Optimizing Energy Efficiency In Electrochemical Hydrogen Compression Systems

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Compression Technology Background and Objectives

Hydrogen compression technology has evolved significantly over the past century, transitioning from conventional mechanical methods to more advanced electrochemical approaches. Traditional compression techniques, including mechanical, hydraulic, and thermal compression, have dominated the hydrogen industry since its inception. However, these conventional methods often suffer from low efficiency, high maintenance requirements, and significant energy losses during operation, particularly when high compression ratios are needed for hydrogen storage and transportation.

Electrochemical hydrogen compression (EHC) emerged in the late 20th century as a promising alternative, offering theoretical advantages in energy efficiency and operational simplicity. The technology leverages principles similar to those in proton exchange membrane (PEM) fuel cells, where hydrogen is compressed through electrochemical potential rather than mechanical force. This approach eliminates many moving parts associated with traditional compressors, potentially reducing maintenance needs and increasing system reliability.

The global push toward hydrogen as a clean energy carrier has accelerated research and development in compression technologies. With hydrogen increasingly viewed as a critical component of decarbonization strategies across transportation, industrial, and energy sectors, the demand for efficient compression systems has grown exponentially. The International Energy Agency (IEA) projects that hydrogen could meet up to 24% of global energy demand by 2050, highlighting the urgent need for technological advancement in this field.

Current EHC systems demonstrate theoretical efficiency advantages but face practical challenges in scaling and real-world implementation. Energy losses during the electrochemical process, membrane degradation, and system integration issues remain significant barriers to widespread adoption. Research indicates that commercial EHC systems typically operate at 50-60% efficiency, falling short of their theoretical potential of 70-80%.

The primary objective of optimizing energy efficiency in electrochemical hydrogen compression systems is to close this gap between theoretical and practical efficiency. Specific goals include reducing parasitic energy losses, enhancing membrane durability, improving electrode performance, and developing advanced system control strategies. Additionally, there is a focus on reducing capital costs, which currently exceed those of conventional compression technologies by approximately 30-40%.

The technology trajectory suggests a convergence of electrochemical principles with advanced materials science and system engineering approaches. Recent breakthroughs in nanomaterials, catalyst design, and membrane technology offer promising pathways for efficiency improvements. The ultimate aim is to develop EHC systems that deliver compression ratios exceeding 700:1 with energy efficiencies above 70%, making hydrogen a more economically viable energy carrier across diverse applications.

Electrochemical hydrogen compression (EHC) emerged in the late 20th century as a promising alternative, offering theoretical advantages in energy efficiency and operational simplicity. The technology leverages principles similar to those in proton exchange membrane (PEM) fuel cells, where hydrogen is compressed through electrochemical potential rather than mechanical force. This approach eliminates many moving parts associated with traditional compressors, potentially reducing maintenance needs and increasing system reliability.

The global push toward hydrogen as a clean energy carrier has accelerated research and development in compression technologies. With hydrogen increasingly viewed as a critical component of decarbonization strategies across transportation, industrial, and energy sectors, the demand for efficient compression systems has grown exponentially. The International Energy Agency (IEA) projects that hydrogen could meet up to 24% of global energy demand by 2050, highlighting the urgent need for technological advancement in this field.

Current EHC systems demonstrate theoretical efficiency advantages but face practical challenges in scaling and real-world implementation. Energy losses during the electrochemical process, membrane degradation, and system integration issues remain significant barriers to widespread adoption. Research indicates that commercial EHC systems typically operate at 50-60% efficiency, falling short of their theoretical potential of 70-80%.

The primary objective of optimizing energy efficiency in electrochemical hydrogen compression systems is to close this gap between theoretical and practical efficiency. Specific goals include reducing parasitic energy losses, enhancing membrane durability, improving electrode performance, and developing advanced system control strategies. Additionally, there is a focus on reducing capital costs, which currently exceed those of conventional compression technologies by approximately 30-40%.

The technology trajectory suggests a convergence of electrochemical principles with advanced materials science and system engineering approaches. Recent breakthroughs in nanomaterials, catalyst design, and membrane technology offer promising pathways for efficiency improvements. The ultimate aim is to develop EHC systems that deliver compression ratios exceeding 700:1 with energy efficiencies above 70%, making hydrogen a more economically viable energy carrier across diverse applications.

Market Analysis for Electrochemical Hydrogen Compression

The global market for electrochemical hydrogen compression (EHC) systems is experiencing significant growth, driven primarily by the expanding hydrogen economy and increasing focus on clean energy solutions. Current market valuations indicate that the EHC segment represents approximately 15% of the overall hydrogen compression market, which was valued at $2.1 billion in 2022 and is projected to reach $3.8 billion by 2028, reflecting a compound annual growth rate (CAGR) of 9.8%.

The demand for EHC technology is particularly strong in regions with advanced hydrogen infrastructure development, including Europe, North America, and parts of Asia. Germany, Japan, and South Korea have emerged as leading markets due to their substantial investments in hydrogen energy systems and favorable regulatory frameworks supporting clean energy transitions.

Market segmentation reveals that industrial applications currently dominate the EHC market, accounting for roughly 60% of total demand. This includes applications in chemical processing, refining, and metallurgy. The transportation sector represents the fastest-growing segment, with a projected CAGR of 14.2% through 2028, driven by the increasing adoption of hydrogen fuel cell vehicles and the need for efficient hydrogen refueling infrastructure.

Customer requirements are evolving rapidly, with end-users increasingly prioritizing energy efficiency, operational reliability, and total cost of ownership over initial capital expenditure. Market surveys indicate that customers are willing to pay a premium of up to 25% for EHC systems that demonstrate superior energy efficiency metrics compared to conventional mechanical compression technologies.

Competitive analysis reveals a market structure characterized by a mix of established industrial gas companies and specialized technology startups. Major players include Hydrogenics (Cummins), Nel Hydrogen, and ITM Power, collectively holding approximately 65% market share. Emerging competitors like Enapter and Plug Power are gaining traction through innovative product offerings and strategic partnerships.

Market barriers include high initial capital costs, limited awareness of EHC benefits among potential end-users, and competition from established mechanical compression technologies. However, these barriers are gradually diminishing as technology advances and economies of scale improve cost structures.

Future market projections indicate that the EHC market will experience accelerated growth between 2025-2030, with an expected CAGR of 12.5%, outpacing the broader hydrogen compression market. This growth will be fueled by increasing hydrogen adoption across multiple sectors, technological improvements in EHC systems, and supportive government policies aimed at decarbonization.

The demand for EHC technology is particularly strong in regions with advanced hydrogen infrastructure development, including Europe, North America, and parts of Asia. Germany, Japan, and South Korea have emerged as leading markets due to their substantial investments in hydrogen energy systems and favorable regulatory frameworks supporting clean energy transitions.

Market segmentation reveals that industrial applications currently dominate the EHC market, accounting for roughly 60% of total demand. This includes applications in chemical processing, refining, and metallurgy. The transportation sector represents the fastest-growing segment, with a projected CAGR of 14.2% through 2028, driven by the increasing adoption of hydrogen fuel cell vehicles and the need for efficient hydrogen refueling infrastructure.

Customer requirements are evolving rapidly, with end-users increasingly prioritizing energy efficiency, operational reliability, and total cost of ownership over initial capital expenditure. Market surveys indicate that customers are willing to pay a premium of up to 25% for EHC systems that demonstrate superior energy efficiency metrics compared to conventional mechanical compression technologies.

Competitive analysis reveals a market structure characterized by a mix of established industrial gas companies and specialized technology startups. Major players include Hydrogenics (Cummins), Nel Hydrogen, and ITM Power, collectively holding approximately 65% market share. Emerging competitors like Enapter and Plug Power are gaining traction through innovative product offerings and strategic partnerships.

Market barriers include high initial capital costs, limited awareness of EHC benefits among potential end-users, and competition from established mechanical compression technologies. However, these barriers are gradually diminishing as technology advances and economies of scale improve cost structures.

Future market projections indicate that the EHC market will experience accelerated growth between 2025-2030, with an expected CAGR of 12.5%, outpacing the broader hydrogen compression market. This growth will be fueled by increasing hydrogen adoption across multiple sectors, technological improvements in EHC systems, and supportive government policies aimed at decarbonization.

Current Status and Technical Challenges in EHC Systems

Electrochemical hydrogen compression (EHC) technology has gained significant attention as a promising alternative to mechanical compression methods. Currently, EHC systems operate with energy efficiencies ranging from 60-85%, depending on system design, operating conditions, and compression ratios. Leading research institutions such as the National Renewable Energy Laboratory (NREL) and commercial entities like HyET Hydrogen have demonstrated functional EHC systems capable of achieving pressures up to 700 bar, suitable for hydrogen refueling stations and storage applications.

The state-of-the-art EHC systems utilize proton exchange membranes (PEM), typically Nafion-based, with platinum-based catalysts. Recent advancements have focused on improving membrane electrode assembly (MEA) designs to enhance proton conductivity while minimizing electrical resistance. Notable progress has been made in developing composite membranes that exhibit superior mechanical stability under high-pressure differentials.

Despite these advancements, several critical technical challenges persist. The primary limitation is energy efficiency degradation at higher compression ratios, where increased electrical resistance and back-diffusion of hydrogen molecules significantly impact system performance. Current systems experience efficiency losses of approximately 10-15% when operating at compression ratios above 500:1, presenting a substantial barrier to widespread commercial adoption.

Material degradation under high-pressure hydrogen environments remains another significant challenge. Membrane deformation and catalyst layer degradation occur during prolonged operation, leading to reduced system lifetimes typically limited to 5,000-10,000 hours—well below the 30,000+ hours required for commercial viability. This degradation is exacerbated by pressure cycling and temperature fluctuations common in real-world applications.

Water management presents a complex challenge in EHC systems. Insufficient hydration reduces proton conductivity, while excessive water accumulation can lead to flooding and increased mass transport limitations. Current water management strategies rely primarily on passive approaches, which lack the precision required for optimized operation across varying compression ratios and operating conditions.

Geographically, EHC technology development is concentrated in North America, Europe, and Japan, with emerging research clusters in South Korea and China. The United States leads in fundamental research through national laboratories and university partnerships, while European companies have made significant progress in system integration and demonstration projects. Japanese efforts have focused on miniaturization and efficiency improvements for mobile applications.

Cost remains a substantial barrier, with current EHC systems priced at approximately $1,000-1,500 per kW—significantly higher than the $500/kW target needed for commercial competitiveness with mechanical compression alternatives. The high costs are primarily attributed to expensive catalyst materials, specialized membrane formulations, and limited manufacturing scale.

The state-of-the-art EHC systems utilize proton exchange membranes (PEM), typically Nafion-based, with platinum-based catalysts. Recent advancements have focused on improving membrane electrode assembly (MEA) designs to enhance proton conductivity while minimizing electrical resistance. Notable progress has been made in developing composite membranes that exhibit superior mechanical stability under high-pressure differentials.

Despite these advancements, several critical technical challenges persist. The primary limitation is energy efficiency degradation at higher compression ratios, where increased electrical resistance and back-diffusion of hydrogen molecules significantly impact system performance. Current systems experience efficiency losses of approximately 10-15% when operating at compression ratios above 500:1, presenting a substantial barrier to widespread commercial adoption.

Material degradation under high-pressure hydrogen environments remains another significant challenge. Membrane deformation and catalyst layer degradation occur during prolonged operation, leading to reduced system lifetimes typically limited to 5,000-10,000 hours—well below the 30,000+ hours required for commercial viability. This degradation is exacerbated by pressure cycling and temperature fluctuations common in real-world applications.

Water management presents a complex challenge in EHC systems. Insufficient hydration reduces proton conductivity, while excessive water accumulation can lead to flooding and increased mass transport limitations. Current water management strategies rely primarily on passive approaches, which lack the precision required for optimized operation across varying compression ratios and operating conditions.

Geographically, EHC technology development is concentrated in North America, Europe, and Japan, with emerging research clusters in South Korea and China. The United States leads in fundamental research through national laboratories and university partnerships, while European companies have made significant progress in system integration and demonstration projects. Japanese efforts have focused on miniaturization and efficiency improvements for mobile applications.

Cost remains a substantial barrier, with current EHC systems priced at approximately $1,000-1,500 per kW—significantly higher than the $500/kW target needed for commercial competitiveness with mechanical compression alternatives. The high costs are primarily attributed to expensive catalyst materials, specialized membrane formulations, and limited manufacturing scale.

Current Energy Efficiency Solutions for EHC Systems

01 Electrochemical cell design for hydrogen compression

Electrochemical hydrogen compression systems can be designed with specialized cell architectures to improve energy efficiency. These designs include optimized electrode materials, membrane configurations, and cell stack arrangements that reduce electrical resistance and minimize energy losses during the compression process. Advanced cell designs can incorporate features that enhance proton conductivity while maintaining mechanical stability under high pressure differentials.- Electrochemical cell design for hydrogen compression: Specific electrochemical cell designs can significantly improve the energy efficiency of hydrogen compression systems. These designs focus on optimizing electrode materials, membrane configurations, and cell architecture to reduce electrical resistance and enhance proton conductivity. Advanced cell designs incorporate features that minimize energy losses during the compression process, resulting in higher overall system efficiency and reduced operational costs.

- Membrane electrode assembly optimization: Optimizing the membrane electrode assembly (MEA) is crucial for improving the energy efficiency of electrochemical hydrogen compression systems. This involves selecting appropriate proton exchange membranes with high conductivity and low gas crossover, developing catalyst layers with enhanced activity and stability, and optimizing the interface between components. Well-designed MEAs can operate at lower voltages while maintaining high compression rates, thereby increasing the overall energy efficiency of the system.

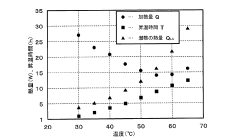

- Thermal management and heat recovery systems: Effective thermal management and heat recovery systems play a significant role in enhancing the energy efficiency of electrochemical hydrogen compression. These systems control operating temperatures to optimize electrochemical reactions while recovering waste heat for other processes. Integrated cooling systems prevent performance degradation due to overheating, and heat exchangers capture thermal energy that would otherwise be lost. Advanced thermal management approaches can significantly reduce the overall energy consumption of hydrogen compression systems.

- Control systems and operational strategies: Sophisticated control systems and operational strategies can substantially improve the energy efficiency of electrochemical hydrogen compression systems. These include adaptive control algorithms that optimize operating parameters based on real-time conditions, load management strategies that balance compression rates with energy consumption, and predictive maintenance approaches that prevent efficiency losses. Advanced control systems can adjust compression rates, current densities, and other parameters to maintain optimal efficiency across varying operating conditions.

- Integration with renewable energy sources: Integrating electrochemical hydrogen compression systems with renewable energy sources can significantly enhance overall system efficiency. These integrated systems can utilize excess renewable electricity for hydrogen compression during periods of high generation, enabling energy storage and later use. Smart grid integration allows for dynamic operation based on electricity availability and pricing. This approach not only improves energy efficiency but also reduces carbon emissions associated with hydrogen compression, making the entire hydrogen value chain more sustainable.

02 Membrane and catalyst optimization

The efficiency of electrochemical hydrogen compression systems heavily depends on the properties of the membranes and catalysts used. High-performance proton exchange membranes with enhanced conductivity and reduced gas crossover can significantly improve compression efficiency. Similarly, advanced catalyst materials with high activity and durability can lower the overpotential required for hydrogen oxidation and evolution reactions, thereby reducing energy consumption during the compression process.Expand Specific Solutions03 Thermal management and heat recovery systems

Effective thermal management is crucial for maintaining high energy efficiency in electrochemical hydrogen compression systems. Heat generated during compression can be recovered and utilized through integrated heat exchangers and thermal management systems. By controlling operating temperatures and implementing heat recovery strategies, these systems can minimize energy losses and improve overall efficiency. Advanced cooling techniques can prevent membrane degradation and maintain optimal operating conditions.Expand Specific Solutions04 System integration and control strategies

Integrated system designs and sophisticated control strategies can significantly enhance the energy efficiency of electrochemical hydrogen compression systems. By optimizing operating parameters such as current density, pressure differentials, and flow rates in real-time, these systems can adapt to varying conditions and maintain peak efficiency. Advanced control algorithms can balance performance metrics and energy consumption, while integration with renewable energy sources can further improve overall system efficiency.Expand Specific Solutions05 Novel materials and hybrid compression approaches

Emerging materials and hybrid compression approaches offer promising pathways to improve the energy efficiency of hydrogen compression systems. These include novel electrode materials, composite membranes, and combined electrochemical-mechanical compression techniques. By leveraging the advantages of different compression methods and incorporating advanced materials with enhanced properties, these hybrid systems can achieve higher compression ratios with lower energy input, leading to significant efficiency improvements.Expand Specific Solutions

Key Industry Players and Competitive Landscape

The electrochemical hydrogen compression (EHC) technology market is currently in its growth phase, with increasing adoption driven by the global hydrogen economy expansion. The market size is projected to reach approximately $300-400 million by 2027, growing at a CAGR of 6-8%. Technology maturity varies across players, with established automotive and energy companies leading development. Hyundai Motor, Kia, and Honda are leveraging their fuel cell expertise to optimize EHC systems, while specialized firms like GRZ Technologies, H2Pump, and Skyre are developing proprietary compression technologies. Research institutions including Tsinghua University and Xi'an Jiaotong University are advancing fundamental electrochemical principles. Industrial giants Panasonic, Bosch, and Toshiba are integrating EHC into broader energy management solutions, focusing on efficiency improvements through materials innovation and system integration.

GRZ Technologies SA

Technical Solution: GRZ Technologies has developed a hybrid approach to hydrogen compression that combines electrochemical compression with metal hydride storage technology. Their system utilizes a low-pressure electrochemical compression stage followed by a metal hydride-based thermal compression stage, creating a synergistic effect that reduces overall energy consumption. The electrochemical stage operates at optimized current densities (typically 0.3-0.5 A/cm²) to maximize efficiency, while the thermal stage leverages waste heat recovery. GRZ's proprietary electrode formulations incorporate reduced platinum group metal loadings (below 0.25 mg/cm²) while maintaining high catalytic activity. Their integrated system architecture includes advanced power electronics with adaptive control algorithms that dynamically adjust operating parameters based on demand and ambient conditions, achieving overall system efficiencies of 70-75% (compared to 55-60% for conventional EHC systems).

Strengths: Hybrid approach leverages advantages of both electrochemical and thermal compression; excellent energy efficiency metrics; reduced dependency on expensive catalyst materials; effective waste heat utilization. Weaknesses: More complex system architecture increases potential failure points; requires sophisticated control systems; metal hydride materials add weight and volume to the overall system.

Skyre, Inc.

Technical Solution: Skyre (formerly Sustainable Innovations) has developed an advanced electrochemical hydrogen compression technology called H2RENEW™. Their system utilizes a proprietary cell architecture that minimizes internal resistance and optimizes proton transport pathways. Skyre's technology incorporates specialized membrane electrode assemblies (MEAs) with gradient catalyst layers that distribute reaction sites optimally across the membrane interface. Their systems feature innovative bipolar plate designs with micro-channeled flow fields that enhance gas distribution while minimizing pressure drops. Skyre has implemented advanced power conditioning systems that deliver precisely controlled current profiles to the cell stack, reducing energy losses during operation. Their latest generation compressors achieve specific energy consumption of approximately 3.8-4.2 kWh/kg H2 when compressing from atmospheric pressure to 450 bar, with demonstrated durability exceeding 20,000 operating hours in field trials.

Strengths: Highly efficient cell architecture with minimized internal resistance; excellent durability metrics; compact system footprint compared to alternatives; sophisticated power management. Weaknesses: Higher manufacturing complexity increases production costs; requires specialized materials that may face supply chain constraints; performance degrades when processing hydrogen with impurities.

Critical Patents and Innovations in EHC Technology

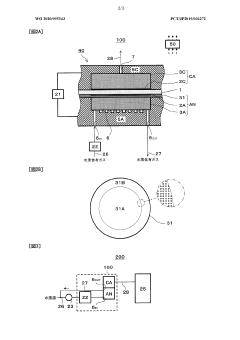

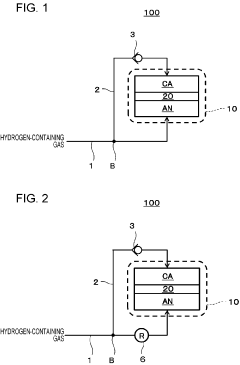

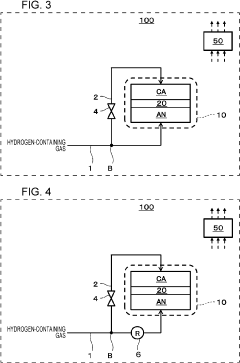

Electrochemical hydrogen compressing apparatus and method for operating electrochemical hydrogen compressing apparatus

PatentWO2020095543A1

Innovation

- The electrochemical hydrogen compression device incorporates a proton-conducting electrolyte membrane with a dew point regulator and controller to adjust the dew point of the hydrogen-containing gas, utilizing latent heat from water vapor condensation and IR loss to reduce energy consumption and maintain optimal operating conditions, thereby improving compression efficiency and preventing flooding.

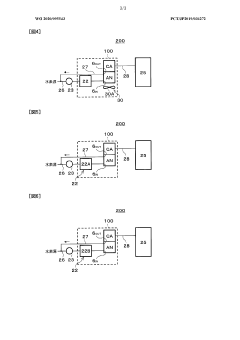

Hydrogen system and hydrogen system operating method

PatentPendingUS20230290969A1

Innovation

- A hydrogen system design that includes a compressor with a check valve or on/off valve in the flow channels to equalize anode and cathode gas pressures by automatically opening the valve when hydrogen is supplied, preventing damage and maintaining efficient compression operations.

Sustainability Impact and Environmental Benefits

Electrochemical hydrogen compression (EHC) systems represent a significant advancement in sustainable energy infrastructure, offering substantial environmental benefits compared to conventional mechanical compression technologies. The elimination of moving parts in EHC systems dramatically reduces the risk of hydrogen leakage, a critical factor considering hydrogen's potent greenhouse effect when released directly into the atmosphere. This inherent design advantage contributes to minimizing the overall environmental footprint of hydrogen as an energy carrier.

The sustainability impact of optimized EHC systems extends beyond operational efficiency to the entire hydrogen value chain. When powered by renewable electricity sources such as solar or wind, these systems enable truly carbon-neutral hydrogen compression, serving as a vital link in green hydrogen production pathways. This integration capability with intermittent renewable energy sources further enhances grid stability and promotes broader renewable energy adoption.

From a lifecycle perspective, EHC systems demonstrate superior environmental credentials. The absence of lubricating oils eliminates the risk of contamination and associated disposal challenges that plague mechanical compressors. Additionally, the reduced maintenance requirements translate to fewer replacement parts over the system lifetime, conserving resources and reducing waste generation. These factors collectively contribute to a significantly lower lifecycle carbon footprint.

Water management represents another critical environmental dimension of EHC technology. Advanced EHC systems incorporate water recovery mechanisms that minimize consumption and enable closed-loop operation in water-scarce regions. This feature is particularly valuable as hydrogen infrastructure expands globally, potentially reducing pressure on local water resources.

The noise pollution reduction achieved through EHC implementation delivers meaningful environmental and social benefits, particularly in urban or sensitive ecological settings. Unlike conventional compressors that generate significant acoustic emissions, EHC systems operate almost silently, enabling deployment in proximity to residential areas without creating noise disturbances.

Looking toward broader environmental impacts, optimized EHC systems facilitate higher hydrogen purity levels without additional purification steps, reducing the energy and resource burden of downstream processes. This capability proves especially valuable in applications demanding ultra-pure hydrogen, such as fuel cells for transportation or stationary power generation, where contaminants can significantly degrade performance and longevity.

The sustainability impact of optimized EHC systems extends beyond operational efficiency to the entire hydrogen value chain. When powered by renewable electricity sources such as solar or wind, these systems enable truly carbon-neutral hydrogen compression, serving as a vital link in green hydrogen production pathways. This integration capability with intermittent renewable energy sources further enhances grid stability and promotes broader renewable energy adoption.

From a lifecycle perspective, EHC systems demonstrate superior environmental credentials. The absence of lubricating oils eliminates the risk of contamination and associated disposal challenges that plague mechanical compressors. Additionally, the reduced maintenance requirements translate to fewer replacement parts over the system lifetime, conserving resources and reducing waste generation. These factors collectively contribute to a significantly lower lifecycle carbon footprint.

Water management represents another critical environmental dimension of EHC technology. Advanced EHC systems incorporate water recovery mechanisms that minimize consumption and enable closed-loop operation in water-scarce regions. This feature is particularly valuable as hydrogen infrastructure expands globally, potentially reducing pressure on local water resources.

The noise pollution reduction achieved through EHC implementation delivers meaningful environmental and social benefits, particularly in urban or sensitive ecological settings. Unlike conventional compressors that generate significant acoustic emissions, EHC systems operate almost silently, enabling deployment in proximity to residential areas without creating noise disturbances.

Looking toward broader environmental impacts, optimized EHC systems facilitate higher hydrogen purity levels without additional purification steps, reducing the energy and resource burden of downstream processes. This capability proves especially valuable in applications demanding ultra-pure hydrogen, such as fuel cells for transportation or stationary power generation, where contaminants can significantly degrade performance and longevity.

Economic Feasibility and Cost Analysis

The economic viability of electrochemical hydrogen compression (EHC) systems represents a critical factor in their widespread adoption. Current cost analyses indicate that EHC systems require significant initial capital investment, with estimates ranging from $1,500 to $3,000 per kW of installed capacity. This investment encompasses membrane electrode assemblies, bipolar plates, power electronics, and balance-of-plant components.

Operating costs present another substantial consideration, primarily dominated by electricity consumption. With EHC systems typically operating at 4-6 kWh per kilogram of hydrogen compressed, electricity costs can account for 60-70% of total operational expenses. Maintenance costs, while lower than mechanical compressors due to fewer moving parts, still require periodic replacement of membrane assemblies and electrode materials, estimated at 5-10% of capital costs annually.

Lifecycle economic assessments reveal promising trends for EHC technology. The levelized cost of hydrogen compression using EHC systems currently ranges from $0.50 to $1.20 per kilogram, depending on electricity prices, utilization rates, and compression ratios. This compares favorably with mechanical compression systems in certain applications, particularly at smaller scales and when renewable electricity is available at competitive rates.

Sensitivity analyses demonstrate that electricity prices significantly impact economic feasibility. A 10% reduction in electricity costs can improve operational economics by approximately 6-7%. Similarly, improvements in energy efficiency through advanced membrane materials could reduce compression costs by 15-20% over the next five years, enhancing the value proposition substantially.

Return on investment calculations indicate payback periods of 5-8 years for most industrial applications, with shorter periods possible in regions with favorable electricity pricing or carbon pricing mechanisms. Government incentives for clean hydrogen infrastructure further improve these economics, with potential to reduce payback periods by 1-3 years in supportive policy environments.

Market projections suggest that continued technological improvements and manufacturing scale economies could reduce capital costs by 40-50% by 2030, bringing EHC systems to cost parity with conventional compression technologies across most applications. This cost trajectory, coupled with the inherent advantages of EHC in terms of reliability and compatibility with renewable energy sources, positions the technology favorably for commercial expansion.

For widespread commercial viability, further cost reductions are necessary, particularly in membrane materials and catalyst loadings, which currently represent approximately 35-45% of system costs. Research indicates that novel manufacturing techniques and alternative catalyst formulations could potentially reduce these component costs by 30-40% in the medium term.

Operating costs present another substantial consideration, primarily dominated by electricity consumption. With EHC systems typically operating at 4-6 kWh per kilogram of hydrogen compressed, electricity costs can account for 60-70% of total operational expenses. Maintenance costs, while lower than mechanical compressors due to fewer moving parts, still require periodic replacement of membrane assemblies and electrode materials, estimated at 5-10% of capital costs annually.

Lifecycle economic assessments reveal promising trends for EHC technology. The levelized cost of hydrogen compression using EHC systems currently ranges from $0.50 to $1.20 per kilogram, depending on electricity prices, utilization rates, and compression ratios. This compares favorably with mechanical compression systems in certain applications, particularly at smaller scales and when renewable electricity is available at competitive rates.

Sensitivity analyses demonstrate that electricity prices significantly impact economic feasibility. A 10% reduction in electricity costs can improve operational economics by approximately 6-7%. Similarly, improvements in energy efficiency through advanced membrane materials could reduce compression costs by 15-20% over the next five years, enhancing the value proposition substantially.

Return on investment calculations indicate payback periods of 5-8 years for most industrial applications, with shorter periods possible in regions with favorable electricity pricing or carbon pricing mechanisms. Government incentives for clean hydrogen infrastructure further improve these economics, with potential to reduce payback periods by 1-3 years in supportive policy environments.

Market projections suggest that continued technological improvements and manufacturing scale economies could reduce capital costs by 40-50% by 2030, bringing EHC systems to cost parity with conventional compression technologies across most applications. This cost trajectory, coupled with the inherent advantages of EHC in terms of reliability and compatibility with renewable energy sources, positions the technology favorably for commercial expansion.

For widespread commercial viability, further cost reductions are necessary, particularly in membrane materials and catalyst loadings, which currently represent approximately 35-45% of system costs. Research indicates that novel manufacturing techniques and alternative catalyst formulations could potentially reduce these component costs by 30-40% in the medium term.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!