Modeling And Simulation Techniques For Electrochemical Hydrogen Compressors

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Electrochemical Hydrogen Compression Background and Objectives

Electrochemical hydrogen compression (EHC) technology represents a paradigm shift in hydrogen processing, offering a solid-state alternative to conventional mechanical compression methods. The evolution of this technology traces back to the early 2000s when researchers began exploring electrochemical principles for hydrogen compression, building upon foundational work in proton exchange membrane (PEM) fuel cells. The technology has since progressed through various developmental stages, from laboratory-scale proof-of-concept to increasingly practical prototypes with improved efficiency and durability.

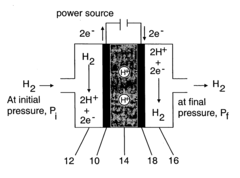

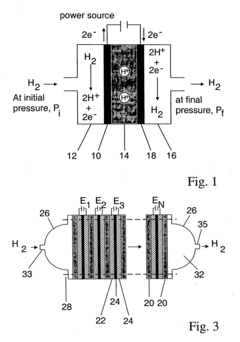

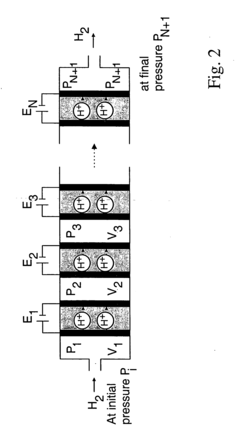

The fundamental principle of EHC involves the electrochemical transport of hydrogen across a membrane, typically a proton-conducting polymer electrolyte, under an applied electrical potential. This process eliminates the need for moving parts, significantly reducing maintenance requirements and potential failure points compared to mechanical compressors. The technology's trajectory has been characterized by continuous improvements in membrane materials, catalyst formulations, and system integration approaches.

Current technical objectives in EHC modeling and simulation focus on developing comprehensive frameworks that accurately predict system performance across varying operational conditions. These models aim to capture the complex interplay between electrochemical reactions, mass transport phenomena, heat transfer, and mechanical stresses within the compressor cells. Advanced simulation techniques are being pursued to optimize cell design, predict degradation mechanisms, and enhance overall system efficiency.

A critical goal is the development of multi-scale models that bridge the gap between molecular-level processes and system-level performance. This includes quantum mechanical simulations of catalyst-hydrogen interactions, mesoscale models of membrane transport properties, and macroscale simulations of complete compressor systems. Such integrated modeling approaches are essential for accelerating technology development and reducing costly experimental iterations.

The industry aims to achieve simulation capabilities that can accurately predict key performance indicators such as compression efficiency, power consumption, hydrogen purity, and system durability. These predictive tools would enable rapid virtual prototyping and optimization of next-generation EHC systems with higher pressure ratios, improved energy efficiency, and extended operational lifetimes.

Long-term technical objectives include the development of digital twins for EHC systems, enabling real-time monitoring, predictive maintenance, and adaptive control strategies. Additionally, there is growing interest in modeling the integration of EHC technology within broader hydrogen infrastructure, including renewable energy systems, storage facilities, and distribution networks, to optimize overall system performance and economics in the emerging hydrogen economy.

The fundamental principle of EHC involves the electrochemical transport of hydrogen across a membrane, typically a proton-conducting polymer electrolyte, under an applied electrical potential. This process eliminates the need for moving parts, significantly reducing maintenance requirements and potential failure points compared to mechanical compressors. The technology's trajectory has been characterized by continuous improvements in membrane materials, catalyst formulations, and system integration approaches.

Current technical objectives in EHC modeling and simulation focus on developing comprehensive frameworks that accurately predict system performance across varying operational conditions. These models aim to capture the complex interplay between electrochemical reactions, mass transport phenomena, heat transfer, and mechanical stresses within the compressor cells. Advanced simulation techniques are being pursued to optimize cell design, predict degradation mechanisms, and enhance overall system efficiency.

A critical goal is the development of multi-scale models that bridge the gap between molecular-level processes and system-level performance. This includes quantum mechanical simulations of catalyst-hydrogen interactions, mesoscale models of membrane transport properties, and macroscale simulations of complete compressor systems. Such integrated modeling approaches are essential for accelerating technology development and reducing costly experimental iterations.

The industry aims to achieve simulation capabilities that can accurately predict key performance indicators such as compression efficiency, power consumption, hydrogen purity, and system durability. These predictive tools would enable rapid virtual prototyping and optimization of next-generation EHC systems with higher pressure ratios, improved energy efficiency, and extended operational lifetimes.

Long-term technical objectives include the development of digital twins for EHC systems, enabling real-time monitoring, predictive maintenance, and adaptive control strategies. Additionally, there is growing interest in modeling the integration of EHC technology within broader hydrogen infrastructure, including renewable energy systems, storage facilities, and distribution networks, to optimize overall system performance and economics in the emerging hydrogen economy.

Market Analysis for Hydrogen Compression Technologies

The global hydrogen compression market is experiencing significant growth, driven by the increasing adoption of hydrogen as a clean energy carrier. The market was valued at approximately $1.5 billion in 2021 and is projected to reach $2.7 billion by 2028, growing at a CAGR of 8.7% during the forecast period. This growth is primarily attributed to the expanding hydrogen infrastructure development across various regions, particularly in North America, Europe, and Asia-Pacific.

Traditional mechanical hydrogen compression technologies currently dominate the market, accounting for roughly 85% of installations. These include reciprocating compressors, diaphragm compressors, and centrifugal compressors. However, electrochemical hydrogen compression (EHC) technology is emerging as a promising alternative, with its market share expected to grow from the current 5% to approximately 15% by 2030.

The demand for electrochemical hydrogen compressors is being driven by several factors. First, the global push for decarbonization has led to increased investments in hydrogen as a clean energy vector. Second, EHC systems offer significant advantages over mechanical compressors, including higher efficiency, lower maintenance requirements, and the ability to achieve higher compression ratios without moving parts. Third, the integration of hydrogen in various sectors such as transportation, power generation, and industrial processes necessitates efficient compression technologies.

Regional analysis indicates that Europe leads in EHC technology adoption, followed by North America and Asia-Pacific. European countries, particularly Germany, France, and the Netherlands, have established ambitious hydrogen strategies with substantial funding allocations. The European market for EHC is expected to grow at a CAGR of 12.3% through 2028, outpacing the global average.

Key market segments for EHC technology include hydrogen refueling stations, industrial applications, and energy storage systems. The hydrogen refueling infrastructure segment is anticipated to witness the highest growth rate at 14.2% annually, driven by the increasing deployment of fuel cell electric vehicles (FCEVs).

Customer requirements are evolving toward more compact, efficient, and reliable compression solutions. End-users are increasingly valuing total cost of ownership over initial capital expenditure, which favors EHC technology despite its currently higher upfront costs. Market surveys indicate that 67% of potential customers consider energy efficiency as the most critical factor in selecting hydrogen compression technology, followed by reliability (58%) and maintenance requirements (52%).

The competitive landscape is characterized by a mix of established industrial gas companies diversifying into EHC and specialized startups focusing exclusively on electrochemical compression technology. This dynamic environment is expected to drive innovation in modeling and simulation techniques for EHC systems, as companies seek to optimize designs and improve performance metrics.

Traditional mechanical hydrogen compression technologies currently dominate the market, accounting for roughly 85% of installations. These include reciprocating compressors, diaphragm compressors, and centrifugal compressors. However, electrochemical hydrogen compression (EHC) technology is emerging as a promising alternative, with its market share expected to grow from the current 5% to approximately 15% by 2030.

The demand for electrochemical hydrogen compressors is being driven by several factors. First, the global push for decarbonization has led to increased investments in hydrogen as a clean energy vector. Second, EHC systems offer significant advantages over mechanical compressors, including higher efficiency, lower maintenance requirements, and the ability to achieve higher compression ratios without moving parts. Third, the integration of hydrogen in various sectors such as transportation, power generation, and industrial processes necessitates efficient compression technologies.

Regional analysis indicates that Europe leads in EHC technology adoption, followed by North America and Asia-Pacific. European countries, particularly Germany, France, and the Netherlands, have established ambitious hydrogen strategies with substantial funding allocations. The European market for EHC is expected to grow at a CAGR of 12.3% through 2028, outpacing the global average.

Key market segments for EHC technology include hydrogen refueling stations, industrial applications, and energy storage systems. The hydrogen refueling infrastructure segment is anticipated to witness the highest growth rate at 14.2% annually, driven by the increasing deployment of fuel cell electric vehicles (FCEVs).

Customer requirements are evolving toward more compact, efficient, and reliable compression solutions. End-users are increasingly valuing total cost of ownership over initial capital expenditure, which favors EHC technology despite its currently higher upfront costs. Market surveys indicate that 67% of potential customers consider energy efficiency as the most critical factor in selecting hydrogen compression technology, followed by reliability (58%) and maintenance requirements (52%).

The competitive landscape is characterized by a mix of established industrial gas companies diversifying into EHC and specialized startups focusing exclusively on electrochemical compression technology. This dynamic environment is expected to drive innovation in modeling and simulation techniques for EHC systems, as companies seek to optimize designs and improve performance metrics.

Current Modeling Challenges in Electrochemical Hydrogen Compression

Despite significant advancements in electrochemical hydrogen compression (EHC) technology, current modeling approaches face substantial challenges that limit their accuracy and applicability. The multiphysics nature of EHC processes—involving electrochemical reactions, heat transfer, fluid dynamics, and material interactions—creates inherent complexity that is difficult to capture in unified models. Most existing models fail to adequately integrate these phenomena, often treating them as isolated components rather than as interconnected systems.

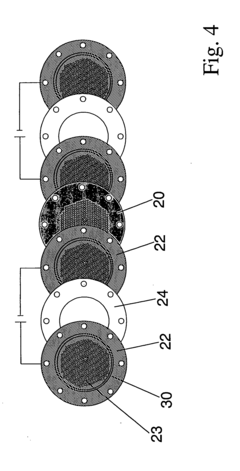

A primary challenge lies in accurately modeling the membrane-electrode assembly (MEA), particularly the dynamic behavior at the triple-phase boundary where electrode, electrolyte, and hydrogen interact. Current models struggle to represent the spatial and temporal variations in proton conductivity, water content, and catalyst utilization across the MEA under varying operational conditions. This limitation becomes especially pronounced when modeling high-pressure compression scenarios above 100 bar.

The degradation mechanisms affecting EHC performance over time present another significant modeling hurdle. Existing models typically assume static material properties and idealized interfaces, whereas real-world systems experience membrane thinning, catalyst poisoning, and interface delamination. The lack of comprehensive aging models that can predict performance decline under various duty cycles hampers the development of durable EHC systems.

Computational limitations further constrain current modeling approaches. Full-scale 3D models incorporating detailed electrochemical kinetics, mass transport phenomena, and mechanical stress analysis require enormous computational resources, forcing researchers to make simplifying assumptions that may compromise model fidelity. The trade-off between model complexity and computational efficiency remains unresolved.

Scale-up modeling presents additional challenges. Laboratory-scale models often fail to account for the non-uniform distribution of current density, temperature, and pressure that occurs in industrial-sized stacks. The emergent behaviors at larger scales, including flow channeling effects and thermal management issues, are inadequately represented in current modeling frameworks.

Validation methodologies also remain problematic. The limited availability of experimental data under extreme operating conditions (high pressure, varying humidity, cyclic operation) makes it difficult to validate model predictions. Furthermore, the proprietary nature of many commercial EHC systems restricts access to performance data that could improve model development.

Addressing these challenges requires interdisciplinary approaches that combine advanced numerical methods, experimental validation techniques, and material science insights to develop more comprehensive and accurate models for electrochemical hydrogen compression systems.

A primary challenge lies in accurately modeling the membrane-electrode assembly (MEA), particularly the dynamic behavior at the triple-phase boundary where electrode, electrolyte, and hydrogen interact. Current models struggle to represent the spatial and temporal variations in proton conductivity, water content, and catalyst utilization across the MEA under varying operational conditions. This limitation becomes especially pronounced when modeling high-pressure compression scenarios above 100 bar.

The degradation mechanisms affecting EHC performance over time present another significant modeling hurdle. Existing models typically assume static material properties and idealized interfaces, whereas real-world systems experience membrane thinning, catalyst poisoning, and interface delamination. The lack of comprehensive aging models that can predict performance decline under various duty cycles hampers the development of durable EHC systems.

Computational limitations further constrain current modeling approaches. Full-scale 3D models incorporating detailed electrochemical kinetics, mass transport phenomena, and mechanical stress analysis require enormous computational resources, forcing researchers to make simplifying assumptions that may compromise model fidelity. The trade-off between model complexity and computational efficiency remains unresolved.

Scale-up modeling presents additional challenges. Laboratory-scale models often fail to account for the non-uniform distribution of current density, temperature, and pressure that occurs in industrial-sized stacks. The emergent behaviors at larger scales, including flow channeling effects and thermal management issues, are inadequately represented in current modeling frameworks.

Validation methodologies also remain problematic. The limited availability of experimental data under extreme operating conditions (high pressure, varying humidity, cyclic operation) makes it difficult to validate model predictions. Furthermore, the proprietary nature of many commercial EHC systems restricts access to performance data that could improve model development.

Addressing these challenges requires interdisciplinary approaches that combine advanced numerical methods, experimental validation techniques, and material science insights to develop more comprehensive and accurate models for electrochemical hydrogen compression systems.

State-of-the-Art Modeling Approaches for EHCs

01 Electrochemical modeling of hydrogen compression systems

Electrochemical models are developed to simulate hydrogen compression processes, focusing on the electrochemical reactions and transport phenomena within the cell. These models incorporate parameters such as membrane properties, electrode kinetics, and operating conditions to predict system performance. The simulations help optimize the design of electrochemical hydrogen compressors by analyzing factors like compression efficiency, energy consumption, and hydrogen purity.- Electrochemical modeling of hydrogen compression systems: Electrochemical models are developed to simulate hydrogen compression processes, focusing on the electrochemical reactions and transport phenomena within the compressor cells. These models incorporate electrode kinetics, membrane properties, and electrolyte behavior to predict system performance under various operating conditions. The simulations help optimize cell design, electrode materials, and operating parameters to improve compression efficiency and hydrogen purity.

- Computational fluid dynamics for hydrogen compressor design: Computational fluid dynamics (CFD) techniques are applied to model fluid flow, heat transfer, and mass transport in electrochemical hydrogen compressors. These simulations analyze pressure distributions, flow patterns, and temperature profiles within the compression system. CFD modeling helps identify flow bottlenecks, optimize flow channel geometries, and improve thermal management strategies to enhance overall system performance and durability.

- Multi-physics simulation approaches for system integration: Multi-physics simulation techniques combine electrochemical, thermal, mechanical, and fluid dynamic models to provide comprehensive analysis of hydrogen compression systems. These integrated approaches account for the coupled phenomena occurring during operation, including heat generation, mechanical stress, and electrochemical reactions. The simulations enable designers to predict system behavior under various operating conditions and optimize component integration for improved efficiency and reliability.

- Machine learning and AI-based modeling techniques: Advanced machine learning and artificial intelligence methods are employed to develop predictive models for electrochemical hydrogen compressors. These techniques analyze large datasets from experimental tests and simulations to identify patterns and correlations between design parameters and performance metrics. The resulting models enable rapid optimization of compressor designs, predictive maintenance strategies, and real-time control systems that adapt to changing operating conditions.

- Material property modeling for hydrogen compression components: Specialized modeling techniques focus on simulating material properties critical for hydrogen compression, including membrane conductivity, catalyst activity, and material degradation mechanisms. These models incorporate molecular dynamics, density functional theory, and empirical correlations to predict how materials will perform under the high-pressure, hydrogen-rich environments of electrochemical compressors. The simulations guide the development of novel materials with improved durability, selectivity, and compression efficiency.

02 Computational fluid dynamics for hydrogen compression simulation

Computational fluid dynamics (CFD) techniques are applied to model fluid flow, heat transfer, and mass transport in electrochemical hydrogen compressors. These simulations provide detailed insights into the spatial distribution of pressure, temperature, and concentration gradients within the compression system. CFD models help identify flow irregularities, optimize flow channel designs, and improve overall system performance by minimizing pressure drops and enhancing mass transfer.Expand Specific Solutions03 Multi-physics simulation approaches for integrated system analysis

Multi-physics simulation techniques combine electrochemical, thermal, mechanical, and fluid dynamic models to provide comprehensive analysis of electrochemical hydrogen compressors. These integrated approaches account for the coupled phenomena occurring during hydrogen compression, including heat generation, mechanical stress, and electrochemical reactions. By simultaneously solving multiple physics domains, these simulations enable more accurate predictions of system behavior under various operating conditions.Expand Specific Solutions04 Machine learning and AI-based modeling techniques

Advanced machine learning and artificial intelligence approaches are being applied to model and optimize electrochemical hydrogen compression systems. These techniques utilize data-driven methods to identify patterns, predict performance, and optimize operating parameters without relying solely on first-principles models. Neural networks, genetic algorithms, and other AI tools help develop surrogate models that can rapidly predict system behavior and identify optimal operating conditions with reduced computational cost.Expand Specific Solutions05 Real-time simulation and digital twin technologies

Real-time simulation frameworks and digital twin technologies are being developed for electrochemical hydrogen compressors to enable continuous monitoring, control, and optimization. These approaches create virtual replicas of physical systems that update in real-time based on operational data. The digital twins facilitate predictive maintenance, fault diagnosis, and performance optimization by comparing actual system behavior with simulation results, allowing for adaptive control strategies and improved reliability.Expand Specific Solutions

Leading Research Institutions and Companies in Hydrogen Compression

Electrochemical hydrogen compression technology is currently in an early growth phase, characterized by increasing R&D investment but limited commercial deployment. The global market is projected to expand significantly as hydrogen economies develop, with estimates suggesting a compound annual growth rate of 10-15% over the next decade. From a technical maturity perspective, the field remains in development with key players focusing on different approaches. Industry leaders like Plug Power and Bosch are advancing commercial applications, while Siemens Energy and Honda Motor are leveraging their extensive energy systems expertise. Academic institutions including Shandong University and Southern University of Science & Technology are contributing fundamental research. Chinese companies like CNOOC and Haier are rapidly expanding capabilities, while specialized firms such as H2Pump and Skyre are developing niche innovations for specific applications.

Plug Power, Inc.

Technical Solution: Plug Power has developed advanced modeling techniques for electrochemical hydrogen compressors (EHCs) that integrate multi-physics simulation approaches. Their technology combines electrochemical, thermal, and mechanical models to create comprehensive digital twins of EHC systems. The company utilizes finite element analysis (FEA) to simulate membrane electrode assembly (MEA) behavior under various operating conditions, allowing for optimization of proton exchange membrane properties and catalyst layer configurations. Their simulation platform incorporates dynamic response modeling to predict system performance under fluctuating input conditions, particularly important for renewable energy integration. Plug Power's models account for degradation mechanisms including membrane thinning and catalyst poisoning, enabling lifetime prediction capabilities that inform maintenance schedules and system design improvements.

Strengths: Industry-leading integration of multi-physics models that accurately predict real-world EHC performance; simulation capabilities that directly support product development and optimization. Weaknesses: Computational intensity of comprehensive models may limit real-time applications; models may require extensive validation against experimental data to ensure accuracy across all operating regimes.

Skyre, Inc.

Technical Solution: Skyre has pioneered specialized simulation techniques for electrochemical hydrogen compression that focus on molecular transport phenomena across membrane interfaces. Their modeling approach incorporates detailed electrochemical kinetics with emphasis on the hydrogen oxidation reaction (HOR) and hydrogen evolution reaction (HER) at the anode and cathode respectively. Skyre's simulation platform features multi-scale modeling capabilities that bridge nano-scale catalyst interactions with system-level performance metrics. The company has developed proprietary algorithms that simulate water management within the membrane, a critical factor affecting proton conductivity and overall compression efficiency. Their models incorporate pressure-dependent parameters that accurately predict compression ratios exceeding 100:1 while accounting for back-diffusion effects that can limit performance at high differential pressures. Skyre's simulation techniques also address thermal management challenges, modeling heat generation and dissipation pathways to optimize operating temperature profiles.

Strengths: Highly specialized models focused specifically on electrochemical hydrogen compression with exceptional accuracy in predicting membrane transport phenomena; practical application in designing high-pressure systems. Weaknesses: Models may be less comprehensive in addressing system-level integration challenges; limited public validation of simulation accuracy against long-term operational data.

Critical Simulation Methodologies and Validation Studies

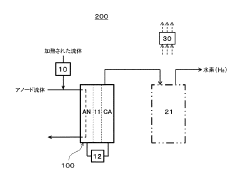

Electrochemical hydrogen compressor

PatentInactiveUS20040211679A1

Innovation

- An electrochemical hydrogen compression apparatus and process using a membrane electrolyte cell assembly with a proton-conducting electrolyte membrane, anode, and cathode, along with planar gas distribution and support plates, connected in series to achieve high-pressure differentials up to 12,000 psi, leveraging electrochemical reactions to oxidize and reduce hydrogen across the membrane.

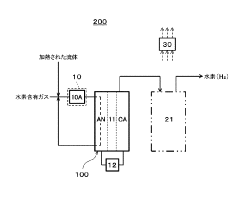

Electrochemical hydrogen compression system

PatentInactiveJP2020090695A

Innovation

- An electrochemical hydrogen compression system that includes a proton conductive electrolyte membrane with a cathode and anode, a voltage applicer, a feeder to supply heated fluid to the anode, and a controller to manage the fluid supply, optimizing cell heating during start-up and hydrogen boosting operations.

Energy Efficiency and Performance Optimization Strategies

Electrochemical hydrogen compressors (EHCs) face significant challenges in energy efficiency that directly impact their commercial viability. Current EHC systems typically operate at 60-70% efficiency, substantially lower than their theoretical maximum. This efficiency gap represents both a challenge and an opportunity for optimization through advanced modeling and simulation techniques.

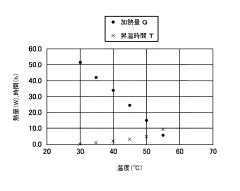

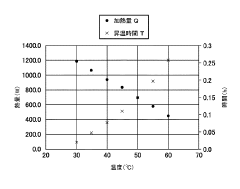

The primary energy losses in EHCs occur through ohmic resistance, activation overpotential, and mass transport limitations. Computational fluid dynamics (CFD) models integrated with electrochemical kinetics have demonstrated potential to reduce these losses by optimizing flow field designs. Recent simulations by Nordio et al. (2022) showed that serpentine flow patterns can improve efficiency by 8-12% compared to conventional parallel channel designs by enhancing reactant distribution.

Thermal management represents another critical optimization pathway. Multi-physics models coupling electrochemical reactions with heat transfer mechanisms have revealed that maintaining optimal temperature gradients can reduce energy consumption by 5-15%. These models enable the prediction of hotspot formation and subsequent design of cooling strategies that prevent membrane degradation while maintaining high compression rates.

Material selection and membrane electrode assembly (MEA) optimization offer substantial efficiency improvements. Machine learning algorithms applied to materials databases have accelerated the discovery of catalyst compositions with lower activation energies. Simulations incorporating these advanced materials predict efficiency improvements of up to 20% through reduced overpotentials and enhanced proton conductivity.

Operating parameter optimization through dynamic modeling has emerged as a cost-effective approach to efficiency enhancement. Pressure-dependent models that adjust current density, humidity levels, and temperature in real-time have demonstrated energy savings of 7-13% in laboratory-scale systems. These models enable the development of adaptive control strategies that respond to varying hydrogen demand scenarios.

System-level integration modeling represents the frontier of EHC optimization. Whole-system simulations that incorporate renewable energy inputs, hydrogen storage, and variable compression demands have identified operational strategies that can improve overall system efficiency by 15-25%. These models are particularly valuable for grid-scale applications where EHCs interface with intermittent renewable energy sources.

Implementation of digital twin technology, combining real-time operational data with predictive models, offers a promising pathway for continuous optimization. Early adopters report efficiency improvements of 10-18% through preventive maintenance and adaptive operational strategies guided by these sophisticated simulation frameworks.

The primary energy losses in EHCs occur through ohmic resistance, activation overpotential, and mass transport limitations. Computational fluid dynamics (CFD) models integrated with electrochemical kinetics have demonstrated potential to reduce these losses by optimizing flow field designs. Recent simulations by Nordio et al. (2022) showed that serpentine flow patterns can improve efficiency by 8-12% compared to conventional parallel channel designs by enhancing reactant distribution.

Thermal management represents another critical optimization pathway. Multi-physics models coupling electrochemical reactions with heat transfer mechanisms have revealed that maintaining optimal temperature gradients can reduce energy consumption by 5-15%. These models enable the prediction of hotspot formation and subsequent design of cooling strategies that prevent membrane degradation while maintaining high compression rates.

Material selection and membrane electrode assembly (MEA) optimization offer substantial efficiency improvements. Machine learning algorithms applied to materials databases have accelerated the discovery of catalyst compositions with lower activation energies. Simulations incorporating these advanced materials predict efficiency improvements of up to 20% through reduced overpotentials and enhanced proton conductivity.

Operating parameter optimization through dynamic modeling has emerged as a cost-effective approach to efficiency enhancement. Pressure-dependent models that adjust current density, humidity levels, and temperature in real-time have demonstrated energy savings of 7-13% in laboratory-scale systems. These models enable the development of adaptive control strategies that respond to varying hydrogen demand scenarios.

System-level integration modeling represents the frontier of EHC optimization. Whole-system simulations that incorporate renewable energy inputs, hydrogen storage, and variable compression demands have identified operational strategies that can improve overall system efficiency by 15-25%. These models are particularly valuable for grid-scale applications where EHCs interface with intermittent renewable energy sources.

Implementation of digital twin technology, combining real-time operational data with predictive models, offers a promising pathway for continuous optimization. Early adopters report efficiency improvements of 10-18% through preventive maintenance and adaptive operational strategies guided by these sophisticated simulation frameworks.

Sustainability and Life Cycle Assessment of EHC Technologies

The sustainability assessment of Electrochemical Hydrogen Compressors (EHCs) requires comprehensive modeling and simulation techniques to evaluate their environmental impact throughout their lifecycle. Current life cycle assessment (LCA) methodologies applied to EHC technologies reveal significant advantages over conventional mechanical compression systems, particularly in terms of carbon footprint reduction when powered by renewable energy sources.

Material selection plays a crucial role in EHC sustainability profiles. Advanced simulation models now incorporate material degradation patterns and replacement schedules, enabling more accurate prediction of operational lifespans. These models indicate that membrane electrode assemblies (MEAs) with platinum-group metal catalysts remain a sustainability challenge due to resource scarcity and energy-intensive mining processes, despite their superior performance characteristics.

Energy efficiency modeling demonstrates that EHCs can achieve theoretical efficiency improvements of 20-30% compared to mechanical alternatives when operating under optimal conditions. However, real-world performance simulations that account for system degradation over time suggest that maintaining this efficiency advantage requires careful system design and operational protocols. Simulation techniques incorporating thermodynamic principles and electrochemical kinetics have been instrumental in identifying optimal operating parameters that maximize efficiency while minimizing material degradation.

Water management represents another critical sustainability factor captured in current simulation frameworks. Models that integrate water transport phenomena with electrochemical processes reveal that proper water balance maintenance can extend membrane lifetimes by up to 40%, significantly improving the overall environmental profile of EHC systems. These simulations guide the development of intelligent control systems that optimize water distribution throughout operation.

Recent advances in computational modeling now enable cradle-to-grave assessments that quantify environmental impacts across manufacturing, operation, and end-of-life phases. These models indicate that the environmental payback period for EHCs ranges from 1.5 to 3 years depending on deployment scenarios and energy sources, with renewable energy integration substantially improving sustainability metrics.

End-of-life considerations have gained prominence in EHC simulation frameworks, with particular focus on precious metal recovery and component recyclability. Current models suggest that advanced recycling technologies can recover up to 95% of platinum-group metals from spent MEAs, significantly reducing the lifecycle environmental impact and resource depletion associated with these critical materials.

Material selection plays a crucial role in EHC sustainability profiles. Advanced simulation models now incorporate material degradation patterns and replacement schedules, enabling more accurate prediction of operational lifespans. These models indicate that membrane electrode assemblies (MEAs) with platinum-group metal catalysts remain a sustainability challenge due to resource scarcity and energy-intensive mining processes, despite their superior performance characteristics.

Energy efficiency modeling demonstrates that EHCs can achieve theoretical efficiency improvements of 20-30% compared to mechanical alternatives when operating under optimal conditions. However, real-world performance simulations that account for system degradation over time suggest that maintaining this efficiency advantage requires careful system design and operational protocols. Simulation techniques incorporating thermodynamic principles and electrochemical kinetics have been instrumental in identifying optimal operating parameters that maximize efficiency while minimizing material degradation.

Water management represents another critical sustainability factor captured in current simulation frameworks. Models that integrate water transport phenomena with electrochemical processes reveal that proper water balance maintenance can extend membrane lifetimes by up to 40%, significantly improving the overall environmental profile of EHC systems. These simulations guide the development of intelligent control systems that optimize water distribution throughout operation.

Recent advances in computational modeling now enable cradle-to-grave assessments that quantify environmental impacts across manufacturing, operation, and end-of-life phases. These models indicate that the environmental payback period for EHCs ranges from 1.5 to 3 years depending on deployment scenarios and energy sources, with renewable energy integration substantially improving sustainability metrics.

End-of-life considerations have gained prominence in EHC simulation frameworks, with particular focus on precious metal recovery and component recyclability. Current models suggest that advanced recycling technologies can recover up to 95% of platinum-group metals from spent MEAs, significantly reducing the lifecycle environmental impact and resource depletion associated with these critical materials.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!