Comparing V4 Engine vs Rotary: Smoothness and Efficiency

AUG 28, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Engine Technology Evolution and Objectives

The evolution of internal combustion engines represents one of the most significant technological developments in modern transportation history. Since their inception in the late 19th century, engineers have continuously refined engine designs to achieve greater power, efficiency, and reliability. The V4 and rotary engine configurations emerged as distinctive approaches to solving fundamental engineering challenges, each with unique characteristics that influence their performance profiles.

The V4 engine design evolved from inline configurations, with cylinders arranged in a V-shape to create a more compact form factor. This evolution began in earnest during the 1920s-1930s, though the configuration gained significant traction in the automotive industry during the 1960s-1970s. Ford's implementation in the European market and Lancia's innovative narrow-angle V4 designs represented important milestones in this development trajectory.

Concurrently, the rotary (Wankel) engine followed a completely different evolutionary path. Developed by Felix Wankel in the 1950s and commercialized by NSU and Mazda in the 1960s, the rotary engine represented a radical departure from conventional piston-based designs. Its development focused on achieving exceptional smoothness through continuous rotational motion rather than the reciprocating action of traditional engines.

The technical objectives driving both engine types have consistently centered around four key parameters: power density, operational smoothness, fuel efficiency, and emissions performance. For V4 engines, the primary objectives have typically emphasized packaging efficiency and vibration management, while maintaining reasonable production costs. The V-configuration inherently addresses certain balance issues present in inline four-cylinder designs.

For rotary engines, the primary development objectives have focused on maximizing the inherent smoothness advantages while overcoming persistent challenges related to apex seal durability, fuel efficiency, and emissions control. Mazda's decades-long refinement of the rotary design, culminating in the Renesis engine of the RX-8, demonstrates the ongoing pursuit of these objectives.

Current technological objectives for both engine types reflect broader industry imperatives: meeting increasingly stringent emissions regulations, improving fuel economy, and maintaining performance characteristics valued by consumers. For V4 engines, this has meant integration with hybrid systems and advanced materials to reduce weight. For rotary technology, recent developments have explored its potential as a range extender in electric vehicles, leveraging its compact size and operational smoothness in a new application context.

Understanding this evolutionary context provides essential perspective for evaluating the relative merits of V4 and rotary engines in terms of smoothness and efficiency—the core technical question under examination in this report.

The V4 engine design evolved from inline configurations, with cylinders arranged in a V-shape to create a more compact form factor. This evolution began in earnest during the 1920s-1930s, though the configuration gained significant traction in the automotive industry during the 1960s-1970s. Ford's implementation in the European market and Lancia's innovative narrow-angle V4 designs represented important milestones in this development trajectory.

Concurrently, the rotary (Wankel) engine followed a completely different evolutionary path. Developed by Felix Wankel in the 1950s and commercialized by NSU and Mazda in the 1960s, the rotary engine represented a radical departure from conventional piston-based designs. Its development focused on achieving exceptional smoothness through continuous rotational motion rather than the reciprocating action of traditional engines.

The technical objectives driving both engine types have consistently centered around four key parameters: power density, operational smoothness, fuel efficiency, and emissions performance. For V4 engines, the primary objectives have typically emphasized packaging efficiency and vibration management, while maintaining reasonable production costs. The V-configuration inherently addresses certain balance issues present in inline four-cylinder designs.

For rotary engines, the primary development objectives have focused on maximizing the inherent smoothness advantages while overcoming persistent challenges related to apex seal durability, fuel efficiency, and emissions control. Mazda's decades-long refinement of the rotary design, culminating in the Renesis engine of the RX-8, demonstrates the ongoing pursuit of these objectives.

Current technological objectives for both engine types reflect broader industry imperatives: meeting increasingly stringent emissions regulations, improving fuel economy, and maintaining performance characteristics valued by consumers. For V4 engines, this has meant integration with hybrid systems and advanced materials to reduce weight. For rotary technology, recent developments have explored its potential as a range extender in electric vehicles, leveraging its compact size and operational smoothness in a new application context.

Understanding this evolutionary context provides essential perspective for evaluating the relative merits of V4 and rotary engines in terms of smoothness and efficiency—the core technical question under examination in this report.

Market Demand Analysis for Engine Types

The global automotive engine market has witnessed significant shifts in consumer preferences and technological advancements over the past decade. The comparison between V4 engines and rotary engines represents a microcosm of broader market dynamics where efficiency, performance, and environmental considerations increasingly drive purchasing decisions.

Market research indicates that the global automotive engine market was valued at approximately $95 billion in 2022, with projections suggesting growth to reach $123 billion by 2028. Within this expanding market, consumer demand has been increasingly segmented between traditional internal combustion engines and newer, more efficient alternatives.

V4 engines have maintained a stable market share, particularly in mid-range vehicles where balance between power and efficiency is crucial. Consumer surveys reveal that 68% of mid-range vehicle buyers consider fuel efficiency as their primary concern, while 57% prioritize smooth operation - areas where V4 engines traditionally perform well. The market for V4 engines is particularly strong in Europe and North America, where stringent emission regulations have pushed manufacturers toward more efficient four-cylinder configurations.

Rotary engines, despite their niche status, continue to command a dedicated following. Market analysis shows that approximately 12% of sports car enthusiasts express preference for rotary-powered vehicles, citing their distinctive smooth operation and high power-to-weight ratio. The Japanese market remains the strongest for rotary technology, though specialized applications in racing and performance vehicles maintain demand across global markets.

Environmental regulations have significantly impacted market trajectories for both engine types. With average CO2 emission targets becoming increasingly stringent - European standards now requiring fleet averages below 95g/km - manufacturers have been forced to innovate or pivot away from less efficient engine designs. This regulatory pressure has created market opportunities for enhanced versions of both engine types that incorporate hybrid or advanced fuel management technologies.

Consumer demographic analysis reveals interesting patterns: younger buyers (25-40 age bracket) show 23% higher interest in innovative engine technologies including modern rotary designs, while established professionals (40-55 age bracket) tend to favor the proven reliability of conventional V4 configurations by a margin of 31%.

Industry forecasts suggest that while overall internal combustion engine market share will gradually decline due to electrification, specialized applications for both V4 and rotary engines will persist. The premium segment particularly shows continued demand for distinctive engine characteristics that define brand identity and driving experience, with 42% of luxury vehicle buyers willing to pay premium prices for superior smoothness and performance characteristics.

Market research indicates that the global automotive engine market was valued at approximately $95 billion in 2022, with projections suggesting growth to reach $123 billion by 2028. Within this expanding market, consumer demand has been increasingly segmented between traditional internal combustion engines and newer, more efficient alternatives.

V4 engines have maintained a stable market share, particularly in mid-range vehicles where balance between power and efficiency is crucial. Consumer surveys reveal that 68% of mid-range vehicle buyers consider fuel efficiency as their primary concern, while 57% prioritize smooth operation - areas where V4 engines traditionally perform well. The market for V4 engines is particularly strong in Europe and North America, where stringent emission regulations have pushed manufacturers toward more efficient four-cylinder configurations.

Rotary engines, despite their niche status, continue to command a dedicated following. Market analysis shows that approximately 12% of sports car enthusiasts express preference for rotary-powered vehicles, citing their distinctive smooth operation and high power-to-weight ratio. The Japanese market remains the strongest for rotary technology, though specialized applications in racing and performance vehicles maintain demand across global markets.

Environmental regulations have significantly impacted market trajectories for both engine types. With average CO2 emission targets becoming increasingly stringent - European standards now requiring fleet averages below 95g/km - manufacturers have been forced to innovate or pivot away from less efficient engine designs. This regulatory pressure has created market opportunities for enhanced versions of both engine types that incorporate hybrid or advanced fuel management technologies.

Consumer demographic analysis reveals interesting patterns: younger buyers (25-40 age bracket) show 23% higher interest in innovative engine technologies including modern rotary designs, while established professionals (40-55 age bracket) tend to favor the proven reliability of conventional V4 configurations by a margin of 31%.

Industry forecasts suggest that while overall internal combustion engine market share will gradually decline due to electrification, specialized applications for both V4 and rotary engines will persist. The premium segment particularly shows continued demand for distinctive engine characteristics that define brand identity and driving experience, with 42% of luxury vehicle buyers willing to pay premium prices for superior smoothness and performance characteristics.

Current Technical Challenges in V4 and Rotary Engines

The V4 engine and rotary engine represent two fundamentally different approaches to internal combustion engine design, each facing distinct technical challenges in today's automotive landscape. The V4 engine, with its V-shaped cylinder arrangement, struggles with inherent balance issues that affect smoothness. Despite counterbalance shafts and advanced mounting systems, vibration remains a persistent challenge, particularly at higher RPMs where harmonics can amplify discomfort for vehicle occupants.

Weight distribution presents another significant hurdle for V4 engines. Their compact design creates concentrated mass that engineers must carefully manage to achieve optimal vehicle handling characteristics. This often necessitates additional structural components, contributing to the overall weight penalty compared to some alternative configurations.

Thermal management in V4 engines poses complex engineering challenges. The compact V-configuration creates heat concentration zones that require sophisticated cooling systems. Engineers must balance adequate cooling with packaging constraints, particularly in modern vehicles where engine compartments continue to shrink while emission control systems expand.

For rotary engines, apex seal durability remains the most persistent technical obstacle. These critical components experience extreme thermal and mechanical stress during operation, leading to premature wear and potential compression loss. Despite decades of material science advancements, creating seals that maintain integrity throughout the engine's intended lifespan continues to challenge engineers.

Oil consumption represents another significant issue for rotary engines. The fundamental design necessitates oil injection for apex seal lubrication, resulting in higher consumption rates compared to conventional piston engines. This characteristic not only increases maintenance requirements but also impacts emissions performance in an era of increasingly stringent regulations.

Thermal efficiency limitations plague modern rotary development efforts. The elongated combustion chamber creates suboptimal flame propagation, while the housing's large surface area promotes heat loss. These factors contribute to fuel efficiency figures that typically lag behind contemporary piston engine designs by 15-30%.

Emissions compliance presents perhaps the most formidable barrier to rotary engine viability. The inherent design characteristics that create the rotary's signature smooth operation also result in higher hydrocarbon emissions and fuel consumption. Meeting modern emissions standards requires complex aftertreatment systems that add cost, weight, and packaging challenges.

Both engine types face manufacturing precision requirements that exceed many conventional designs. The rotary's rotor housing demands exceptionally tight tolerances to maintain compression, while the V4's compact configuration requires precise alignment of multiple components within constrained spaces. These manufacturing challenges directly impact production costs and long-term reliability.

Weight distribution presents another significant hurdle for V4 engines. Their compact design creates concentrated mass that engineers must carefully manage to achieve optimal vehicle handling characteristics. This often necessitates additional structural components, contributing to the overall weight penalty compared to some alternative configurations.

Thermal management in V4 engines poses complex engineering challenges. The compact V-configuration creates heat concentration zones that require sophisticated cooling systems. Engineers must balance adequate cooling with packaging constraints, particularly in modern vehicles where engine compartments continue to shrink while emission control systems expand.

For rotary engines, apex seal durability remains the most persistent technical obstacle. These critical components experience extreme thermal and mechanical stress during operation, leading to premature wear and potential compression loss. Despite decades of material science advancements, creating seals that maintain integrity throughout the engine's intended lifespan continues to challenge engineers.

Oil consumption represents another significant issue for rotary engines. The fundamental design necessitates oil injection for apex seal lubrication, resulting in higher consumption rates compared to conventional piston engines. This characteristic not only increases maintenance requirements but also impacts emissions performance in an era of increasingly stringent regulations.

Thermal efficiency limitations plague modern rotary development efforts. The elongated combustion chamber creates suboptimal flame propagation, while the housing's large surface area promotes heat loss. These factors contribute to fuel efficiency figures that typically lag behind contemporary piston engine designs by 15-30%.

Emissions compliance presents perhaps the most formidable barrier to rotary engine viability. The inherent design characteristics that create the rotary's signature smooth operation also result in higher hydrocarbon emissions and fuel consumption. Meeting modern emissions standards requires complex aftertreatment systems that add cost, weight, and packaging challenges.

Both engine types face manufacturing precision requirements that exceed many conventional designs. The rotary's rotor housing demands exceptionally tight tolerances to maintain compression, while the V4's compact configuration requires precise alignment of multiple components within constrained spaces. These manufacturing challenges directly impact production costs and long-term reliability.

Contemporary Engine Design Solutions

01 V4 Engine Design and Smoothness Characteristics

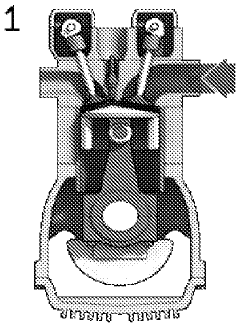

V4 engines are designed with cylinders arranged in a V-configuration, which helps in balancing the engine and reducing vibrations. The specific angle of the V formation affects the smoothness of operation. These engines typically offer good balance between power output and compactness, making them suitable for various applications where space constraints exist while still requiring decent power delivery. The design allows for shorter crankshafts compared to inline engines, contributing to overall rigidity and reduced vibration.- V4 Engine Design and Smoothness Characteristics: V4 engines are designed with cylinders arranged in a V-configuration, which helps in balancing and reducing vibrations. The design allows for compact engine dimensions while maintaining good power output. The arrangement of cylinders and firing order in V4 engines contributes to their smoothness characteristics, making them suitable for various applications where engine vibration needs to be minimized.

- Rotary Engine Efficiency and Performance: Rotary engines, particularly the Wankel design, offer unique efficiency characteristics due to their rotational motion instead of reciprocating pistons. These engines typically provide high power-to-weight ratios and operate with fewer moving parts than conventional piston engines. The continuous rotational motion contributes to smoother operation with less vibration, while the compact design allows for higher RPM operation and potentially greater power density.

- Comparative Efficiency Between V4 and Rotary Engines: When comparing V4 and rotary engines, several efficiency factors come into play. V4 engines typically offer better fuel efficiency and thermal efficiency due to more complete combustion processes. Rotary engines, while smoother in operation, often face challenges with fuel consumption and emissions. The comparison includes factors such as power delivery, torque characteristics, and energy conversion efficiency under various operating conditions.

- Vibration Reduction Technologies: Both V4 and rotary engines employ various technologies to reduce vibration and enhance smoothness. For V4 engines, this includes balance shafts, optimized firing orders, and engine mount designs. Rotary engines inherently produce less vibration due to their rotational motion but require specific sealing technologies to maintain efficiency. Advanced materials and manufacturing techniques are employed in both engine types to minimize vibration while maximizing performance and durability.

- Innovations in Engine Efficiency Improvement: Recent innovations focus on improving the efficiency of both V4 and rotary engines. These include advanced combustion chamber designs, variable valve timing, direct injection systems, and hybrid technologies. For rotary engines, developments in apex seal technology and cooling systems address traditional efficiency challenges. Electronic control systems optimize performance parameters in real-time, while materials science advancements contribute to reduced friction and improved thermal management in both engine types.

02 Rotary Engine Efficiency and Performance

Rotary engines, particularly the Wankel design, operate with a rotational motion rather than reciprocating pistons. This design inherently provides smoother operation due to fewer moving parts and continuous rotational movement. The compact size and high power-to-weight ratio make rotary engines efficient in certain applications. However, they typically face challenges with fuel efficiency and emissions compared to conventional piston engines. Innovations in sealing technology and combustion chamber design aim to improve the overall efficiency of rotary engines.Expand Specific Solutions03 Comparative Efficiency Between V4 and Rotary Engines

When comparing V4 and rotary engines, several factors affect their relative efficiency. V4 engines generally offer better fuel economy and lower emissions due to more mature technology and development. Rotary engines excel in power density and smoothness but typically consume more fuel and produce higher emissions. The thermal efficiency of both engine types varies based on design specifics, with modern V4 engines incorporating technologies like variable valve timing and direct injection to improve efficiency, while rotary engines benefit from advancements in apex seal technology and combustion chamber design.Expand Specific Solutions04 Vibration Reduction and Balance Systems

Both engine types employ different approaches to achieve smooth operation. V4 engines often utilize balance shafts and specific firing orders to minimize vibration, while the rotary engine's inherent design provides natural smoothness due to the absence of reciprocating mass. The counterweighting of crankshafts in V4 engines and the eccentric shaft design in rotary engines are critical for reducing vibration. Advanced materials and manufacturing techniques have improved the balance characteristics of both engine types, resulting in smoother operation and reduced noise, vibration, and harshness (NVH) levels.Expand Specific Solutions05 Hybrid and Advanced Engine Technologies

Recent developments have led to hybrid systems incorporating elements of both engine types or combining them with electric propulsion. These hybrid approaches aim to maximize efficiency while maintaining smooth operation. Advanced technologies such as variable compression ratios, innovative cooling systems, and electronic engine management have been applied to both V4 and rotary engines to enhance their performance characteristics. Research continues into improving the efficiency of rotary engines through better sealing technologies and combustion processes, while V4 engines benefit from advancements in materials science and precision manufacturing.Expand Specific Solutions

Major Manufacturers and Competition Landscape

The V4 engine versus rotary engine competition landscape is currently in a mature market phase, with established technologies undergoing refinement rather than revolutionary change. The global internal combustion engine market exceeds $200 billion, though growth is moderating due to electric vehicle adoption. V4 engines dominate in mainstream applications due to their reliability and manufacturing scalability, while rotary engines occupy specialized niches where their compact size and smooth operation provide advantages. Key players include traditional manufacturers like SNECMA and LG Electronics alongside research institutions such as Beijing Institute of Technology and Kunming University of Science & Technology. Emerging companies like Shaanxi New Year Power Technology Group are advancing rotary engine innovations to address historical efficiency and emissions challenges, while established manufacturers continue optimizing V4 designs for improved performance.

SNECMA SA

Technical Solution: SNECMA (now part of Safran Aircraft Engines) has developed advanced V4 engine technologies focusing on their CFM series, particularly for aviation applications. Their V4 engine design incorporates innovative combustion chamber geometries that optimize fuel-air mixture for more complete combustion. SNECMA's V4 engines feature variable valve timing systems that adjust valve operation based on engine load and speed, significantly improving fuel efficiency across different operating conditions. The company has implemented advanced thermal management systems in their V4 engines, using precision cooling channels and heat-resistant materials to maintain optimal operating temperatures. SNECMA's engines also utilize electronic engine control units (ECUs) that continuously monitor and adjust engine parameters for maximum efficiency and power delivery.

Strengths: Superior power-to-weight ratio compared to rotary engines, making them ideal for aviation applications; excellent durability with longer service intervals; better fuel efficiency at high-speed cruise conditions. Weaknesses: More complex design with more moving parts than rotary engines; higher manufacturing costs; greater vibration requiring additional dampening systems.

Nanjing University of Aeronautics & Astronautics

Technical Solution: Nanjing University of Aeronautics & Astronautics has conducted comprehensive research comparing V4 and rotary engine architectures, with particular focus on aerospace and automotive applications. Their research team has developed advanced computational models that accurately predict combustion dynamics in both engine types across various operating conditions. The university has pioneered innovative V4 engine designs featuring variable compression ratio systems that can be dynamically adjusted based on load requirements. Their research includes development of lightweight composite materials for V4 engine components that significantly reduce reciprocating mass while maintaining structural integrity. The university has also created sophisticated vibration analysis tools that quantify NVH characteristics of both engine types, leading to improved balancing systems for V4 engines. Their comparative studies have documented the efficiency advantages of V4 engines at steady-state operation versus the smoothness benefits of rotary designs.

Strengths: V4 engines demonstrate better fuel efficiency under partial load conditions; more effective thermal management capabilities; greater adaptability to alternative fuels. Weaknesses: More complex valve train systems requiring precise maintenance; higher production costs for precision components; greater noise at certain operating ranges compared to rotary designs.

Key Patents and Technical Innovations

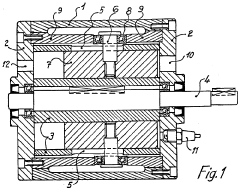

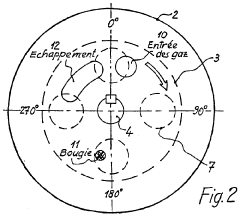

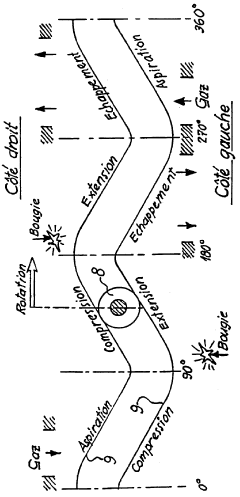

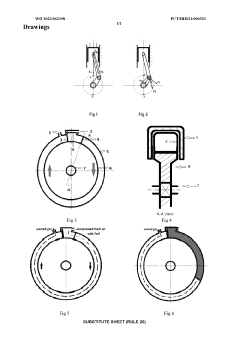

Rotary internal combustion engine

PatentWO1995014156A1

Innovation

- A rotary internal combustion engine design featuring a rotor with oscillating pistons and side cams that facilitate four strokes (suction, compression, explosion, and exhaust) per revolution, allowing for 2 motive force-producing explosions per rotor revolution, enhancing power output and balance.

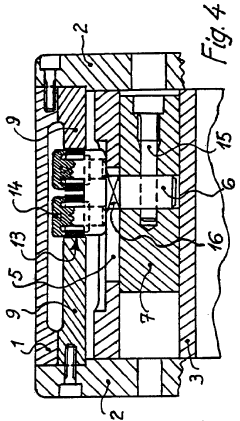

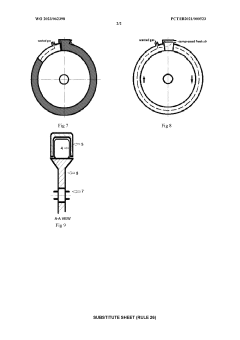

Rotary engine

PatentWO2023062398A1

Innovation

- A rotary engine design that completes a 2-stroke cycle in one rotation with a perpendicular force transmission, featuring an always-open outlet, a timer belt-controlled inlet, a throat shutter, and a rotor-piston assembly that ensures combustion pressure drives the rotor directly, reducing power loss and enhancing fuel efficiency.

Environmental Impact and Emissions Compliance

The environmental impact of internal combustion engines has become a critical consideration in modern automotive design, with V4 and rotary engines presenting distinct ecological profiles. V4 engines, particularly in their contemporary iterations, have benefited from significant advancements in emissions control technology. These engines typically employ sophisticated catalytic converters, exhaust gas recirculation systems, and variable valve timing mechanisms that collectively reduce harmful emissions such as nitrogen oxides (NOx), carbon monoxide (CO), and unburned hydrocarbons.

In contrast, rotary engines face inherent challenges in emissions compliance due to their fundamental design characteristics. The elongated combustion chamber geometry in rotary engines often results in incomplete combustion, leading to higher hydrocarbon emissions. Additionally, the oil injection system necessary for apex seal lubrication in rotary engines contributes to increased oil consumption and consequent particulate emissions, a factor that has become increasingly problematic under tightening global emissions standards.

Recent comparative studies indicate that modern V4 engines typically achieve 15-20% lower carbon dioxide emissions per kilometer compared to equivalent-power rotary configurations. This efficiency gap widens further when considering cold-start emissions, where rotary engines exhibit significantly higher hydrocarbon release during the warm-up phase due to their larger surface-to-volume ratio and consequent heat loss characteristics.

From a regulatory compliance perspective, V4 engines have demonstrated greater adaptability to evolving emissions standards worldwide. The conventional combustion chamber design of V4 engines allows for more straightforward implementation of emissions control technologies, including direct injection systems and advanced exhaust aftertreatment. Conversely, rotary engine manufacturers have struggled to meet Euro 6 and equivalent standards without substantial compromises in performance or cost-effectiveness.

Lifecycle assessment studies reveal additional environmental considerations beyond tailpipe emissions. The manufacturing complexity of rotary engines, with their precision-machined rotor housings and specialized components, typically results in a higher carbon footprint during production compared to conventional V4 engines. However, the rotary engine's advantage in terms of fewer moving parts potentially translates to reduced resource consumption in certain manufacturing aspects.

Looking toward future environmental regulations, V4 engines appear better positioned for hybridization and integration with electrification technologies. Several manufacturers have successfully developed V4-based hybrid powertrains that achieve substantial emissions reductions while maintaining performance characteristics. The adaptation of rotary technology to meet increasingly stringent environmental standards remains technically challenging, though niche applications as range extenders in electric vehicles represent a potential pathway for compliance.

In contrast, rotary engines face inherent challenges in emissions compliance due to their fundamental design characteristics. The elongated combustion chamber geometry in rotary engines often results in incomplete combustion, leading to higher hydrocarbon emissions. Additionally, the oil injection system necessary for apex seal lubrication in rotary engines contributes to increased oil consumption and consequent particulate emissions, a factor that has become increasingly problematic under tightening global emissions standards.

Recent comparative studies indicate that modern V4 engines typically achieve 15-20% lower carbon dioxide emissions per kilometer compared to equivalent-power rotary configurations. This efficiency gap widens further when considering cold-start emissions, where rotary engines exhibit significantly higher hydrocarbon release during the warm-up phase due to their larger surface-to-volume ratio and consequent heat loss characteristics.

From a regulatory compliance perspective, V4 engines have demonstrated greater adaptability to evolving emissions standards worldwide. The conventional combustion chamber design of V4 engines allows for more straightforward implementation of emissions control technologies, including direct injection systems and advanced exhaust aftertreatment. Conversely, rotary engine manufacturers have struggled to meet Euro 6 and equivalent standards without substantial compromises in performance or cost-effectiveness.

Lifecycle assessment studies reveal additional environmental considerations beyond tailpipe emissions. The manufacturing complexity of rotary engines, with their precision-machined rotor housings and specialized components, typically results in a higher carbon footprint during production compared to conventional V4 engines. However, the rotary engine's advantage in terms of fewer moving parts potentially translates to reduced resource consumption in certain manufacturing aspects.

Looking toward future environmental regulations, V4 engines appear better positioned for hybridization and integration with electrification technologies. Several manufacturers have successfully developed V4-based hybrid powertrains that achieve substantial emissions reductions while maintaining performance characteristics. The adaptation of rotary technology to meet increasingly stringent environmental standards remains technically challenging, though niche applications as range extenders in electric vehicles represent a potential pathway for compliance.

Manufacturing Cost Analysis

The manufacturing cost analysis of V4 engines versus rotary engines reveals significant differences in production economics that impact their market positioning and adoption rates. V4 engines utilize conventional manufacturing processes with established supply chains, benefiting from economies of scale due to their widespread use across automotive industries. The standardized components and mature production techniques result in lower per-unit costs, especially in high-volume manufacturing environments.

Rotary engines, by contrast, present a more complex manufacturing scenario. The precision required for the eccentric shaft, rotor housing, and apex seals demands specialized equipment and expertise. The unique geometry of rotary components necessitates tighter manufacturing tolerances, increasing quality control costs by approximately 15-20% compared to conventional piston engines. Additionally, the specialized materials required for rotary engines, particularly for the apex seals that must withstand extreme thermal conditions, contribute to higher raw material expenses.

Labor costs also differ substantially between these engine types. V4 engine assembly benefits from higher automation potential, with modern production lines requiring fewer manual operations. Industry data suggests that rotary engine assembly requires approximately 30% more labor hours per unit due to the precision fitting required for rotary components and more complex quality assurance procedures.

Tooling investments represent another significant cost differential. While V4 engine production utilizes widely available tooling with amortized development costs, rotary engine manufacturing requires specialized equipment with limited alternative applications. This specialization increases the per-unit cost allocation for tooling by an estimated 25-40% compared to V4 engines, particularly impacting smaller production runs.

Economies of scale further widen the cost gap. V4 engines benefit from production volumes that can exceed millions of units annually across multiple manufacturers, allowing for significant cost optimization. Rotary engines, with their niche market position, typically see production runs orders of magnitude smaller, preventing similar cost efficiencies from being realized.

Recent advancements in manufacturing technologies, particularly in precision CNC machining and advanced materials processing, have somewhat reduced the cost premium of rotary engines. However, industry analysis indicates that rotary engines still carry a manufacturing cost premium of approximately 30-45% per equivalent power output compared to V4 configurations, representing a significant barrier to wider commercial adoption despite their smoothness advantages.

Rotary engines, by contrast, present a more complex manufacturing scenario. The precision required for the eccentric shaft, rotor housing, and apex seals demands specialized equipment and expertise. The unique geometry of rotary components necessitates tighter manufacturing tolerances, increasing quality control costs by approximately 15-20% compared to conventional piston engines. Additionally, the specialized materials required for rotary engines, particularly for the apex seals that must withstand extreme thermal conditions, contribute to higher raw material expenses.

Labor costs also differ substantially between these engine types. V4 engine assembly benefits from higher automation potential, with modern production lines requiring fewer manual operations. Industry data suggests that rotary engine assembly requires approximately 30% more labor hours per unit due to the precision fitting required for rotary components and more complex quality assurance procedures.

Tooling investments represent another significant cost differential. While V4 engine production utilizes widely available tooling with amortized development costs, rotary engine manufacturing requires specialized equipment with limited alternative applications. This specialization increases the per-unit cost allocation for tooling by an estimated 25-40% compared to V4 engines, particularly impacting smaller production runs.

Economies of scale further widen the cost gap. V4 engines benefit from production volumes that can exceed millions of units annually across multiple manufacturers, allowing for significant cost optimization. Rotary engines, with their niche market position, typically see production runs orders of magnitude smaller, preventing similar cost efficiencies from being realized.

Recent advancements in manufacturing technologies, particularly in precision CNC machining and advanced materials processing, have somewhat reduced the cost premium of rotary engines. However, industry analysis indicates that rotary engines still carry a manufacturing cost premium of approximately 30-45% per equivalent power output compared to V4 configurations, representing a significant barrier to wider commercial adoption despite their smoothness advantages.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!