Failure Modes And Reliability Testing For Electrochemical Hydrogen Compressors

SEP 12, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Hydrogen Compressor Technology Background and Objectives

Electrochemical hydrogen compressors (EHCs) represent a transformative technology in the hydrogen energy ecosystem, offering a promising alternative to conventional mechanical compression methods. The evolution of EHCs can be traced back to the early developments in proton exchange membrane (PEM) technology in the 1960s, initially focused on fuel cells rather than compression applications. By the 1990s, researchers began exploring the potential of electrochemical systems for hydrogen compression, recognizing their inherent advantages in efficiency and reliability.

The fundamental principle of EHCs leverages the electrochemical potential to drive hydrogen ions across a membrane, enabling compression without moving parts. This approach has evolved through several technological generations, from basic proof-of-concept designs to today's sophisticated multi-stage systems capable of achieving compression ratios exceeding 100:1 at industrial scales.

Current technological trends in EHC development focus on enhancing membrane durability, improving electrode catalysts, and optimizing system integration. The field has witnessed significant breakthroughs in recent years, particularly in membrane materials that can withstand higher differential pressures and contamination resistance, addressing key limitations of earlier designs.

The primary technical objectives for EHC advancement center on reliability enhancement and failure mode mitigation. Specifically, the industry aims to extend operational lifetimes beyond 30,000 hours, improve compression efficiency to exceed 70% (compared to 50-60% in current systems), and develop robust testing protocols that can accurately predict performance degradation under various operating conditions.

Understanding failure modes represents a critical research priority, as EHCs face unique challenges including membrane dehydration, catalyst poisoning, and mechanical stress at high-pressure differentials. These failure mechanisms differ substantially from those in fuel cells despite similar underlying technology, necessitating specialized research approaches.

The global transition toward hydrogen-based energy systems has accelerated interest in EHC technology, with particular emphasis on green hydrogen production and distribution infrastructure. Technical objectives now include developing EHCs capable of operating with variable input streams, accommodating fluctuations in hydrogen purity that typically accompany renewable energy-powered electrolysis.

Emerging research directions include novel composite membranes with self-healing properties, advanced diagnostic tools for real-time failure prediction, and hybrid compression systems that combine electrochemical and mechanical approaches to optimize performance across different operating regimes. These innovations aim to position EHCs as a cornerstone technology in the hydrogen economy, supporting applications from energy storage to transportation and industrial processes.

The fundamental principle of EHCs leverages the electrochemical potential to drive hydrogen ions across a membrane, enabling compression without moving parts. This approach has evolved through several technological generations, from basic proof-of-concept designs to today's sophisticated multi-stage systems capable of achieving compression ratios exceeding 100:1 at industrial scales.

Current technological trends in EHC development focus on enhancing membrane durability, improving electrode catalysts, and optimizing system integration. The field has witnessed significant breakthroughs in recent years, particularly in membrane materials that can withstand higher differential pressures and contamination resistance, addressing key limitations of earlier designs.

The primary technical objectives for EHC advancement center on reliability enhancement and failure mode mitigation. Specifically, the industry aims to extend operational lifetimes beyond 30,000 hours, improve compression efficiency to exceed 70% (compared to 50-60% in current systems), and develop robust testing protocols that can accurately predict performance degradation under various operating conditions.

Understanding failure modes represents a critical research priority, as EHCs face unique challenges including membrane dehydration, catalyst poisoning, and mechanical stress at high-pressure differentials. These failure mechanisms differ substantially from those in fuel cells despite similar underlying technology, necessitating specialized research approaches.

The global transition toward hydrogen-based energy systems has accelerated interest in EHC technology, with particular emphasis on green hydrogen production and distribution infrastructure. Technical objectives now include developing EHCs capable of operating with variable input streams, accommodating fluctuations in hydrogen purity that typically accompany renewable energy-powered electrolysis.

Emerging research directions include novel composite membranes with self-healing properties, advanced diagnostic tools for real-time failure prediction, and hybrid compression systems that combine electrochemical and mechanical approaches to optimize performance across different operating regimes. These innovations aim to position EHCs as a cornerstone technology in the hydrogen economy, supporting applications from energy storage to transportation and industrial processes.

Market Demand Analysis for Hydrogen Compression Technologies

The global hydrogen market is experiencing unprecedented growth, driven by the increasing focus on decarbonization and clean energy transitions. Hydrogen compression technologies, particularly Electrochemical Hydrogen Compressors (EHCs), are witnessing significant demand growth as they represent a critical component in the hydrogen value chain. Current market projections indicate that the global hydrogen compression market is expected to grow substantially through 2030, with EHCs gaining market share due to their efficiency advantages over mechanical compressors.

The demand for reliable hydrogen compression technologies stems from multiple sectors. The transportation sector, particularly fuel cell electric vehicles (FCEVs), requires high-pressure hydrogen for onboard storage. The refueling infrastructure for these vehicles necessitates compression systems that can deliver hydrogen at 700 bar or higher, creating a substantial market opportunity for EHC technologies that can achieve these pressures with fewer compression stages than conventional systems.

Industrial applications represent another significant market segment, with petroleum refining, ammonia production, and methanol synthesis collectively consuming large volumes of hydrogen. These industries increasingly seek more energy-efficient compression solutions with lower maintenance requirements, positioning EHCs as an attractive alternative to traditional mechanical compressors.

The emerging green hydrogen economy is perhaps the most promising market driver. As electrolysis capacity expands globally, the need for efficient compression technologies that can handle varying input pressures from electrolyzers while maintaining high efficiency is growing rapidly. EHCs offer particular advantages in this application due to their ability to handle wet hydrogen streams and operate with variable input conditions.

Energy storage applications present another growth vector, with hydrogen increasingly viewed as a solution for long-duration energy storage. Grid-scale projects require compression technologies that can operate efficiently at partial loads and respond quickly to fluctuating renewable energy inputs – operational characteristics where EHCs excel compared to mechanical alternatives.

Market analysis reveals that customers across these segments prioritize reliability and durability in hydrogen compression technologies. The total cost of ownership, rather than initial capital expenditure, is becoming the primary decision factor. This shift benefits EHC technologies, which typically offer lower maintenance requirements and longer operational lifetimes despite higher upfront costs.

Geographically, Europe and East Asia currently lead in hydrogen infrastructure investments, with North America showing accelerated growth. Regulatory frameworks supporting hydrogen adoption, particularly in the EU with its Hydrogen Strategy, are creating market pull for advanced compression technologies with proven reliability credentials.

The demand for reliable hydrogen compression technologies stems from multiple sectors. The transportation sector, particularly fuel cell electric vehicles (FCEVs), requires high-pressure hydrogen for onboard storage. The refueling infrastructure for these vehicles necessitates compression systems that can deliver hydrogen at 700 bar or higher, creating a substantial market opportunity for EHC technologies that can achieve these pressures with fewer compression stages than conventional systems.

Industrial applications represent another significant market segment, with petroleum refining, ammonia production, and methanol synthesis collectively consuming large volumes of hydrogen. These industries increasingly seek more energy-efficient compression solutions with lower maintenance requirements, positioning EHCs as an attractive alternative to traditional mechanical compressors.

The emerging green hydrogen economy is perhaps the most promising market driver. As electrolysis capacity expands globally, the need for efficient compression technologies that can handle varying input pressures from electrolyzers while maintaining high efficiency is growing rapidly. EHCs offer particular advantages in this application due to their ability to handle wet hydrogen streams and operate with variable input conditions.

Energy storage applications present another growth vector, with hydrogen increasingly viewed as a solution for long-duration energy storage. Grid-scale projects require compression technologies that can operate efficiently at partial loads and respond quickly to fluctuating renewable energy inputs – operational characteristics where EHCs excel compared to mechanical alternatives.

Market analysis reveals that customers across these segments prioritize reliability and durability in hydrogen compression technologies. The total cost of ownership, rather than initial capital expenditure, is becoming the primary decision factor. This shift benefits EHC technologies, which typically offer lower maintenance requirements and longer operational lifetimes despite higher upfront costs.

Geographically, Europe and East Asia currently lead in hydrogen infrastructure investments, with North America showing accelerated growth. Regulatory frameworks supporting hydrogen adoption, particularly in the EU with its Hydrogen Strategy, are creating market pull for advanced compression technologies with proven reliability credentials.

Current Status and Challenges in EHC Reliability

Electrochemical Hydrogen Compressors (EHCs) have emerged as promising alternatives to mechanical compressors for hydrogen applications, yet their widespread adoption faces significant reliability challenges. Current EHC technologies demonstrate limited operational lifetimes, typically ranging from 1,000 to 5,000 hours under continuous operation conditions, falling short of the 20,000+ hours required for commercial viability in industrial and transportation applications.

The primary failure modes observed in contemporary EHCs include membrane degradation, catalyst poisoning, and electrode delamination. Membrane degradation manifests through chemical decomposition, mechanical stress-induced tearing, and pinhole formation, particularly at high differential pressures. Studies indicate that Nafion-based membranes experience accelerated degradation rates when operating at compression ratios exceeding 100:1, with failure rates increasing exponentially beyond 350 bar output pressure.

Catalyst poisoning represents another critical challenge, with platinum-based catalysts showing susceptibility to contamination from carbon monoxide, hydrogen sulfide, and ammonia, even at parts-per-billion concentrations. Recent field tests reveal that catalyst activity can decrease by up to 40% after just 500 hours of operation in non-laboratory environments, significantly reducing compression efficiency and increasing energy consumption.

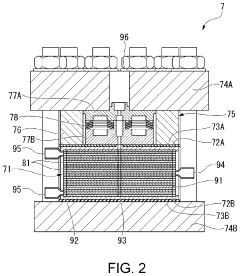

Electrode delamination occurs due to differential expansion between components during pressure and temperature cycling. Current manufacturing techniques achieve interfacial adhesion strengths of 0.5-2 MPa, whereas theoretical models suggest minimum requirements of 3-5 MPa for long-term stability. This mechanical failure mode accounts for approximately 35% of observed EHC failures according to industry reliability data.

The testing methodologies for EHC reliability remain non-standardized, creating challenges for comparative analysis and technology advancement. Accelerated stress tests vary widely across research institutions, with inconsistent protocols for temperature cycling (typically 20-80°C), pressure differential testing (1-700 bar), and humidity control. The lack of standardized testing hampers meaningful comparison between different EHC designs and materials.

Geographically, EHC reliability research is concentrated in North America, Europe, and Japan, with emerging contributions from China and South Korea. European research institutions lead in fundamental membrane durability studies, while North American entities focus on system-level integration and real-world testing. Japanese research emphasizes novel material development for enhanced durability, particularly in high-pressure applications.

The technical constraints limiting EHC reliability improvement include insufficient understanding of degradation mechanisms at the molecular level, limited availability of alternative membrane materials with both high proton conductivity and mechanical stability, and inadequate in-situ diagnostic capabilities for early failure detection. These challenges are compounded by the complex interplay between operating conditions, material properties, and system design parameters.

The primary failure modes observed in contemporary EHCs include membrane degradation, catalyst poisoning, and electrode delamination. Membrane degradation manifests through chemical decomposition, mechanical stress-induced tearing, and pinhole formation, particularly at high differential pressures. Studies indicate that Nafion-based membranes experience accelerated degradation rates when operating at compression ratios exceeding 100:1, with failure rates increasing exponentially beyond 350 bar output pressure.

Catalyst poisoning represents another critical challenge, with platinum-based catalysts showing susceptibility to contamination from carbon monoxide, hydrogen sulfide, and ammonia, even at parts-per-billion concentrations. Recent field tests reveal that catalyst activity can decrease by up to 40% after just 500 hours of operation in non-laboratory environments, significantly reducing compression efficiency and increasing energy consumption.

Electrode delamination occurs due to differential expansion between components during pressure and temperature cycling. Current manufacturing techniques achieve interfacial adhesion strengths of 0.5-2 MPa, whereas theoretical models suggest minimum requirements of 3-5 MPa for long-term stability. This mechanical failure mode accounts for approximately 35% of observed EHC failures according to industry reliability data.

The testing methodologies for EHC reliability remain non-standardized, creating challenges for comparative analysis and technology advancement. Accelerated stress tests vary widely across research institutions, with inconsistent protocols for temperature cycling (typically 20-80°C), pressure differential testing (1-700 bar), and humidity control. The lack of standardized testing hampers meaningful comparison between different EHC designs and materials.

Geographically, EHC reliability research is concentrated in North America, Europe, and Japan, with emerging contributions from China and South Korea. European research institutions lead in fundamental membrane durability studies, while North American entities focus on system-level integration and real-world testing. Japanese research emphasizes novel material development for enhanced durability, particularly in high-pressure applications.

The technical constraints limiting EHC reliability improvement include insufficient understanding of degradation mechanisms at the molecular level, limited availability of alternative membrane materials with both high proton conductivity and mechanical stability, and inadequate in-situ diagnostic capabilities for early failure detection. These challenges are compounded by the complex interplay between operating conditions, material properties, and system design parameters.

Current Failure Testing Methodologies for EHCs

01 Membrane degradation and failure mechanisms

Electrochemical hydrogen compressors often face issues with membrane degradation, which can lead to system failure. The membrane can deteriorate due to chemical reactions, mechanical stress, or thermal cycling. This degradation reduces the efficiency of hydrogen compression and can lead to gas crossover, compromising the purity of the compressed hydrogen. Understanding these failure mechanisms is crucial for improving the reliability and longevity of electrochemical hydrogen compression systems.- Membrane degradation and failure mechanisms: Electrochemical hydrogen compressors often fail due to membrane degradation. This can occur through mechanical stress, chemical degradation, or thermal cycling. The polymer electrolyte membranes may develop pinholes, cracks, or thinning over time, leading to gas crossover and reduced efficiency. Understanding these degradation mechanisms is crucial for improving the reliability and longevity of electrochemical hydrogen compression systems.

- Electrode catalyst degradation and poisoning: The performance and reliability of electrochemical hydrogen compressors are significantly affected by catalyst degradation. Catalysts can be poisoned by impurities in the hydrogen stream, such as carbon monoxide or sulfur compounds. Additionally, catalyst particles may agglomerate or detach from electrode surfaces during operation. These issues reduce the active surface area and catalytic activity, leading to decreased compression efficiency and eventual system failure.

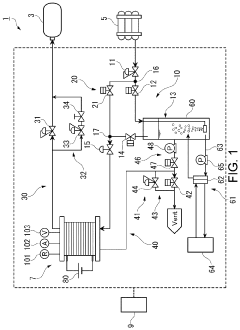

- Control system and monitoring solutions: Advanced control systems and monitoring solutions are essential for improving the reliability of electrochemical hydrogen compressors. These systems can detect early signs of failure through parameters such as cell voltage, current density, temperature distribution, and pressure differentials. Implementing predictive maintenance algorithms and fault detection systems helps prevent catastrophic failures and extends the operational lifetime of the compressor systems.

- Thermal management and pressure-related failures: Thermal management issues and pressure-related failures are common in electrochemical hydrogen compressors. Uneven temperature distribution can cause localized hot spots, membrane dehydration, and thermal stress. High differential pressures across the membrane can lead to mechanical failures and gas crossover. Effective thermal management systems and pressure regulation mechanisms are critical for maintaining reliable operation and preventing premature system failure.

- Water management and balance of plant issues: Water management is crucial for the reliable operation of electrochemical hydrogen compressors. Insufficient hydration leads to increased membrane resistance and reduced efficiency, while excessive water can cause flooding and mass transport limitations. Balance of plant components such as humidifiers, water separators, and purification systems also impact overall system reliability. Proper water management strategies and robust auxiliary systems design are essential for preventing failures related to membrane dehydration or flooding.

02 Electrode catalyst degradation and poisoning

The performance and reliability of electrochemical hydrogen compressors are significantly affected by electrode catalyst degradation and poisoning. Contaminants in the feed gas can adsorb onto catalyst surfaces, reducing active sites for hydrogen oxidation and evolution reactions. Over time, catalyst particles can agglomerate or detach from electrode surfaces, leading to decreased compression efficiency and eventual system failure. Developing poison-resistant catalysts and implementing effective purification systems can enhance compressor reliability.Expand Specific Solutions03 Control system and monitoring for reliability enhancement

Advanced control systems and monitoring technologies play a crucial role in enhancing the reliability of electrochemical hydrogen compressors. Real-time monitoring of key parameters such as cell voltage, current density, temperature, and pressure differentials allows for early detection of potential failure modes. Implementing predictive maintenance strategies based on these monitoring systems can prevent catastrophic failures and extend the operational lifetime of the compressor. Automated safety protocols can also be integrated to respond to abnormal operating conditions.Expand Specific Solutions04 Thermal management and pressure-related failures

Effective thermal management is essential for preventing failure in electrochemical hydrogen compressors. Uneven temperature distribution can cause localized hot spots, leading to membrane deformation or degradation. High differential pressures across the membrane can cause mechanical stress and eventual rupture. Implementing proper cooling systems and pressure regulation mechanisms is critical for maintaining optimal operating conditions and preventing premature failure of compressor components.Expand Specific Solutions05 Sealing and interface failures

Sealing and interface failures represent significant reliability challenges in electrochemical hydrogen compressors. Hydrogen, being a small molecule, can easily leak through imperfect seals or interfaces between different components. Over time, gaskets and sealing materials may degrade due to chemical exposure or mechanical stress, leading to gas leakage and decreased compression efficiency. Proper selection of sealing materials compatible with hydrogen environments and careful design of component interfaces can significantly improve system reliability and safety.Expand Specific Solutions

Key Industry Players in Electrochemical Hydrogen Compression

The electrochemical hydrogen compressor (EHC) technology market is currently in its early growth phase, characterized by increasing research focus on reliability testing and failure modes. The global market size is projected to expand significantly as hydrogen gains importance in clean energy transitions, though still relatively small compared to mechanical compression technologies. From a technical maturity perspective, the field is advancing with key players demonstrating varying levels of expertise. Hydrogenics Corp (now part of Cummins) and H2gremm lead with commercial EHC solutions, while Ergosup SA offers innovative approaches. Research institutions like Advanced Industrial Science & Technology and universities including Tongji, Chongqing, and Dalian University of Technology are advancing fundamental understanding of failure mechanisms. Industrial giants Robert Bosch GmbH and LG Energy Solution are leveraging their electrochemical expertise to address reliability challenges in this emerging field.

Robert Bosch GmbH

Technical Solution: Bosch has engineered a robust electrochemical hydrogen compression system with integrated failure detection mechanisms. Their approach focuses on a modular cell stack design that allows for individual cell monitoring and replacement. The system incorporates real-time impedance spectroscopy to detect membrane thinning and potential failure points before catastrophic failure occurs. Their reliability testing methodology includes both ex-situ accelerated stress tests and in-situ operational testing under variable load conditions. Bosch's testing protocol specifically addresses thermal management challenges, with proprietary cooling systems that maintain optimal temperature distribution across the cell stack even under high compression ratios. Their failure mode analysis has identified contaminant sensitivity profiles for different membrane formulations, allowing for application-specific optimization. Testing data shows their systems maintain 95% efficiency after 5,000 operational cycles, with degradation rates of less than 2% per 1,000 hours under standard operating conditions.

Strengths: Advanced diagnostic capabilities that predict and prevent failures before they occur; modular design allowing for maintenance without complete system replacement; excellent thermal management under high compression ratios. Weaknesses: Higher complexity in control systems increases potential electronic failure points; relatively limited field deployment data compared to conventional technologies; performance degradation in presence of certain fuel contaminants.

Hydrogenics Corp.

Technical Solution: Hydrogenics has developed advanced electrochemical hydrogen compression (EHC) technology that utilizes proton exchange membrane (PEM) cells to compress hydrogen without mechanical parts. Their system operates by applying voltage across the membrane, causing hydrogen ions to migrate from anode to cathode, effectively compressing hydrogen from low to high pressure. Their reliability testing protocol includes accelerated stress tests simulating over 10,000 operational hours, thermal cycling between -40°C and 85°C, and pressure differential tests up to 700 bar. They've identified key failure modes including membrane degradation, catalyst poisoning, and seal deterioration. Their proprietary membrane formulation shows 50% improved durability under high differential pressure conditions compared to standard membranes, with specialized coatings that reduce platinum catalyst degradation by approximately 30% during long-term operation.

Strengths: Industry-leading membrane technology with superior durability under high pressure differentials; comprehensive testing protocols that accurately predict field performance; advanced catalyst formulations resistant to contamination. Weaknesses: Higher initial system cost compared to mechanical compressors; limited maximum pressure capability (currently ~700 bar); requires ultra-pure input hydrogen to prevent accelerated degradation.

Critical Failure Modes Analysis and Mitigation Strategies

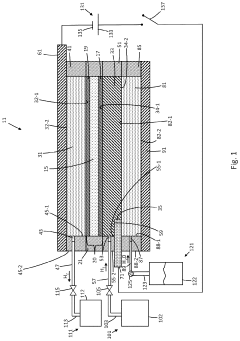

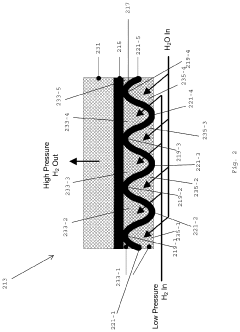

Method and system for electrochemically compressing gaseous hydrogen

PatentPendingUS20240123398A1

Innovation

- A polymer electrolyte membrane-based electrochemical hydrogen compressor system with a water management membrane that passively supplies water to the membrane electrode assembly, ensuring stable operation from ambient to high pressures without external humidification, using a selectively permeable membrane to maintain optimal hydration and prevent membrane dehydration.

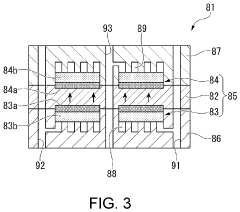

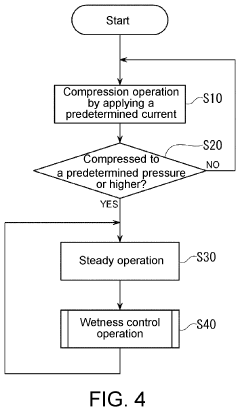

Electrochemical hydrogen compression system

PatentActiveUS11872526B2

Innovation

- An electrochemical hydrogen compression system that includes a control device to regulate the discharge of hydrogen based on the wet state of the electrolyte film, using a humidifier and distribution pipelines to maintain a uniform wet state across unit cells, ensuring optimal proton conductivity and energy efficiency.

Safety Standards and Certification Requirements for Hydrogen Systems

The safety landscape for hydrogen systems, particularly for Electrochemical Hydrogen Compressors (EHCs), is governed by a comprehensive framework of standards and certification requirements. These regulations are essential for ensuring the safe operation, installation, and maintenance of hydrogen compression technologies in various applications.

International standards such as ISO 16111 and ISO 19880 provide foundational guidelines for hydrogen storage systems and fueling stations, respectively. For EHCs specifically, compliance with IEC 62282 standards for fuel cell technologies is often required, as these compressors share similar electrochemical principles and safety considerations. The European Pressure Equipment Directive (PED) and ASME Boiler and Pressure Vessel Code also apply to hydrogen compression systems, establishing requirements for pressure-bearing components.

Certification processes for EHCs typically involve rigorous testing protocols to verify compliance with explosion protection standards such as ATEX in Europe or Class I, Division 1 hazardous location requirements in North America. These standards address the inherent risks associated with hydrogen's wide flammability range (4-75% concentration in air) and low ignition energy.

Material compatibility certifications are particularly critical for EHC systems due to hydrogen embrittlement concerns. Standards such as ASME B31.12 for hydrogen piping and pipelines provide specific requirements for material selection and testing to ensure long-term integrity under hydrogen service conditions. Additionally, electrical safety certifications like UL or CE marking are mandatory for the power supply and control systems of electrochemical compressors.

Risk assessment methodologies prescribed by standards such as ISO 31000 or IEC 61508 for functional safety must be applied during the design and validation phases of EHC development. These assessments help identify potential failure modes specific to electrochemical compression technology and establish appropriate mitigation measures.

For commercial deployment, EHCs must undergo third-party certification by recognized bodies such as TÜV, UL, or DNV GL. This certification process typically includes design review, prototype testing, and manufacturing facility audits to ensure consistent quality and safety compliance. Periodic recertification may be required, especially when design modifications are implemented or after significant operational incidents.

Emerging standards specifically addressing electrochemical hydrogen compression are being developed through organizations like ISO TC 197 (Hydrogen Technologies) and IEC TC 105 (Fuel Cell Technologies). These standards aim to address the unique safety considerations of membrane-based compression systems, including membrane degradation mechanisms, catalyst poisoning, and electrical fault protection specific to EHC operation.

International standards such as ISO 16111 and ISO 19880 provide foundational guidelines for hydrogen storage systems and fueling stations, respectively. For EHCs specifically, compliance with IEC 62282 standards for fuel cell technologies is often required, as these compressors share similar electrochemical principles and safety considerations. The European Pressure Equipment Directive (PED) and ASME Boiler and Pressure Vessel Code also apply to hydrogen compression systems, establishing requirements for pressure-bearing components.

Certification processes for EHCs typically involve rigorous testing protocols to verify compliance with explosion protection standards such as ATEX in Europe or Class I, Division 1 hazardous location requirements in North America. These standards address the inherent risks associated with hydrogen's wide flammability range (4-75% concentration in air) and low ignition energy.

Material compatibility certifications are particularly critical for EHC systems due to hydrogen embrittlement concerns. Standards such as ASME B31.12 for hydrogen piping and pipelines provide specific requirements for material selection and testing to ensure long-term integrity under hydrogen service conditions. Additionally, electrical safety certifications like UL or CE marking are mandatory for the power supply and control systems of electrochemical compressors.

Risk assessment methodologies prescribed by standards such as ISO 31000 or IEC 61508 for functional safety must be applied during the design and validation phases of EHC development. These assessments help identify potential failure modes specific to electrochemical compression technology and establish appropriate mitigation measures.

For commercial deployment, EHCs must undergo third-party certification by recognized bodies such as TÜV, UL, or DNV GL. This certification process typically includes design review, prototype testing, and manufacturing facility audits to ensure consistent quality and safety compliance. Periodic recertification may be required, especially when design modifications are implemented or after significant operational incidents.

Emerging standards specifically addressing electrochemical hydrogen compression are being developed through organizations like ISO TC 197 (Hydrogen Technologies) and IEC TC 105 (Fuel Cell Technologies). These standards aim to address the unique safety considerations of membrane-based compression systems, including membrane degradation mechanisms, catalyst poisoning, and electrical fault protection specific to EHC operation.

Economic Viability and Lifecycle Cost Analysis of EHC Technologies

The economic viability of Electrochemical Hydrogen Compressors (EHCs) represents a critical factor in their market adoption and commercial success. Current cost analyses indicate that EHCs require significant initial capital investment, with prices ranging from $1,000-3,000 per kW depending on scale and specifications. This positions them at a premium compared to conventional mechanical compressors, which typically cost $500-1,500 per kW for comparable hydrogen throughput capacities.

Lifecycle cost analysis reveals several economic advantages that may offset the higher acquisition costs. EHCs demonstrate operational expenditure reductions of 30-45% compared to mechanical alternatives, primarily due to their lower energy consumption (typically 4-6 kWh/kg H₂ versus 6-10 kWh/kg for mechanical systems). The absence of moving parts substantially reduces maintenance requirements, with estimated maintenance costs of 2-3% of capital expenditure annually, compared to 5-8% for conventional technologies.

The durability and lifetime of EHC systems significantly impact their economic proposition. Current generation EHCs demonstrate operational lifetimes of 20,000-30,000 hours before performance degradation necessitates major component replacement. This translates to approximately 3-5 years of continuous operation, which remains shorter than the 5-8 year lifetime of high-quality mechanical compressors. Improving membrane durability could extend operational lifetimes to 40,000+ hours, dramatically improving return on investment calculations.

Total cost of ownership (TCO) models indicate that EHCs become economically competitive with mechanical compressors after 3-4 years of operation in most applications, with the break-even point occurring earlier in scenarios with high electricity costs or where system reliability commands premium value. For hydrogen refueling stations, the TCO analysis shows potential savings of 15-25% over a 10-year operational period when accounting for all direct and indirect costs.

Scale economies present significant opportunities for cost reduction. Manufacturing volume increases from current prototype/small-batch production to mass manufacturing could potentially reduce unit costs by 40-60%. Material innovations, particularly in membrane technology and catalyst loading reductions, offer pathways to decrease production costs by an additional 20-30% within the next five years.

Government incentives and carbon pricing mechanisms further enhance the economic case for EHCs. In jurisdictions with carbon taxes or emissions trading schemes, the lower carbon footprint of EHCs (when powered by renewable electricity) provides additional economic advantages of $0.10-0.30 per kg of hydrogen compressed, depending on the carbon price and electricity source.

Lifecycle cost analysis reveals several economic advantages that may offset the higher acquisition costs. EHCs demonstrate operational expenditure reductions of 30-45% compared to mechanical alternatives, primarily due to their lower energy consumption (typically 4-6 kWh/kg H₂ versus 6-10 kWh/kg for mechanical systems). The absence of moving parts substantially reduces maintenance requirements, with estimated maintenance costs of 2-3% of capital expenditure annually, compared to 5-8% for conventional technologies.

The durability and lifetime of EHC systems significantly impact their economic proposition. Current generation EHCs demonstrate operational lifetimes of 20,000-30,000 hours before performance degradation necessitates major component replacement. This translates to approximately 3-5 years of continuous operation, which remains shorter than the 5-8 year lifetime of high-quality mechanical compressors. Improving membrane durability could extend operational lifetimes to 40,000+ hours, dramatically improving return on investment calculations.

Total cost of ownership (TCO) models indicate that EHCs become economically competitive with mechanical compressors after 3-4 years of operation in most applications, with the break-even point occurring earlier in scenarios with high electricity costs or where system reliability commands premium value. For hydrogen refueling stations, the TCO analysis shows potential savings of 15-25% over a 10-year operational period when accounting for all direct and indirect costs.

Scale economies present significant opportunities for cost reduction. Manufacturing volume increases from current prototype/small-batch production to mass manufacturing could potentially reduce unit costs by 40-60%. Material innovations, particularly in membrane technology and catalyst loading reductions, offer pathways to decrease production costs by an additional 20-30% within the next five years.

Government incentives and carbon pricing mechanisms further enhance the economic case for EHCs. In jurisdictions with carbon taxes or emissions trading schemes, the lower carbon footprint of EHCs (when powered by renewable electricity) provides additional economic advantages of $0.10-0.30 per kg of hydrogen compressed, depending on the carbon price and electricity source.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!