standardization for widespread adoption.

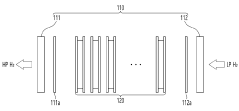

Robert Bosch GmbH

Technical Solution: Robert Bosch GmbH has developed an advanced electrochemical hydrogen compression system designed specifically as a retrofit solution for existing hydrogen refueling stations. Their technology utilizes a sophisticated proton exchange membrane (PEM) architecture that enables efficient hydrogen compression without mechanical components. The Bosch system employs a multi-cell stack configuration with proprietary membrane electrode assemblies that achieve compression ratios exceeding 800:1 while maintaining high efficiency across varying operational conditions. Their retrofit solution features a modular design that can be scaled to match the capacity requirements of different station sizes, with individual modules capable of processing 5-50 kg/hour of hydrogen. The system incorporates advanced thermal management using liquid cooling circuits that maintain optimal operating temperatures to maximize efficiency and membrane longevity. Bosch's retrofit package includes sophisticated power electronics that optimize electricity consumption based on demand patterns and input pressure conditions, achieving energy savings of up to 25% compared to conventional mechanical compressors. The control system integrates seamlessly with existing station management software through standardized communication protocols, enabling remote monitoring and predictive maintenance capabilities.

Strengths: Exceptional reliability with estimated maintenance intervals 3-4 times longer than mechanical alternatives; significantly reduced noise and vibration improves station neighborhood compatibility; compact footprint allows installation in space-constrained facilities; consistent performance across varying ambient conditions. Weaknesses: Higher initial investment compared to mechanical compressor replacements; requires specialized technical expertise for installation and commissioning; performance sensitivity to certain impurities necessitates careful integration with existing gas cleaning systems; technology has limited long-term operational data in commercial refueling applications.

Electric Hydrogen Co.

Technical Solution: Electric Hydrogen has developed a comprehensive electrochemical compression retrofit solution specifically designed for existing hydrogen refueling stations. Their technology utilizes advanced proton-conducting membranes combined with specialized catalysts to enable efficient hydrogen compression without mechanical components. The system operates through a multi-stage electrochemical process where hydrogen molecules are split into protons at the anode, transported across a selective membrane under an electric potential, and recombined at the cathode at significantly higher pressure. Electric Hydrogen's retrofit package includes a modular compression unit that can achieve compression ratios up to 900:1 while maintaining efficiency across varying flow rates. Their solution incorporates intelligent power electronics that optimize energy consumption based on demand patterns and hydrogen input conditions. The retrofit design features standardized interfaces that facilitate integration with existing station infrastructure, including storage systems, dispensers, and control architecture. Additionally, their system includes comprehensive monitoring capabilities that provide real-time performance data and predictive maintenance alerts to maximize uptime.

Strengths: Eliminates oil contamination issues present in mechanical compressors; significantly reduced maintenance requirements with no mechanical wear components; scalable design allows for capacity expansion as demand grows; operates with minimal noise and vibration. Weaknesses: Higher initial capital expenditure compared to conventional compressor replacements; requires specialized technical expertise for installation and commissioning; performance can be affected by certain contaminants in hydrogen stream; technology has limited long-term operational data in high-pressure applications.

Core Patents and Innovations in Electrochemical Compression

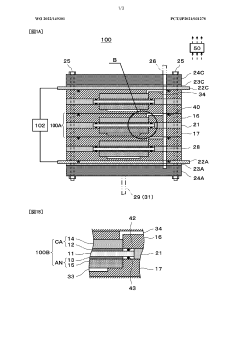

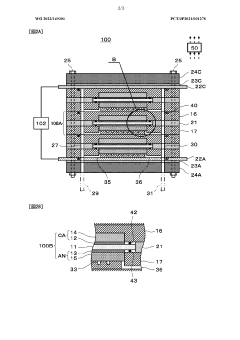

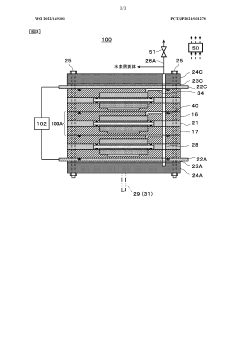

Electrochemical hydrogen compressor with repeatable compression

PatentInactiveKR1020240047517A

Innovation

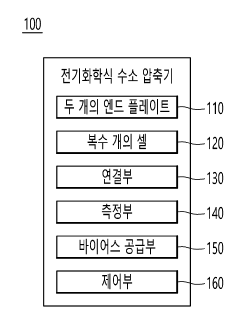

- The electrochemical hydrogen compressor employs a repetitive compression function that allows hydrogen to be compressed multiple times within a stack by circulating compressed hydrogen through a connection part, utilizing a measuring unit to determine pressure, and a control unit to manage bias application, thereby optimizing compression without increasing the number of cells.

Compressor and method for controlling compressor

PatentWO2022149301A1

Innovation

- An electrochemical compressor design with a controller that applies a voltage between an anode and a cathode, ensuring the voltage remains below the corrosion potential of the metal anode separator, and includes a gas flow path with a valve to manage hydrogen purity and flow, using a solid polymer membrane and resistant metal separators like SUS316 or SUS316L to prevent membrane deterioration and maintain high hydrogen purity.

Economic Feasibility and ROI Analysis

The economic feasibility of retrofitting existing hydrogen stations with electrochemical compressors (ECCs) represents a critical consideration for station operators and investors. Initial capital expenditure for ECC retrofit ranges from $250,000 to $500,000 per station, depending on capacity requirements and existing infrastructure compatibility. This investment includes equipment costs, installation, system integration, and potential downtime during conversion.

Operating expenditure comparisons reveal significant advantages for ECCs over mechanical compressors. Energy consumption analysis indicates potential electricity savings of 30-40% with ECCs, translating to approximately $40,000-60,000 annual reduction in operating costs for medium-sized stations. Maintenance costs are projected to decrease by 25-35% due to fewer moving parts and reduced mechanical wear, representing an additional $15,000-25,000 in annual savings.

Return on investment calculations demonstrate promising outcomes across different station profiles. Small stations (100-200 kg/day capacity) can expect ROI periods of 4-6 years, while larger stations (500+ kg/day) may achieve breakeven in 2.5-3.5 years. These calculations incorporate current electricity prices and hydrogen throughput volumes, with sensitivity analysis showing accelerated ROI potential as electricity costs increase or as hydrogen demand grows.

Government incentives significantly impact economic viability. Federal tax credits under clean energy initiatives can offset 10-30% of retrofit costs, while state-level programs in California, New York, and Washington offer additional grants covering up to 40% of conversion expenses. These incentives can reduce payback periods by 1-2 years on average.

Lifecycle cost analysis over a 10-year operational period demonstrates compelling long-term economics. Total cost of ownership for ECC-retrofitted stations is projected to be 15-25% lower than continuing with mechanical compression systems. This analysis factors in equipment replacement cycles, energy costs with projected increases, and maintenance requirements.

Risk assessment identifies several economic uncertainties, including fluctuating electricity prices, potential changes to incentive structures, and evolving hydrogen demand patterns. Mitigation strategies include phased implementation approaches, power purchase agreements to stabilize electricity costs, and diversified station operations to ensure consistent throughput volumes regardless of market fluctuations.

Operating expenditure comparisons reveal significant advantages for ECCs over mechanical compressors. Energy consumption analysis indicates potential electricity savings of 30-40% with ECCs, translating to approximately $40,000-60,000 annual reduction in operating costs for medium-sized stations. Maintenance costs are projected to decrease by 25-35% due to fewer moving parts and reduced mechanical wear, representing an additional $15,000-25,000 in annual savings.

Return on investment calculations demonstrate promising outcomes across different station profiles. Small stations (100-200 kg/day capacity) can expect ROI periods of 4-6 years, while larger stations (500+ kg/day) may achieve breakeven in 2.5-3.5 years. These calculations incorporate current electricity prices and hydrogen throughput volumes, with sensitivity analysis showing accelerated ROI potential as electricity costs increase or as hydrogen demand grows.

Government incentives significantly impact economic viability. Federal tax credits under clean energy initiatives can offset 10-30% of retrofit costs, while state-level programs in California, New York, and Washington offer additional grants covering up to 40% of conversion expenses. These incentives can reduce payback periods by 1-2 years on average.

Lifecycle cost analysis over a 10-year operational period demonstrates compelling long-term economics. Total cost of ownership for ECC-retrofitted stations is projected to be 15-25% lower than continuing with mechanical compression systems. This analysis factors in equipment replacement cycles, energy costs with projected increases, and maintenance requirements.

Risk assessment identifies several economic uncertainties, including fluctuating electricity prices, potential changes to incentive structures, and evolving hydrogen demand patterns. Mitigation strategies include phased implementation approaches, power purchase agreements to stabilize electricity costs, and diversified station operations to ensure consistent throughput volumes regardless of market fluctuations.

Safety and Regulatory Compliance Requirements

The implementation of electrochemical compressor retrofit solutions for existing hydrogen stations necessitates strict adherence to comprehensive safety and regulatory compliance requirements. These requirements are primarily governed by international standards such as ISO 19880 (Gaseous hydrogen fueling stations), NFPA 2 (Hydrogen Technologies Code), and regional regulations including EU Directive 2014/94/EU for alternative fuels infrastructure and U.S. DOE Hydrogen Safety Codes and Standards.

Safety considerations for electrochemical compressor retrofits must address multiple critical aspects. Hydrogen, being highly flammable with a wide flammability range (4-75% in air), requires specialized leak detection systems with appropriate sensitivity thresholds. Electrochemical compressors introduce unique safety challenges compared to mechanical compressors, particularly regarding electrical safety and potential chemical hazards from membrane electrolytes. Retrofit installations must incorporate robust ventilation systems designed specifically for hydrogen service, with explosion-proof electrical components rated for hazardous locations per IEC 60079 or equivalent standards.

Risk assessment methodologies such as HAZOP (Hazard and Operability Study) and LOPA (Layer of Protection Analysis) must be conducted prior to retrofit implementation. These assessments should specifically evaluate the integration points between existing station infrastructure and new electrochemical compression technology, identifying potential failure modes and establishing appropriate mitigation measures. Particular attention must be paid to pressure boundary integrity, electrical isolation, and emergency shutdown capabilities.

Regulatory compliance extends beyond safety to include environmental considerations. Electrochemical compressors typically utilize specialized membrane materials and electrolytes that may be subject to chemical regulations such as REACH in Europe or TSCA in the United States. Proper documentation of chemical inventories and management plans must be maintained. Additionally, noise regulations must be considered, though electrochemical compressors generally offer advantages in this area compared to mechanical alternatives.

Certification requirements vary by jurisdiction but typically include pressure equipment certification (PED in Europe, ASME BPVC in North America), electrical safety certification (IEC/UL standards), and hydrogen-specific certifications. Third-party verification by notified bodies is generally required before commissioning retrofitted systems. Ongoing compliance necessitates the implementation of regular inspection protocols, with documentation maintained according to jurisdictional requirements.

Personnel safety training represents another critical compliance element. Station operators must receive comprehensive training on the safe operation, maintenance, and emergency response procedures specific to electrochemical compression technology. This training should be documented and periodically refreshed to maintain operational competency and safety awareness.

Safety considerations for electrochemical compressor retrofits must address multiple critical aspects. Hydrogen, being highly flammable with a wide flammability range (4-75% in air), requires specialized leak detection systems with appropriate sensitivity thresholds. Electrochemical compressors introduce unique safety challenges compared to mechanical compressors, particularly regarding electrical safety and potential chemical hazards from membrane electrolytes. Retrofit installations must incorporate robust ventilation systems designed specifically for hydrogen service, with explosion-proof electrical components rated for hazardous locations per IEC 60079 or equivalent standards.

Risk assessment methodologies such as HAZOP (Hazard and Operability Study) and LOPA (Layer of Protection Analysis) must be conducted prior to retrofit implementation. These assessments should specifically evaluate the integration points between existing station infrastructure and new electrochemical compression technology, identifying potential failure modes and establishing appropriate mitigation measures. Particular attention must be paid to pressure boundary integrity, electrical isolation, and emergency shutdown capabilities.

Regulatory compliance extends beyond safety to include environmental considerations. Electrochemical compressors typically utilize specialized membrane materials and electrolytes that may be subject to chemical regulations such as REACH in Europe or TSCA in the United States. Proper documentation of chemical inventories and management plans must be maintained. Additionally, noise regulations must be considered, though electrochemical compressors generally offer advantages in this area compared to mechanical alternatives.

Certification requirements vary by jurisdiction but typically include pressure equipment certification (PED in Europe, ASME BPVC in North America), electrical safety certification (IEC/UL standards), and hydrogen-specific certifications. Third-party verification by notified bodies is generally required before commissioning retrofitted systems. Ongoing compliance necessitates the implementation of regular inspection protocols, with documentation maintained according to jurisdictional requirements.

Personnel safety training represents another critical compliance element. Station operators must receive comprehensive training on the safe operation, maintenance, and emergency response procedures specific to electrochemical compression technology. This training should be documented and periodically refreshed to maintain operational competency and safety awareness.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!