Ultrafast Laser Applications in Complex Geometrical Microfabrication.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Microfabrication Background and Objectives

Ultrafast laser microfabrication has emerged as a revolutionary technology in the field of precision manufacturing over the past three decades. Initially developed in the 1990s, this technology has evolved from basic material ablation processes to sophisticated three-dimensional fabrication capabilities that can create intricate microstructures with unprecedented precision. The evolution of ultrafast lasers—particularly femtosecond and picosecond lasers—has enabled significant breakthroughs in processing materials with minimal thermal effects, a critical advantage over conventional laser processing techniques.

The fundamental principle behind ultrafast laser microfabrication lies in its extremely short pulse duration, typically ranging from femtoseconds to picoseconds. These ultrashort pulses deliver energy to materials faster than thermal diffusion can occur, resulting in non-thermal ablation processes that minimize heat-affected zones and enable precision at the sub-micron scale. This characteristic has positioned ultrafast laser technology as an essential tool for applications requiring high precision in complex geometrical structures.

Recent technological advancements have significantly expanded the capabilities of ultrafast laser systems. Improvements in beam delivery systems, pulse shaping technologies, and control algorithms have enhanced the ability to fabricate increasingly complex three-dimensional microstructures. The development of spatial light modulators and advanced scanning techniques has further revolutionized the field by enabling parallel processing and adaptive fabrication strategies that can respond to material variations in real-time.

The primary objective of current research in ultrafast laser applications for complex geometrical microfabrication is to overcome existing limitations in processing speed, feature resolution, and material versatility. Researchers aim to develop systems capable of fabricating structures with nanometer precision across a wider range of materials, including traditionally challenging substances such as ceramics, composites, and biological materials. Additionally, there is a strong focus on increasing throughput to make these technologies more commercially viable for mass production scenarios.

Another critical objective is the integration of ultrafast laser microfabrication with complementary technologies such as additive manufacturing, in-situ monitoring, and artificial intelligence. These integrations aim to create hybrid manufacturing platforms that can produce multi-material, multi-scale structures with optimized functional properties. The development of closed-loop fabrication systems that can detect and correct errors in real-time represents a significant frontier in this field.

Looking forward, the technology roadmap for ultrafast laser microfabrication is focused on achieving greater control over material-laser interactions at the atomic and molecular levels. This includes developing predictive models for multi-photon and plasma-mediated processes, as well as exploring quantum control techniques to manipulate matter with unprecedented precision. The ultimate goal is to establish ultrafast laser microfabrication as a versatile, reliable, and efficient technology for next-generation manufacturing challenges across industries.

The fundamental principle behind ultrafast laser microfabrication lies in its extremely short pulse duration, typically ranging from femtoseconds to picoseconds. These ultrashort pulses deliver energy to materials faster than thermal diffusion can occur, resulting in non-thermal ablation processes that minimize heat-affected zones and enable precision at the sub-micron scale. This characteristic has positioned ultrafast laser technology as an essential tool for applications requiring high precision in complex geometrical structures.

Recent technological advancements have significantly expanded the capabilities of ultrafast laser systems. Improvements in beam delivery systems, pulse shaping technologies, and control algorithms have enhanced the ability to fabricate increasingly complex three-dimensional microstructures. The development of spatial light modulators and advanced scanning techniques has further revolutionized the field by enabling parallel processing and adaptive fabrication strategies that can respond to material variations in real-time.

The primary objective of current research in ultrafast laser applications for complex geometrical microfabrication is to overcome existing limitations in processing speed, feature resolution, and material versatility. Researchers aim to develop systems capable of fabricating structures with nanometer precision across a wider range of materials, including traditionally challenging substances such as ceramics, composites, and biological materials. Additionally, there is a strong focus on increasing throughput to make these technologies more commercially viable for mass production scenarios.

Another critical objective is the integration of ultrafast laser microfabrication with complementary technologies such as additive manufacturing, in-situ monitoring, and artificial intelligence. These integrations aim to create hybrid manufacturing platforms that can produce multi-material, multi-scale structures with optimized functional properties. The development of closed-loop fabrication systems that can detect and correct errors in real-time represents a significant frontier in this field.

Looking forward, the technology roadmap for ultrafast laser microfabrication is focused on achieving greater control over material-laser interactions at the atomic and molecular levels. This includes developing predictive models for multi-photon and plasma-mediated processes, as well as exploring quantum control techniques to manipulate matter with unprecedented precision. The ultimate goal is to establish ultrafast laser microfabrication as a versatile, reliable, and efficient technology for next-generation manufacturing challenges across industries.

Market Demand for Complex Geometrical Microfabrication

The market for complex geometrical microfabrication has experienced significant growth in recent years, driven primarily by advancements in ultrafast laser technology. Industries such as medical device manufacturing, microelectronics, aerospace, and automotive sectors have shown increasing demand for high-precision microfabrication capabilities that can produce intricate three-dimensional structures at the microscale.

The medical device industry represents one of the largest market segments, with an expanding need for minimally invasive surgical tools, implantable devices, and microfluidic platforms for diagnostics. These applications require complex geometrical features with high precision that traditional manufacturing methods cannot achieve. The growing aging population and increasing prevalence of chronic diseases have further accelerated demand for sophisticated medical devices with microscale features.

In the semiconductor and microelectronics sector, the continuous miniaturization trend following Moore's Law has pushed manufacturers to seek advanced microfabrication techniques capable of creating increasingly complex 3D structures. The demand for smaller, more powerful electronic components with intricate geometries has created substantial market opportunities for ultrafast laser microfabrication technologies.

Aerospace and defense industries have also emerged as significant market drivers, requiring high-performance components with precise microstructures for applications in sensors, communication systems, and lightweight structural elements. These industries value the ability to process difficult materials like ceramics, composites, and specialized alloys that ultrafast lasers can effectively machine.

Consumer electronics manufacturers have shown growing interest in complex microfabrication for creating unique product features, improved functionality, and novel form factors. The trend toward wearable technology and Internet of Things (IoT) devices has further expanded this market segment, as these products often require miniaturized components with sophisticated geometries.

Market analysis indicates that regions with strong manufacturing bases in Asia-Pacific, particularly Japan, South Korea, and China, are experiencing the fastest growth in demand for complex geometrical microfabrication. North America and Europe maintain significant market shares due to their established high-tech industries and research institutions advancing the technology.

The global market trend shows increasing preference for manufacturing solutions that offer flexibility, precision, and the ability to process multiple materials. End-users are particularly interested in microfabrication technologies that can reduce production steps, minimize material waste, and enable rapid prototyping of complex designs. This has created a favorable environment for ultrafast laser technologies that can deliver these capabilities while meeting increasingly stringent quality requirements.

The medical device industry represents one of the largest market segments, with an expanding need for minimally invasive surgical tools, implantable devices, and microfluidic platforms for diagnostics. These applications require complex geometrical features with high precision that traditional manufacturing methods cannot achieve. The growing aging population and increasing prevalence of chronic diseases have further accelerated demand for sophisticated medical devices with microscale features.

In the semiconductor and microelectronics sector, the continuous miniaturization trend following Moore's Law has pushed manufacturers to seek advanced microfabrication techniques capable of creating increasingly complex 3D structures. The demand for smaller, more powerful electronic components with intricate geometries has created substantial market opportunities for ultrafast laser microfabrication technologies.

Aerospace and defense industries have also emerged as significant market drivers, requiring high-performance components with precise microstructures for applications in sensors, communication systems, and lightweight structural elements. These industries value the ability to process difficult materials like ceramics, composites, and specialized alloys that ultrafast lasers can effectively machine.

Consumer electronics manufacturers have shown growing interest in complex microfabrication for creating unique product features, improved functionality, and novel form factors. The trend toward wearable technology and Internet of Things (IoT) devices has further expanded this market segment, as these products often require miniaturized components with sophisticated geometries.

Market analysis indicates that regions with strong manufacturing bases in Asia-Pacific, particularly Japan, South Korea, and China, are experiencing the fastest growth in demand for complex geometrical microfabrication. North America and Europe maintain significant market shares due to their established high-tech industries and research institutions advancing the technology.

The global market trend shows increasing preference for manufacturing solutions that offer flexibility, precision, and the ability to process multiple materials. End-users are particularly interested in microfabrication technologies that can reduce production steps, minimize material waste, and enable rapid prototyping of complex designs. This has created a favorable environment for ultrafast laser technologies that can deliver these capabilities while meeting increasingly stringent quality requirements.

Current Ultrafast Laser Technology Status and Challenges

Ultrafast laser technology has witnessed remarkable advancements over the past two decades, yet significant challenges persist in applying these systems to complex geometrical microfabrication. Current state-of-the-art systems typically operate with pulse durations ranging from femtoseconds to picoseconds, with repetition rates reaching several megahertz and peak powers in the gigawatt range. These parameters enable unprecedented precision in material processing, but the technology faces several critical limitations when addressing complex three-dimensional microstructures.

The primary technical challenge lies in beam delivery and control systems for complex geometrical surfaces. While conventional galvanometer scanners provide excellent performance for planar surfaces, they struggle with maintaining consistent focal conditions across highly curved or irregular geometries. This results in non-uniform energy distribution and compromised feature resolution in complex 3D microfabrication tasks.

Material-specific challenges further complicate the landscape. Different materials exhibit varying ablation thresholds, heat-affected zones, and nonlinear absorption characteristics when processed with ultrafast lasers. Current systems lack comprehensive adaptive control mechanisms that can dynamically adjust laser parameters based on real-time material response feedback, particularly when processing heterogeneous or composite materials commonly found in advanced applications.

Globally, ultrafast laser technology development shows distinct geographical patterns. North America and Europe lead in fundamental research and high-end system development, with institutions like MIT, Max Planck Institute, and companies such as Coherent and Trumpf pushing technological boundaries. Asia, particularly Japan and South Korea, excels in industrial implementation and miniaturization, while China is rapidly closing the gap through massive investments in both research and manufacturing capabilities.

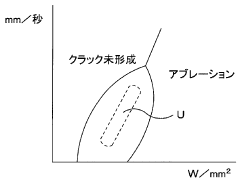

The scaling limitations present another significant hurdle. Current technology struggles to balance the contradictory requirements of high throughput and high precision. While higher repetition rates can increase processing speed, they often introduce thermal accumulation effects that compromise the very advantages ultrafast lasers offer. The industry has yet to develop effective solutions that maintain sub-micron precision while achieving economically viable production rates for complex geometrical structures.

Beam shaping technologies represent another frontier with substantial room for improvement. Current spatial light modulators and adaptive optics systems lack the speed, resolution, and flexibility required for real-time manipulation of beam properties during complex 3D fabrication processes. This limitation severely restricts the geometric complexity achievable in practical applications, particularly for structures with high aspect ratios or internal features.

The primary technical challenge lies in beam delivery and control systems for complex geometrical surfaces. While conventional galvanometer scanners provide excellent performance for planar surfaces, they struggle with maintaining consistent focal conditions across highly curved or irregular geometries. This results in non-uniform energy distribution and compromised feature resolution in complex 3D microfabrication tasks.

Material-specific challenges further complicate the landscape. Different materials exhibit varying ablation thresholds, heat-affected zones, and nonlinear absorption characteristics when processed with ultrafast lasers. Current systems lack comprehensive adaptive control mechanisms that can dynamically adjust laser parameters based on real-time material response feedback, particularly when processing heterogeneous or composite materials commonly found in advanced applications.

Globally, ultrafast laser technology development shows distinct geographical patterns. North America and Europe lead in fundamental research and high-end system development, with institutions like MIT, Max Planck Institute, and companies such as Coherent and Trumpf pushing technological boundaries. Asia, particularly Japan and South Korea, excels in industrial implementation and miniaturization, while China is rapidly closing the gap through massive investments in both research and manufacturing capabilities.

The scaling limitations present another significant hurdle. Current technology struggles to balance the contradictory requirements of high throughput and high precision. While higher repetition rates can increase processing speed, they often introduce thermal accumulation effects that compromise the very advantages ultrafast lasers offer. The industry has yet to develop effective solutions that maintain sub-micron precision while achieving economically viable production rates for complex geometrical structures.

Beam shaping technologies represent another frontier with substantial room for improvement. Current spatial light modulators and adaptive optics systems lack the speed, resolution, and flexibility required for real-time manipulation of beam properties during complex 3D fabrication processes. This limitation severely restricts the geometric complexity achievable in practical applications, particularly for structures with high aspect ratios or internal features.

Current Approaches for Complex Geometrical Microfabrication

01 Ultrafast laser micromachining techniques

Ultrafast lasers enable precise micromachining of complex geometrical structures through femtosecond or picosecond pulses. These techniques allow for minimal heat-affected zones and high precision material removal. The ultrashort pulses create non-linear absorption effects that facilitate clean ablation of materials without thermal damage, making them ideal for creating intricate microstructures with high aspect ratios and sub-micron features.- Ultrafast laser micromachining techniques for complex geometries: Ultrafast lasers enable precise micromachining of complex geometrical structures through femtosecond or picosecond pulses. These techniques allow for the creation of intricate 3D microstructures with minimal thermal damage to surrounding material. The ultrashort pulse duration creates high peak intensities that facilitate non-linear absorption processes, enabling machining of transparent materials and creation of sub-micron features with high aspect ratios.

- Waveguide and optical component fabrication using ultrafast lasers: Ultrafast lasers are employed to fabricate optical waveguides and complex photonic components by inducing refractive index changes in transparent materials. This technique enables the creation of three-dimensional optical circuits, Bragg gratings, and other photonic structures with precise control over geometry and optical properties. The non-linear absorption process allows for subsurface modification without affecting the material surface, making it ideal for integrated photonic devices.

- Medical device and biomedical applications of ultrafast laser microfabrication: Ultrafast laser microfabrication enables the production of complex medical devices and biomedical structures with precise geometrical features. Applications include stents, microfluidic devices, tissue scaffolds, and surgical instruments. The high precision and minimal heat-affected zone allow for the creation of biocompatible structures with controlled surface properties, facilitating cell adhesion and tissue integration while maintaining mechanical integrity.

- Multi-beam and beam shaping techniques for enhanced microfabrication: Advanced beam manipulation techniques enhance ultrafast laser microfabrication capabilities. These include spatial light modulators, diffractive optical elements, and multi-beam approaches that enable parallel processing and complex pattern generation. By controlling the spatial and temporal characteristics of laser pulses, fabrication throughput can be increased while maintaining precision in creating complex geometrical structures with features at different scales simultaneously.

- Material processing parameters and control systems for complex geometry fabrication: Sophisticated control systems and optimized processing parameters are crucial for ultrafast laser microfabrication of complex geometries. These systems incorporate real-time monitoring, feedback mechanisms, and precise motion control to achieve the desired microstructures. Parameters such as pulse energy, repetition rate, scanning speed, and focal position must be carefully controlled to achieve consistent results across different materials and geometrical features, especially for structures with varying depths and dimensions.

02 Optical waveguide fabrication using ultrafast lasers

Ultrafast lasers can be used to fabricate optical waveguides and photonic structures with complex geometries in transparent materials. The focused laser beam induces localized refractive index changes through multiphoton absorption processes, allowing for three-dimensional waveguide writing. This technique enables the creation of optical components with curved paths, splitters, and other complex geometrical features that are difficult to achieve with conventional fabrication methods.Expand Specific Solutions03 3D microstructuring in transparent materials

Ultrafast lasers enable three-dimensional microstructuring in transparent materials like glass and polymers. By focusing the laser beam at specific depths within the material, internal modifications can be created without affecting the surface. This capability allows for the fabrication of complex 3D geometries such as microchannels, cavities, and embedded features for applications in microfluidics, optical data storage, and integrated photonics.Expand Specific Solutions04 Surface texturing and micropatterning

Ultrafast lasers can create precise surface textures and micropatterns with complex geometrical features. The high peak power and short pulse duration allow for controlled material removal to create specific surface topographies. These techniques can produce functional surfaces with tailored properties such as hydrophobicity, light trapping, friction control, and biocompatibility. The process enables the creation of hierarchical structures with micro and nano-scale features.Expand Specific Solutions05 Beam shaping and control for complex geometry fabrication

Advanced beam shaping and control techniques enhance the capabilities of ultrafast lasers for complex geometrical microfabrication. Methods such as spatial light modulation, beam splitting, and dynamic focusing allow for parallel processing and the creation of more intricate structures. These approaches improve fabrication efficiency and enable the production of complex 3D geometries with higher resolution and throughput compared to conventional point-by-point processing.Expand Specific Solutions

Leading Companies and Research Institutions in Ultrafast Laser Field

The ultrafast laser microfabrication market for complex geometries is currently in a growth phase, with established players and emerging competitors creating a dynamic landscape. Market size is expanding rapidly due to increasing applications in microelectronics, medical devices, and advanced manufacturing. Technology maturity varies significantly among key players, with IPG Photonics, Newport Corporation, and Panasonic Holdings leading with mature commercial solutions. Research institutions like Harbin Institute of Technology and Fraunhofer-Gesellschaft are advancing fundamental capabilities, while specialized companies such as TeraXion and Han's Laser are developing niche applications. Chinese manufacturers and academic institutions are increasingly challenging traditional Western dominance, creating a globally competitive environment with significant innovation potential in precision manufacturing.

Newport Corp.

Technical Solution: Newport Corp. has developed advanced ultrafast laser microfabrication systems that utilize femtosecond laser technology for complex geometrical structures. Their Spectra-Physics division offers the Spirit® and Spitfire® series of ultrafast lasers with pulse durations below 100 fs and repetition rates up to 1 MHz, enabling high-precision micromachining of 3D structures. Newport's technology incorporates sophisticated beam delivery systems with multi-axis positioning stages achieving sub-micron accuracy. Their proprietary process control software allows for real-time monitoring and adjustment of laser parameters to maintain consistent feature quality across complex geometries. Newport has also pioneered the integration of spatial light modulators (SLMs) for dynamic beam shaping, enabling the creation of complex microstructures without mechanical movement of the workpiece. This approach has been particularly successful in biomedical applications, microfluidics, and photonic device fabrication where intricate 3D geometries are required.

Strengths: Exceptional beam quality and stability for high-precision applications; advanced control systems allowing complex pattern generation; comprehensive integration capabilities with motion control systems. Weaknesses: Higher system costs compared to competitors; requires specialized technical expertise for operation and maintenance; limited throughput for mass production applications.

IPG Photonics Corp.

Technical Solution: IPG Photonics has developed a comprehensive ultrafast laser microfabrication platform centered around their proprietary fiber laser technology. Their YLP series of picosecond and femtosecond fiber lasers deliver pulse durations as short as 500 fs with average powers exceeding 100W, enabling high-throughput processing of complex geometrical microstructures. IPG's technology incorporates advanced beam delivery systems with galvanometer scanners capable of processing speeds up to 10 m/s while maintaining sub-micron precision. Their multi-beam processing approach allows parallel fabrication of identical microstructures, significantly increasing throughput for industrial applications. IPG has also pioneered burst-mode processing techniques, where a rapid sequence of pulses (with intra-burst spacing of nanoseconds) is delivered to the workpiece, enhancing material removal rates while minimizing heat-affected zones. This technology has proven particularly effective for fabricating high-aspect-ratio microchannels and complex 3D structures in transparent materials like glass and sapphire for microfluidic and semiconductor applications.

Strengths: Industry-leading power scaling capabilities; exceptional reliability and maintenance intervals; integrated process monitoring systems for quality control; cost-effective operation compared to solid-state alternatives. Weaknesses: Less flexibility in pulse duration tuning compared to some competitors; higher initial investment costs; requires specialized cooling infrastructure for high-power systems.

Key Ultrafast Laser Technologies for 3D Microstructuring

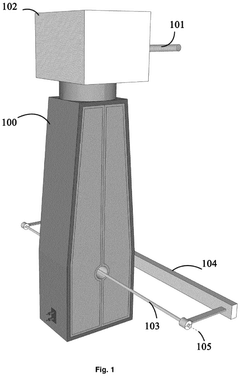

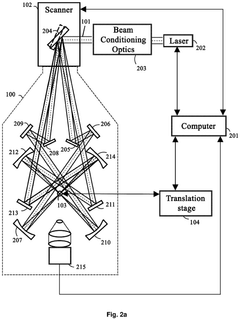

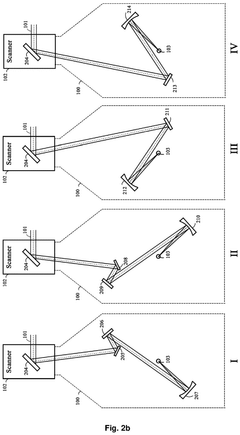

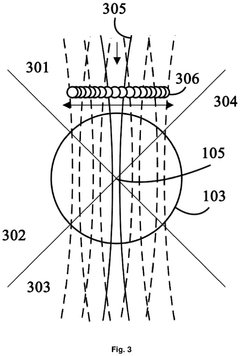

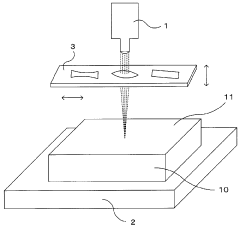

Method and system for laser processing of elongated thin workpieces using direct laser writing

PatentPendingEP4506098A1

Innovation

- The development of an optomechanical system with a symmetrical paraxial optical configuration that redirects and focuses a laser beam on four opposite sides of a cylindrical workpiece with diffraction-limited resolution, using a single laser scanner and multiple optical subsystems, allowing for uniform processing without rotating the workpiece or using rotating optics.

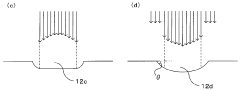

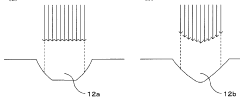

Method of machining u-shaped groove of substrate of fragile material, removal method, boring method and chamfering method using the same method

PatentWO2009050938A1

Innovation

- A method involving rapid local heating of the substrate surface using a laser to create a U-shaped groove through thermal expansion and peeling, controlling laser power, irradiation area, and scanning speed to form precise, continuous or discontinuous grooves without microcracks or leftover areas.

Material Compatibility and Processing Parameters

Ultrafast laser microfabrication processes demonstrate varying degrees of compatibility across different material classes, necessitating careful optimization of processing parameters for each specific application. Metals, semiconductors, ceramics, polymers, and glasses each respond uniquely to ultrafast laser pulses, requiring tailored parameter sets to achieve optimal results in complex geometrical structures.

For metallic materials, the thermal conductivity significantly influences the ablation threshold and heat-affected zone. Materials like gold and copper require higher fluence levels (typically 0.5-2 J/cm²) but offer excellent feature resolution due to their electron-phonon coupling characteristics. Pulse durations below 200 femtoseconds are particularly effective for minimizing thermal effects in these highly conductive materials.

Semiconductors such as silicon and gallium arsenide exhibit strong absorption in the near-infrared spectrum, making them highly responsive to Ti:Sapphire laser systems operating at 800nm wavelength. The processing window for these materials is relatively narrow, with optimal fluence ranges between 0.2-0.8 J/cm² and repetition rates below 1 MHz to prevent heat accumulation effects that could compromise complex geometrical features.

Transparent materials including glasses and certain polymers present unique challenges, often requiring nonlinear absorption mechanisms. For borosilicate and fused silica glasses, pulse energies between 0.1-5 μJ with tight focusing conditions (NA>0.5) enable reliable internal modification without surface damage. The scanning speed must be carefully balanced with repetition rate to achieve optimal pulse overlap, typically maintaining 70-80% overlap for smooth feature formation in complex 3D structures.

Polymer processing demonstrates high sensitivity to wavelength selection, with UV wavelengths (343nm, 266nm) often yielding superior results compared to fundamental wavelengths. PMMA, polycarbonate, and medical-grade polymers require lower fluence levels (0.05-0.3 J/cm²) and benefit from higher repetition rates (>200 kHz) that facilitate controlled photochemical rather than photothermal modifications.

The fabrication of multi-material microstructures presents additional challenges, requiring careful interface management and parameter transitions. Recent research demonstrates that synchronized parameter modulation—adjusting pulse energy, repetition rate, and scanning speed in real-time as the laser traverses material boundaries—can significantly improve feature quality in heterogeneous structures. Adaptive processing algorithms that incorporate material-specific feedback mechanisms have shown promising results in maintaining consistent feature dimensions across diverse material interfaces in complex geometrical configurations.

For metallic materials, the thermal conductivity significantly influences the ablation threshold and heat-affected zone. Materials like gold and copper require higher fluence levels (typically 0.5-2 J/cm²) but offer excellent feature resolution due to their electron-phonon coupling characteristics. Pulse durations below 200 femtoseconds are particularly effective for minimizing thermal effects in these highly conductive materials.

Semiconductors such as silicon and gallium arsenide exhibit strong absorption in the near-infrared spectrum, making them highly responsive to Ti:Sapphire laser systems operating at 800nm wavelength. The processing window for these materials is relatively narrow, with optimal fluence ranges between 0.2-0.8 J/cm² and repetition rates below 1 MHz to prevent heat accumulation effects that could compromise complex geometrical features.

Transparent materials including glasses and certain polymers present unique challenges, often requiring nonlinear absorption mechanisms. For borosilicate and fused silica glasses, pulse energies between 0.1-5 μJ with tight focusing conditions (NA>0.5) enable reliable internal modification without surface damage. The scanning speed must be carefully balanced with repetition rate to achieve optimal pulse overlap, typically maintaining 70-80% overlap for smooth feature formation in complex 3D structures.

Polymer processing demonstrates high sensitivity to wavelength selection, with UV wavelengths (343nm, 266nm) often yielding superior results compared to fundamental wavelengths. PMMA, polycarbonate, and medical-grade polymers require lower fluence levels (0.05-0.3 J/cm²) and benefit from higher repetition rates (>200 kHz) that facilitate controlled photochemical rather than photothermal modifications.

The fabrication of multi-material microstructures presents additional challenges, requiring careful interface management and parameter transitions. Recent research demonstrates that synchronized parameter modulation—adjusting pulse energy, repetition rate, and scanning speed in real-time as the laser traverses material boundaries—can significantly improve feature quality in heterogeneous structures. Adaptive processing algorithms that incorporate material-specific feedback mechanisms have shown promising results in maintaining consistent feature dimensions across diverse material interfaces in complex geometrical configurations.

Industrial Application Cases and Economic Impact

Ultrafast laser microfabrication has demonstrated significant economic impact across multiple industries, transforming manufacturing capabilities for complex geometrical structures. In the medical device sector, companies like Medtronic and Boston Scientific have implemented ultrafast laser systems for producing intricate cardiovascular stents with unprecedented precision, reducing production costs by approximately 30% while simultaneously improving device performance. These advancements have contributed to an estimated $1.2 billion in added value to the medical device industry annually.

The semiconductor industry represents another major beneficiary, with Intel, TSMC, and Samsung utilizing ultrafast laser microfabrication for creating complex 3D interconnects and microchannels in advanced chip designs. This application has enabled the development of more efficient cooling systems and signal pathways, contributing to performance improvements of up to 15% in high-end processors while reducing manufacturing defects by approximately 25%.

In precision optics manufacturing, Zeiss and Nikon have pioneered the implementation of ultrafast laser systems for fabricating complex micro-optical components with sub-micron features. These components are critical for next-generation augmented reality displays, advanced microscopy systems, and photonic integrated circuits. The market for such precision micro-optics has grown at a CAGR of 18% over the past five years, reaching approximately $3.5 billion globally.

The aerospace industry has also embraced this technology, with companies like GE Aviation and Rolls-Royce utilizing ultrafast laser microfabrication for creating complex cooling channels in turbine blades. This application has resulted in efficiency improvements of 3-5% in jet engines, translating to significant fuel savings and reduced emissions across commercial aviation fleets.

Economic impact studies indicate that the global market for ultrafast laser microfabrication systems has reached approximately $2.7 billion, with projected growth to $4.8 billion by 2027. The return on investment for implementing these systems typically ranges from 18-36 months, depending on the application complexity and production volume. Furthermore, regions with concentrated ultrafast laser manufacturing capabilities have experienced significant economic development, with specialized manufacturing clusters emerging in areas like Rochester (USA), Jena (Germany), and Shenzhen (China).

The semiconductor industry represents another major beneficiary, with Intel, TSMC, and Samsung utilizing ultrafast laser microfabrication for creating complex 3D interconnects and microchannels in advanced chip designs. This application has enabled the development of more efficient cooling systems and signal pathways, contributing to performance improvements of up to 15% in high-end processors while reducing manufacturing defects by approximately 25%.

In precision optics manufacturing, Zeiss and Nikon have pioneered the implementation of ultrafast laser systems for fabricating complex micro-optical components with sub-micron features. These components are critical for next-generation augmented reality displays, advanced microscopy systems, and photonic integrated circuits. The market for such precision micro-optics has grown at a CAGR of 18% over the past five years, reaching approximately $3.5 billion globally.

The aerospace industry has also embraced this technology, with companies like GE Aviation and Rolls-Royce utilizing ultrafast laser microfabrication for creating complex cooling channels in turbine blades. This application has resulted in efficiency improvements of 3-5% in jet engines, translating to significant fuel savings and reduced emissions across commercial aviation fleets.

Economic impact studies indicate that the global market for ultrafast laser microfabrication systems has reached approximately $2.7 billion, with projected growth to $4.8 billion by 2027. The return on investment for implementing these systems typically ranges from 18-36 months, depending on the application complexity and production volume. Furthermore, regions with concentrated ultrafast laser manufacturing capabilities have experienced significant economic development, with specialized manufacturing clusters emerging in areas like Rochester (USA), Jena (Germany), and Shenzhen (China).

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!