Control Strategies For Stable Operation Of Electrochemical Hydrogen Compressors

SEP 12, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

EHC Technology Background and Objectives

Electrochemical hydrogen compression (EHC) technology represents a significant advancement in hydrogen processing systems, offering a solid-state alternative to traditional mechanical compression methods. The evolution of this technology can be traced back to the early developments in proton exchange membrane (PEM) fuel cells in the 1960s, with the fundamental principles of electrochemical hydrogen compression being recognized shortly thereafter. Over the past two decades, EHC has gained substantial attention due to its potential to address the growing demands for efficient hydrogen handling in various applications.

The technological trajectory of EHC has been characterized by continuous improvements in membrane materials, catalyst formulations, and system integration approaches. Initially limited by low efficiency and durability concerns, modern EHC systems have achieved compression ratios exceeding 100:1 and demonstrated operational lifetimes suitable for commercial deployment. This progress has been driven by parallel advancements in PEM fuel cell technology, which shares many core materials and design principles with EHC systems.

Current research and development efforts in EHC technology are primarily focused on enhancing operational stability under varying conditions, improving energy efficiency, and extending system longevity. These objectives align with the broader hydrogen economy goals of reducing the total cost of hydrogen as an energy carrier and ensuring reliable performance across diverse applications, from refueling stations to industrial processes.

The technical objectives for stable operation control strategies of EHC systems encompass several critical dimensions. First, developing robust control algorithms capable of maintaining optimal performance despite fluctuations in input pressure, temperature, and hydrogen purity. Second, implementing effective water management techniques to prevent membrane dehydration or flooding, both of which can severely impact compression efficiency and system durability. Third, designing intelligent fault detection and mitigation systems to identify potential failure modes before they compromise system integrity.

Additionally, there is a growing emphasis on creating adaptive control systems that can optimize EHC operation in real-time based on changing external conditions and performance parameters. These systems aim to maximize efficiency while minimizing degradation mechanisms that affect long-term stability. The ultimate goal is to develop control strategies that enable EHC technology to operate reliably in diverse environments with minimal maintenance requirements, thereby facilitating broader adoption across various hydrogen infrastructure applications.

As hydrogen continues to gain prominence in the global energy transition, the development of sophisticated control strategies for EHC systems represents a critical enabling technology that will help unlock the full potential of hydrogen as a clean energy carrier.

The technological trajectory of EHC has been characterized by continuous improvements in membrane materials, catalyst formulations, and system integration approaches. Initially limited by low efficiency and durability concerns, modern EHC systems have achieved compression ratios exceeding 100:1 and demonstrated operational lifetimes suitable for commercial deployment. This progress has been driven by parallel advancements in PEM fuel cell technology, which shares many core materials and design principles with EHC systems.

Current research and development efforts in EHC technology are primarily focused on enhancing operational stability under varying conditions, improving energy efficiency, and extending system longevity. These objectives align with the broader hydrogen economy goals of reducing the total cost of hydrogen as an energy carrier and ensuring reliable performance across diverse applications, from refueling stations to industrial processes.

The technical objectives for stable operation control strategies of EHC systems encompass several critical dimensions. First, developing robust control algorithms capable of maintaining optimal performance despite fluctuations in input pressure, temperature, and hydrogen purity. Second, implementing effective water management techniques to prevent membrane dehydration or flooding, both of which can severely impact compression efficiency and system durability. Third, designing intelligent fault detection and mitigation systems to identify potential failure modes before they compromise system integrity.

Additionally, there is a growing emphasis on creating adaptive control systems that can optimize EHC operation in real-time based on changing external conditions and performance parameters. These systems aim to maximize efficiency while minimizing degradation mechanisms that affect long-term stability. The ultimate goal is to develop control strategies that enable EHC technology to operate reliably in diverse environments with minimal maintenance requirements, thereby facilitating broader adoption across various hydrogen infrastructure applications.

As hydrogen continues to gain prominence in the global energy transition, the development of sophisticated control strategies for EHC systems represents a critical enabling technology that will help unlock the full potential of hydrogen as a clean energy carrier.

Hydrogen Market Demand Analysis

The global hydrogen market is experiencing unprecedented growth, driven by the increasing focus on decarbonization and clean energy transition. Current estimates value the global hydrogen market at approximately 150 billion USD, with projections indicating potential growth to 600 billion USD by 2050. This substantial market expansion underscores the critical importance of efficient hydrogen compression technologies, particularly Electrochemical Hydrogen Compressors (EHCs).

Industrial applications represent the largest segment of hydrogen demand, accounting for roughly 70% of current consumption. Traditional sectors such as ammonia production, petroleum refining, and methanol synthesis continue to dominate industrial hydrogen usage. However, emerging applications in steel manufacturing, where hydrogen serves as a reducing agent replacing coal, are rapidly gaining traction as industries seek to reduce carbon emissions.

The transportation sector presents perhaps the most dynamic growth opportunity for hydrogen demand. Fuel cell electric vehicles (FCEVs) are increasingly being adopted for heavy-duty transport applications where battery electric solutions face limitations. Commercial deployment of hydrogen-powered trucks, buses, and trains is accelerating across Europe, Asia, and North America, with annual growth rates exceeding 30% in some regions.

Energy storage applications represent another significant market driver for hydrogen technologies. As renewable energy penetration increases, the need for long-duration energy storage solutions becomes critical. Hydrogen produced through electrolysis during periods of excess renewable generation can be compressed, stored, and later reconverted to electricity, providing a versatile solution for grid balancing and seasonal storage needs.

Regional analysis reveals distinct market characteristics. Europe leads in policy support for hydrogen adoption, with ambitious targets for green hydrogen production capacity. Asia, particularly China, Japan, and South Korea, demonstrates strong commercial deployment of hydrogen technologies across multiple sectors. North America shows increasing investment in hydrogen infrastructure, though somewhat behind the European and Asian markets.

The demand for efficient compression technologies directly correlates with these market trends. EHCs offer significant advantages over mechanical compressors in terms of efficiency, reliability, and scalability. However, their widespread adoption depends on addressing operational stability challenges through advanced control strategies. Market research indicates that improvements in EHC control systems could reduce operational costs by 15-20%, significantly enhancing their commercial viability across various applications.

Industrial applications represent the largest segment of hydrogen demand, accounting for roughly 70% of current consumption. Traditional sectors such as ammonia production, petroleum refining, and methanol synthesis continue to dominate industrial hydrogen usage. However, emerging applications in steel manufacturing, where hydrogen serves as a reducing agent replacing coal, are rapidly gaining traction as industries seek to reduce carbon emissions.

The transportation sector presents perhaps the most dynamic growth opportunity for hydrogen demand. Fuel cell electric vehicles (FCEVs) are increasingly being adopted for heavy-duty transport applications where battery electric solutions face limitations. Commercial deployment of hydrogen-powered trucks, buses, and trains is accelerating across Europe, Asia, and North America, with annual growth rates exceeding 30% in some regions.

Energy storage applications represent another significant market driver for hydrogen technologies. As renewable energy penetration increases, the need for long-duration energy storage solutions becomes critical. Hydrogen produced through electrolysis during periods of excess renewable generation can be compressed, stored, and later reconverted to electricity, providing a versatile solution for grid balancing and seasonal storage needs.

Regional analysis reveals distinct market characteristics. Europe leads in policy support for hydrogen adoption, with ambitious targets for green hydrogen production capacity. Asia, particularly China, Japan, and South Korea, demonstrates strong commercial deployment of hydrogen technologies across multiple sectors. North America shows increasing investment in hydrogen infrastructure, though somewhat behind the European and Asian markets.

The demand for efficient compression technologies directly correlates with these market trends. EHCs offer significant advantages over mechanical compressors in terms of efficiency, reliability, and scalability. However, their widespread adoption depends on addressing operational stability challenges through advanced control strategies. Market research indicates that improvements in EHC control systems could reduce operational costs by 15-20%, significantly enhancing their commercial viability across various applications.

EHC Operational Challenges and Technical Barriers

Electrochemical Hydrogen Compressors (EHCs) face several critical operational challenges that impede their widespread commercial adoption. The primary technical barrier is membrane degradation during long-term operation, particularly under high differential pressure conditions. This degradation manifests as mechanical failures, chemical decomposition, and reduced proton conductivity, significantly shortening the operational lifespan of EHC systems.

Water management represents another substantial challenge, as proper hydration levels must be maintained for optimal proton conductivity. Excessive dehydration leads to increased membrane resistance and reduced efficiency, while over-hydration can cause flooding and gas transport limitations. This delicate balance is difficult to maintain across varying operational conditions and pressure differentials.

Hydrogen crossover presents a significant safety and efficiency concern. As pressure differentials increase, hydrogen molecules increasingly permeate through the membrane from the anode to cathode, reducing faradaic efficiency and creating potential safety hazards. Current membrane technologies struggle to minimize this crossover effect while maintaining high proton conductivity.

Temperature control poses another critical challenge, as EHCs generate heat during operation due to ohmic resistance and electrochemical reactions. Inadequate thermal management leads to hotspots, accelerated degradation, and potential system failures. The development of effective cooling strategies that maintain uniform temperature distribution remains technically challenging.

Catalyst degradation and poisoning significantly impact long-term performance stability. Platinum-based catalysts, commonly used in EHCs, are susceptible to contamination from feed gas impurities and can undergo dissolution and agglomeration during operational cycling, reducing active surface area and catalytic activity over time.

Control system limitations represent a fundamental barrier to stable EHC operation. Current control architectures often lack the sophistication to respond dynamically to changing operational conditions, resulting in suboptimal performance and increased stress on system components. Advanced sensing capabilities and real-time feedback mechanisms are needed but remain underdeveloped.

Scale-up challenges persist as laboratory-scale successes have proven difficult to translate to industrial applications. Issues related to uniform gas distribution, pressure management across larger membrane areas, and system integration complexities have limited commercial viability of large-scale EHC systems.

Economic barriers compound these technical challenges, as high-cost materials (particularly noble metal catalysts and specialized membranes) and manufacturing complexities result in capital costs that currently exceed conventional mechanical compression technologies, despite the potential for lower operational expenses.

Water management represents another substantial challenge, as proper hydration levels must be maintained for optimal proton conductivity. Excessive dehydration leads to increased membrane resistance and reduced efficiency, while over-hydration can cause flooding and gas transport limitations. This delicate balance is difficult to maintain across varying operational conditions and pressure differentials.

Hydrogen crossover presents a significant safety and efficiency concern. As pressure differentials increase, hydrogen molecules increasingly permeate through the membrane from the anode to cathode, reducing faradaic efficiency and creating potential safety hazards. Current membrane technologies struggle to minimize this crossover effect while maintaining high proton conductivity.

Temperature control poses another critical challenge, as EHCs generate heat during operation due to ohmic resistance and electrochemical reactions. Inadequate thermal management leads to hotspots, accelerated degradation, and potential system failures. The development of effective cooling strategies that maintain uniform temperature distribution remains technically challenging.

Catalyst degradation and poisoning significantly impact long-term performance stability. Platinum-based catalysts, commonly used in EHCs, are susceptible to contamination from feed gas impurities and can undergo dissolution and agglomeration during operational cycling, reducing active surface area and catalytic activity over time.

Control system limitations represent a fundamental barrier to stable EHC operation. Current control architectures often lack the sophistication to respond dynamically to changing operational conditions, resulting in suboptimal performance and increased stress on system components. Advanced sensing capabilities and real-time feedback mechanisms are needed but remain underdeveloped.

Scale-up challenges persist as laboratory-scale successes have proven difficult to translate to industrial applications. Issues related to uniform gas distribution, pressure management across larger membrane areas, and system integration complexities have limited commercial viability of large-scale EHC systems.

Economic barriers compound these technical challenges, as high-cost materials (particularly noble metal catalysts and specialized membranes) and manufacturing complexities result in capital costs that currently exceed conventional mechanical compression technologies, despite the potential for lower operational expenses.

Current Control Strategies for EHC Stability

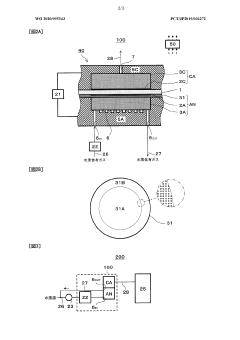

01 Membrane electrode assembly design for stable operation

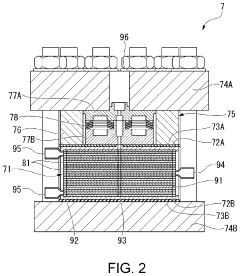

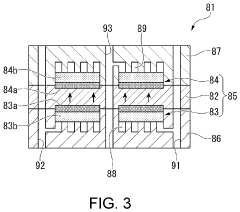

The design of membrane electrode assemblies (MEAs) is crucial for the stable operation of electrochemical hydrogen compressors. Key aspects include optimizing the catalyst layer composition, membrane thickness, and electrode structure to enhance proton conductivity while minimizing gas crossover. Advanced MEA designs incorporate reinforced membranes and gradient catalyst layers to withstand high differential pressures and maintain performance during long-term operation. These improvements help prevent membrane degradation and ensure consistent hydrogen compression efficiency.- Membrane and electrode assembly design for stable operation: The design of membrane and electrode assemblies (MEAs) is crucial for the stable operation of electrochemical hydrogen compressors. Optimized MEAs with proper catalyst loading, membrane thickness, and electrode structure can enhance hydrogen transport efficiency while maintaining operational stability. Advanced membrane materials with high proton conductivity and low gas permeability help prevent crossover issues and improve compression efficiency. Proper integration of these components ensures consistent performance during long-term operation.

- Thermal management and pressure control systems: Effective thermal management and pressure control are essential for stable operation of electrochemical hydrogen compressors. Systems that regulate temperature distribution across the compression cells prevent membrane dehydration and catalyst degradation. Advanced pressure control mechanisms, including pressure sensors and regulators, maintain optimal differential pressure across the membrane to avoid mechanical stress and failure. These systems work together to ensure consistent compression performance and extend the operational lifetime of the compressor.

- Water management and humidification strategies: Proper water management is critical for the stable operation of electrochemical hydrogen compressors. Controlled humidification of feed gases and membranes prevents dehydration at high current densities and pressure differentials. Advanced water management systems incorporate humidity sensors, water recovery units, and recirculation loops to maintain optimal membrane hydration. These strategies ensure consistent proton conductivity across the membrane while preventing flooding of electrodes, thereby enhancing operational stability and efficiency.

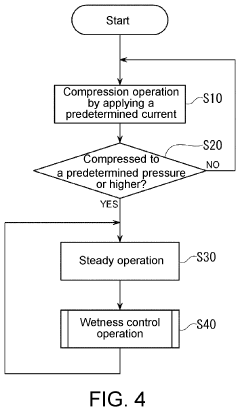

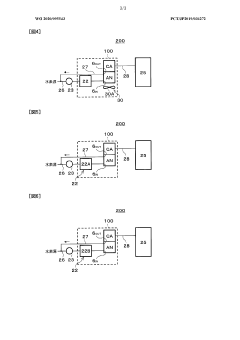

- Control systems and operational protocols: Sophisticated control systems and operational protocols are vital for maintaining stable operation of electrochemical hydrogen compressors. These include automated monitoring of key parameters such as current density, cell voltage, temperature, and pressure differentials. Advanced control algorithms adjust operating conditions in real-time to prevent degradation mechanisms and performance fluctuations. Proper start-up and shutdown procedures, along with fault detection systems, help avoid damage to components and ensure reliable long-term operation under varying conditions.

- Novel materials and component designs: Innovative materials and component designs significantly improve the stability of electrochemical hydrogen compressors. These include corrosion-resistant bipolar plates, advanced catalyst formulations with enhanced durability, and novel membrane materials with improved mechanical strength. Specialized sealing technologies prevent gas leakage at high pressure differentials, while optimized flow field designs ensure uniform distribution of reactants. These advancements collectively address key degradation mechanisms and enhance the overall reliability and operational stability of the compression system.

02 Thermal management and cooling systems

Effective thermal management is essential for stable operation of electrochemical hydrogen compressors. Heat generated during compression can lead to membrane dehydration and reduced efficiency. Advanced cooling systems incorporate liquid cooling channels, heat exchangers, and thermal sensors to maintain optimal operating temperatures. Some designs feature integrated cooling plates or fins that dissipate heat efficiently. Proper thermal management prevents hotspots, extends component lifespan, and ensures consistent compression performance across varying operating conditions.Expand Specific Solutions03 Water management and humidification strategies

Water management is critical for the stable operation of electrochemical hydrogen compressors. Proper humidification of the membrane prevents dehydration at high current densities while avoiding flooding that can block gas transport pathways. Advanced systems incorporate integrated humidifiers, water recovery systems, and precise humidity control mechanisms. Some designs feature self-humidifying membranes or gradient structures that maintain optimal water content across pressure differentials. Effective water management ensures consistent proton conductivity and prevents mechanical stress on the membrane during operation.Expand Specific Solutions04 Control systems and operational parameters

Sophisticated control systems are essential for maintaining stable operation of electrochemical hydrogen compressors. These systems monitor and adjust key parameters such as current density, temperature, pressure differentials, and humidity levels in real-time. Advanced controllers implement predictive algorithms to anticipate operational changes and prevent instability. Feedback loops continuously optimize performance based on sensor data, while safety protocols automatically respond to abnormal conditions. Proper control strategies enable efficient operation across varying compression ratios and hydrogen flow rates while extending system lifetime.Expand Specific Solutions05 Novel materials and component designs

Innovative materials and component designs significantly enhance the stability of electrochemical hydrogen compressors. Advanced polymer membranes with reinforced structures offer improved mechanical strength and chemical stability under high-pressure differentials. Novel catalyst formulations reduce degradation and maintain activity over extended operation. Some designs incorporate composite bipolar plates with enhanced corrosion resistance and conductivity. Specialized sealing materials and compression hardware prevent gas leakage while accommodating thermal expansion. These material innovations collectively improve durability, efficiency, and operational stability of hydrogen compression systems.Expand Specific Solutions

Key Industry Players in EHC Development

The electrochemical hydrogen compressor (EHC) market is currently in an early growth phase, characterized by increasing R&D investments and emerging commercial applications. The global market size is projected to expand significantly as hydrogen gains importance in clean energy transitions, with estimates suggesting a compound annual growth rate exceeding 25% through 2030. Technologically, EHCs are advancing rapidly but remain in the early-to-mid maturity stage. Leading players demonstrate varying levels of technical expertise: Ergosup and H2gremm have developed specialized high-pressure compressor solutions; Skyre and Electric Hydrogen focus on integrated electrolyzer-compressor systems; while established industrial giants like Air Liquide, Bosch, and Honda are leveraging their manufacturing capabilities to scale the technology. Research institutions including Korea Institute of Machinery & Materials and Commissariat à l'énergie atomique are driving fundamental innovations in membrane technology and control systems essential for stable EHC operation.

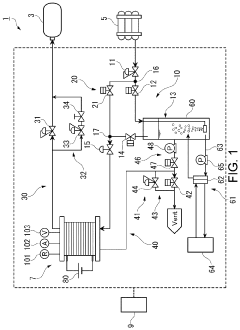

Robert Bosch GmbH

Technical Solution: Bosch has developed a comprehensive control strategy for electrochemical hydrogen compressors that leverages their extensive experience in automotive and industrial control systems. Their approach centers on a modular stack design with individually monitored cells that allows for precise control of compression parameters. Bosch's system employs advanced thermal management using liquid cooling circuits with variable flow rates that respond to localized temperature variations within the stack. Their control architecture incorporates predictive load management algorithms that optimize current density distribution based on anticipated demand patterns. The technology features sophisticated membrane hydration control that maintains optimal water content through controlled humidification and integrated water recovery systems. Bosch has implemented high-precision pressure regulation using electronic back-pressure valves that maintain stable differential pressures across the membrane regardless of flow rate variations. Their system includes comprehensive safety protocols with redundant monitoring of critical parameters and automated shutdown sequences to prevent damage during abnormal operating conditions.

Strengths: Exceptional system integration capabilities leveraging Bosch's expertise in industrial controls; robust design suitable for automotive and heavy-duty applications; high reliability with comprehensive fault detection and management. Weaknesses: Higher cost compared to conventional technologies; complex system architecture requires specialized maintenance; optimization primarily focused on automotive applications which may limit flexibility for other use cases.

Ergosup SA

Technical Solution: Ergosup has pioneered an integrated electrochemical hydrogen production and compression system that combines electrolysis and compression in a single process. Their control strategy centers on a zinc-based redox mechanism that enables simultaneous hydrogen generation and compression. The system utilizes proprietary electrode materials and cell architecture to achieve high-pressure hydrogen without separate compression stages. Ergosup's control approach incorporates dynamic electrolyte management that adjusts zinc concentration and flow rates based on operational parameters. Their technology employs sophisticated pressure ramping protocols that gradually increase compression to prevent membrane stress and extend component life. The control system features adaptive power management that optimizes energy consumption based on hydrogen demand and grid conditions, making it particularly suitable for integration with renewable energy sources. Ergosup has developed specialized sensors and monitoring systems that track electrolyte properties and cell performance to maintain stable operation across varying load conditions.

Strengths: Single-step production and compression process reduces system complexity and footprint; ability to reach very high pressures (>350 bar) directly from electrolysis; excellent energy efficiency compared to separate electrolysis and compression systems. Weaknesses: Limited scalability for very large applications; specialized electrolyte requires periodic maintenance and replacement; technology is less mature than conventional PEM-based systems.

Critical Patents and Innovations in EHC Control Systems

Electrochemical hydrogen compression system

PatentActiveUS11872526B2

Innovation

- An electrochemical hydrogen compression system that includes a control device to regulate the discharge of hydrogen based on the wet state of the electrolyte film, using a humidifier and distribution pipelines to maintain a uniform wet state across unit cells, ensuring optimal proton conductivity and energy efficiency.

Electrochemical hydrogen compressing apparatus and method for operating electrochemical hydrogen compressing apparatus

PatentWO2020095543A1

Innovation

- The electrochemical hydrogen compression device incorporates a proton-conducting electrolyte membrane with a dew point regulator and controller to adjust the dew point of the hydrogen-containing gas, utilizing latent heat from water vapor condensation and IR loss to reduce energy consumption and maintain optimal operating conditions, thereby improving compression efficiency and preventing flooding.

Safety Standards and Compliance Requirements

The operation of Electrochemical Hydrogen Compressors (EHCs) involves significant safety considerations due to the handling of hydrogen gas, which is highly flammable and can form explosive mixtures with air. Compliance with international and regional safety standards is therefore paramount for manufacturers, operators, and maintenance personnel involved with EHC systems.

Key international standards governing hydrogen systems include ISO 16111 for transportable hydrogen storage systems, ISO 22734 for hydrogen generators using water electrolysis processes, and IEC 62282 series for fuel cell technologies. These standards establish baseline requirements for materials compatibility, pressure vessel design, electrical safety, and control system reliability that directly impact EHC operation.

Regional regulations add another layer of compliance requirements. In the European Union, the ATEX Directive (2014/34/EU) regulates equipment intended for use in potentially explosive atmospheres, while the Pressure Equipment Directive (2014/68/EU) covers pressure vessels and systems. In the United States, NFPA 2 (Hydrogen Technologies Code) provides comprehensive safety guidelines for hydrogen systems, complemented by ASME BPVC standards for pressure vessel construction.

Control strategies for EHCs must incorporate safety-critical functions as mandated by these standards. This includes implementing reliable pressure monitoring with redundant sensors, automatic shutdown capabilities triggered by abnormal operating conditions, and hydrogen leak detection systems with appropriate alarm thresholds. The control architecture must also feature fail-safe designs that default to a safe state during power loss or component failure.

Risk assessment methodologies such as HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis) are required during the design phase of control systems. These assessments help identify potential failure modes and establish appropriate mitigation measures within the control strategy. Documentation of these assessments becomes part of the compliance package for certification.

Certification requirements vary by jurisdiction but typically involve third-party verification of design documentation, manufacturing processes, and testing results. For EHC control systems, this often includes functional safety certification according to IEC 61508 or similar standards, with appropriate Safety Integrity Level (SIL) ratings based on risk assessment outcomes.

Ongoing compliance maintenance requires periodic inspection and testing protocols to be embedded within the control strategy. This includes regular calibration of sensors, validation of safety-critical control functions, and documentation of system performance within specified safety parameters. These maintenance activities must be logged and available for regulatory inspection.

Key international standards governing hydrogen systems include ISO 16111 for transportable hydrogen storage systems, ISO 22734 for hydrogen generators using water electrolysis processes, and IEC 62282 series for fuel cell technologies. These standards establish baseline requirements for materials compatibility, pressure vessel design, electrical safety, and control system reliability that directly impact EHC operation.

Regional regulations add another layer of compliance requirements. In the European Union, the ATEX Directive (2014/34/EU) regulates equipment intended for use in potentially explosive atmospheres, while the Pressure Equipment Directive (2014/68/EU) covers pressure vessels and systems. In the United States, NFPA 2 (Hydrogen Technologies Code) provides comprehensive safety guidelines for hydrogen systems, complemented by ASME BPVC standards for pressure vessel construction.

Control strategies for EHCs must incorporate safety-critical functions as mandated by these standards. This includes implementing reliable pressure monitoring with redundant sensors, automatic shutdown capabilities triggered by abnormal operating conditions, and hydrogen leak detection systems with appropriate alarm thresholds. The control architecture must also feature fail-safe designs that default to a safe state during power loss or component failure.

Risk assessment methodologies such as HAZOP (Hazard and Operability Study) and FMEA (Failure Mode and Effects Analysis) are required during the design phase of control systems. These assessments help identify potential failure modes and establish appropriate mitigation measures within the control strategy. Documentation of these assessments becomes part of the compliance package for certification.

Certification requirements vary by jurisdiction but typically involve third-party verification of design documentation, manufacturing processes, and testing results. For EHC control systems, this often includes functional safety certification according to IEC 61508 or similar standards, with appropriate Safety Integrity Level (SIL) ratings based on risk assessment outcomes.

Ongoing compliance maintenance requires periodic inspection and testing protocols to be embedded within the control strategy. This includes regular calibration of sensors, validation of safety-critical control functions, and documentation of system performance within specified safety parameters. These maintenance activities must be logged and available for regulatory inspection.

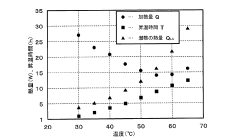

Energy Efficiency and Performance Metrics

Energy efficiency is a critical parameter in evaluating the performance of Electrochemical Hydrogen Compressors (EHCs). Current EHC systems demonstrate energy efficiency ranging from 60% to 85%, depending on operating conditions, membrane materials, and control strategies implemented. This efficiency is calculated as the ratio between the theoretical minimum compression work and the actual electrical energy consumed during operation.

Performance metrics for EHCs must be comprehensively evaluated through multiple parameters beyond simple efficiency calculations. Key metrics include hydrogen throughput (typically measured in standard liters per minute), compression ratio (ranging from 10:1 to 300:1 in advanced systems), specific energy consumption (kWh/kg H₂), and system durability under varying load conditions.

The relationship between control strategies and energy efficiency is particularly significant. Adaptive control systems that optimize current density based on real-time monitoring of membrane hydration levels have demonstrated efficiency improvements of 12-18% compared to fixed-parameter operation. Pulse-width modulation techniques applied to the power supply have shown promise in reducing energy losses during transient operations by maintaining optimal membrane conductivity.

Temperature management represents another crucial aspect of EHC performance metrics. Studies indicate that maintaining operation within the 60-80°C range typically maximizes efficiency, with precise temperature control systems yielding up to 9% efficiency gains compared to systems with basic thermal management.

Pressure ramp rate control directly impacts both energy efficiency and membrane longevity. Gradual pressure increases of 0.5-2 bar/minute have been shown to reduce energy consumption by 7-11% compared to rapid compression cycles, while simultaneously extending membrane service life by an estimated 30-40%.

Recent advances in real-time impedance spectroscopy as a diagnostic tool have enabled dynamic efficiency optimization. These systems can detect membrane resistance changes with millisecond response times, allowing control algorithms to adjust operating parameters before efficiency degradation occurs. Implementation of machine learning algorithms for predictive control has demonstrated potential efficiency improvements of 5-8% in laboratory settings, though commercial validation remains ongoing.

The trade-off between maximum compression ratio and energy efficiency presents a significant challenge for control system design. Higher compression ratios typically result in decreased efficiency, with each doubling of pressure ratio generally causing a 3-7% efficiency reduction, depending on system architecture and control methodology.

Performance metrics for EHCs must be comprehensively evaluated through multiple parameters beyond simple efficiency calculations. Key metrics include hydrogen throughput (typically measured in standard liters per minute), compression ratio (ranging from 10:1 to 300:1 in advanced systems), specific energy consumption (kWh/kg H₂), and system durability under varying load conditions.

The relationship between control strategies and energy efficiency is particularly significant. Adaptive control systems that optimize current density based on real-time monitoring of membrane hydration levels have demonstrated efficiency improvements of 12-18% compared to fixed-parameter operation. Pulse-width modulation techniques applied to the power supply have shown promise in reducing energy losses during transient operations by maintaining optimal membrane conductivity.

Temperature management represents another crucial aspect of EHC performance metrics. Studies indicate that maintaining operation within the 60-80°C range typically maximizes efficiency, with precise temperature control systems yielding up to 9% efficiency gains compared to systems with basic thermal management.

Pressure ramp rate control directly impacts both energy efficiency and membrane longevity. Gradual pressure increases of 0.5-2 bar/minute have been shown to reduce energy consumption by 7-11% compared to rapid compression cycles, while simultaneously extending membrane service life by an estimated 30-40%.

Recent advances in real-time impedance spectroscopy as a diagnostic tool have enabled dynamic efficiency optimization. These systems can detect membrane resistance changes with millisecond response times, allowing control algorithms to adjust operating parameters before efficiency degradation occurs. Implementation of machine learning algorithms for predictive control has demonstrated potential efficiency improvements of 5-8% in laboratory settings, though commercial validation remains ongoing.

The trade-off between maximum compression ratio and energy efficiency presents a significant challenge for control system design. Higher compression ratios typically result in decreased efficiency, with each doubling of pressure ratio generally causing a 3-7% efficiency reduction, depending on system architecture and control methodology.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!