Cryogenic Electronics: Compliance and Qualification Challenges

SEP 29, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Cryogenic Electronics Background and Objectives

Cryogenic electronics represents a specialized field of electronic engineering that focuses on the design, development, and operation of electronic systems at extremely low temperatures, typically below 123K (-150°C). The evolution of this technology can be traced back to the mid-20th century, with significant advancements occurring in parallel with developments in superconductivity research. Initially driven by space exploration and quantum computing requirements, cryogenic electronics has expanded into various applications including medical imaging, particle physics, and advanced computing systems.

The technological trajectory of cryogenic electronics has been characterized by progressive improvements in material science, semiconductor physics, and thermal management techniques. Early systems primarily utilized specialized semiconductor materials that could maintain functionality at low temperatures. Recent developments have focused on integrating superconducting elements with conventional semiconductor technologies to create hybrid systems that leverage the advantages of both approaches.

The primary objective of cryogenic electronics research is to develop electronic components and systems capable of reliable operation in extreme cold environments while maintaining or enhancing performance metrics such as speed, power efficiency, and signal integrity. This includes addressing fundamental challenges related to material behavior, thermal cycling effects, and quantum mechanical phenomena that emerge at cryogenic temperatures.

Current research goals include developing standardized qualification methodologies specifically tailored for cryogenic applications, as traditional electronic testing frameworks prove inadequate for these extreme conditions. Additionally, there is significant focus on creating compliance standards that address the unique reliability concerns of cryogenic systems, including thermal stress management, interconnect stability, and long-term performance degradation mechanisms.

The field aims to bridge the gap between theoretical understanding of low-temperature electronic behavior and practical implementation challenges. This involves creating predictive models for component behavior, establishing accelerated testing protocols that accurately reflect cryogenic operating conditions, and developing specialized measurement techniques that function reliably at extreme temperatures.

As quantum computing and space exploration continue to advance, cryogenic electronics faces increasing demands for higher integration density, improved energy efficiency, and enhanced reliability. The technology roadmap includes developing cryogenic-specific integrated circuits, specialized packaging solutions that minimize thermal gradients, and novel testing methodologies that can accurately predict long-term performance in these challenging environments.

The technological trajectory of cryogenic electronics has been characterized by progressive improvements in material science, semiconductor physics, and thermal management techniques. Early systems primarily utilized specialized semiconductor materials that could maintain functionality at low temperatures. Recent developments have focused on integrating superconducting elements with conventional semiconductor technologies to create hybrid systems that leverage the advantages of both approaches.

The primary objective of cryogenic electronics research is to develop electronic components and systems capable of reliable operation in extreme cold environments while maintaining or enhancing performance metrics such as speed, power efficiency, and signal integrity. This includes addressing fundamental challenges related to material behavior, thermal cycling effects, and quantum mechanical phenomena that emerge at cryogenic temperatures.

Current research goals include developing standardized qualification methodologies specifically tailored for cryogenic applications, as traditional electronic testing frameworks prove inadequate for these extreme conditions. Additionally, there is significant focus on creating compliance standards that address the unique reliability concerns of cryogenic systems, including thermal stress management, interconnect stability, and long-term performance degradation mechanisms.

The field aims to bridge the gap between theoretical understanding of low-temperature electronic behavior and practical implementation challenges. This involves creating predictive models for component behavior, establishing accelerated testing protocols that accurately reflect cryogenic operating conditions, and developing specialized measurement techniques that function reliably at extreme temperatures.

As quantum computing and space exploration continue to advance, cryogenic electronics faces increasing demands for higher integration density, improved energy efficiency, and enhanced reliability. The technology roadmap includes developing cryogenic-specific integrated circuits, specialized packaging solutions that minimize thermal gradients, and novel testing methodologies that can accurately predict long-term performance in these challenging environments.

Market Analysis for Cryogenic Electronic Applications

The cryogenic electronics market is experiencing significant growth driven by quantum computing, space exploration, and scientific research applications. Current market estimates value the global cryogenic equipment sector at approximately $2.5 billion, with specialized cryogenic electronics components representing a rapidly expanding segment projected to reach $500 million by 2026, growing at a CAGR of 8.7%.

Quantum computing represents the largest application segment, accounting for nearly 40% of the cryogenic electronics market. Major technology companies including IBM, Google, and Intel are making substantial investments in quantum computing infrastructure that requires superconducting circuits operating at temperatures near absolute zero. This segment alone is expected to triple in size over the next five years as quantum computing moves from research to commercial applications.

Space exploration constitutes the second-largest market segment at 25%, with NASA, ESA, and emerging private space companies requiring radiation-hardened, cryogenic-capable electronics for deep space missions. The increasing number of planned missions to outer planets and beyond is creating steady demand growth estimated at 12% annually through 2030.

Scientific research applications, including particle physics experiments, astronomical observatories, and medical imaging systems, represent approximately 20% of the market. The remaining 15% encompasses niche applications in defense, medical cryopreservation, and specialized industrial processes requiring extreme-cold electronics.

Geographically, North America dominates with 45% market share due to concentrated quantum computing research and space exploration activities. Europe follows at 30%, with Asia-Pacific representing the fastest-growing region at 18% annual growth, driven by China's aggressive investments in quantum technologies and cryogenic research infrastructure.

Key market challenges include the high cost of cryogenic cooling systems, which can represent up to 70% of total system costs, creating significant barriers to entry. Additionally, the specialized nature of cryogenic electronics limits the supplier base, with fewer than 20 companies worldwide capable of producing qualified components for mission-critical applications.

Customer requirements are increasingly focused on reliability at extreme temperatures, with failure rates below 0.001% being demanded for space and quantum computing applications. Power efficiency is another critical factor, as cooling costs escalate exponentially as temperatures approach absolute zero, with each watt of power dissipation requiring approximately 1,000 watts of cooling capacity at 4 Kelvin.

Market forecasts indicate continued strong growth as quantum computing commercialization accelerates and space exploration missions increase in frequency and complexity. The development of more efficient cooling technologies and standardized qualification protocols could potentially reduce system costs by 30-40%, significantly expanding market accessibility.

Quantum computing represents the largest application segment, accounting for nearly 40% of the cryogenic electronics market. Major technology companies including IBM, Google, and Intel are making substantial investments in quantum computing infrastructure that requires superconducting circuits operating at temperatures near absolute zero. This segment alone is expected to triple in size over the next five years as quantum computing moves from research to commercial applications.

Space exploration constitutes the second-largest market segment at 25%, with NASA, ESA, and emerging private space companies requiring radiation-hardened, cryogenic-capable electronics for deep space missions. The increasing number of planned missions to outer planets and beyond is creating steady demand growth estimated at 12% annually through 2030.

Scientific research applications, including particle physics experiments, astronomical observatories, and medical imaging systems, represent approximately 20% of the market. The remaining 15% encompasses niche applications in defense, medical cryopreservation, and specialized industrial processes requiring extreme-cold electronics.

Geographically, North America dominates with 45% market share due to concentrated quantum computing research and space exploration activities. Europe follows at 30%, with Asia-Pacific representing the fastest-growing region at 18% annual growth, driven by China's aggressive investments in quantum technologies and cryogenic research infrastructure.

Key market challenges include the high cost of cryogenic cooling systems, which can represent up to 70% of total system costs, creating significant barriers to entry. Additionally, the specialized nature of cryogenic electronics limits the supplier base, with fewer than 20 companies worldwide capable of producing qualified components for mission-critical applications.

Customer requirements are increasingly focused on reliability at extreme temperatures, with failure rates below 0.001% being demanded for space and quantum computing applications. Power efficiency is another critical factor, as cooling costs escalate exponentially as temperatures approach absolute zero, with each watt of power dissipation requiring approximately 1,000 watts of cooling capacity at 4 Kelvin.

Market forecasts indicate continued strong growth as quantum computing commercialization accelerates and space exploration missions increase in frequency and complexity. The development of more efficient cooling technologies and standardized qualification protocols could potentially reduce system costs by 30-40%, significantly expanding market accessibility.

Current Challenges in Cryogenic Electronics Development

The development of cryogenic electronics faces numerous technical challenges that impede widespread adoption and commercialization. One of the primary obstacles is material compatibility at extremely low temperatures. Traditional semiconductor materials and packaging components often exhibit altered electrical properties, mechanical stress, and thermal contraction issues when operating at temperatures approaching absolute zero. This creates significant reliability concerns and necessitates specialized material selection and qualification processes.

Thermal management presents another critical challenge. The interface between cryogenic components and room-temperature control systems creates substantial thermal gradients that must be carefully managed. Heat leakage through interconnects and support structures can significantly impact cooling efficiency and system performance, requiring innovative thermal isolation techniques and specialized interface designs.

Manufacturing processes for cryogenic electronics demand extraordinary precision and cleanliness. Contaminants that might be inconsequential at room temperature can become performance-limiting factors in cryogenic environments. Current fabrication facilities lack standardized protocols for cryogenic qualification, resulting in inconsistent performance across production batches and limiting scalability.

Testing and validation methodologies represent a substantial hurdle. Conventional electronic testing equipment is not designed to operate at cryogenic temperatures, necessitating complex test setups with remote sensing and measurement capabilities. The lack of standardized testing protocols specifically for cryogenic electronics creates difficulties in comparing performance across different technologies and establishing industry benchmarks.

Power efficiency remains a significant concern. Cooling systems required to maintain cryogenic temperatures consume substantial energy, often negating the efficiency gains achieved by the cryogenic electronics themselves. This creates a challenging optimization problem that requires holistic system-level approaches rather than component-level solutions.

Reliability and aging effects are poorly understood in cryogenic environments. Long-term performance degradation mechanisms differ significantly from those at room temperature, and accelerated life testing methodologies have not been adequately developed for cryogenic applications. This creates uncertainty regarding operational lifetimes and maintenance requirements for deployed systems.

Integration with conventional electronics presents interface challenges. Level shifting, signal integrity, and timing synchronization between cryogenic and room-temperature components require specialized interface circuits that can operate reliably across extreme temperature gradients while maintaining signal fidelity and minimizing heat introduction.

Standardization efforts remain in nascent stages. The lack of industry-wide standards for cryogenic electronic components hampers interoperability and increases development costs. Without established compliance frameworks, manufacturers must develop proprietary solutions, leading to fragmentation in the market and slowing overall technology adoption.

Thermal management presents another critical challenge. The interface between cryogenic components and room-temperature control systems creates substantial thermal gradients that must be carefully managed. Heat leakage through interconnects and support structures can significantly impact cooling efficiency and system performance, requiring innovative thermal isolation techniques and specialized interface designs.

Manufacturing processes for cryogenic electronics demand extraordinary precision and cleanliness. Contaminants that might be inconsequential at room temperature can become performance-limiting factors in cryogenic environments. Current fabrication facilities lack standardized protocols for cryogenic qualification, resulting in inconsistent performance across production batches and limiting scalability.

Testing and validation methodologies represent a substantial hurdle. Conventional electronic testing equipment is not designed to operate at cryogenic temperatures, necessitating complex test setups with remote sensing and measurement capabilities. The lack of standardized testing protocols specifically for cryogenic electronics creates difficulties in comparing performance across different technologies and establishing industry benchmarks.

Power efficiency remains a significant concern. Cooling systems required to maintain cryogenic temperatures consume substantial energy, often negating the efficiency gains achieved by the cryogenic electronics themselves. This creates a challenging optimization problem that requires holistic system-level approaches rather than component-level solutions.

Reliability and aging effects are poorly understood in cryogenic environments. Long-term performance degradation mechanisms differ significantly from those at room temperature, and accelerated life testing methodologies have not been adequately developed for cryogenic applications. This creates uncertainty regarding operational lifetimes and maintenance requirements for deployed systems.

Integration with conventional electronics presents interface challenges. Level shifting, signal integrity, and timing synchronization between cryogenic and room-temperature components require specialized interface circuits that can operate reliably across extreme temperature gradients while maintaining signal fidelity and minimizing heat introduction.

Standardization efforts remain in nascent stages. The lack of industry-wide standards for cryogenic electronic components hampers interoperability and increases development costs. Without established compliance frameworks, manufacturers must develop proprietary solutions, leading to fragmentation in the market and slowing overall technology adoption.

Existing Compliance Solutions for Extreme Temperature Electronics

01 Cryogenic electronic component testing and qualification

Testing and qualification procedures for electronic components operating in cryogenic environments involve specialized methodologies to ensure reliability at extremely low temperatures. These procedures include thermal cycling, performance verification, and durability testing under cryogenic conditions. Qualification standards ensure that components maintain functionality, structural integrity, and performance specifications when subjected to the harsh conditions of cryogenic operations.- Cryogenic electronic component testing and qualification: Testing and qualification procedures for electronic components operating in cryogenic environments involve specialized methodologies to ensure reliability at extremely low temperatures. These procedures include thermal cycling, performance verification, and durability testing under cryogenic conditions. Qualification standards ensure that components maintain functionality, structural integrity, and performance specifications when subjected to the harsh conditions of cryogenic operations.

- Cryogenic electronic systems compliance standards: Compliance standards for cryogenic electronic systems establish requirements for materials, design specifications, and operational parameters to ensure safe and reliable performance in extreme cold environments. These standards address thermal management, electrical insulation, mechanical stress tolerance, and compatibility with cryogenic fluids. Regulatory frameworks provide guidelines for certification, documentation, and verification of compliance with industry-specific requirements for cryogenic electronics.

- Cryogenic computing and data processing systems: Specialized computing and data processing systems designed for cryogenic environments incorporate unique architectures to maintain operational integrity at extremely low temperatures. These systems feature specialized materials, thermal isolation techniques, and modified circuit designs to ensure reliable performance. Qualification processes for cryogenic computing systems include verification of processing capabilities, data integrity, and system stability under prolonged exposure to cryogenic conditions.

- Cryogenic electronic materials and manufacturing compliance: Materials and manufacturing processes for cryogenic electronics require specific compliance standards to ensure functionality at extremely low temperatures. This includes specialized semiconductor materials, substrate compositions, and connection technologies that maintain electrical properties in cryogenic environments. Manufacturing compliance involves controlled production environments, specialized testing protocols, and quality assurance measures to verify that components meet the stringent requirements for cryogenic operation.

- Cryogenic electronic systems security and certification: Security protocols and certification processes for cryogenic electronic systems ensure both operational safety and data protection in critical applications. These systems often require specialized encryption methods that function reliably at extremely low temperatures and certification procedures that verify compliance with industry-specific security standards. The qualification process includes vulnerability assessments, penetration testing adapted for cryogenic environments, and verification of security features under extreme temperature conditions.

02 Cryogenic system compliance standards and regulations

Compliance frameworks for cryogenic electronics encompass industry standards, regulatory requirements, and certification processes specific to extremely low-temperature operations. These standards address safety protocols, material specifications, operational parameters, and risk management for cryogenic systems. Compliance documentation includes verification of thermal management capabilities, electrical performance at low temperatures, and adherence to international safety standards for cryogenic applications.Expand Specific Solutions03 Cryogenic electronics reliability and failure analysis

Reliability assessment for cryogenic electronics involves specialized methodologies for predicting and analyzing potential failure modes in extreme cold environments. This includes accelerated life testing, thermal stress analysis, and performance degradation monitoring. Failure analysis techniques specific to cryogenic applications help identify material weaknesses, connection failures, and component degradation patterns that may occur at ultra-low temperatures, enabling the development of more robust designs and qualification procedures.Expand Specific Solutions04 Cryogenic-compatible materials and manufacturing processes

Specialized materials and manufacturing processes are required for electronics that must function reliably in cryogenic environments. These include low-temperature compatible substrates, specialized soldering techniques, thermal expansion-matched components, and cryogenic-specific encapsulation methods. Qualification procedures verify that materials maintain their electrical, mechanical, and thermal properties at extremely low temperatures, ensuring long-term reliability and performance in cryogenic applications.Expand Specific Solutions05 Cryogenic electronics certification and documentation systems

Certification and documentation systems for cryogenic electronics establish formal processes for verifying compliance with industry standards and regulatory requirements. These systems include detailed documentation of test results, qualification procedures, material specifications, and performance parameters. Certification frameworks may include third-party verification, standardized testing protocols, and comprehensive documentation requirements to ensure that cryogenic electronic systems meet all necessary safety and performance standards.Expand Specific Solutions

Leading Organizations in Cryogenic Electronics Industry

Cryogenic electronics is currently in a transitional phase from research to early commercialization, with a global market estimated at $1.5-2 billion and growing at 15-20% annually. The technology faces significant compliance and qualification challenges due to extreme operating conditions. Leading players include IBM and Northrop Grumman developing superconducting quantum computing systems, while Sumitomo Cryogenics and Messer France provide specialized cooling infrastructure. Research institutions like CEA and Naval Research Laboratory collaborate with companies such as Applied Materials and Microsoft to address standardization issues. The qualification process remains complex, with companies like Advantest and Rohde & Schwarz developing specialized testing protocols for ultra-low temperature environments.

International Business Machines Corp.

Technical Solution: IBM has developed advanced cryogenic electronics systems focused on quantum computing applications. Their approach integrates superconducting qubits operating at millikelvin temperatures with specialized cryogenic control electronics. IBM's cryogenic electronics qualification process includes rigorous thermal cycling tests between room temperature and operational temperatures near absolute zero, with components undergoing thousands of cycles to ensure reliability. Their compliance framework addresses both conventional electronics standards and specialized requirements for quantum computing environments. IBM has pioneered the development of cryogenic CMOS circuits that can operate at 4K temperatures, significantly reducing the thermal load on dilution refrigerators while maintaining proximity to quantum processors. Their cryogenic multiplexing technology allows for controlling thousands of qubits with minimal thermal impact, addressing one of the key scaling challenges in quantum computing.

Strengths: Industry-leading expertise in quantum computing systems integration; proprietary testing methodologies for cryogenic components; advanced cryogenic CMOS technology. Weaknesses: Highly specialized solutions primarily focused on quantum computing applications rather than broader cryogenic electronics markets; significant cost associated with qualification processes; reliance on specialized fabrication techniques.

HRL Laboratories LLC

Technical Solution: HRL Laboratories has developed an innovative qualification methodology for cryogenic electronics focused on aerospace and defense applications. Their approach integrates traditional reliability engineering with specialized cryogenic testing protocols to address the unique challenges of electronics operating near absolute zero. HRL's compliance framework incorporates both military standards and specialized requirements for space-based systems, with particular emphasis on thermal cycling resilience and radiation hardness at cryogenic temperatures. Their qualification process includes specialized test fixtures that enable in-situ electrical characterization during temperature transitions, providing critical data on performance degradation mechanisms. HRL has pioneered accelerated aging techniques specifically calibrated for cryogenic electronics, enabling more efficient qualification while maintaining statistical confidence in lifetime predictions. Their approach includes comprehensive materials characterization to identify potential failure modes unique to cryogenic operation, such as altered electromigration mechanisms and modified semiconductor physics. HRL's qualification methodology addresses the specialized packaging challenges of cryogenic electronics, including thermal expansion mismatch and vacuum integrity maintenance.

Strengths: Deep expertise in aerospace qualification methodologies; advanced in-situ testing capabilities; strong integration with defense qualification standards. Weaknesses: Highly specialized approach with limited commercial applicability; significant infrastructure requirements for comprehensive testing; challenges in standardizing qualification across diverse cryogenic applications.

Key Patents and Research in Cryogenic Qualification Methods

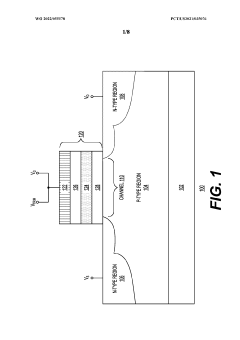

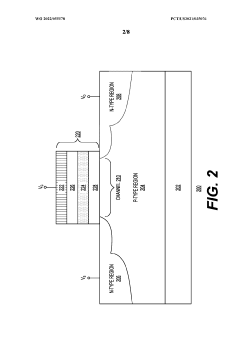

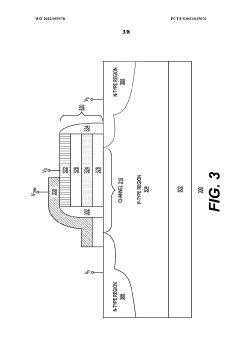

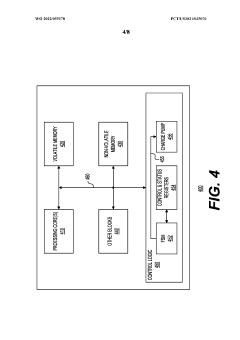

Low power CRYO-CMOS circuits with non-volatile threshold voltage offset compensation

PatentWO2022055578A1

Innovation

- The system modifies threshold voltages of CMOS devices by injecting or removing charge from floating gates using mechanisms like Fowler-Nordheim tunneling and Hot Carrier Injection, reducing variance and enabling lower supply voltage usage.

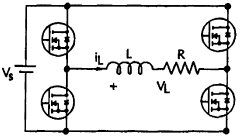

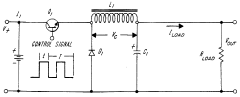

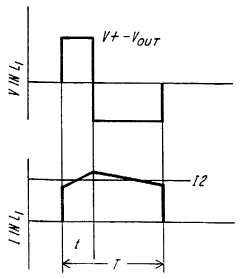

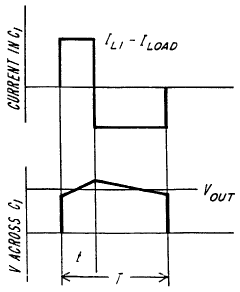

Cryogenic electronics power supply

PatentInactiveAU707457B2

Innovation

- Embedding high-temperature superconducting inductors in a cryogenically cooled environment, along with other components, to reduce component stress and improve performance, allowing for higher power output with reduced size and cost, by operating at frequencies above 500 Hertz and using cryogenic cooling to achieve superconductivity.

Material Science Advancements for Cryogenic Applications

The evolution of cryogenic electronics has been significantly influenced by advancements in material science. Traditional electronic materials often fail to maintain their properties at extremely low temperatures, necessitating the development of specialized materials capable of functioning reliably in cryogenic environments. Recent breakthroughs in superconducting materials have expanded the temperature ranges at which quantum coherence can be maintained, with high-temperature superconductors now operational at temperatures approaching 77K.

Novel composite materials incorporating rare earth elements have demonstrated enhanced thermal stability and electrical conductivity at temperatures below 4K. These materials exhibit minimal thermal expansion coefficients, reducing mechanical stress during thermal cycling—a critical factor for maintaining component integrity in cryogenic systems. Additionally, researchers have developed specialized dielectric materials that maintain consistent permittivity across wide temperature ranges, enabling stable capacitive elements in cryogenic circuits.

Packaging materials have also undergone significant innovation, with new polymer composites offering both thermal isolation and mechanical robustness. These materials feature tailored coefficients of thermal expansion that match those of semiconductor substrates, minimizing thermally-induced stress during cooling cycles. Advanced ceramic substrates with embedded thermal management structures have emerged as platforms for complex cryogenic circuits, providing both electrical isolation and efficient heat dissipation pathways.

Surface treatment technologies have evolved to address issues of material interface degradation at cryogenic temperatures. Specialized coating processes now enable the creation of stable metal-semiconductor junctions that maintain consistent electrical characteristics across thermal cycles. These treatments have proven particularly valuable for maintaining reliable electrical contacts in superconducting quantum computing circuits.

Thin-film deposition techniques have been refined to create ultra-pure material layers with precisely controlled thicknesses, critical for quantum devices where material impurities can significantly impact performance. Atomic layer deposition methods now allow for the creation of barrier layers that prevent atomic diffusion between materials at cryogenic temperatures, extending device lifetimes and reliability.

The qualification of these materials presents unique challenges, requiring specialized testing protocols that evaluate performance across extreme temperature ranges. Accelerated aging tests must account for different degradation mechanisms that emerge only at cryogenic temperatures. Industry standards are gradually evolving to incorporate specific requirements for cryogenic material qualification, though significant gaps remain in standardization efforts.

Novel composite materials incorporating rare earth elements have demonstrated enhanced thermal stability and electrical conductivity at temperatures below 4K. These materials exhibit minimal thermal expansion coefficients, reducing mechanical stress during thermal cycling—a critical factor for maintaining component integrity in cryogenic systems. Additionally, researchers have developed specialized dielectric materials that maintain consistent permittivity across wide temperature ranges, enabling stable capacitive elements in cryogenic circuits.

Packaging materials have also undergone significant innovation, with new polymer composites offering both thermal isolation and mechanical robustness. These materials feature tailored coefficients of thermal expansion that match those of semiconductor substrates, minimizing thermally-induced stress during cooling cycles. Advanced ceramic substrates with embedded thermal management structures have emerged as platforms for complex cryogenic circuits, providing both electrical isolation and efficient heat dissipation pathways.

Surface treatment technologies have evolved to address issues of material interface degradation at cryogenic temperatures. Specialized coating processes now enable the creation of stable metal-semiconductor junctions that maintain consistent electrical characteristics across thermal cycles. These treatments have proven particularly valuable for maintaining reliable electrical contacts in superconducting quantum computing circuits.

Thin-film deposition techniques have been refined to create ultra-pure material layers with precisely controlled thicknesses, critical for quantum devices where material impurities can significantly impact performance. Atomic layer deposition methods now allow for the creation of barrier layers that prevent atomic diffusion between materials at cryogenic temperatures, extending device lifetimes and reliability.

The qualification of these materials presents unique challenges, requiring specialized testing protocols that evaluate performance across extreme temperature ranges. Accelerated aging tests must account for different degradation mechanisms that emerge only at cryogenic temperatures. Industry standards are gradually evolving to incorporate specific requirements for cryogenic material qualification, though significant gaps remain in standardization efforts.

Standards Development for Cryogenic Electronics Testing

The development of comprehensive standards for cryogenic electronics testing represents a critical frontier in advancing this specialized field. Currently, the standards landscape for cryogenic electronics remains fragmented and incomplete, with most existing guidelines adapted from conventional temperature range electronics rather than being purpose-built for extreme cold environments. Organizations such as IEEE, IEC, and JEDEC have begun preliminary work on specialized standards, but these efforts remain in nascent stages compared to the rapidly evolving technology.

A significant challenge in standards development stems from the diverse application requirements across quantum computing, space exploration, and medical imaging sectors. Each domain presents unique operational parameters, reliability thresholds, and performance metrics that complicate the creation of unified testing protocols. For instance, quantum computing applications may require testing at millikelvin temperatures with stringent electromagnetic interference controls, while space applications prioritize radiation hardness alongside cryogenic performance.

Testing methodology standardization presents particular difficulties due to the specialized equipment required and the complex thermal management considerations. Current efforts focus on establishing reproducible test conditions, defining appropriate thermal cycling protocols, and creating standardized measurement techniques for parameters that behave non-linearly at cryogenic temperatures. The development of reference materials and calibration standards specifically designed for cryogenic environments represents another crucial area of ongoing work.

International collaboration has emerged as a key driver in accelerating standards development. Joint working groups comprising industry leaders, academic institutions, and national laboratories are coordinating efforts to pool expertise and resources. Notable initiatives include the Cryogenic Electronics Standardization Consortium and the Quantum Economic Development Consortium (QED-C), which have established technical committees specifically addressing testing standardization challenges.

The roadmap for standards development encompasses several critical phases, beginning with terminology harmonization and basic measurement protocols, followed by more complex reliability testing frameworks and eventually comprehensive qualification methodologies. Industry stakeholders anticipate that initial foundational standards could be formalized within 2-3 years, with more comprehensive frameworks requiring 5-7 years of continued development and refinement.

Regulatory bodies have recognized the strategic importance of cryogenic electronics standards, with several national metrology institutes investing in specialized facilities and expertise. These investments signal growing recognition that standardized testing protocols will be essential for market development, supply chain maturation, and technology commercialization in this emerging field.

A significant challenge in standards development stems from the diverse application requirements across quantum computing, space exploration, and medical imaging sectors. Each domain presents unique operational parameters, reliability thresholds, and performance metrics that complicate the creation of unified testing protocols. For instance, quantum computing applications may require testing at millikelvin temperatures with stringent electromagnetic interference controls, while space applications prioritize radiation hardness alongside cryogenic performance.

Testing methodology standardization presents particular difficulties due to the specialized equipment required and the complex thermal management considerations. Current efforts focus on establishing reproducible test conditions, defining appropriate thermal cycling protocols, and creating standardized measurement techniques for parameters that behave non-linearly at cryogenic temperatures. The development of reference materials and calibration standards specifically designed for cryogenic environments represents another crucial area of ongoing work.

International collaboration has emerged as a key driver in accelerating standards development. Joint working groups comprising industry leaders, academic institutions, and national laboratories are coordinating efforts to pool expertise and resources. Notable initiatives include the Cryogenic Electronics Standardization Consortium and the Quantum Economic Development Consortium (QED-C), which have established technical committees specifically addressing testing standardization challenges.

The roadmap for standards development encompasses several critical phases, beginning with terminology harmonization and basic measurement protocols, followed by more complex reliability testing frameworks and eventually comprehensive qualification methodologies. Industry stakeholders anticipate that initial foundational standards could be formalized within 2-3 years, with more comprehensive frameworks requiring 5-7 years of continued development and refinement.

Regulatory bodies have recognized the strategic importance of cryogenic electronics standards, with several national metrology institutes investing in specialized facilities and expertise. These investments signal growing recognition that standardized testing protocols will be essential for market development, supply chain maturation, and technology commercialization in this emerging field.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!