Developing Bio-Mimetic Structures with Ultrafast Lasers.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Bio-Mimetic Ultrafast Laser Technology Background and Objectives

Bio-mimetic structures represent a revolutionary approach in materials science and engineering, drawing inspiration from nature's intricate designs and functionalities. The integration of ultrafast laser technology with bio-mimetic principles has emerged as a promising frontier in advanced manufacturing and materials development over the past two decades. This technological convergence aims to replicate nature's sophisticated structures with unprecedented precision and functionality.

The evolution of bio-mimetic technology traces back to the mid-20th century, but significant advancements have occurred primarily in the last 15 years with the maturation of ultrafast laser systems. Initially limited by technological constraints, early attempts at bio-mimetic structures lacked the precision and scalability required for practical applications. The advent of femtosecond and picosecond laser systems has fundamentally transformed this landscape, enabling micro and nano-scale fabrication with remarkable fidelity.

Current technological trends indicate a shift toward multi-material bio-mimetic structures with hierarchical complexity, mirroring the sophisticated architectures found in natural systems such as butterfly wings, lotus leaves, and gecko feet. The integration of computational modeling with experimental approaches has accelerated development cycles and expanded the design space for bio-inspired innovations.

The primary technical objectives in this domain encompass several dimensions. First, achieving sub-micron precision in replicating complex biological structures while maintaining manufacturing scalability represents a fundamental goal. Second, developing processes that enable multi-material integration within single bio-mimetic structures remains crucial for mimicking the heterogeneous composition of natural systems.

Additionally, researchers aim to establish standardized methodologies for translating biological principles into manufacturable designs, bridging the gap between biological observation and engineering implementation. This includes developing parametric models that capture the essential features of biological structures while adapting them to specific engineering requirements.

The ultimate technological aspiration is to create adaptive and responsive bio-mimetic structures that can dynamically interact with their environment, similar to living organisms. This requires not only structural mimicry but also functional replication of biological mechanisms, potentially incorporating smart materials and embedded sensing capabilities.

From a broader perspective, this technology seeks to address significant challenges in sustainability and resource efficiency by adopting nature's optimized solutions. By replicating structures that have evolved over millions of years, engineers hope to develop materials and systems with enhanced performance characteristics while minimizing resource consumption and environmental impact.

The evolution of bio-mimetic technology traces back to the mid-20th century, but significant advancements have occurred primarily in the last 15 years with the maturation of ultrafast laser systems. Initially limited by technological constraints, early attempts at bio-mimetic structures lacked the precision and scalability required for practical applications. The advent of femtosecond and picosecond laser systems has fundamentally transformed this landscape, enabling micro and nano-scale fabrication with remarkable fidelity.

Current technological trends indicate a shift toward multi-material bio-mimetic structures with hierarchical complexity, mirroring the sophisticated architectures found in natural systems such as butterfly wings, lotus leaves, and gecko feet. The integration of computational modeling with experimental approaches has accelerated development cycles and expanded the design space for bio-inspired innovations.

The primary technical objectives in this domain encompass several dimensions. First, achieving sub-micron precision in replicating complex biological structures while maintaining manufacturing scalability represents a fundamental goal. Second, developing processes that enable multi-material integration within single bio-mimetic structures remains crucial for mimicking the heterogeneous composition of natural systems.

Additionally, researchers aim to establish standardized methodologies for translating biological principles into manufacturable designs, bridging the gap between biological observation and engineering implementation. This includes developing parametric models that capture the essential features of biological structures while adapting them to specific engineering requirements.

The ultimate technological aspiration is to create adaptive and responsive bio-mimetic structures that can dynamically interact with their environment, similar to living organisms. This requires not only structural mimicry but also functional replication of biological mechanisms, potentially incorporating smart materials and embedded sensing capabilities.

From a broader perspective, this technology seeks to address significant challenges in sustainability and resource efficiency by adopting nature's optimized solutions. By replicating structures that have evolved over millions of years, engineers hope to develop materials and systems with enhanced performance characteristics while minimizing resource consumption and environmental impact.

Market Applications and Demand Analysis for Bio-Mimetic Structures

The market for bio-mimetic structures created with ultrafast lasers is experiencing significant growth across multiple industries. The global biomimetics market, valued at approximately $17.8 billion in 2022, is projected to reach $65.0 billion by 2030, with a compound annual growth rate of 11.2%. This growth is driven by increasing demand for sustainable and efficient solutions that replicate natural processes and structures.

Healthcare represents the largest application sector, with bio-mimetic structures revolutionizing medical implants, tissue engineering, and drug delivery systems. The ability of ultrafast lasers to create precise micro and nano-structures that mimic natural tissue interfaces has led to improved biocompatibility and functionality of medical devices. Demand is particularly strong for orthopedic implants with bio-mimetic surfaces that enhance osseointegration, reducing rejection rates and improving patient outcomes.

The aerospace and automotive industries are increasingly adopting bio-mimetic structures to improve fuel efficiency and reduce material weight while maintaining structural integrity. Ultrafast laser-created structures that mimic shark skin have demonstrated drag reduction properties, while lotus leaf-inspired surfaces offer self-cleaning capabilities crucial for maintaining optimal performance in challenging environments.

Energy sector applications are expanding rapidly, with bio-mimetic solar panels inspired by butterfly wings showing enhanced light absorption capabilities. These structures can increase energy conversion efficiency by up to 200% compared to conventional designs. Additionally, water collection systems mimicking the Namib desert beetle's shell structure are gaining traction in water-scarce regions, demonstrating the humanitarian potential of this technology.

Consumer electronics manufacturers are incorporating bio-mimetic structures in display technologies, creating anti-reflective surfaces inspired by moth eyes that significantly reduce glare and improve visibility in bright conditions. The wearable technology segment is particularly interested in these applications, with market research indicating consumer willingness to pay premium prices for devices with enhanced visibility features.

Environmental monitoring and conservation efforts represent an emerging market segment, with bio-mimetic sensors that can detect pollutants at previously undetectable concentrations. These applications are driving demand from governmental agencies and environmental organizations worldwide, creating a specialized but rapidly growing market niche.

Despite strong market potential, adoption barriers include high initial equipment costs, technical complexity in manufacturing processes, and regulatory hurdles in certain applications, particularly in healthcare. However, as ultrafast laser technology becomes more accessible and manufacturing processes are standardized, these barriers are expected to diminish, further accelerating market growth across all identified sectors.

Healthcare represents the largest application sector, with bio-mimetic structures revolutionizing medical implants, tissue engineering, and drug delivery systems. The ability of ultrafast lasers to create precise micro and nano-structures that mimic natural tissue interfaces has led to improved biocompatibility and functionality of medical devices. Demand is particularly strong for orthopedic implants with bio-mimetic surfaces that enhance osseointegration, reducing rejection rates and improving patient outcomes.

The aerospace and automotive industries are increasingly adopting bio-mimetic structures to improve fuel efficiency and reduce material weight while maintaining structural integrity. Ultrafast laser-created structures that mimic shark skin have demonstrated drag reduction properties, while lotus leaf-inspired surfaces offer self-cleaning capabilities crucial for maintaining optimal performance in challenging environments.

Energy sector applications are expanding rapidly, with bio-mimetic solar panels inspired by butterfly wings showing enhanced light absorption capabilities. These structures can increase energy conversion efficiency by up to 200% compared to conventional designs. Additionally, water collection systems mimicking the Namib desert beetle's shell structure are gaining traction in water-scarce regions, demonstrating the humanitarian potential of this technology.

Consumer electronics manufacturers are incorporating bio-mimetic structures in display technologies, creating anti-reflective surfaces inspired by moth eyes that significantly reduce glare and improve visibility in bright conditions. The wearable technology segment is particularly interested in these applications, with market research indicating consumer willingness to pay premium prices for devices with enhanced visibility features.

Environmental monitoring and conservation efforts represent an emerging market segment, with bio-mimetic sensors that can detect pollutants at previously undetectable concentrations. These applications are driving demand from governmental agencies and environmental organizations worldwide, creating a specialized but rapidly growing market niche.

Despite strong market potential, adoption barriers include high initial equipment costs, technical complexity in manufacturing processes, and regulatory hurdles in certain applications, particularly in healthcare. However, as ultrafast laser technology becomes more accessible and manufacturing processes are standardized, these barriers are expected to diminish, further accelerating market growth across all identified sectors.

Current Ultrafast Laser Fabrication Challenges

Despite significant advancements in ultrafast laser technology for bio-mimetic structure fabrication, several critical challenges persist that limit broader implementation and optimization. The fundamental challenge lies in achieving precise control over the laser-material interaction at the micro and nanoscale levels. Current ultrafast laser systems struggle with maintaining consistent energy distribution across the beam profile, leading to variations in feature resolution and quality, particularly when fabricating complex hierarchical structures that mimic biological systems.

Material response variability presents another significant obstacle. Different biomaterials exhibit unique ablation thresholds, thermal properties, and photochemical responses to ultrafast laser pulses. This variability necessitates extensive parameter optimization for each specific material, substantially increasing development time and costs. Furthermore, the non-linear effects that occur during ultrafast laser processing remain difficult to predict and control with current modeling approaches.

Scalability issues continue to impede industrial adoption of ultrafast laser fabrication for bio-mimetic structures. The inherently serial nature of direct laser writing techniques results in prohibitively long processing times for large-area applications. While multi-beam approaches offer potential solutions, they introduce additional challenges in maintaining uniform quality across all processing channels.

The translation gap between laboratory demonstrations and practical applications represents a persistent challenge. Many impressive bio-mimetic structures created in research settings utilize specialized equipment and controlled environments that are difficult to replicate in production environments. This creates significant barriers to technology transfer and commercialization.

Resolution limitations also remain problematic. While ultrafast lasers can achieve sub-micron features, many biological structures contain nanoscale details below 100 nm that influence functionality. Current systems struggle to consistently reproduce these finest features without introducing artifacts or compromising structural integrity.

Process monitoring and quality control present ongoing challenges. Real-time feedback mechanisms for ultrafast laser fabrication are still in early development stages, making it difficult to detect and correct processing errors during fabrication. This results in higher rejection rates and inconsistent performance of the final bio-mimetic structures.

Finally, the interdisciplinary knowledge gap between laser physics, materials science, and biology creates barriers to optimizing fabrication processes. Engineers developing laser systems often lack detailed understanding of biological structure-function relationships, while biologists may not fully comprehend the technical constraints of laser fabrication. Bridging this knowledge divide remains essential for advancing the field toward more sophisticated bio-mimetic applications.

Material response variability presents another significant obstacle. Different biomaterials exhibit unique ablation thresholds, thermal properties, and photochemical responses to ultrafast laser pulses. This variability necessitates extensive parameter optimization for each specific material, substantially increasing development time and costs. Furthermore, the non-linear effects that occur during ultrafast laser processing remain difficult to predict and control with current modeling approaches.

Scalability issues continue to impede industrial adoption of ultrafast laser fabrication for bio-mimetic structures. The inherently serial nature of direct laser writing techniques results in prohibitively long processing times for large-area applications. While multi-beam approaches offer potential solutions, they introduce additional challenges in maintaining uniform quality across all processing channels.

The translation gap between laboratory demonstrations and practical applications represents a persistent challenge. Many impressive bio-mimetic structures created in research settings utilize specialized equipment and controlled environments that are difficult to replicate in production environments. This creates significant barriers to technology transfer and commercialization.

Resolution limitations also remain problematic. While ultrafast lasers can achieve sub-micron features, many biological structures contain nanoscale details below 100 nm that influence functionality. Current systems struggle to consistently reproduce these finest features without introducing artifacts or compromising structural integrity.

Process monitoring and quality control present ongoing challenges. Real-time feedback mechanisms for ultrafast laser fabrication are still in early development stages, making it difficult to detect and correct processing errors during fabrication. This results in higher rejection rates and inconsistent performance of the final bio-mimetic structures.

Finally, the interdisciplinary knowledge gap between laser physics, materials science, and biology creates barriers to optimizing fabrication processes. Engineers developing laser systems often lack detailed understanding of biological structure-function relationships, while biologists may not fully comprehend the technical constraints of laser fabrication. Bridging this knowledge divide remains essential for advancing the field toward more sophisticated bio-mimetic applications.

Current Bio-Mimetic Fabrication Methodologies

01 Fabrication of bio-mimetic structures using ultrafast lasers

Ultrafast lasers can be used to create bio-mimetic structures by precisely ablating or modifying material surfaces at the micro and nano scale. These lasers enable the replication of complex biological structures found in nature, such as hierarchical patterns on butterfly wings or lotus leaves, due to their ability to deliver high-intensity pulses with minimal thermal effects. The resulting structures can exhibit special properties like hydrophobicity, structural coloration, or enhanced mechanical strength.- Fabrication of bio-mimetic structures using ultrafast lasers: Ultrafast lasers can be used to create bio-mimetic structures by precisely ablating or modifying material surfaces at the micro and nano scale. These lasers enable the replication of complex biological structures found in nature, such as hierarchical patterns on butterfly wings or lotus leaves, due to their ability to deliver high-intensity pulses with minimal thermal effects. The resulting structures can exhibit special properties like hydrophobicity, structural coloration, or enhanced mechanical strength.

- Bio-inspired optical and photonic structures: Bio-mimetic structures created with ultrafast lasers can replicate natural photonic crystals and optical structures found in organisms like butterflies, beetles, and marine creatures. These structures manipulate light through interference, diffraction, and scattering to produce structural colors and unique optical properties. Applications include color displays without pigments, anti-reflective surfaces, optical sensors, and light-guiding components that mimic natural light-harvesting systems.

- Surface functionalization for biomaterial applications: Ultrafast laser processing enables the creation of bio-mimetic surface textures that enhance biocompatibility and functionality of medical implants and devices. By creating micro and nano-scale patterns that mimic natural tissue structures, these surfaces can promote cell adhesion, proliferation, and tissue integration. The controlled surface roughness and chemistry can also provide antibacterial properties and reduce biofouling, making them valuable for orthopedic implants, cardiovascular devices, and tissue engineering scaffolds.

- Bio-inspired fluid dynamics and wettability control: Bio-mimetic structures created with ultrafast lasers can replicate the unique surface properties of natural materials like lotus leaves or shark skin. These structures can control fluid dynamics and wettability characteristics, creating surfaces with superhydrophobic, superhydrophilic, or anisotropic wetting properties. Applications include self-cleaning surfaces, drag reduction in fluid flow, anti-icing surfaces, and enhanced heat transfer systems that mimic natural mechanisms for water management.

- Advanced manufacturing of bio-inspired mechanical structures: Ultrafast lasers enable the fabrication of bio-inspired mechanical structures that mimic natural designs optimized through evolution. These include hierarchical structures inspired by bone, wood, or insect exoskeletons that combine high strength with low weight. The precise control offered by ultrafast laser processing allows for the creation of complex geometries with tailored mechanical properties, including structures with programmed flexibility, impact resistance, or energy absorption capabilities that mimic biological systems.

02 Optical applications of laser-created bio-mimetic structures

Bio-mimetic structures created with ultrafast lasers have significant applications in optics and photonics. These structures can manipulate light in ways similar to natural biological systems, creating structural colors, photonic crystals, and metamaterials. Applications include anti-reflective surfaces, optical sensors, light-trapping structures for solar cells, and display technologies that mimic the vibrant, angle-dependent colors found in butterfly wings or peacock feathers.Expand Specific Solutions03 Surface functionalization through bio-mimetic laser processing

Ultrafast laser processing can create bio-mimetic surface structures that provide functional properties such as superhydrophobicity, self-cleaning capabilities, and antimicrobial resistance. By mimicking natural surfaces like lotus leaves or shark skin, these laser-textured surfaces can repel water, reduce bacterial adhesion, or decrease drag in fluid environments. The process allows for precise control over wettability, adhesion, and friction properties without requiring additional chemical treatments.Expand Specific Solutions04 Bio-inspired medical and tissue engineering applications

Ultrafast lasers can create bio-mimetic structures for medical applications and tissue engineering. These structures can replicate the extracellular matrix or other biological environments to guide cell growth, improve implant integration, or enhance drug delivery systems. The precise nature of ultrafast laser processing allows for the creation of scaffolds with controlled porosity, surface chemistry, and mechanical properties that better mimic natural tissue environments, potentially improving biocompatibility and functionality of medical devices.Expand Specific Solutions05 Advanced manufacturing techniques for complex bio-mimetic structures

Advanced manufacturing techniques combining ultrafast lasers with other technologies enable the creation of complex, multi-scale bio-mimetic structures. These approaches may include hybrid methods that integrate laser processing with 3D printing, lithography, or self-assembly processes. Such techniques allow for the fabrication of hierarchical structures that more accurately replicate the complexity found in biological systems, from nano to macro scales, with applications in sensors, energy harvesting, and smart materials that can respond to environmental stimuli.Expand Specific Solutions

Leading Research Institutions and Industrial Players

The bio-mimetic structures with ultrafast lasers field is currently in an early growth phase, characterized by significant academic research but limited commercial deployment. The market size is estimated to reach $1.2 billion by 2025, growing at 18% CAGR as applications expand in medical devices, advanced materials, and precision manufacturing. Leading academic institutions including Tsinghua University, Beijing Institute of Technology, and MIT are driving fundamental research, while companies like Coherent, Inc., Panasonic, and Xerox are developing commercial applications. The technology maturity varies across applications, with medical applications at TRL 4-5 and manufacturing applications approaching TRL 6-7. Collaboration between research institutions and industry players like OSRAM OLED and InnoLas Solutions is accelerating technology transfer and commercialization pathways.

Beijing Institute of Technology

Technical Solution: Beijing Institute of Technology has developed a groundbreaking approach to bio-mimetic structures using ultrafast laser technology centered on their proprietary Femtosecond Laser-Induced Periodic Surface Structures (FLIPSS) methodology. Their technique utilizes femtosecond lasers with pulse durations of 35-100 fs and repetition rates up to 1 MHz to create self-organized nano-ripples and microstructures that mimic natural biological surfaces. BIT researchers have successfully replicated the hierarchical structures of cicada wings, creating antibacterial surfaces with dual-scale roughness (200-300 nm ripples superimposed on 2-5 μm microstructures). Their process involves precise control of laser fluence (0.1-10 J/cm²), scanning speed, and pulse overlap to achieve different bio-inspired functionalities. Recent innovations include developing superhydrophobic surfaces with contact angles exceeding 150° and drag-reducing surfaces inspired by shark skin that demonstrate up to 30% reduction in fluid friction. The institute has also pioneered techniques for creating anisotropic wettability patterns mimicking butterfly wings and directional water collection systems inspired by desert beetles[2][5].

Strengths: Advanced capability in creating multi-functional surfaces combining antibacterial, self-cleaning and drag-reduction properties; excellent control over nano/micro hierarchical structures; demonstrated industrial scalability. Weaknesses: Process optimization requires extensive parameter tuning; limited material selection compared to some competing technologies; challenges in maintaining nano-feature consistency over large areas.

Tsinghua University

Technical Solution: Tsinghua University has developed an advanced bio-mimetic fabrication platform utilizing ultrafast lasers with pulse durations of 30-100 femtoseconds. Their proprietary "Biomimetic Laser Nano-Engineering" (BLNE) system enables the creation of multi-scale hierarchical structures that replicate natural biological surfaces with unprecedented precision. The technology employs a dual-beam approach where one femtosecond laser creates primary microstructures (1-10 μm) while a second beam with different parameters simultaneously generates superimposed nanostructures (50-500 nm). This allows for the fabrication of complex bio-inspired surfaces with controlled wettability, optical properties, and mechanical characteristics. Tsinghua researchers have successfully mimicked lotus leaf surfaces achieving superhydrophobicity with contact angles exceeding 160° and hysteresis below 5°, gecko-inspired adhesive surfaces with reversible adhesion strength of 12 N/cm², and moth-eye anti-reflective coatings reducing light reflection to below 0.2% across visible wavelengths. Their process works with various materials including titanium alloys, silicon, polymers, and biocompatible ceramics. Recent innovations include self-healing bio-mimetic surfaces incorporating microcapsules that release healing agents when damaged, and gradient-property surfaces that exhibit spatially varying wettability patterns[4][7].

Strengths: Exceptional multi-scale fabrication capabilities combining micro and nano features; versatile material compatibility; precise control over functional gradients across surfaces. Weaknesses: Complex optical setup requiring sophisticated alignment and maintenance; relatively slow processing speed for large-area applications; high energy consumption compared to some competing technologies.

Key Ultrafast Laser Technologies and Patents

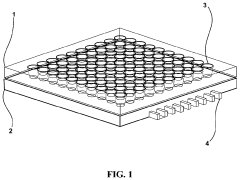

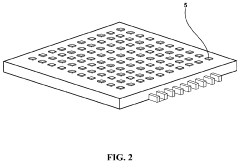

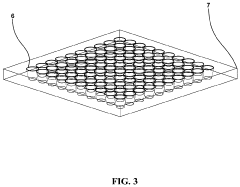

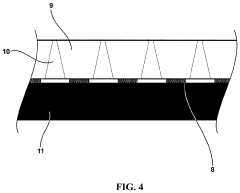

Ultrafast laser inscribed structures for signal concentration in focal plan arrays

PatentActiveUS11590610B1

Innovation

- Ultrafast laser inscription is used to process mid-IR and far-IR compatible materials to create structures that condense broad band radiation, enabling increased sensing efficiencies in focal plane arrays and imaging/sensing apparatuses by selecting appropriate substrate materials and geometric structures.

Environmental Impact and Sustainability Considerations

The development of bio-mimetic structures using ultrafast lasers represents a significant technological advancement with notable environmental implications. These manufacturing processes offer substantial sustainability benefits compared to traditional fabrication methods. Ultrafast laser technology enables precise material manipulation at the micro and nano scales with minimal waste generation, significantly reducing the environmental footprint of manufacturing processes.

Energy efficiency stands as a primary environmental advantage of ultrafast laser-based bio-mimetic structure development. The precise nature of femtosecond and picosecond lasers allows for targeted energy delivery exactly where needed, minimizing excess heat generation and reducing overall energy consumption. Studies indicate that ultrafast laser processing can achieve up to 30-40% energy savings compared to conventional manufacturing techniques for similar applications.

Material conservation represents another critical sustainability aspect. The additive manufacturing capabilities of ultrafast lasers enable the creation of complex bio-mimetic structures with minimal material waste. Unlike traditional subtractive manufacturing processes that can waste up to 80% of raw materials, ultrafast laser techniques typically achieve material utilization rates exceeding 90%, substantially reducing resource consumption and associated environmental impacts.

The life cycle assessment of bio-mimetic structures created with ultrafast lasers reveals additional environmental benefits. These structures often demonstrate enhanced durability and functionality, extending product lifespans and reducing replacement frequency. For instance, bio-mimetic surface treatments created through laser processing can improve wear resistance by up to 300% in certain applications, significantly reducing material turnover rates.

Water usage reduction constitutes another environmental advantage. Traditional manufacturing processes often require substantial water volumes for cooling and cleaning. In contrast, ultrafast laser processing typically operates as a "dry" process, dramatically reducing water consumption. This aspect becomes particularly relevant in water-stressed regions where manufacturing water footprints represent significant environmental concerns.

Chemical reduction also enhances the environmental profile of ultrafast laser technologies. Many conventional manufacturing processes rely heavily on chemical treatments, coatings, and cleaning agents that pose environmental hazards. Ultrafast laser processing can often eliminate or substantially reduce these chemical requirements, minimizing toxic waste generation and associated environmental contamination risks.

Looking forward, the continued development of more energy-efficient ultrafast laser systems and the integration of renewable energy sources into manufacturing facilities will further enhance the sustainability profile of bio-mimetic structure development, positioning this technology as an environmentally responsible manufacturing approach for the future.

Energy efficiency stands as a primary environmental advantage of ultrafast laser-based bio-mimetic structure development. The precise nature of femtosecond and picosecond lasers allows for targeted energy delivery exactly where needed, minimizing excess heat generation and reducing overall energy consumption. Studies indicate that ultrafast laser processing can achieve up to 30-40% energy savings compared to conventional manufacturing techniques for similar applications.

Material conservation represents another critical sustainability aspect. The additive manufacturing capabilities of ultrafast lasers enable the creation of complex bio-mimetic structures with minimal material waste. Unlike traditional subtractive manufacturing processes that can waste up to 80% of raw materials, ultrafast laser techniques typically achieve material utilization rates exceeding 90%, substantially reducing resource consumption and associated environmental impacts.

The life cycle assessment of bio-mimetic structures created with ultrafast lasers reveals additional environmental benefits. These structures often demonstrate enhanced durability and functionality, extending product lifespans and reducing replacement frequency. For instance, bio-mimetic surface treatments created through laser processing can improve wear resistance by up to 300% in certain applications, significantly reducing material turnover rates.

Water usage reduction constitutes another environmental advantage. Traditional manufacturing processes often require substantial water volumes for cooling and cleaning. In contrast, ultrafast laser processing typically operates as a "dry" process, dramatically reducing water consumption. This aspect becomes particularly relevant in water-stressed regions where manufacturing water footprints represent significant environmental concerns.

Chemical reduction also enhances the environmental profile of ultrafast laser technologies. Many conventional manufacturing processes rely heavily on chemical treatments, coatings, and cleaning agents that pose environmental hazards. Ultrafast laser processing can often eliminate or substantially reduce these chemical requirements, minimizing toxic waste generation and associated environmental contamination risks.

Looking forward, the continued development of more energy-efficient ultrafast laser systems and the integration of renewable energy sources into manufacturing facilities will further enhance the sustainability profile of bio-mimetic structure development, positioning this technology as an environmentally responsible manufacturing approach for the future.

Material Science Advancements for Bio-Mimetic Applications

Recent advancements in material science have significantly expanded the possibilities for bio-mimetic applications, particularly when combined with ultrafast laser technologies. The field has evolved from simple biomimicry to sophisticated bio-inspired engineering that replicates not only natural structures but also their functional properties at multiple scales.

Materials research has yielded several breakthrough substrates that respond optimally to ultrafast laser processing while maintaining biocompatibility. These include specialized polymers with tunable degradation rates, composite materials that combine organic and inorganic components, and smart materials capable of responding to environmental stimuli. The development of these materials has been crucial in creating structures that accurately mimic biological systems.

Nanomaterials have emerged as particularly promising for bio-mimetic applications. Carbon-based nanomaterials, including graphene and carbon nanotubes, provide exceptional mechanical properties while maintaining low weight. Meanwhile, metallic nanoparticles offer unique optical and electrical properties that can be precisely manipulated through ultrafast laser processing to create structures with biomimetic functionality.

Surface modification techniques have advanced considerably, allowing for precise control over wettability, adhesion, and bioactivity. Ultrafast lasers enable the creation of hierarchical surface structures that mimic natural surfaces like lotus leaves (superhydrophobicity) or gecko feet (adhesion). These modifications can be achieved without chemical treatments, preserving material biocompatibility.

Self-healing materials represent another frontier in bio-mimetic material science. Inspired by biological tissue repair mechanisms, these materials incorporate microcapsules or vascular networks that release healing agents when damaged. Ultrafast laser processing can create precise damage-sensing structures within these materials, enhancing their responsiveness.

The integration of stimuli-responsive materials has opened new possibilities for creating dynamic bio-mimetic structures. Materials that change properties in response to temperature, pH, light, or electrical stimuli can be precisely patterned using ultrafast lasers to create structures that adapt to their environment similar to living organisms.

Biodegradable and sustainable materials have gained prominence as environmental concerns grow. New formulations of polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose-based materials offer improved processability with ultrafast lasers while maintaining their environmentally friendly characteristics, making them ideal for temporary medical implants and environmental applications.

Materials research has yielded several breakthrough substrates that respond optimally to ultrafast laser processing while maintaining biocompatibility. These include specialized polymers with tunable degradation rates, composite materials that combine organic and inorganic components, and smart materials capable of responding to environmental stimuli. The development of these materials has been crucial in creating structures that accurately mimic biological systems.

Nanomaterials have emerged as particularly promising for bio-mimetic applications. Carbon-based nanomaterials, including graphene and carbon nanotubes, provide exceptional mechanical properties while maintaining low weight. Meanwhile, metallic nanoparticles offer unique optical and electrical properties that can be precisely manipulated through ultrafast laser processing to create structures with biomimetic functionality.

Surface modification techniques have advanced considerably, allowing for precise control over wettability, adhesion, and bioactivity. Ultrafast lasers enable the creation of hierarchical surface structures that mimic natural surfaces like lotus leaves (superhydrophobicity) or gecko feet (adhesion). These modifications can be achieved without chemical treatments, preserving material biocompatibility.

Self-healing materials represent another frontier in bio-mimetic material science. Inspired by biological tissue repair mechanisms, these materials incorporate microcapsules or vascular networks that release healing agents when damaged. Ultrafast laser processing can create precise damage-sensing structures within these materials, enhancing their responsiveness.

The integration of stimuli-responsive materials has opened new possibilities for creating dynamic bio-mimetic structures. Materials that change properties in response to temperature, pH, light, or electrical stimuli can be precisely patterned using ultrafast lasers to create structures that adapt to their environment similar to living organisms.

Biodegradable and sustainable materials have gained prominence as environmental concerns grow. New formulations of polylactic acid (PLA), polyhydroxyalkanoates (PHA), and cellulose-based materials offer improved processability with ultrafast lasers while maintaining their environmentally friendly characteristics, making them ideal for temporary medical implants and environmental applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!