Thermal Management Techniques For High-Pressure Electrochemical Compressors

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Compressor Thermal Challenges and Objectives

Electrochemical compressors (ECCs) represent a significant advancement in compression technology, offering a solid-state alternative to traditional mechanical compressors. The evolution of this technology has been marked by progressive improvements in efficiency, durability, and operational capacity since its conceptual development in the mid-20th century. Recent advancements have particularly focused on high-pressure applications, where thermal management has emerged as a critical challenge.

The thermal dynamics within high-pressure ECCs are complex and multifaceted. During operation, these systems generate substantial heat through electrochemical reactions, Joule heating, and entropy changes. This heat generation intensifies with increasing pressure ratios, creating a significant thermal management challenge that directly impacts system efficiency, component longevity, and operational stability.

Current research indicates that temperature variations as small as 5-10°C can reduce ECC efficiency by 15-20%, highlighting the sensitivity of these systems to thermal conditions. Additionally, temperature gradients within the cell stack can lead to uneven current distribution, accelerated degradation of membrane electrode assemblies (MEAs), and potential thermal runaway scenarios in extreme cases.

The primary technical objective in this domain is to develop thermal management techniques that can effectively dissipate heat while maintaining optimal operating temperatures across the entire ECC system. This includes achieving uniform temperature distribution within cell stacks, preventing localized hotspots, and ensuring efficient heat removal from critical components such as MEAs and bipolar plates.

Secondary objectives include minimizing parasitic power consumption of cooling systems, reducing the overall thermal management footprint to enhance system compactness, and developing adaptive thermal control strategies that can respond to varying operational conditions and load profiles. These objectives must be achieved while maintaining or improving the pressure ratios and flow rates that make high-pressure ECCs attractive for industrial applications.

Long-term technical goals focus on enabling ECCs to operate reliably at pressure ratios exceeding 10:1 while maintaining thermal stability, developing materials with enhanced thermal conductivity and electrochemical performance, and creating integrated thermal-electrochemical models that can accurately predict system behavior under diverse operating conditions.

The achievement of these objectives would position high-pressure ECCs as viable alternatives in applications currently dominated by mechanical compressors, including refrigeration systems, fuel cell pressurization, and industrial gas compression. The potential for significant energy savings, reduced maintenance requirements, and elimination of refrigerants with high global warming potential makes this technology particularly relevant to global sustainability efforts.

The thermal dynamics within high-pressure ECCs are complex and multifaceted. During operation, these systems generate substantial heat through electrochemical reactions, Joule heating, and entropy changes. This heat generation intensifies with increasing pressure ratios, creating a significant thermal management challenge that directly impacts system efficiency, component longevity, and operational stability.

Current research indicates that temperature variations as small as 5-10°C can reduce ECC efficiency by 15-20%, highlighting the sensitivity of these systems to thermal conditions. Additionally, temperature gradients within the cell stack can lead to uneven current distribution, accelerated degradation of membrane electrode assemblies (MEAs), and potential thermal runaway scenarios in extreme cases.

The primary technical objective in this domain is to develop thermal management techniques that can effectively dissipate heat while maintaining optimal operating temperatures across the entire ECC system. This includes achieving uniform temperature distribution within cell stacks, preventing localized hotspots, and ensuring efficient heat removal from critical components such as MEAs and bipolar plates.

Secondary objectives include minimizing parasitic power consumption of cooling systems, reducing the overall thermal management footprint to enhance system compactness, and developing adaptive thermal control strategies that can respond to varying operational conditions and load profiles. These objectives must be achieved while maintaining or improving the pressure ratios and flow rates that make high-pressure ECCs attractive for industrial applications.

Long-term technical goals focus on enabling ECCs to operate reliably at pressure ratios exceeding 10:1 while maintaining thermal stability, developing materials with enhanced thermal conductivity and electrochemical performance, and creating integrated thermal-electrochemical models that can accurately predict system behavior under diverse operating conditions.

The achievement of these objectives would position high-pressure ECCs as viable alternatives in applications currently dominated by mechanical compressors, including refrigeration systems, fuel cell pressurization, and industrial gas compression. The potential for significant energy savings, reduced maintenance requirements, and elimination of refrigerants with high global warming potential makes this technology particularly relevant to global sustainability efforts.

Market Analysis for High-Pressure Electrochemical Compression Systems

The global market for high-pressure electrochemical compression systems is experiencing significant growth, driven by increasing demand for clean energy solutions and hydrogen technologies. Current market valuations indicate that the hydrogen compression market reached approximately $1.5 billion in 2022, with electrochemical compression technologies representing a growing segment within this space. Industry forecasts project a compound annual growth rate of 6-8% through 2030, with particularly strong growth in regions prioritizing hydrogen infrastructure development.

The market demand for advanced thermal management in electrochemical compressors stems from several key factors. First, industrial applications requiring high-pressure hydrogen (300+ bar) are expanding rapidly, particularly in fuel cell vehicles, hydrogen refueling stations, and industrial processes. These applications demand compression systems with improved efficiency and reliability, which directly correlates with effective thermal management capabilities.

Energy efficiency requirements represent another significant market driver. Traditional mechanical compression methods typically achieve only 65-70% efficiency, whereas electrochemical compression systems with optimized thermal management can potentially reach 80-85% efficiency. This efficiency differential translates to substantial operational cost savings over system lifetimes, creating strong market pull for thermally optimized solutions.

Regional market analysis reveals varying adoption patterns. Europe leads in market development, with countries like Germany, the Netherlands, and Denmark making substantial investments in hydrogen infrastructure that incorporates electrochemical compression. The Asia-Pacific region, particularly Japan, South Korea, and increasingly China, shows the fastest growth trajectory, supported by government hydrogen strategies and industrial policy initiatives.

Customer segmentation indicates three primary market categories: transportation infrastructure (hydrogen refueling stations), industrial gas suppliers, and energy storage system integrators. The transportation segment currently represents the largest market share at approximately 45%, followed by industrial applications at 35% and energy storage at 20%.

Pricing analysis reveals that while electrochemical compression systems with advanced thermal management command a 15-25% premium over conventional systems, the total cost of ownership calculations increasingly favor these solutions due to lower maintenance requirements, extended operational lifetimes, and energy savings. Market acceptance is accelerating as payback periods decrease from 5-7 years historically to 3-4 years with current technology.

Market barriers include high initial capital costs, limited awareness of electrochemical compression benefits among potential end-users, and competition from established mechanical compression technologies with entrenched market positions. However, these barriers are gradually diminishing as technology matures and demonstration projects validate performance claims.

The market demand for advanced thermal management in electrochemical compressors stems from several key factors. First, industrial applications requiring high-pressure hydrogen (300+ bar) are expanding rapidly, particularly in fuel cell vehicles, hydrogen refueling stations, and industrial processes. These applications demand compression systems with improved efficiency and reliability, which directly correlates with effective thermal management capabilities.

Energy efficiency requirements represent another significant market driver. Traditional mechanical compression methods typically achieve only 65-70% efficiency, whereas electrochemical compression systems with optimized thermal management can potentially reach 80-85% efficiency. This efficiency differential translates to substantial operational cost savings over system lifetimes, creating strong market pull for thermally optimized solutions.

Regional market analysis reveals varying adoption patterns. Europe leads in market development, with countries like Germany, the Netherlands, and Denmark making substantial investments in hydrogen infrastructure that incorporates electrochemical compression. The Asia-Pacific region, particularly Japan, South Korea, and increasingly China, shows the fastest growth trajectory, supported by government hydrogen strategies and industrial policy initiatives.

Customer segmentation indicates three primary market categories: transportation infrastructure (hydrogen refueling stations), industrial gas suppliers, and energy storage system integrators. The transportation segment currently represents the largest market share at approximately 45%, followed by industrial applications at 35% and energy storage at 20%.

Pricing analysis reveals that while electrochemical compression systems with advanced thermal management command a 15-25% premium over conventional systems, the total cost of ownership calculations increasingly favor these solutions due to lower maintenance requirements, extended operational lifetimes, and energy savings. Market acceptance is accelerating as payback periods decrease from 5-7 years historically to 3-4 years with current technology.

Market barriers include high initial capital costs, limited awareness of electrochemical compression benefits among potential end-users, and competition from established mechanical compression technologies with entrenched market positions. However, these barriers are gradually diminishing as technology matures and demonstration projects validate performance claims.

Current Thermal Management Limitations and Barriers

Despite significant advancements in electrochemical compressor technology, thermal management remains a critical bottleneck limiting widespread adoption and performance optimization. Current high-pressure electrochemical compressors face several substantial thermal challenges that impede their efficiency and operational reliability.

The primary limitation stems from the inherent exothermic nature of electrochemical compression processes. As pressure increases, the heat generated during operation rises exponentially, creating thermal hotspots that can lead to membrane degradation and catalyst deactivation. Measurements indicate temperature gradients of up to 40°C across membrane electrode assemblies during high-pressure operation, significantly exceeding the optimal temperature window of 60-80°C for most proton exchange membranes.

Existing cooling systems demonstrate inadequate heat transfer capabilities when dealing with the concentrated heat generation in stack cores. Conventional liquid cooling plates typically achieve heat flux removal of only 0.5-1.0 W/cm², whereas high-pressure operation can generate localized heat fluxes exceeding 3.0 W/cm². This mismatch creates persistent thermal management challenges, particularly at pressure ratios above 10:1.

Material compatibility issues further complicate thermal management strategies. Many high-performance thermal interface materials and coolants exhibit chemical incompatibility with the corrosive environment of electrochemical cells, limiting cooling options. Additionally, the high electrical conductivity requirements of stack components often conflict with optimal thermal conductivity properties, forcing design compromises.

Spatial constraints represent another significant barrier. The compact design requirements for practical applications leave minimal room for implementing comprehensive cooling systems. Current cooling channel designs occupy 15-25% of the total stack volume, yet still fail to provide uniform temperature distribution across active areas exceeding 100 cm².

Power density limitations directly correlate with thermal management capabilities. Current systems typically operate at 0.3-0.5 W/cm² to avoid thermal runaway, significantly below the theoretical performance potential of 1.5-2.0 W/cm² that could be achieved with advanced thermal management.

Transient thermal response presents additional challenges during startup, shutdown, and load-following operations. Temperature fluctuations of 5-10°C per minute during dynamic operation can induce thermal stress, leading to mechanical failures at sealing interfaces and reduced system durability. Most existing thermal control systems exhibit response times of 30-60 seconds, insufficient for rapid load changes in practical applications.

These limitations collectively constrain the operational envelope of high-pressure electrochemical compressors, necessitating breakthrough innovations in thermal management to unlock their full potential for commercial applications.

The primary limitation stems from the inherent exothermic nature of electrochemical compression processes. As pressure increases, the heat generated during operation rises exponentially, creating thermal hotspots that can lead to membrane degradation and catalyst deactivation. Measurements indicate temperature gradients of up to 40°C across membrane electrode assemblies during high-pressure operation, significantly exceeding the optimal temperature window of 60-80°C for most proton exchange membranes.

Existing cooling systems demonstrate inadequate heat transfer capabilities when dealing with the concentrated heat generation in stack cores. Conventional liquid cooling plates typically achieve heat flux removal of only 0.5-1.0 W/cm², whereas high-pressure operation can generate localized heat fluxes exceeding 3.0 W/cm². This mismatch creates persistent thermal management challenges, particularly at pressure ratios above 10:1.

Material compatibility issues further complicate thermal management strategies. Many high-performance thermal interface materials and coolants exhibit chemical incompatibility with the corrosive environment of electrochemical cells, limiting cooling options. Additionally, the high electrical conductivity requirements of stack components often conflict with optimal thermal conductivity properties, forcing design compromises.

Spatial constraints represent another significant barrier. The compact design requirements for practical applications leave minimal room for implementing comprehensive cooling systems. Current cooling channel designs occupy 15-25% of the total stack volume, yet still fail to provide uniform temperature distribution across active areas exceeding 100 cm².

Power density limitations directly correlate with thermal management capabilities. Current systems typically operate at 0.3-0.5 W/cm² to avoid thermal runaway, significantly below the theoretical performance potential of 1.5-2.0 W/cm² that could be achieved with advanced thermal management.

Transient thermal response presents additional challenges during startup, shutdown, and load-following operations. Temperature fluctuations of 5-10°C per minute during dynamic operation can induce thermal stress, leading to mechanical failures at sealing interfaces and reduced system durability. Most existing thermal control systems exhibit response times of 30-60 seconds, insufficient for rapid load changes in practical applications.

These limitations collectively constrain the operational envelope of high-pressure electrochemical compressors, necessitating breakthrough innovations in thermal management to unlock their full potential for commercial applications.

Existing Thermal Management Solutions for Electrochemical Compressors

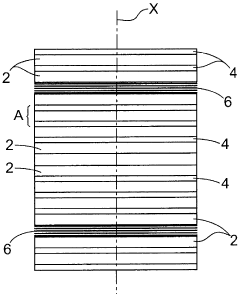

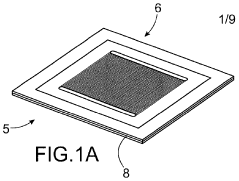

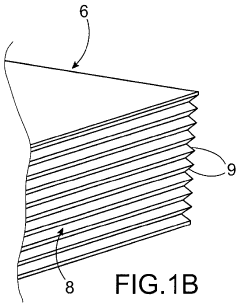

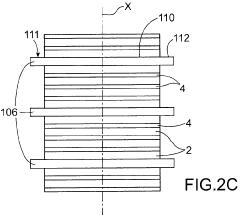

01 Electrochemical compressor design for thermal management

Electrochemical compressors can be designed specifically for thermal management applications. These designs focus on optimizing the electrochemical cell structure to efficiently transfer heat while maintaining compression capabilities. The compressors utilize electrochemical reactions to create pressure differentials that drive thermal management systems, offering advantages over traditional mechanical compressors including reduced noise, fewer moving parts, and better energy efficiency.- Electrochemical compressor design for thermal management: Electrochemical compressors can be designed specifically for thermal management applications. These designs focus on optimizing the electrochemical cell structure to efficiently transfer heat while maintaining compression capabilities. Key design elements include electrode configuration, membrane selection, and overall system integration to maximize thermal transfer efficiency while minimizing energy consumption. These specialized designs enable effective cooling or heating in various applications.

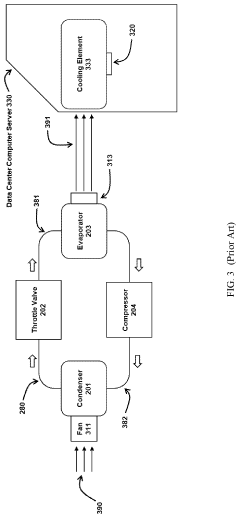

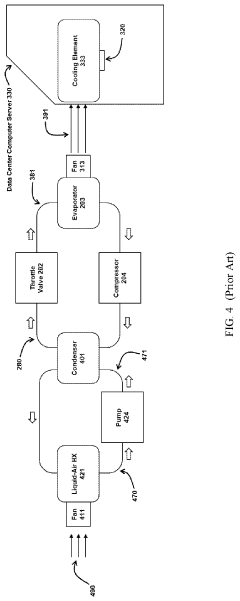

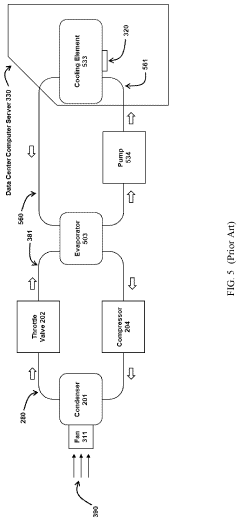

- Integration with cooling systems: Electrochemical compressors can be integrated with various cooling systems to enhance thermal management performance. These integrated systems combine the electrochemical compression process with heat exchangers, cooling loops, or refrigeration cycles to provide efficient temperature control. The integration allows for compact cooling solutions that can be applied in electronics, automotive systems, and industrial equipment where traditional mechanical compressors may be less effective or efficient.

- Battery thermal management applications: Electrochemical compressors are particularly valuable for battery thermal management systems. These applications utilize the compressors to maintain optimal operating temperatures for battery packs, especially in electric vehicles and energy storage systems. By precisely controlling temperature distribution and preventing hotspots, these systems can extend battery life, improve performance, and enhance safety by preventing thermal runaway conditions.

- Advanced control systems for thermal optimization: Advanced control systems can be implemented to optimize the thermal management capabilities of electrochemical compressors. These control systems utilize sensors, feedback loops, and predictive algorithms to adjust compressor operation based on real-time thermal demands. By dynamically modulating compression rates, flow patterns, and power input, these systems can achieve precise temperature control while maximizing energy efficiency across varying operating conditions.

- Novel materials and electrolytes for improved performance: The development of novel materials and electrolytes can significantly enhance the thermal management capabilities of electrochemical compressors. Advanced membrane materials, electrode compositions, and specialized electrolyte formulations can improve ion transport, reduce internal resistance, and enhance overall system efficiency. These material innovations enable higher compression ratios, better thermal conductivity, and improved durability under thermal cycling conditions.

02 Integration with cooling systems

Electrochemical compressors can be integrated with various cooling systems to enhance thermal management. These integrated systems combine the electrochemical compression technology with heat exchangers, cooling circuits, and thermal control mechanisms. The integration allows for more efficient heat transfer, better temperature regulation, and improved overall system performance in applications ranging from electronics cooling to HVAC systems.Expand Specific Solutions03 Battery thermal management applications

Electrochemical compressors are particularly useful for battery thermal management systems. These applications utilize the compressors to regulate temperature in battery packs, preventing overheating and maintaining optimal operating conditions. The systems can be designed to provide cooling during high-discharge operations or heating in cold conditions, extending battery life and improving performance in electric vehicles and energy storage systems.Expand Specific Solutions04 Advanced control systems for thermal regulation

Advanced control systems can be implemented to optimize the performance of electrochemical compressors in thermal management applications. These control systems utilize sensors, microprocessors, and algorithms to monitor operating conditions and adjust compressor parameters accordingly. By implementing sophisticated control strategies, the thermal management system can respond dynamically to changing heat loads, environmental conditions, and power availability, maximizing efficiency and reliability.Expand Specific Solutions05 Novel materials and configurations for enhanced efficiency

Novel materials and configurations can significantly improve the efficiency of electrochemical compressors for thermal management. These innovations include advanced electrode materials, specialized membranes, and optimized cell geometries that enhance ion transport and reaction kinetics. By incorporating these materials and design elements, electrochemical compressors can achieve higher compression ratios, better energy efficiency, and improved thermal transfer capabilities while maintaining compact form factors.Expand Specific Solutions

Leading Manufacturers and Research Institutions in the Field

The thermal management market for high-pressure electrochemical compressors is currently in its growth phase, with increasing adoption across automotive, HVAC, and energy storage sectors. The global market is projected to expand significantly as hydrogen technologies gain traction, with an estimated value of $2-3 billion by 2030. Leading players demonstrate varying levels of technical maturity: Air Products & Chemicals and Energy Internet Corp. have advanced electrochemical compression technologies, while automotive giants like Honda, Rolls-Royce, and Renault are integrating these systems into hydrogen fuel cell vehicles. HVAC specialists including Gree, Haier, Midea, and Carrier are developing residential applications, with Emerson Climate Technologies and Copeland focusing on commercial solutions. Chinese manufacturers are rapidly advancing, particularly in cost-effective production, while European and American companies maintain advantages in high-performance applications and system integration.

Hanon Systems

Technical Solution: Hanon Systems has developed an integrated thermal management solution specifically designed for high-pressure electrochemical compressors used in hydrogen applications. Their technology employs a multi-layered approach to thermal control, combining active liquid cooling with passive heat spreading structures. The system features a proprietary coolant formulation with enhanced thermal properties that enables efficient heat removal even at high operating pressures. Hanon's design incorporates specially engineered cooling channels that follow the contours of the electrochemical cells, ensuring uniform temperature distribution across the entire active area. A key innovation is their pulsed cooling technology that dynamically adjusts coolant flow based on real-time thermal mapping, preventing both overheating and overcooling scenarios. The system also includes advanced thermal isolation between compression stages to prevent heat transfer between components operating at different temperature requirements. Hanon Systems has demonstrated this technology in hydrogen compression applications achieving pressures up to 900 bar while maintaining cell temperatures within the optimal 65-75°C range. Their solution also incorporates smart diagnostics that can detect early signs of thermal anomalies before they develop into system failures.

Strengths: Highly optimized for hydrogen compression applications; excellent thermal uniformity across large active areas; intelligent cooling control reduces energy consumption. Weaknesses: Specialized coolant formulations may require periodic replacement; complex channel designs increase manufacturing complexity; system optimization required for different operating pressure ranges.

Air Products & Chemicals, Inc.

Technical Solution: Air Products has developed advanced thermal management systems for high-pressure electrochemical compressors that utilize multi-stage heat exchangers with phase-change materials. Their technology implements a cascaded cooling approach where heat is systematically removed at different pressure stages of the compression process. The system incorporates microchannels with enhanced heat transfer surfaces that maximize thermal conductivity while minimizing pressure drop. A key innovation is their proprietary bipolar plate design with integrated cooling channels that allow for direct cooling of the membrane electrode assembly (MEA) during operation. This approach maintains optimal operating temperatures (typically 60-80°C) even under high-pressure conditions exceeding 700 bar, preventing membrane degradation and extending system lifetime. Their thermal management system also includes adaptive control algorithms that adjust cooling parameters based on real-time temperature monitoring across multiple points in the compressor.

Strengths: Superior heat dissipation efficiency through integrated cooling channels; proven capability to maintain stable temperatures at very high pressures; reduced system complexity through direct cooling approach. Weaknesses: Higher manufacturing costs due to complex bipolar plate designs; requires specialized materials compatible with both electrochemical processes and cooling media; system optimization needed for different operating conditions.

Critical Patents and Innovations in Heat Dissipation Technologies

High-temperature or fuel-cell electrochemical system having improved thermal management

PatentActiveCA2853314C

Innovation

- Incorporating radiative plates with increased surface areas for heat transfer by radiation into the stack, which are thicker than traditional interconnectors and structured with features like ribs or fins, to enhance thermal management by increasing radiative heat exchange, especially at operating temperatures, and optionally incorporating phase-change materials or convection channels for additional thermal control.

High temperature electronic device thermal management system

PatentActiveUS11963341B2

Innovation

- A low energy usage data center cooling system that utilizes a management system and flow controlling elements to maintain coolant temperatures above ambient, allowing for elevated coolant temperatures, thereby eliminating the need for refrigeration cycles and enabling efficient waste heat recovery by operating at or above 55°C.

Energy Efficiency and Sustainability Considerations

Energy efficiency represents a critical dimension in the evaluation and advancement of high-pressure electrochemical compressor (ECC) technologies. Current ECC systems demonstrate theoretical energy efficiency advantages over conventional mechanical compressors, particularly in hydrogen applications, with potential efficiency ratings of 50-60% compared to 30-40% for mechanical alternatives. However, thermal management challenges significantly impact these efficiency metrics in practical implementations.

The relationship between thermal management and energy efficiency in ECCs is bidirectional. Effective thermal control minimizes energy losses through heat dissipation, while simultaneously reducing the electrical resistance within the cell stack. Temperature optimization maintains membrane hydration at ideal levels, preventing both dehydration and flooding scenarios that would otherwise increase energy consumption.

From a sustainability perspective, ECCs offer compelling advantages when integrated with renewable energy systems. Unlike mechanical compressors, ECCs can operate efficiently at variable loads, making them particularly suitable for integration with intermittent renewable energy sources such as solar and wind power. This capability enables green hydrogen production and compression within a single system, potentially reducing overall carbon footprint by 30-45% compared to conventional hydrogen compression methods.

Life cycle assessment (LCA) studies indicate that the environmental impact of ECCs is heavily influenced by thermal management strategies. Systems employing passive cooling techniques demonstrate 15-20% lower lifetime carbon emissions compared to those requiring active cooling infrastructure. Additionally, the elimination of lubricants in ECC systems prevents potential environmental contamination associated with conventional compression technologies.

Material sustainability considerations are equally important in thermal management design. Current research focuses on replacing rare earth elements and platinum group metals with more abundant alternatives. Thermal management systems utilizing recyclable heat exchange materials and bio-based thermal interface materials show promise in reducing environmental impact while maintaining performance parameters.

Energy recovery systems represent another frontier in ECC sustainability. Waste heat captured from the compression process can be redirected to support auxiliary systems or pre-heat incoming gas streams, potentially improving overall system efficiency by 10-15%. Advanced thermal energy storage integration further enhances this capability, allowing for temporal decoupling of compression operations from energy availability.

The regulatory landscape increasingly favors technologies with superior energy efficiency profiles. ECCs with optimized thermal management systems are positioned to benefit from carbon pricing mechanisms, energy efficiency incentives, and sustainability-focused procurement policies across major markets.

The relationship between thermal management and energy efficiency in ECCs is bidirectional. Effective thermal control minimizes energy losses through heat dissipation, while simultaneously reducing the electrical resistance within the cell stack. Temperature optimization maintains membrane hydration at ideal levels, preventing both dehydration and flooding scenarios that would otherwise increase energy consumption.

From a sustainability perspective, ECCs offer compelling advantages when integrated with renewable energy systems. Unlike mechanical compressors, ECCs can operate efficiently at variable loads, making them particularly suitable for integration with intermittent renewable energy sources such as solar and wind power. This capability enables green hydrogen production and compression within a single system, potentially reducing overall carbon footprint by 30-45% compared to conventional hydrogen compression methods.

Life cycle assessment (LCA) studies indicate that the environmental impact of ECCs is heavily influenced by thermal management strategies. Systems employing passive cooling techniques demonstrate 15-20% lower lifetime carbon emissions compared to those requiring active cooling infrastructure. Additionally, the elimination of lubricants in ECC systems prevents potential environmental contamination associated with conventional compression technologies.

Material sustainability considerations are equally important in thermal management design. Current research focuses on replacing rare earth elements and platinum group metals with more abundant alternatives. Thermal management systems utilizing recyclable heat exchange materials and bio-based thermal interface materials show promise in reducing environmental impact while maintaining performance parameters.

Energy recovery systems represent another frontier in ECC sustainability. Waste heat captured from the compression process can be redirected to support auxiliary systems or pre-heat incoming gas streams, potentially improving overall system efficiency by 10-15%. Advanced thermal energy storage integration further enhances this capability, allowing for temporal decoupling of compression operations from energy availability.

The regulatory landscape increasingly favors technologies with superior energy efficiency profiles. ECCs with optimized thermal management systems are positioned to benefit from carbon pricing mechanisms, energy efficiency incentives, and sustainability-focused procurement policies across major markets.

Safety Standards and Risk Mitigation Strategies

The implementation of high-pressure electrochemical compressors necessitates rigorous adherence to comprehensive safety standards and robust risk mitigation strategies. Current international standards, including ISO 16111 for hydrogen storage systems and IEC 62282 for fuel cell technologies, provide foundational guidelines for the safe operation of electrochemical systems under pressure. These standards establish critical parameters for material selection, pressure vessel design, and operational limits that manufacturers must comply with to ensure system integrity.

Risk assessment methodologies specific to electrochemical compressors have evolved to incorporate both qualitative and quantitative approaches. Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Study (HAZOP) are widely employed to systematically identify potential failure points related to thermal management. These assessments particularly focus on thermal runaway scenarios, which represent a significant risk in high-pressure environments where heat dissipation challenges are magnified.

Containment strategies form a critical component of safety protocols, with modern designs incorporating multiple redundant safety mechanisms. Pressure relief devices, thermal fuses, and automatic shutdown systems triggered by temperature thresholds provide layered protection against catastrophic failures. Advanced monitoring systems utilizing distributed temperature sensors enable real-time detection of hotspots before they escalate to dangerous levels.

Material compatibility considerations have gained prominence in safety standards, with particular attention to hydrogen embrittlement and material degradation under cyclic thermal stress. Qualification testing now routinely includes accelerated aging under thermal cycling conditions to validate long-term material stability and safety performance. This approach has significantly reduced incidents related to material failure in high-pressure electrochemical systems.

Emergency response protocols have been standardized across the industry, with clear procedures for managing thermal events. These protocols typically include staged response mechanisms based on the severity of thermal anomalies detected, ranging from load reduction to complete system isolation and controlled venting procedures. Training requirements for operational personnel have similarly evolved to emphasize recognition of early warning signs of thermal management failures.

Regulatory frameworks continue to adapt to technological advancements, with recent updates focusing on the unique challenges posed by electrochemical compression technologies. Notable developments include the introduction of specific thermal management certification requirements in several jurisdictions and harmonization efforts to standardize safety approaches across international markets, facilitating broader commercial deployment while maintaining rigorous safety standards.

Risk assessment methodologies specific to electrochemical compressors have evolved to incorporate both qualitative and quantitative approaches. Failure Mode and Effects Analysis (FMEA) and Hazard and Operability Study (HAZOP) are widely employed to systematically identify potential failure points related to thermal management. These assessments particularly focus on thermal runaway scenarios, which represent a significant risk in high-pressure environments where heat dissipation challenges are magnified.

Containment strategies form a critical component of safety protocols, with modern designs incorporating multiple redundant safety mechanisms. Pressure relief devices, thermal fuses, and automatic shutdown systems triggered by temperature thresholds provide layered protection against catastrophic failures. Advanced monitoring systems utilizing distributed temperature sensors enable real-time detection of hotspots before they escalate to dangerous levels.

Material compatibility considerations have gained prominence in safety standards, with particular attention to hydrogen embrittlement and material degradation under cyclic thermal stress. Qualification testing now routinely includes accelerated aging under thermal cycling conditions to validate long-term material stability and safety performance. This approach has significantly reduced incidents related to material failure in high-pressure electrochemical systems.

Emergency response protocols have been standardized across the industry, with clear procedures for managing thermal events. These protocols typically include staged response mechanisms based on the severity of thermal anomalies detected, ranging from load reduction to complete system isolation and controlled venting procedures. Training requirements for operational personnel have similarly evolved to emphasize recognition of early warning signs of thermal management failures.

Regulatory frameworks continue to adapt to technological advancements, with recent updates focusing on the unique challenges posed by electrochemical compression technologies. Notable developments include the introduction of specific thermal management certification requirements in several jurisdictions and harmonization efforts to standardize safety approaches across international markets, facilitating broader commercial deployment while maintaining rigorous safety standards.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!