Integration Strategies For Electrochemical Compressors With PEM Electrolyzers

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Integration Background and Objectives

Electrochemical compression and PEM (Proton Exchange Membrane) electrolysis represent two pivotal technologies in the evolving landscape of clean energy systems. The integration of these technologies has emerged as a promising frontier for enhancing hydrogen production efficiency and addressing storage challenges. Historically, these systems have developed along separate technological trajectories, with electrochemical compressors evolving from early experimental concepts in the 1980s to practical applications in the 2000s, while PEM electrolyzers have progressed from laboratory demonstrations to commercial deployments over a similar timeframe.

The convergence of these technologies is driven by the growing recognition of hydrogen's role in decarbonization strategies and the need for more efficient, integrated energy systems. Traditional hydrogen production and compression methods involve separate processes, resulting in energy losses at each conversion stage. The integration of electrochemical compression directly with PEM electrolyzers presents an opportunity to streamline this process, potentially reducing energy consumption by 15-25% compared to conventional mechanical compression methods.

Current technological objectives focus on developing seamless integration strategies that maximize efficiency while minimizing system complexity and cost. Key goals include achieving compression ratios exceeding 100:1 within integrated systems, maintaining high hydrogen purity (>99.999%), and ensuring operational stability across varying load conditions—critical for applications coupled with renewable energy sources.

The evolution of materials science has been instrumental in advancing both technologies, with developments in membrane materials, catalyst formulations, and electrode structures enabling higher performance and durability. Recent breakthroughs in perfluorosulfonic acid (PFSA) membranes and platinum-group metal catalysts have significantly enhanced the efficiency and operational lifetime of both electrochemical compressors and PEM electrolyzers.

Looking forward, the integration pathway aims to establish unified electrochemical systems capable of simultaneous hydrogen production and compression, potentially revolutionizing hydrogen infrastructure by enabling distributed, high-pressure hydrogen generation at points of use. This would eliminate transportation requirements and associated costs while supporting the deployment of hydrogen refueling stations and industrial applications.

The technical trajectory is increasingly focused on modular designs that can scale from kilowatt to megawatt applications, with particular emphasis on system architectures that optimize thermal management and water balance across integrated components. These developments align with broader energy transition goals, positioning integrated electrochemical systems as critical enablers for hydrogen economy infrastructure.

The convergence of these technologies is driven by the growing recognition of hydrogen's role in decarbonization strategies and the need for more efficient, integrated energy systems. Traditional hydrogen production and compression methods involve separate processes, resulting in energy losses at each conversion stage. The integration of electrochemical compression directly with PEM electrolyzers presents an opportunity to streamline this process, potentially reducing energy consumption by 15-25% compared to conventional mechanical compression methods.

Current technological objectives focus on developing seamless integration strategies that maximize efficiency while minimizing system complexity and cost. Key goals include achieving compression ratios exceeding 100:1 within integrated systems, maintaining high hydrogen purity (>99.999%), and ensuring operational stability across varying load conditions—critical for applications coupled with renewable energy sources.

The evolution of materials science has been instrumental in advancing both technologies, with developments in membrane materials, catalyst formulations, and electrode structures enabling higher performance and durability. Recent breakthroughs in perfluorosulfonic acid (PFSA) membranes and platinum-group metal catalysts have significantly enhanced the efficiency and operational lifetime of both electrochemical compressors and PEM electrolyzers.

Looking forward, the integration pathway aims to establish unified electrochemical systems capable of simultaneous hydrogen production and compression, potentially revolutionizing hydrogen infrastructure by enabling distributed, high-pressure hydrogen generation at points of use. This would eliminate transportation requirements and associated costs while supporting the deployment of hydrogen refueling stations and industrial applications.

The technical trajectory is increasingly focused on modular designs that can scale from kilowatt to megawatt applications, with particular emphasis on system architectures that optimize thermal management and water balance across integrated components. These developments align with broader energy transition goals, positioning integrated electrochemical systems as critical enablers for hydrogen economy infrastructure.

Market Analysis for Integrated Electrochemical Systems

The integration of electrochemical compressors with PEM electrolyzers represents a significant market opportunity within the clean energy transition landscape. Current market analysis indicates that the global hydrogen production equipment market is experiencing robust growth, valued at approximately $4.5 billion in 2022 with projections to reach $13.6 billion by 2030, representing a compound annual growth rate of 14.8%.

The demand for integrated electrochemical systems is primarily driven by three key market factors. First, the increasing global focus on decarbonization has accelerated investment in green hydrogen infrastructure, with over $300 billion in hydrogen projects announced globally since 2020. Second, energy storage requirements for intermittent renewable sources have created new market segments for hydrogen-based solutions. Third, industrial sectors seeking to reduce carbon emissions are exploring hydrogen as an alternative feedstock and fuel.

Market segmentation reveals distinct customer profiles for integrated electrochemical systems. The industrial sector, particularly chemical manufacturing, ammonia production, and refining, represents approximately 42% of potential end-users. Energy utilities exploring hydrogen for grid balancing and storage comprise roughly 28% of the market. Transportation applications, including hydrogen refueling infrastructure, account for 18%, while specialized applications in electronics and pharmaceuticals make up the remaining 12%.

Regional market analysis shows Europe leading adoption with substantial policy support through initiatives like the European Hydrogen Strategy and €5.4 billion in funding through Important Projects of Common European Interest (IPCEI). Asia-Pacific follows closely with China, Japan, and South Korea making significant investments in hydrogen technology development. North America shows growing interest, particularly following recent legislative support through the Inflation Reduction Act.

Competitive landscape assessment reveals traditional industrial gas companies expanding their electrolyzer portfolios, while specialized electrochemical technology providers are developing integrated compression solutions. Several strategic partnerships between electrolyzer manufacturers and compression technology companies have emerged in the past 24 months, indicating market recognition of integration benefits.

Market barriers include high capital costs, with integrated systems currently commanding a 30-40% premium over standalone components. Technical standardization remains limited, creating interoperability challenges. Additionally, the market faces a knowledge gap among potential end-users regarding the benefits of integrated electrochemical compression versus conventional mechanical approaches.

The demand for integrated electrochemical systems is primarily driven by three key market factors. First, the increasing global focus on decarbonization has accelerated investment in green hydrogen infrastructure, with over $300 billion in hydrogen projects announced globally since 2020. Second, energy storage requirements for intermittent renewable sources have created new market segments for hydrogen-based solutions. Third, industrial sectors seeking to reduce carbon emissions are exploring hydrogen as an alternative feedstock and fuel.

Market segmentation reveals distinct customer profiles for integrated electrochemical systems. The industrial sector, particularly chemical manufacturing, ammonia production, and refining, represents approximately 42% of potential end-users. Energy utilities exploring hydrogen for grid balancing and storage comprise roughly 28% of the market. Transportation applications, including hydrogen refueling infrastructure, account for 18%, while specialized applications in electronics and pharmaceuticals make up the remaining 12%.

Regional market analysis shows Europe leading adoption with substantial policy support through initiatives like the European Hydrogen Strategy and €5.4 billion in funding through Important Projects of Common European Interest (IPCEI). Asia-Pacific follows closely with China, Japan, and South Korea making significant investments in hydrogen technology development. North America shows growing interest, particularly following recent legislative support through the Inflation Reduction Act.

Competitive landscape assessment reveals traditional industrial gas companies expanding their electrolyzer portfolios, while specialized electrochemical technology providers are developing integrated compression solutions. Several strategic partnerships between electrolyzer manufacturers and compression technology companies have emerged in the past 24 months, indicating market recognition of integration benefits.

Market barriers include high capital costs, with integrated systems currently commanding a 30-40% premium over standalone components. Technical standardization remains limited, creating interoperability challenges. Additionally, the market faces a knowledge gap among potential end-users regarding the benefits of integrated electrochemical compression versus conventional mechanical approaches.

Technical Challenges in ECC-PEM Integration

The integration of Electrochemical Compressors (ECCs) with Proton Exchange Membrane (PEM) electrolyzers presents several significant technical challenges that must be addressed for successful implementation. One primary challenge involves the management of differential pressure across the membrane. PEM electrolyzers typically operate at pressures ranging from 30-80 bar, while ECCs may need to compress hydrogen to 350-700 bar for storage applications. This substantial pressure differential creates mechanical stress on the membrane, potentially leading to accelerated degradation and reduced operational lifetime.

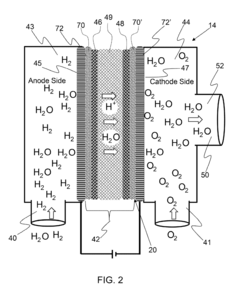

Material compatibility issues also pose significant obstacles. The membrane materials must simultaneously withstand high pressures, maintain proton conductivity, and resist chemical degradation in both electrolyzer and compressor operational modes. Current Nafion-based membranes exhibit limitations in mechanical strength at higher differential pressures, necessitating the development of composite or reinforced membrane structures that maintain conductivity while enhancing mechanical durability.

Thermal management represents another critical challenge. PEM electrolyzers generate heat during operation, while ECCs may experience temperature fluctuations during compression cycles. The integrated system requires sophisticated thermal management strategies to maintain optimal operating temperatures for both components, as temperature variations can significantly impact efficiency, membrane durability, and overall system performance.

Water management across the integrated system presents complex engineering challenges. PEM electrolyzers require precise water supply for the hydrogen evolution reaction, while ECCs need controlled humidity levels for optimal proton transport. Balancing these requirements in an integrated system demands advanced water management strategies to prevent membrane dehydration or flooding, both of which can severely impact system efficiency and longevity.

Control system integration poses substantial difficulties due to the different operational dynamics of electrolyzers and compressors. Electrolyzers typically operate at steady-state conditions, while compressors may function in more dynamic compression cycles. Developing control algorithms that can harmonize these different operational modes while optimizing overall system efficiency remains a significant technical hurdle.

Catalyst layer optimization presents another challenge, as catalysts must function effectively in both electrolyzer and compressor modes. The catalyst layers must maintain activity and stability under varying conditions of pressure, humidity, and electrical potential, requiring novel approaches to catalyst design and electrode structure that can accommodate the dual functionality of hydrogen production and compression.

Material compatibility issues also pose significant obstacles. The membrane materials must simultaneously withstand high pressures, maintain proton conductivity, and resist chemical degradation in both electrolyzer and compressor operational modes. Current Nafion-based membranes exhibit limitations in mechanical strength at higher differential pressures, necessitating the development of composite or reinforced membrane structures that maintain conductivity while enhancing mechanical durability.

Thermal management represents another critical challenge. PEM electrolyzers generate heat during operation, while ECCs may experience temperature fluctuations during compression cycles. The integrated system requires sophisticated thermal management strategies to maintain optimal operating temperatures for both components, as temperature variations can significantly impact efficiency, membrane durability, and overall system performance.

Water management across the integrated system presents complex engineering challenges. PEM electrolyzers require precise water supply for the hydrogen evolution reaction, while ECCs need controlled humidity levels for optimal proton transport. Balancing these requirements in an integrated system demands advanced water management strategies to prevent membrane dehydration or flooding, both of which can severely impact system efficiency and longevity.

Control system integration poses substantial difficulties due to the different operational dynamics of electrolyzers and compressors. Electrolyzers typically operate at steady-state conditions, while compressors may function in more dynamic compression cycles. Developing control algorithms that can harmonize these different operational modes while optimizing overall system efficiency remains a significant technical hurdle.

Catalyst layer optimization presents another challenge, as catalysts must function effectively in both electrolyzer and compressor modes. The catalyst layers must maintain activity and stability under varying conditions of pressure, humidity, and electrical potential, requiring novel approaches to catalyst design and electrode structure that can accommodate the dual functionality of hydrogen production and compression.

Current Integration Architectures and Methods

01 Integration of electrochemical compressors with PEM electrolyzers

Systems that combine electrochemical compressors with PEM electrolyzers to create integrated hydrogen production and compression solutions. These integrated systems allow for more efficient hydrogen production and delivery by eliminating the need for separate mechanical compression stages. The electrochemical compressor uses similar principles to the electrolyzer but is optimized for pressurizing the hydrogen gas produced, enabling direct high-pressure hydrogen output from a single integrated unit.- Integration of electrochemical compressors with PEM electrolyzers: Systems that integrate electrochemical compressors with PEM electrolyzers to enhance hydrogen production and compression efficiency. These integrated systems allow for direct compression of hydrogen produced by electrolysis, eliminating the need for separate mechanical compression stages. The integration optimizes energy consumption and improves overall system efficiency by utilizing the same electrochemical principles for both hydrogen production and compression.

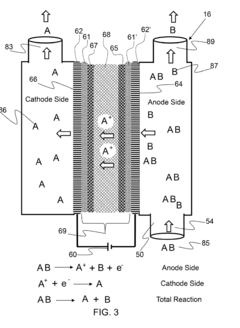

- Membrane electrode assembly designs for dual functionality: Specialized membrane electrode assembly (MEA) designs that can function both as electrolyzer cells and compression cells. These dual-function MEAs incorporate catalysts and membrane materials that support both water electrolysis and hydrogen compression processes. The designs focus on optimizing proton conductivity, mechanical stability, and gas permeation resistance to withstand the pressure differentials required for compression while maintaining high electrolysis efficiency.

- Pressure management systems for integrated electrochemical devices: Pressure management systems specifically designed for integrated electrochemical compressor and electrolyzer applications. These systems include pressure control mechanisms, safety valves, and pressure differential monitoring to ensure optimal operation across varying pressure conditions. The pressure management systems enable gradual compression of hydrogen through multiple stages while maintaining safe operating conditions and preventing membrane damage from excessive pressure differentials.

- Thermal management for combined electrolyzer-compressor systems: Thermal management solutions for integrated electrochemical compressor and PEM electrolyzer systems. These solutions address the heat generation and dissipation challenges in combined systems, including cooling channels, heat exchangers, and temperature control mechanisms. Effective thermal management is crucial for maintaining optimal operating temperatures, preventing membrane degradation, and ensuring consistent performance across both electrolysis and compression functions.

- Control systems for coordinated operation of integrated components: Advanced control systems that coordinate the operation of integrated electrochemical compressors and PEM electrolyzers. These control systems manage power distribution, pressure levels, gas flow rates, and system transitions between different operating modes. The control architecture includes sensors, actuators, and algorithms that optimize hydrogen production and compression based on demand requirements, available power, and system conditions, ensuring efficient and safe operation of the integrated system.

02 Membrane electrode assembly designs for dual-function systems

Specialized membrane electrode assembly (MEA) designs that can function in both electrolyzer and compressor modes. These MEAs feature optimized catalyst layers, membrane materials, and electrode structures that support both the water-splitting reaction and the electrochemical compression process. The designs focus on materials that can withstand high differential pressures while maintaining high ionic conductivity and minimizing gas crossover, which is critical for safe and efficient operation of integrated systems.Expand Specific Solutions03 Pressure management and control systems

Advanced pressure management and control systems specifically designed for integrated electrochemical compressor and PEM electrolyzer units. These systems include pressure sensors, electronic controllers, and pressure regulation mechanisms that maintain optimal operating conditions across both functions. The control systems enable dynamic switching between electrolyzer and compressor modes while managing differential pressures to prevent membrane damage and ensure safe operation at high pressures.Expand Specific Solutions04 Thermal management integration

Thermal management solutions that address the heat generation and cooling requirements of combined electrochemical compressor and PEM electrolyzer systems. These innovations include integrated cooling channels, heat exchangers, and thermal control systems that maintain optimal operating temperatures across both functions. Effective thermal management is crucial for extending component lifetimes, maintaining efficiency, and ensuring safe operation, particularly when systems operate at high current densities or pressures.Expand Specific Solutions05 Power management and efficiency optimization

Power management systems and efficiency optimization techniques for integrated electrochemical compressor and PEM electrolyzer units. These innovations include advanced power electronics, control algorithms, and operational strategies that optimize energy consumption across both functions. The systems can dynamically allocate power between hydrogen production and compression based on demand, pressure requirements, and available renewable energy inputs, maximizing overall system efficiency and reducing operational costs.Expand Specific Solutions

Industry Leaders in Electrochemical Systems

The integration of electrochemical compressors with PEM electrolyzers is evolving in an early growth market phase, with significant potential for expansion as hydrogen technologies gain traction in the energy transition landscape. The global market is projected to grow substantially as green hydrogen production becomes increasingly critical for decarbonization efforts. Leading companies like W.L. Gore & Associates, Plug Power, and Siemens Energy are advancing membrane technology and system integration capabilities, while specialized players such as HyAxiom, ITM Power, and SinoHytec focus on electrolyzer optimization. Research institutions like CEA and industrial giants including Bosch and 3M are contributing to technological maturity through materials innovation and component standardization, though commercial-scale integration solutions remain in development stages requiring further efficiency improvements.

Plug Power, Inc.

Technical Solution: Plug Power has developed an integrated system that combines electrochemical compressors with PEM electrolyzers to create a more efficient hydrogen production and compression solution. Their approach utilizes a unified membrane electrode assembly (MEA) design that serves both electrolysis and compression functions, reducing system complexity. The technology employs specialized bipolar plates with integrated flow fields that allow for seamless transition between hydrogen generation and compression stages. Plug Power's system operates at differential pressures up to 700 bar, eliminating the need for mechanical compression in many applications. Their integration strategy includes advanced control systems that dynamically adjust operating parameters based on demand, power availability, and system conditions, optimizing overall efficiency. The company has implemented this technology in their GenFuel infrastructure solutions, demonstrating successful field deployment with reported energy savings of 20-30% compared to conventional separate systems.

Strengths: Unified MEA design reduces component count and system complexity; eliminates mechanical compression components, reducing maintenance requirements; dynamic control system optimizes performance across varying conditions. Weaknesses: Higher initial capital costs compared to separate systems; specialized components may limit serviceability in the field; membrane durability challenges under combined electrolysis and compression duty cycles.

ITM Power (Trading) Ltd.

Technical Solution: ITM Power has pioneered an integrated electrochemical compression and PEM electrolyzer system that leverages their expertise in high-pressure PEM technology. Their approach focuses on a staged compression strategy where hydrogen produced in the electrolyzer undergoes progressive electrochemical compression within the same system architecture. The company's proprietary stack design incorporates specialized membrane materials with graduated thickness profiles to handle increasing pressure differentials across compression stages. ITM's integration strategy includes innovative bipolar plate designs with pressure-optimized flow channels that maintain efficiency across varying compression ratios. Their system achieves outlet pressures exceeding 80 bar directly from the electrolyzer, with subsequent electrochemical compression stages capable of reaching 350+ bar without mechanical compressors. The technology employs advanced water management techniques to prevent membrane dehydration at high pressures, including recirculation systems that maintain optimal membrane hydration throughout the compression process. ITM has deployed this technology in several hydrogen refueling stations across Europe, demonstrating reliable operation in real-world conditions.

Strengths: Eliminates mechanical compression for mid-pressure applications; reduced system footprint through integration; lower operational noise compared to mechanical compression systems; demonstrated field reliability. Weaknesses: Higher power consumption at very high compression ratios compared to some mechanical systems; specialized membrane materials increase replacement costs; limited to specific pressure ranges for optimal efficiency.

Key Patents in ECC-PEM Integration Technology

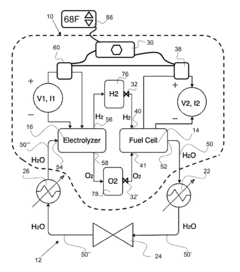

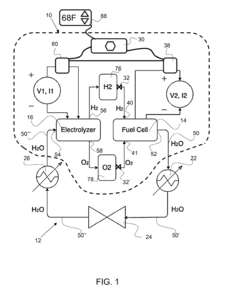

Electrochemical compressor utilizing an electrolysis

PatentPendingHK1231523A

Innovation

- An electrochemical compressor system utilizing an electrolyzer and a fuel cell, where hydrogen is introduced and consumed locally near the membrane electrode assembly, reducing its impact on the compression system and simplifying the process by using hydrogen generated by a separate electrolyzer to react with oxygen and reform water at a higher pressure.

Electrochemical compressor utilizing an electrolysis

PatentActiveUS20160024666A1

Innovation

- Localized hydrogen generation near the fuel cell using an electrolyzer, where hydrogen produced is introduced to the anode side and reacts with oxygen from another electrolyzer at the cathode side to reform water, reducing hydrogen's impact on the compression system and simplifying the process by eliminating the need for hydrogen separation from the working fluid.

Energy Efficiency Considerations

Energy efficiency represents a critical parameter in the integration of electrochemical compressors with PEM electrolyzers. The combined system's overall efficiency directly impacts operational costs, environmental footprint, and economic viability in hydrogen production and compression applications. Current PEM electrolyzers typically operate at efficiency levels between 65-75%, while electrochemical compressors demonstrate efficiencies ranging from 60-70% depending on operating conditions and design parameters.

When integrating these technologies, efficiency losses occur at multiple interface points. The electrical power consumption for both systems must be carefully managed to minimize conversion losses. Thermal management becomes particularly challenging as both systems generate heat during operation, with temperature differentials potentially causing efficiency degradation if not properly addressed. Studies indicate that integrated systems can achieve 5-8% higher overall efficiency compared to separate standalone units through strategic heat recovery and power management.

Pressure differential management between the electrolyzer output and compressor input stages represents another significant efficiency consideration. Direct coupling without intermediate pressure regulation can reduce energy losses by eliminating throttling effects, potentially improving system efficiency by 3-5%. However, this approach requires precise control systems to maintain optimal operating parameters across varying load conditions.

Material selection for membranes, catalysts, and electrodes significantly impacts energy efficiency. Advanced composite membranes with high proton conductivity and low gas crossover can improve efficiency by reducing internal resistance and parasitic losses. Platinum-group metal catalysts with optimized loading and distribution patterns have demonstrated efficiency improvements of 2-4% in laboratory settings, though cost considerations remain a challenge for commercial implementation.

System architecture decisions, such as staged compression versus single-stage designs, create important efficiency trade-offs. Multi-stage compression with intercooling has shown efficiency advantages of up to 10% for high-pressure applications (>350 bar), while single-stage designs offer simplicity and potentially lower capital costs for moderate pressure requirements. The optimal configuration depends heavily on the specific application requirements and operational parameters.

Control system integration represents perhaps the most promising frontier for efficiency improvements. Advanced model predictive control algorithms that dynamically optimize operating parameters based on real-time conditions have demonstrated efficiency gains of 7-12% in pilot installations. These systems can balance multiple efficiency factors simultaneously, adapting to changing input conditions while maintaining optimal performance across the integrated system.

When integrating these technologies, efficiency losses occur at multiple interface points. The electrical power consumption for both systems must be carefully managed to minimize conversion losses. Thermal management becomes particularly challenging as both systems generate heat during operation, with temperature differentials potentially causing efficiency degradation if not properly addressed. Studies indicate that integrated systems can achieve 5-8% higher overall efficiency compared to separate standalone units through strategic heat recovery and power management.

Pressure differential management between the electrolyzer output and compressor input stages represents another significant efficiency consideration. Direct coupling without intermediate pressure regulation can reduce energy losses by eliminating throttling effects, potentially improving system efficiency by 3-5%. However, this approach requires precise control systems to maintain optimal operating parameters across varying load conditions.

Material selection for membranes, catalysts, and electrodes significantly impacts energy efficiency. Advanced composite membranes with high proton conductivity and low gas crossover can improve efficiency by reducing internal resistance and parasitic losses. Platinum-group metal catalysts with optimized loading and distribution patterns have demonstrated efficiency improvements of 2-4% in laboratory settings, though cost considerations remain a challenge for commercial implementation.

System architecture decisions, such as staged compression versus single-stage designs, create important efficiency trade-offs. Multi-stage compression with intercooling has shown efficiency advantages of up to 10% for high-pressure applications (>350 bar), while single-stage designs offer simplicity and potentially lower capital costs for moderate pressure requirements. The optimal configuration depends heavily on the specific application requirements and operational parameters.

Control system integration represents perhaps the most promising frontier for efficiency improvements. Advanced model predictive control algorithms that dynamically optimize operating parameters based on real-time conditions have demonstrated efficiency gains of 7-12% in pilot installations. These systems can balance multiple efficiency factors simultaneously, adapting to changing input conditions while maintaining optimal performance across the integrated system.

Scalability and Commercial Implementation Roadmap

The scalability of integrated electrochemical compressor and PEM electrolyzer systems represents a critical factor in their commercial viability. Current laboratory-scale demonstrations have shown promising results, but significant engineering challenges remain for industrial implementation. The transition from kilowatt to megawatt scale requires addressing issues related to heat management, pressure differentials, and system integration complexity.

Manufacturing scalability presents both challenges and opportunities. The shared materials and manufacturing processes between electrochemical compressors and PEM electrolyzers create potential for streamlined production lines and reduced capital costs. Companies pioneering this integration can leverage economies of scale by utilizing similar membrane electrode assembly (MEA) production techniques, catalyst application methods, and bipolar plate manufacturing processes.

A phased commercial implementation roadmap appears most practical. Phase one (2023-2025) focuses on pilot demonstrations at 100-500 kW scale, establishing proof of concept in real-world environments. Phase two (2025-2028) targets early commercial deployments at 1-5 MW scale, with emphasis on optimizing system integration and developing standardized interfaces. Phase three (2028-2032) aims for full commercial deployment at 10+ MW scale with fully integrated systems designed from the ground up.

Key economic drivers for commercial implementation include hydrogen production cost reduction, elimination of mechanical compression equipment, and decreased operational complexity. Financial modeling suggests that integrated systems could achieve a 15-20% reduction in levelized cost of hydrogen compared to conventional separate systems, primarily through energy efficiency gains and reduced capital expenditure.

Regulatory frameworks and standards development will significantly impact implementation timelines. Currently, standards for integrated electrochemical compression-electrolysis systems remain underdeveloped. Industry consortia such as Hydrogen Europe and the International Association for Hydrogen Safety are working to establish safety protocols and performance metrics specific to these integrated systems.

Market entry strategies should prioritize applications where high-pressure hydrogen is immediately required post-production, such as hydrogen refueling stations and industrial processes requiring pressurized hydrogen. These early adoption markets can provide the necessary revenue streams to support continued development while manufacturing scales to meet broader market demands.

Manufacturing scalability presents both challenges and opportunities. The shared materials and manufacturing processes between electrochemical compressors and PEM electrolyzers create potential for streamlined production lines and reduced capital costs. Companies pioneering this integration can leverage economies of scale by utilizing similar membrane electrode assembly (MEA) production techniques, catalyst application methods, and bipolar plate manufacturing processes.

A phased commercial implementation roadmap appears most practical. Phase one (2023-2025) focuses on pilot demonstrations at 100-500 kW scale, establishing proof of concept in real-world environments. Phase two (2025-2028) targets early commercial deployments at 1-5 MW scale, with emphasis on optimizing system integration and developing standardized interfaces. Phase three (2028-2032) aims for full commercial deployment at 10+ MW scale with fully integrated systems designed from the ground up.

Key economic drivers for commercial implementation include hydrogen production cost reduction, elimination of mechanical compression equipment, and decreased operational complexity. Financial modeling suggests that integrated systems could achieve a 15-20% reduction in levelized cost of hydrogen compared to conventional separate systems, primarily through energy efficiency gains and reduced capital expenditure.

Regulatory frameworks and standards development will significantly impact implementation timelines. Currently, standards for integrated electrochemical compression-electrolysis systems remain underdeveloped. Industry consortia such as Hydrogen Europe and the International Association for Hydrogen Safety are working to establish safety protocols and performance metrics specific to these integrated systems.

Market entry strategies should prioritize applications where high-pressure hydrogen is immediately required post-production, such as hydrogen refueling stations and industrial processes requiring pressurized hydrogen. These early adoption markets can provide the necessary revenue streams to support continued development while manufacturing scales to meet broader market demands.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!