Hydrogen Purification And Compression: Combining Electrochemical Pumps With Membranes

SEP 3, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Hydrogen Purification Technology Evolution and Objectives

Hydrogen purification technology has evolved significantly over the past century, transitioning from rudimentary chemical processes to sophisticated membrane and electrochemical systems. The journey began in the early 20th century with pressure swing adsorption (PSA) and cryogenic distillation methods, which, while effective, were energy-intensive and often yielded hydrogen with limited purity levels.

The 1960s marked a pivotal shift with the introduction of palladium-based membranes, offering unprecedented selectivity for hydrogen molecules. This innovation laid the groundwork for membrane technology that continues to evolve today. By the 1980s, polymeric membranes emerged as cost-effective alternatives, though they initially struggled with the selectivity-permeability trade-off that remains a central challenge.

Electrochemical hydrogen pumping technology developed in parallel, with significant advancements in the 1990s when proton exchange membrane (PEM) systems demonstrated their capability to both purify and compress hydrogen in a single step. This dual functionality represented a paradigm shift in hydrogen processing efficiency.

The 2000s witnessed accelerated development in both membrane materials and electrochemical systems, driven by growing interest in hydrogen as a clean energy carrier. Ceramic membranes, metal-organic frameworks (MOFs), and graphene-based materials expanded the toolkit for hydrogen separation, each offering unique advantages in specific operational contexts.

Current technological objectives center on addressing several persistent challenges. Foremost is improving energy efficiency across the purification-compression continuum, as conventional methods still consume 25-35% of the energy content of the hydrogen processed. Enhancing membrane durability under industrial conditions—particularly resistance to contaminants like carbon monoxide, hydrogen sulfide, and ammonia—remains critical for practical implementation.

The integration of electrochemical pumps with advanced membrane systems represents a promising frontier, potentially offering simultaneous purification and compression with minimal energy penalties. Research objectives include developing hybrid systems that leverage the selectivity of membranes with the compression capabilities of electrochemical cells, while maintaining operational stability across varying pressure differentials and feed compositions.

Looking forward, the field aims to achieve hydrogen purification systems capable of delivering 99.999% pure hydrogen (essential for fuel cell applications) while consuming less than 10% of hydrogen's energy content. Additional objectives include developing modular, scalable designs suitable for both centralized industrial facilities and distributed hydrogen production scenarios, supporting the evolving hydrogen economy infrastructure.

The 1960s marked a pivotal shift with the introduction of palladium-based membranes, offering unprecedented selectivity for hydrogen molecules. This innovation laid the groundwork for membrane technology that continues to evolve today. By the 1980s, polymeric membranes emerged as cost-effective alternatives, though they initially struggled with the selectivity-permeability trade-off that remains a central challenge.

Electrochemical hydrogen pumping technology developed in parallel, with significant advancements in the 1990s when proton exchange membrane (PEM) systems demonstrated their capability to both purify and compress hydrogen in a single step. This dual functionality represented a paradigm shift in hydrogen processing efficiency.

The 2000s witnessed accelerated development in both membrane materials and electrochemical systems, driven by growing interest in hydrogen as a clean energy carrier. Ceramic membranes, metal-organic frameworks (MOFs), and graphene-based materials expanded the toolkit for hydrogen separation, each offering unique advantages in specific operational contexts.

Current technological objectives center on addressing several persistent challenges. Foremost is improving energy efficiency across the purification-compression continuum, as conventional methods still consume 25-35% of the energy content of the hydrogen processed. Enhancing membrane durability under industrial conditions—particularly resistance to contaminants like carbon monoxide, hydrogen sulfide, and ammonia—remains critical for practical implementation.

The integration of electrochemical pumps with advanced membrane systems represents a promising frontier, potentially offering simultaneous purification and compression with minimal energy penalties. Research objectives include developing hybrid systems that leverage the selectivity of membranes with the compression capabilities of electrochemical cells, while maintaining operational stability across varying pressure differentials and feed compositions.

Looking forward, the field aims to achieve hydrogen purification systems capable of delivering 99.999% pure hydrogen (essential for fuel cell applications) while consuming less than 10% of hydrogen's energy content. Additional objectives include developing modular, scalable designs suitable for both centralized industrial facilities and distributed hydrogen production scenarios, supporting the evolving hydrogen economy infrastructure.

Market Analysis for High-Purity Hydrogen Applications

The high-purity hydrogen market is experiencing robust growth driven by multiple sectors requiring ultra-clean hydrogen with purity levels exceeding 99.999%. The semiconductor industry represents a significant demand driver, requiring hydrogen with impurity levels below parts per billion for manufacturing processes including silicon wafer production and chemical vapor deposition. This segment alone is projected to grow at 6-7% annually through 2030, creating substantial demand for advanced purification technologies.

Fuel cell applications constitute another major market segment, with automotive fuel cells requiring hydrogen purity of 99.999% to prevent catalyst poisoning. As fuel cell electric vehicles gain market traction, particularly in commercial transportation, demand for high-purity hydrogen is expected to increase substantially. The stationary fuel cell market for backup power and distributed generation further amplifies this demand trajectory.

The pharmaceutical and biotechnology industries represent premium markets for ultra-pure hydrogen, used in hydrogenation reactions for drug synthesis and as a carrier gas in analytical instruments. These applications demand hydrogen with minimal contaminants to ensure product quality and analytical accuracy, with pharmaceutical companies willing to pay premium prices for guaranteed purity levels.

Electronics manufacturing beyond semiconductors, including display technologies and specialty electronics, requires high-purity hydrogen for various processes. This segment is growing at approximately 8% annually, driven by consumer electronics demand and technological advancements in manufacturing processes.

Space exploration and aerospace applications constitute a specialized but high-value market segment. Liquid hydrogen fuel for rockets and satellites demands exceptional purity standards, with NASA and private space companies implementing stringent specifications that exceed commercial standards.

The market structure features premium pricing for higher purity levels, with significant price differentials between 99.99% (4N) and 99.9999% (6N) hydrogen. This tiered pricing model creates strong economic incentives for advanced purification technologies that can achieve higher purity levels with lower energy consumption.

Geographically, the market shows concentration in technology-intensive regions including East Asia (particularly Japan, South Korea, and Taiwan), North America, and Western Europe. However, emerging markets in China and India are showing accelerated growth as their semiconductor and electronics manufacturing sectors expand.

Fuel cell applications constitute another major market segment, with automotive fuel cells requiring hydrogen purity of 99.999% to prevent catalyst poisoning. As fuel cell electric vehicles gain market traction, particularly in commercial transportation, demand for high-purity hydrogen is expected to increase substantially. The stationary fuel cell market for backup power and distributed generation further amplifies this demand trajectory.

The pharmaceutical and biotechnology industries represent premium markets for ultra-pure hydrogen, used in hydrogenation reactions for drug synthesis and as a carrier gas in analytical instruments. These applications demand hydrogen with minimal contaminants to ensure product quality and analytical accuracy, with pharmaceutical companies willing to pay premium prices for guaranteed purity levels.

Electronics manufacturing beyond semiconductors, including display technologies and specialty electronics, requires high-purity hydrogen for various processes. This segment is growing at approximately 8% annually, driven by consumer electronics demand and technological advancements in manufacturing processes.

Space exploration and aerospace applications constitute a specialized but high-value market segment. Liquid hydrogen fuel for rockets and satellites demands exceptional purity standards, with NASA and private space companies implementing stringent specifications that exceed commercial standards.

The market structure features premium pricing for higher purity levels, with significant price differentials between 99.99% (4N) and 99.9999% (6N) hydrogen. This tiered pricing model creates strong economic incentives for advanced purification technologies that can achieve higher purity levels with lower energy consumption.

Geographically, the market shows concentration in technology-intensive regions including East Asia (particularly Japan, South Korea, and Taiwan), North America, and Western Europe. However, emerging markets in China and India are showing accelerated growth as their semiconductor and electronics manufacturing sectors expand.

Current Challenges in Hydrogen Purification and Compression

The hydrogen industry faces significant challenges in purification and compression processes that are critical for the effective deployment of hydrogen as a clean energy carrier. Current purification methods predominantly rely on pressure swing adsorption (PSA), cryogenic distillation, and membrane separation technologies. While these technologies have established track records, they present substantial energy efficiency limitations, with energy consumption often exceeding 30% of the hydrogen's energy content during processing.

Membrane-based purification systems, though promising for their selectivity, struggle with durability issues when exposed to impurities like hydrogen sulfide and carbon monoxide. These contaminants can cause irreversible damage to membrane structures, particularly in palladium-based systems, leading to decreased separation efficiency and shortened operational lifespans. Additionally, the trade-off between permeability and selectivity remains a fundamental challenge, as higher throughput often comes at the cost of reduced purity.

Compression technologies present another set of critical challenges. Conventional mechanical compressors used for hydrogen service suffer from high maintenance requirements due to hydrogen embrittlement of metal components and the need for specialized sealing systems to prevent leakage of the small hydrogen molecules. These mechanical systems typically achieve compression ratios of 2:1 to 3:1 per stage, necessitating multi-stage configurations that increase complexity, footprint, and capital costs.

Electrochemical hydrogen compression (EHC) has emerged as a promising alternative, offering theoretical advantages in energy efficiency and operational simplicity. However, practical implementations face challenges related to membrane degradation under high differential pressure conditions and limited current density capabilities that restrict throughput. Most existing EHC systems struggle to maintain efficiency when scaling to industrial throughput requirements above 100 kg/day.

The integration of purification and compression processes presents additional complexities. Current systems typically treat these as separate unit operations, resulting in efficiency losses at the interfaces and increased system complexity. The temperature and pressure differentials between purification and compression stages often necessitate intermediate cooling or heating steps that further reduce overall system efficiency.

Economic barriers compound these technical challenges. The capital expenditure for high-purity hydrogen processing equipment remains prohibitively high for many potential applications, with costs typically exceeding $1,000 per kilogram of daily hydrogen processing capacity. Operating expenses are similarly elevated due to high energy consumption, frequent maintenance requirements, and the need for specialized materials resistant to hydrogen embrittlement.

Membrane-based purification systems, though promising for their selectivity, struggle with durability issues when exposed to impurities like hydrogen sulfide and carbon monoxide. These contaminants can cause irreversible damage to membrane structures, particularly in palladium-based systems, leading to decreased separation efficiency and shortened operational lifespans. Additionally, the trade-off between permeability and selectivity remains a fundamental challenge, as higher throughput often comes at the cost of reduced purity.

Compression technologies present another set of critical challenges. Conventional mechanical compressors used for hydrogen service suffer from high maintenance requirements due to hydrogen embrittlement of metal components and the need for specialized sealing systems to prevent leakage of the small hydrogen molecules. These mechanical systems typically achieve compression ratios of 2:1 to 3:1 per stage, necessitating multi-stage configurations that increase complexity, footprint, and capital costs.

Electrochemical hydrogen compression (EHC) has emerged as a promising alternative, offering theoretical advantages in energy efficiency and operational simplicity. However, practical implementations face challenges related to membrane degradation under high differential pressure conditions and limited current density capabilities that restrict throughput. Most existing EHC systems struggle to maintain efficiency when scaling to industrial throughput requirements above 100 kg/day.

The integration of purification and compression processes presents additional complexities. Current systems typically treat these as separate unit operations, resulting in efficiency losses at the interfaces and increased system complexity. The temperature and pressure differentials between purification and compression stages often necessitate intermediate cooling or heating steps that further reduce overall system efficiency.

Economic barriers compound these technical challenges. The capital expenditure for high-purity hydrogen processing equipment remains prohibitively high for many potential applications, with costs typically exceeding $1,000 per kilogram of daily hydrogen processing capacity. Operating expenses are similarly elevated due to high energy consumption, frequent maintenance requirements, and the need for specialized materials resistant to hydrogen embrittlement.

Integrated Electrochemical-Membrane Purification Solutions

01 Electrochemical hydrogen pump systems with membrane integration

Electrochemical hydrogen pump systems incorporate specialized membranes to facilitate hydrogen separation and compression. These systems utilize electrochemical principles to drive hydrogen across membranes, allowing for simultaneous purification and compression. The integration of membranes enhances selectivity, enabling the removal of impurities while maintaining high hydrogen purity. These systems can operate at various pressure differentials, making them suitable for applications requiring both purification and compression of hydrogen gas.- Electrochemical hydrogen pump systems with membrane integration: Electrochemical hydrogen pump systems incorporate specialized membranes to facilitate hydrogen separation and compression. These systems utilize electrochemical principles to drive hydrogen across membrane barriers, allowing for simultaneous purification and pressurization. The integration of membranes enhances selectivity, enabling the removal of impurities while maintaining high hydrogen recovery rates. These systems typically operate at lower energy consumption compared to traditional mechanical compression methods.

- Proton exchange membrane technology for hydrogen purification: Proton exchange membranes (PEMs) serve as key components in electrochemical hydrogen purification systems. These membranes selectively transport protons while blocking other gas molecules, resulting in high-purity hydrogen production. The technology leverages the electrochemical potential difference to drive protons through the membrane, which then recombine with electrons to form purified hydrogen gas. This approach enables efficient separation of hydrogen from gas mixtures while simultaneously achieving compression.

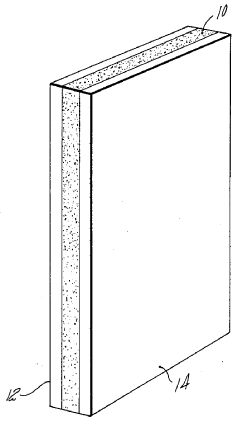

- Integrated compression and purification systems for hydrogen processing: Integrated systems combine electrochemical hydrogen pumping with membrane separation to achieve both compression and purification in a single process. These systems utilize electrochemical cells with specialized membrane assemblies to selectively transport hydrogen while increasing its pressure. The integration reduces system complexity, footprint, and energy requirements compared to conventional multi-stage processes. Such systems are particularly valuable for applications requiring high-purity hydrogen at elevated pressures.

- Advanced membrane materials for enhanced hydrogen separation: Novel membrane materials have been developed to improve the efficiency and selectivity of hydrogen separation processes. These materials include composite membranes, metal alloy membranes, and functionalized polymer membranes designed to maximize hydrogen permeability while minimizing the passage of contaminants. Advanced membrane formulations offer improved durability under harsh operating conditions, resistance to poisoning, and enhanced separation factors, leading to higher purity hydrogen and more efficient compression.

- System configurations for optimized hydrogen processing: Various system configurations have been developed to optimize the performance of electrochemical hydrogen pump and membrane systems. These include multi-stage arrangements, cascade systems, and hybrid approaches that combine electrochemical pumping with other separation technologies. Optimized configurations feature improved heat management, pressure control mechanisms, and efficient electrode designs to enhance overall system efficiency. These systems are tailored to specific application requirements, balancing factors such as purity levels, compression ratios, and energy consumption.

02 Proton exchange membrane technology for hydrogen purification

Proton exchange membranes (PEMs) are utilized in hydrogen purification systems to selectively transport protons while blocking other gas molecules. These membranes enable high-purity hydrogen production by allowing only protons to pass through while impurities are rejected. The PEM-based systems can operate at lower temperatures compared to traditional purification methods, offering energy efficiency advantages. Additionally, these membranes can withstand pressure differentials, making them suitable for combined purification and compression applications in hydrogen processing.Expand Specific Solutions03 Integrated hydrogen compression and purification systems

Integrated systems combine hydrogen purification and compression functions into a single unit, improving efficiency and reducing footprint. These systems utilize electrochemical cells with specialized membranes to simultaneously purify hydrogen and increase its pressure. The integration eliminates the need for separate purification and compression equipment, resulting in more compact and energy-efficient hydrogen processing. Such systems can achieve high compression ratios while maintaining hydrogen purity, making them valuable for applications where space and energy efficiency are critical.Expand Specific Solutions04 Advanced membrane materials for hydrogen separation

Advanced membrane materials enhance hydrogen separation efficiency and durability in electrochemical hydrogen pumps. These materials include composite membranes, metal alloys, and ceramic-based structures designed to withstand harsh operating conditions while maintaining high hydrogen selectivity. The development of these materials focuses on improving hydrogen permeability, mechanical strength, and chemical stability. Innovations in membrane composition and structure contribute to higher hydrogen recovery rates, reduced energy consumption, and extended operational lifetimes in hydrogen purification and compression applications.Expand Specific Solutions05 Control systems for electrochemical hydrogen pump operation

Sophisticated control systems optimize the performance of electrochemical hydrogen pumps by regulating key operational parameters. These systems monitor and adjust factors such as current density, temperature, pressure differentials, and feed gas composition to maintain optimal hydrogen purification and compression efficiency. Advanced control algorithms enable dynamic response to changing conditions, ensuring consistent hydrogen quality and compression rates. Integration of sensors and automated control mechanisms allows for precise operation, fault detection, and preventive maintenance, enhancing the reliability and safety of hydrogen processing systems.Expand Specific Solutions

Leading Companies in Hydrogen Purification Industry

The hydrogen purification and compression market is currently in a growth phase, characterized by increasing demand for clean hydrogen technologies across energy, transportation, and industrial sectors. The market size is expanding rapidly, driven by global decarbonization efforts and hydrogen economy initiatives. Technologically, the integration of electrochemical pumps with membranes represents an emerging approach with medium maturity. Industry leaders include Plug Power, which has deployed over 40,000 fuel cell systems and built extensive hydrogen infrastructure, alongside established players like Panasonic, Bosch, and Shell advancing proprietary solutions. Research institutions such as Dalian Institute of Chemical Physics and National Institute of Clean & Low Carbon Energy are accelerating innovation, while specialized firms like H2Pump LLC and H2PowerTech are developing breakthrough 3-in-1 technologies combining pumping, compression, and purification capabilities.

H2 PowerTech LLC

Technical Solution: H2 PowerTech LLC has pioneered a hybrid electrochemical-membrane hydrogen purification and compression system that leverages the complementary strengths of both technologies. Their approach utilizes a staged process where hydrogen-containing gas mixtures first pass through a palladium-based membrane system for initial purification, followed by electrochemical compression using specialized proton-conducting membranes. The electrochemical stage employs a novel cell design with optimized electrode structures that minimize activation losses and enhance proton transport efficiency. Their system can process hydrogen from various sources including reformed natural gas, biomass-derived streams, and industrial byproduct gases. The technology achieves compression ratios up to 300:1 while simultaneously removing contaminants including CO, CO2, CH4, and sulfur compounds to produce ultra-high purity hydrogen (99.9999%). The modular design allows for scalable deployment across applications ranging from small-scale distributed hydrogen generation to industrial-scale centralized facilities.

Strengths: Exceptional purification capabilities that exceed requirements for even the most demanding applications like semiconductor manufacturing; high energy efficiency compared to conventional technologies; modular design enables flexible deployment and easy capacity expansion. Weaknesses: Complex system integration requires sophisticated control systems; higher sensitivity to certain feed gas contaminants; relatively limited commercial-scale operational history compared to established technologies.

Plug Power, Inc.

Technical Solution: Plug Power has developed an integrated hydrogen purification and compression system that combines electrochemical hydrogen pumping with advanced membrane technology. Their solution incorporates a multi-stage electrochemical cell architecture that enables progressive hydrogen compression while simultaneously filtering impurities through selective membranes. The system utilizes specialized catalyst-coated membranes that enhance proton conductivity while maintaining high selectivity for hydrogen. Plug Power's technology can achieve compression from near-atmospheric pressure to over 700 bar for hydrogen refueling applications while maintaining purity levels above 99.999%. Their system architecture incorporates thermal management subsystems that optimize efficiency across varying operating conditions and load profiles. The company has integrated this technology into their GenFuel hydrogen infrastructure solutions, providing end-to-end hydrogen handling capabilities from production through compression, storage, and dispensing.

Strengths: Highly scalable system architecture suitable for both distributed and centralized hydrogen infrastructure; excellent integration with renewable energy sources for green hydrogen applications; reduced operational costs compared to mechanical compression systems. Weaknesses: Higher upfront capital investment compared to conventional technologies; requires specialized maintenance expertise; performance degradation in the presence of certain contaminants requires additional pre-filtering in some applications.

Key Patents in Electrochemical Hydrogen Pump Technology

Device and method for combined purification and compression of hydrogen containing co and the use thereof in fuel cell assemblies

PatentWO1997040542A1

Innovation

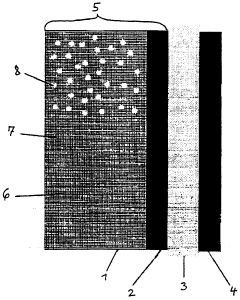

- A device using a polymer electrolyte membrane (PEM) cell with a double-layer anode, featuring a CO oxidation-selective catalyst layer and an electrochemically active layer, selectively oxidizes CO to CO2 and compresses hydrogen to at least 10 bar, preventing electrode crack formation through a flat porous carrier and reinforced current collector design.

Composite hydrogen purification membrane and method for purifying hydrogen

PatentInactiveUS4911803A

Innovation

- A composite hydrogen purification membrane comprising an anode for hydrogen oxidation, a cathode for hydrogen ion reduction, and a proton conductor and electron conductor means, which oxidizes hydrogen to protons and electrons, allowing their recombination at the cathode to maintain a hydrogen partial pressure differential for selective separation.

Energy Efficiency Analysis of Combined Technologies

The integration of electrochemical hydrogen pumps with membrane technologies represents a significant advancement in hydrogen purification and compression systems. When analyzing the energy efficiency of these combined technologies, it becomes evident that this hybrid approach offers substantial advantages over conventional methods.

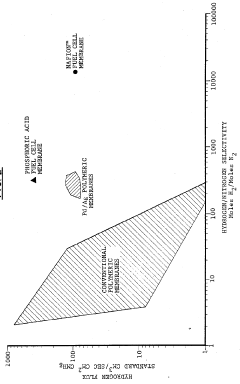

Traditional hydrogen purification and compression systems typically rely on energy-intensive processes such as pressure swing adsorption (PSA) and mechanical compression, which can consume between 8-12 kWh/kg H₂. In contrast, the combined electrochemical pump-membrane system demonstrates potential energy consumption reductions of 30-45% under optimal operating conditions.

The energy efficiency gains stem primarily from the electrochemical pump's ability to simultaneously purify and compress hydrogen in a single step. This eliminates the need for separate purification and mechanical compression stages, reducing parasitic energy losses associated with multiple process transitions. Quantitative analyses indicate that electrochemical hydrogen pumps operate at 65-75% electrical efficiency, compared to 50-60% for conventional mechanical compressors.

Membrane integration further enhances system efficiency by providing preliminary purification, reducing the electrochemical load on the pump. High-selectivity palladium-based or polymer membranes can achieve 99.9% hydrogen purity with minimal pressure differential requirements, thereby decreasing the overall energy input needed for the electrochemical compression stage.

Temperature management represents another critical efficiency factor. Combined systems operating at moderate temperatures (80-120°C) demonstrate optimal energy performance, balancing membrane permeability with electrochemical reaction kinetics. This temperature range enables efficient operation while minimizing thermal management energy requirements.

Scale-dependent efficiency analysis reveals that larger integrated systems (>100 kg H₂/day) achieve better energy performance due to reduced relative heat losses and improved electrical efficiency at scale. Laboratory-scale systems typically show 10-15% lower efficiency than industrial-scale implementations.

Economic modeling indicates that the energy cost savings from these combined technologies can reduce operational expenses by 25-35% compared to conventional systems, with payback periods of 3-5 years depending on hydrogen throughput and electricity costs. This favorable energy-economic profile makes the technology particularly attractive for green hydrogen applications where energy efficiency directly impacts production costs.

Future efficiency improvements are anticipated through advanced materials development, optimized system integration, and intelligent control systems that can dynamically adjust operating parameters based on feed composition and output requirements.

Traditional hydrogen purification and compression systems typically rely on energy-intensive processes such as pressure swing adsorption (PSA) and mechanical compression, which can consume between 8-12 kWh/kg H₂. In contrast, the combined electrochemical pump-membrane system demonstrates potential energy consumption reductions of 30-45% under optimal operating conditions.

The energy efficiency gains stem primarily from the electrochemical pump's ability to simultaneously purify and compress hydrogen in a single step. This eliminates the need for separate purification and mechanical compression stages, reducing parasitic energy losses associated with multiple process transitions. Quantitative analyses indicate that electrochemical hydrogen pumps operate at 65-75% electrical efficiency, compared to 50-60% for conventional mechanical compressors.

Membrane integration further enhances system efficiency by providing preliminary purification, reducing the electrochemical load on the pump. High-selectivity palladium-based or polymer membranes can achieve 99.9% hydrogen purity with minimal pressure differential requirements, thereby decreasing the overall energy input needed for the electrochemical compression stage.

Temperature management represents another critical efficiency factor. Combined systems operating at moderate temperatures (80-120°C) demonstrate optimal energy performance, balancing membrane permeability with electrochemical reaction kinetics. This temperature range enables efficient operation while minimizing thermal management energy requirements.

Scale-dependent efficiency analysis reveals that larger integrated systems (>100 kg H₂/day) achieve better energy performance due to reduced relative heat losses and improved electrical efficiency at scale. Laboratory-scale systems typically show 10-15% lower efficiency than industrial-scale implementations.

Economic modeling indicates that the energy cost savings from these combined technologies can reduce operational expenses by 25-35% compared to conventional systems, with payback periods of 3-5 years depending on hydrogen throughput and electricity costs. This favorable energy-economic profile makes the technology particularly attractive for green hydrogen applications where energy efficiency directly impacts production costs.

Future efficiency improvements are anticipated through advanced materials development, optimized system integration, and intelligent control systems that can dynamically adjust operating parameters based on feed composition and output requirements.

Scalability and Cost Considerations for Industrial Implementation

The industrial implementation of combined electrochemical hydrogen pumps and membrane systems presents significant scalability and cost challenges that must be addressed for widespread adoption. Current pilot-scale implementations demonstrate promising results, but scaling to industrial capacities of 100+ tons per day requires substantial engineering modifications and capital investment. The estimated capital expenditure for large-scale integrated systems ranges from $1,500-3,000 per kilowatt of processing capacity, significantly higher than conventional pressure swing adsorption (PSA) systems at $800-1,200 per kilowatt.

Material costs constitute approximately 40-45% of total system expenses, with electrochemical cell components—particularly noble metal catalysts and specialized membranes—representing the most significant cost drivers. Platinum and palladium catalysts alone account for 15-20% of material costs, creating vulnerability to precious metal price fluctuations. Recent advancements in catalyst development have reduced loading requirements by 30-35% compared to early-generation systems, but further reductions remain necessary for economic viability.

Energy consumption presents another critical consideration, with current systems requiring 8-12 kWh per kilogram of processed hydrogen. This energy requirement translates to operational costs of $0.40-0.60 per kilogram at industrial electricity rates, necessitating integration with renewable energy sources to maintain economic and environmental sustainability. Modeling suggests that achieving grid parity would require reducing energy consumption to below 7 kWh/kg while simultaneously decreasing capital costs by at least 25%.

Manufacturing scalability introduces additional complexities, particularly regarding membrane production and electrochemical cell assembly. Current manufacturing processes remain largely semi-automated, with limited economies of scale. Industry analysis indicates that achieving a ten-fold increase in production volume would reduce unit costs by only 30-35%, insufficient for meeting cost targets without fundamental process innovations.

Maintenance requirements and system longevity further impact total cost of ownership. Current electrochemical systems demonstrate membrane degradation rates of 1-2% per 1,000 operating hours, necessitating replacement every 2-3 years. This maintenance schedule compares unfavorably with PSA systems, which typically require major overhauls only every 5-7 years. Improving membrane durability represents a critical path toward reducing lifetime operational costs and enhancing industrial viability.

Despite these challenges, economic modeling suggests that integrated electrochemical-membrane systems could achieve cost parity with conventional technologies by 2028-2030, assuming continued technological advancement and manufacturing optimization. This timeline aligns with projected hydrogen infrastructure expansion in major industrial economies, potentially creating favorable market conditions for widespread implementation.

Material costs constitute approximately 40-45% of total system expenses, with electrochemical cell components—particularly noble metal catalysts and specialized membranes—representing the most significant cost drivers. Platinum and palladium catalysts alone account for 15-20% of material costs, creating vulnerability to precious metal price fluctuations. Recent advancements in catalyst development have reduced loading requirements by 30-35% compared to early-generation systems, but further reductions remain necessary for economic viability.

Energy consumption presents another critical consideration, with current systems requiring 8-12 kWh per kilogram of processed hydrogen. This energy requirement translates to operational costs of $0.40-0.60 per kilogram at industrial electricity rates, necessitating integration with renewable energy sources to maintain economic and environmental sustainability. Modeling suggests that achieving grid parity would require reducing energy consumption to below 7 kWh/kg while simultaneously decreasing capital costs by at least 25%.

Manufacturing scalability introduces additional complexities, particularly regarding membrane production and electrochemical cell assembly. Current manufacturing processes remain largely semi-automated, with limited economies of scale. Industry analysis indicates that achieving a ten-fold increase in production volume would reduce unit costs by only 30-35%, insufficient for meeting cost targets without fundamental process innovations.

Maintenance requirements and system longevity further impact total cost of ownership. Current electrochemical systems demonstrate membrane degradation rates of 1-2% per 1,000 operating hours, necessitating replacement every 2-3 years. This maintenance schedule compares unfavorably with PSA systems, which typically require major overhauls only every 5-7 years. Improving membrane durability represents a critical path toward reducing lifetime operational costs and enhancing industrial viability.

Despite these challenges, economic modeling suggests that integrated electrochemical-membrane systems could achieve cost parity with conventional technologies by 2028-2030, assuming continued technological advancement and manufacturing optimization. This timeline aligns with projected hydrogen infrastructure expansion in major industrial economies, potentially creating favorable market conditions for widespread implementation.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!