Comparative Efficiency: Lithium Iron Phosphate vs. Solid-State Batteries

AUG 8, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Battery Tech Evolution

The evolution of battery technology has been a critical factor in the advancement of portable electronics, electric vehicles, and renewable energy storage systems. Over the past few decades, we have witnessed significant improvements in battery performance, efficiency, and safety.

Lithium-ion batteries, introduced in the early 1990s, marked a revolutionary step in energy storage. These batteries offered higher energy density, longer cycle life, and better performance compared to their predecessors. The development of lithium iron phosphate (LiFePO4) cathodes in the late 1990s further enhanced the safety and stability of lithium-ion batteries, making them suitable for a wider range of applications.

As the demand for higher energy density and faster charging capabilities grew, researchers began exploring new materials and designs. This led to the emergence of solid-state battery technology, which promises to overcome many limitations of traditional lithium-ion batteries.

Solid-state batteries replace the liquid or gel electrolyte found in conventional lithium-ion batteries with a solid electrolyte. This fundamental change offers several potential advantages, including higher energy density, improved safety, and faster charging times. However, the technology is still in its early stages of development and faces challenges in terms of manufacturing scalability and cost-effectiveness.

The comparison between lithium iron phosphate (LFP) and solid-state batteries represents a crucial juncture in battery technology evolution. LFP batteries have established themselves as a reliable and safe option, particularly in electric vehicles and grid storage applications. They offer excellent thermal stability, long cycle life, and lower production costs compared to other lithium-ion chemistries.

On the other hand, solid-state batteries are seen as the next major leap in battery technology. They promise even higher energy densities, potentially enabling electric vehicles with longer ranges and consumer electronics with significantly longer battery life. Additionally, the solid electrolyte eliminates the risk of electrolyte leakage and reduces the potential for thermal runaway, addressing key safety concerns associated with traditional lithium-ion batteries.

As research and development efforts continue, we can expect to see further improvements in both LFP and solid-state battery technologies. The evolution of these technologies will likely lead to a diversification of battery solutions, with different chemistries and designs optimized for specific applications and use cases.

Lithium-ion batteries, introduced in the early 1990s, marked a revolutionary step in energy storage. These batteries offered higher energy density, longer cycle life, and better performance compared to their predecessors. The development of lithium iron phosphate (LiFePO4) cathodes in the late 1990s further enhanced the safety and stability of lithium-ion batteries, making them suitable for a wider range of applications.

As the demand for higher energy density and faster charging capabilities grew, researchers began exploring new materials and designs. This led to the emergence of solid-state battery technology, which promises to overcome many limitations of traditional lithium-ion batteries.

Solid-state batteries replace the liquid or gel electrolyte found in conventional lithium-ion batteries with a solid electrolyte. This fundamental change offers several potential advantages, including higher energy density, improved safety, and faster charging times. However, the technology is still in its early stages of development and faces challenges in terms of manufacturing scalability and cost-effectiveness.

The comparison between lithium iron phosphate (LFP) and solid-state batteries represents a crucial juncture in battery technology evolution. LFP batteries have established themselves as a reliable and safe option, particularly in electric vehicles and grid storage applications. They offer excellent thermal stability, long cycle life, and lower production costs compared to other lithium-ion chemistries.

On the other hand, solid-state batteries are seen as the next major leap in battery technology. They promise even higher energy densities, potentially enabling electric vehicles with longer ranges and consumer electronics with significantly longer battery life. Additionally, the solid electrolyte eliminates the risk of electrolyte leakage and reduces the potential for thermal runaway, addressing key safety concerns associated with traditional lithium-ion batteries.

As research and development efforts continue, we can expect to see further improvements in both LFP and solid-state battery technologies. The evolution of these technologies will likely lead to a diversification of battery solutions, with different chemistries and designs optimized for specific applications and use cases.

Market Demand Analysis

The market demand for advanced battery technologies, particularly Lithium Iron Phosphate (LFP) and Solid-State Batteries (SSB), has been experiencing significant growth in recent years. This surge is primarily driven by the increasing adoption of electric vehicles (EVs) and the growing need for efficient energy storage solutions in various sectors.

LFP batteries have gained substantial traction in the EV market due to their lower cost, improved safety, and longer cycle life compared to traditional lithium-ion batteries. Major automakers, including Tesla and Volkswagen, have announced plans to incorporate LFP batteries in their entry-level EV models, indicating a strong market demand for this technology.

The global LFP battery market is projected to grow at a compound annual growth rate (CAGR) of over 20% from 2021 to 2026. This growth is attributed to the increasing demand for EVs, particularly in China, which is the largest market for LFP batteries. The technology's adoption is also expanding in other regions, including Europe and North America, as manufacturers seek cost-effective and sustainable battery solutions.

Solid-state batteries, while still in the early stages of commercialization, are garnering significant interest from both the automotive and consumer electronics industries. The promise of higher energy density, faster charging times, and enhanced safety has led to substantial investments in SSB research and development. Major automakers such as Toyota, BMW, and Ford have announced partnerships or investments in solid-state battery technology, signaling strong market expectations for this emerging technology.

The global solid-state battery market is expected to grow at a CAGR of over 30% from 2021 to 2028. This rapid growth is driven by the potential advantages of SSBs over conventional lithium-ion batteries, including higher energy density, improved safety, and longer lifespan. However, the market penetration of SSBs is currently limited due to high production costs and technical challenges in large-scale manufacturing.

In the energy storage sector, both LFP and solid-state batteries are attracting attention for grid-scale applications. LFP batteries are already being deployed in stationary energy storage systems due to their long cycle life and safety advantages. The potential for solid-state batteries in this sector is also significant, with expectations of improved energy density and reduced maintenance requirements.

The market demand for both technologies is further bolstered by increasing government regulations and incentives aimed at reducing carbon emissions and promoting clean energy technologies. As countries worldwide set ambitious targets for EV adoption and renewable energy integration, the demand for advanced battery technologies is expected to continue its upward trajectory.

LFP batteries have gained substantial traction in the EV market due to their lower cost, improved safety, and longer cycle life compared to traditional lithium-ion batteries. Major automakers, including Tesla and Volkswagen, have announced plans to incorporate LFP batteries in their entry-level EV models, indicating a strong market demand for this technology.

The global LFP battery market is projected to grow at a compound annual growth rate (CAGR) of over 20% from 2021 to 2026. This growth is attributed to the increasing demand for EVs, particularly in China, which is the largest market for LFP batteries. The technology's adoption is also expanding in other regions, including Europe and North America, as manufacturers seek cost-effective and sustainable battery solutions.

Solid-state batteries, while still in the early stages of commercialization, are garnering significant interest from both the automotive and consumer electronics industries. The promise of higher energy density, faster charging times, and enhanced safety has led to substantial investments in SSB research and development. Major automakers such as Toyota, BMW, and Ford have announced partnerships or investments in solid-state battery technology, signaling strong market expectations for this emerging technology.

The global solid-state battery market is expected to grow at a CAGR of over 30% from 2021 to 2028. This rapid growth is driven by the potential advantages of SSBs over conventional lithium-ion batteries, including higher energy density, improved safety, and longer lifespan. However, the market penetration of SSBs is currently limited due to high production costs and technical challenges in large-scale manufacturing.

In the energy storage sector, both LFP and solid-state batteries are attracting attention for grid-scale applications. LFP batteries are already being deployed in stationary energy storage systems due to their long cycle life and safety advantages. The potential for solid-state batteries in this sector is also significant, with expectations of improved energy density and reduced maintenance requirements.

The market demand for both technologies is further bolstered by increasing government regulations and incentives aimed at reducing carbon emissions and promoting clean energy technologies. As countries worldwide set ambitious targets for EV adoption and renewable energy integration, the demand for advanced battery technologies is expected to continue its upward trajectory.

Current Challenges

The current challenges in comparing the efficiency of Lithium Iron Phosphate (LFP) and Solid-State Batteries (SSB) are multifaceted and complex. One of the primary obstacles is the disparity in technological maturity between these two battery types. LFP batteries have been in commercial use for years, with well-established manufacturing processes and performance metrics. In contrast, solid-state batteries are still largely in the research and development phase, with limited real-world data available.

This discrepancy in development stages makes direct comparisons of efficiency challenging. While LFP batteries have known performance characteristics in various applications and environmental conditions, solid-state batteries are still being optimized for practical use. The lack of standardized testing protocols for solid-state batteries further complicates the comparison process, as different research groups and companies may report results using varied methodologies.

Another significant challenge is the dynamic nature of battery technology. Both LFP and solid-state batteries are undergoing continuous improvements, with new materials, manufacturing techniques, and designs being developed rapidly. This constant evolution makes it difficult to establish a definitive comparison, as today's benchmarks may quickly become outdated.

The definition of "efficiency" itself presents a challenge in this comparison. Efficiency in battery technology can encompass various factors, including energy density, power density, charging speed, cycle life, and thermal management. LFP and solid-state batteries may excel in different areas, making a holistic comparison complex. For instance, solid-state batteries are expected to offer higher energy density, but their power delivery capabilities are still being refined.

Cost considerations add another layer of complexity to the efficiency comparison. While LFP batteries benefit from economies of scale and established supply chains, solid-state batteries face challenges in scaling up production and reducing costs. The economic viability of new technologies plays a crucial role in their adoption and, consequently, in the resources allocated to their development and optimization.

Environmental factors and safety concerns also influence the efficiency assessment. LFP batteries are known for their thermal stability and safety, while solid-state batteries promise even greater safety due to their non-flammable electrolytes. However, the long-term environmental impact and recyclability of solid-state batteries are yet to be fully understood, adding uncertainty to their overall efficiency evaluation.

Lastly, the integration of these battery technologies into existing and future applications poses a challenge in comparing their practical efficiency. The performance of batteries can vary significantly depending on the specific use case, whether it's in electric vehicles, grid storage, or portable electronics. Adapting solid-state battery technology to meet the diverse requirements of these applications while maintaining its theoretical advantages is an ongoing challenge that impacts efficiency comparisons.

This discrepancy in development stages makes direct comparisons of efficiency challenging. While LFP batteries have known performance characteristics in various applications and environmental conditions, solid-state batteries are still being optimized for practical use. The lack of standardized testing protocols for solid-state batteries further complicates the comparison process, as different research groups and companies may report results using varied methodologies.

Another significant challenge is the dynamic nature of battery technology. Both LFP and solid-state batteries are undergoing continuous improvements, with new materials, manufacturing techniques, and designs being developed rapidly. This constant evolution makes it difficult to establish a definitive comparison, as today's benchmarks may quickly become outdated.

The definition of "efficiency" itself presents a challenge in this comparison. Efficiency in battery technology can encompass various factors, including energy density, power density, charging speed, cycle life, and thermal management. LFP and solid-state batteries may excel in different areas, making a holistic comparison complex. For instance, solid-state batteries are expected to offer higher energy density, but their power delivery capabilities are still being refined.

Cost considerations add another layer of complexity to the efficiency comparison. While LFP batteries benefit from economies of scale and established supply chains, solid-state batteries face challenges in scaling up production and reducing costs. The economic viability of new technologies plays a crucial role in their adoption and, consequently, in the resources allocated to their development and optimization.

Environmental factors and safety concerns also influence the efficiency assessment. LFP batteries are known for their thermal stability and safety, while solid-state batteries promise even greater safety due to their non-flammable electrolytes. However, the long-term environmental impact and recyclability of solid-state batteries are yet to be fully understood, adding uncertainty to their overall efficiency evaluation.

Lastly, the integration of these battery technologies into existing and future applications poses a challenge in comparing their practical efficiency. The performance of batteries can vary significantly depending on the specific use case, whether it's in electric vehicles, grid storage, or portable electronics. Adapting solid-state battery technology to meet the diverse requirements of these applications while maintaining its theoretical advantages is an ongoing challenge that impacts efficiency comparisons.

Existing Solutions

01 Lithium Iron Phosphate (LFP) battery efficiency improvements

Advancements in LFP battery technology focus on enhancing energy density, cycle life, and charging speed. Researchers are exploring novel cathode materials, optimizing particle size and morphology, and developing advanced manufacturing processes to improve overall battery efficiency.- Lithium Iron Phosphate (LFP) battery efficiency improvements: Advancements in LFP battery technology focus on enhancing energy density, charge/discharge rates, and overall efficiency. This includes optimizing electrode materials, improving electrolyte compositions, and refining manufacturing processes to increase battery performance and longevity.

- Solid-State battery efficiency enhancements: Solid-state batteries are being developed to improve energy density, safety, and charging speeds. Research focuses on new solid electrolyte materials, interface engineering between electrodes and electrolytes, and innovative cell designs to overcome current limitations and increase overall efficiency.

- Hybrid and composite battery systems: Combining LFP and solid-state technologies or creating hybrid systems with other battery chemistries aims to leverage the strengths of each technology. These approaches seek to optimize performance, safety, and cost-effectiveness for various applications, from electric vehicles to grid storage.

- Advanced manufacturing techniques for battery efficiency: Novel manufacturing methods, including 3D printing, roll-to-roll processing, and precision coating techniques, are being developed to enhance battery efficiency. These techniques aim to improve material utilization, reduce production costs, and enable the creation of more complex battery architectures.

- Battery management systems for optimized efficiency: Sophisticated battery management systems are being developed to maximize the efficiency of both LFP and solid-state batteries. These systems employ advanced algorithms, real-time monitoring, and predictive analytics to optimize charging, discharging, and overall battery performance throughout their lifecycle.

02 Solid-state battery efficiency enhancements

Solid-state batteries are being developed to offer higher energy density, improved safety, and faster charging capabilities compared to traditional lithium-ion batteries. Research efforts are concentrated on developing stable solid electrolytes, optimizing electrode-electrolyte interfaces, and addressing manufacturing challenges to increase efficiency.Expand Specific Solutions03 Hybrid LFP and solid-state battery technologies

Researchers are exploring hybrid approaches that combine the benefits of LFP and solid-state technologies. These hybrid systems aim to leverage the stability and cost-effectiveness of LFP with the high energy density and safety of solid-state electrolytes, potentially offering a balanced solution for improved battery efficiency.Expand Specific Solutions04 Advanced manufacturing techniques for battery efficiency

Novel manufacturing processes are being developed to enhance the efficiency of both LFP and solid-state batteries. These include precision coating methods, advanced sintering techniques, and innovative assembly processes that aim to improve battery performance, reduce production costs, and increase scalability.Expand Specific Solutions05 Battery management systems for optimized efficiency

Sophisticated battery management systems are being designed to maximize the efficiency of LFP and solid-state batteries. These systems incorporate advanced algorithms for charge-discharge control, thermal management, and state-of-health monitoring, ensuring optimal performance and longevity of the battery cells.Expand Specific Solutions

Key Industry Players

The competitive landscape for lithium iron phosphate (LFP) and solid-state batteries is evolving rapidly, with the industry in a transitional phase. The market for these technologies is expanding, driven by the growing demand for electric vehicles and energy storage solutions. While LFP batteries are more mature and widely adopted, solid-state batteries are still in the early stages of development. Companies like Contemporary Amperex Technology (CATL), LG Energy Solution, and Panasonic are leading in LFP technology, while Toyota, Samsung, and Murata Manufacturing are making significant strides in solid-state battery research. The market is characterized by intense competition and substantial investments in R&D, with both established players and startups vying for technological breakthroughs and market share.

Panasonic Intellectual Property Management Co. Ltd.

Technical Solution: Panasonic has been a pioneer in battery technology, with significant investments in both LFP and solid-state batteries. Their LFP batteries focus on high durability and safety, achieving over 4,000 charge cycles while maintaining 80% capacity[7]. For solid-state batteries, Panasonic is developing a unique "bipolar structure" that allows for higher voltage and energy density. Their prototypes have demonstrated energy densities of up to 1,000 Wh/L, nearly double that of current lithium-ion batteries[8]. Panasonic's solid-state design also aims to reduce charging times by up to one-third compared to conventional batteries.

Strengths: Long history in battery innovation, strong partnerships with automotive manufacturers. Weaknesses: Solid-state technology still in early stages, facing challenges in mass production.

LG Energy Solution Ltd.

Technical Solution: LG Energy Solution has made significant strides in both LFP and solid-state battery technologies. For LFP, they've developed a proprietary manufacturing process that increases energy density and reduces production costs[4]. Their LFP cells achieve energy densities of up to 200 Wh/kg, competitive with other market leaders[5]. In the solid-state realm, LG is focusing on sulfide-based solid electrolytes, which offer high ionic conductivity. They've demonstrated prototype cells with energy densities exceeding 900 Wh/L, significantly higher than conventional lithium-ion batteries[6]. LG's approach includes using a lithium metal anode to further boost energy density and charging speeds.

Strengths: Strong R&D capabilities, progress in both LFP and solid-state technologies. Weaknesses: Solid-state batteries still face challenges in scaling up production and long-term stability.

Core Innovations

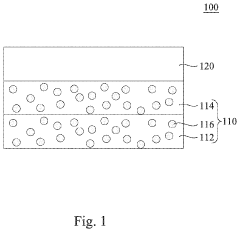

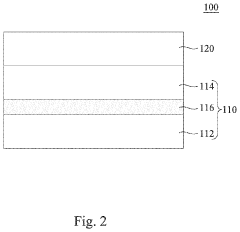

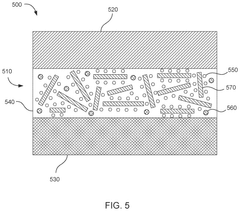

Composite cathode for solid-state battery

PatentPendingUS20230335720A1

Innovation

- A composite cathode structure is introduced, comprising a cathode sheet, an interface layer with a plasticized polymer, an adhesive polymer, and an ion conductor, and a solid electrolyte layer, which reduces interfacial impedance and enhances lithium ionic conductivity by optimizing the arrangement and materials used in the interface between the cathode and solid electrolyte.

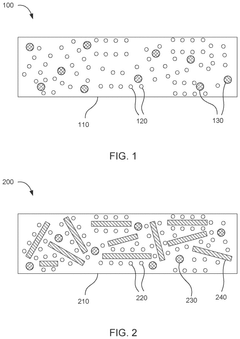

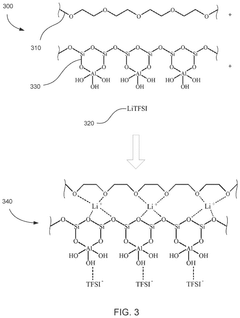

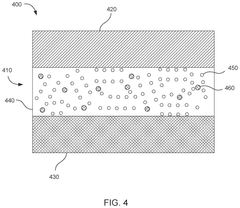

Solid state battery cell having a composite solid electrolyte including lithium iron phosphate

PatentActiveUS12074284B2

Innovation

- A composite solid electrolyte comprising a solid polymer with lithium salt and lithium iron phosphate, combined with phyllosilicate nanoparticles, which enhances lithium ion conductivity and compatibility with lithium iron phosphate cathodes, forming a flexible thin membrane for improved safety and performance across a wide temperature range.

Environmental Impact

The environmental impact of battery technologies is a critical consideration in the ongoing transition to sustainable energy systems. When comparing Lithium Iron Phosphate (LFP) batteries with Solid-State Batteries (SSBs), several key factors come into play.

LFP batteries have gained popularity due to their relatively lower environmental footprint compared to other lithium-ion chemistries. The iron and phosphate used in LFP batteries are abundant and less toxic than materials used in some alternative battery types. This reduces the environmental impact associated with raw material extraction and processing. Additionally, LFP batteries have a longer cycle life, which means they need to be replaced less frequently, potentially reducing waste generation over time.

However, the production of LFP batteries still involves energy-intensive processes and the use of some potentially harmful materials. The manufacturing of these batteries requires significant energy inputs, contributing to carbon emissions if not powered by renewable sources. Furthermore, while less toxic than some alternatives, the electrolyte used in LFP batteries can still pose environmental risks if not properly managed at the end of the battery's life.

Solid-state batteries, on the other hand, offer potential environmental advantages over traditional lithium-ion batteries, including LFP. The most significant benefit is the elimination of liquid electrolytes, which are flammable and can pose safety and environmental hazards. SSBs use solid electrolytes, which are generally more stable and less reactive, potentially reducing the risk of fires and chemical leakage.

The production of SSBs may also require less energy-intensive processes compared to conventional lithium-ion batteries, potentially lowering the carbon footprint associated with manufacturing. Additionally, the materials used in some SSB designs are more environmentally friendly and easier to recycle, which could lead to improved end-of-life management and reduced waste.

However, it's important to note that SSB technology is still in its early stages, and large-scale production processes have not been fully established. The environmental impact of mass-producing SSBs remains uncertain and will depend on the specific materials and manufacturing techniques adopted as the technology matures.

In terms of resource utilization, both LFP and SSB technologies aim to reduce reliance on scarce or problematic materials like cobalt. This shift could help mitigate some of the social and environmental issues associated with cobalt mining, particularly in regions with poor labor practices and environmental regulations.

Ultimately, the comparative environmental impact of LFP and solid-state batteries will depend on factors such as production scale, manufacturing efficiency, material sourcing, and end-of-life management practices. As both technologies continue to evolve, ongoing research and life cycle assessments will be crucial in determining their long-term environmental sustainability and guiding the development of more eco-friendly energy storage solutions.

LFP batteries have gained popularity due to their relatively lower environmental footprint compared to other lithium-ion chemistries. The iron and phosphate used in LFP batteries are abundant and less toxic than materials used in some alternative battery types. This reduces the environmental impact associated with raw material extraction and processing. Additionally, LFP batteries have a longer cycle life, which means they need to be replaced less frequently, potentially reducing waste generation over time.

However, the production of LFP batteries still involves energy-intensive processes and the use of some potentially harmful materials. The manufacturing of these batteries requires significant energy inputs, contributing to carbon emissions if not powered by renewable sources. Furthermore, while less toxic than some alternatives, the electrolyte used in LFP batteries can still pose environmental risks if not properly managed at the end of the battery's life.

Solid-state batteries, on the other hand, offer potential environmental advantages over traditional lithium-ion batteries, including LFP. The most significant benefit is the elimination of liquid electrolytes, which are flammable and can pose safety and environmental hazards. SSBs use solid electrolytes, which are generally more stable and less reactive, potentially reducing the risk of fires and chemical leakage.

The production of SSBs may also require less energy-intensive processes compared to conventional lithium-ion batteries, potentially lowering the carbon footprint associated with manufacturing. Additionally, the materials used in some SSB designs are more environmentally friendly and easier to recycle, which could lead to improved end-of-life management and reduced waste.

However, it's important to note that SSB technology is still in its early stages, and large-scale production processes have not been fully established. The environmental impact of mass-producing SSBs remains uncertain and will depend on the specific materials and manufacturing techniques adopted as the technology matures.

In terms of resource utilization, both LFP and SSB technologies aim to reduce reliance on scarce or problematic materials like cobalt. This shift could help mitigate some of the social and environmental issues associated with cobalt mining, particularly in regions with poor labor practices and environmental regulations.

Ultimately, the comparative environmental impact of LFP and solid-state batteries will depend on factors such as production scale, manufacturing efficiency, material sourcing, and end-of-life management practices. As both technologies continue to evolve, ongoing research and life cycle assessments will be crucial in determining their long-term environmental sustainability and guiding the development of more eco-friendly energy storage solutions.

Safety Considerations

Safety considerations are paramount when comparing lithium iron phosphate (LFP) and solid-state batteries. LFP batteries have established a reputation for enhanced safety compared to other lithium-ion chemistries. They exhibit excellent thermal and chemical stability, reducing the risk of thermal runaway and fire. LFP's olivine structure provides inherent resistance to oxygen release, a critical factor in preventing battery fires.

Solid-state batteries, on the other hand, promise even greater safety advantages. By replacing the liquid electrolyte with a solid one, they eliminate the risk of electrolyte leakage and significantly reduce the potential for internal short circuits. This design also enhances thermal stability, allowing for operation at higher temperatures without compromising safety.

However, the safety of solid-state batteries is not without challenges. The interface between the solid electrolyte and electrodes can be prone to degradation over time, potentially leading to capacity loss and increased internal resistance. Additionally, the mechanical stress caused by volume changes during charging and discharging cycles may create microcracks in the solid electrolyte, compromising its integrity.

Both battery types have undergone extensive testing to ensure compliance with international safety standards. LFP batteries have demonstrated excellent performance in nail penetration, crush, and overcharge tests. Solid-state batteries have shown promising results in similar tests, with some prototypes exhibiting remarkable resilience to physical damage.

In terms of operational safety, LFP batteries benefit from a well-established battery management system (BMS) infrastructure. These systems effectively monitor and control temperature, voltage, and current to prevent unsafe conditions. Solid-state batteries will require the development of new BMS protocols tailored to their unique characteristics, which is an ongoing area of research and development.

Environmental considerations also play a role in safety assessments. LFP batteries contain no cobalt, reducing concerns about toxic material exposure during production and recycling. Solid-state batteries may offer similar advantages, depending on their specific chemistry, but more research is needed to fully understand their environmental impact throughout their lifecycle.

As the technology evolves, ongoing safety evaluations will be crucial. While both LFP and solid-state batteries offer significant safety improvements over traditional lithium-ion batteries, continued research and development are essential to address remaining challenges and further enhance their safety profiles.

Solid-state batteries, on the other hand, promise even greater safety advantages. By replacing the liquid electrolyte with a solid one, they eliminate the risk of electrolyte leakage and significantly reduce the potential for internal short circuits. This design also enhances thermal stability, allowing for operation at higher temperatures without compromising safety.

However, the safety of solid-state batteries is not without challenges. The interface between the solid electrolyte and electrodes can be prone to degradation over time, potentially leading to capacity loss and increased internal resistance. Additionally, the mechanical stress caused by volume changes during charging and discharging cycles may create microcracks in the solid electrolyte, compromising its integrity.

Both battery types have undergone extensive testing to ensure compliance with international safety standards. LFP batteries have demonstrated excellent performance in nail penetration, crush, and overcharge tests. Solid-state batteries have shown promising results in similar tests, with some prototypes exhibiting remarkable resilience to physical damage.

In terms of operational safety, LFP batteries benefit from a well-established battery management system (BMS) infrastructure. These systems effectively monitor and control temperature, voltage, and current to prevent unsafe conditions. Solid-state batteries will require the development of new BMS protocols tailored to their unique characteristics, which is an ongoing area of research and development.

Environmental considerations also play a role in safety assessments. LFP batteries contain no cobalt, reducing concerns about toxic material exposure during production and recycling. Solid-state batteries may offer similar advantages, depending on their specific chemistry, but more research is needed to fully understand their environmental impact throughout their lifecycle.

As the technology evolves, ongoing safety evaluations will be crucial. While both LFP and solid-state batteries offer significant safety improvements over traditional lithium-ion batteries, continued research and development are essential to address remaining challenges and further enhance their safety profiles.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!