Ultrafast Laser Methods in Energy Efficient Production Processes.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Technology Evolution and Objectives

Ultrafast laser technology has evolved significantly over the past three decades, transforming from laboratory curiosities to essential industrial tools. The journey began in the 1980s with the development of the first femtosecond lasers, which initially found applications primarily in scientific research. By the 1990s, titanium-sapphire lasers emerged as the dominant ultrafast laser technology, offering unprecedented pulse durations in the femtosecond range with relatively high average powers.

The early 2000s marked a pivotal shift with the commercialization of fiber-based ultrafast lasers, which dramatically improved reliability and reduced maintenance requirements compared to their solid-state counterparts. This transition enabled the expansion of ultrafast laser applications beyond research laboratories into industrial settings. The subsequent decade witnessed significant advancements in pulse energy, average power, and beam quality, making these systems increasingly viable for manufacturing processes.

Recent technological breakthroughs have focused on enhancing energy efficiency, with modern ultrafast laser systems achieving wall-plug efficiencies exceeding 30%, compared to less than 10% a decade ago. This improvement directly addresses the growing industrial demand for sustainable manufacturing technologies. Parallel developments in beam delivery systems, scanning technologies, and process monitoring capabilities have further expanded the practical applications of ultrafast lasers in production environments.

The primary objective of ultrafast laser implementation in energy-efficient production processes is to minimize the heat-affected zone during material processing. Unlike conventional lasers, ultrafast systems deliver energy in extremely short pulses (picoseconds to femtoseconds), allowing for "cold ablation" where material is removed before heat can diffuse to surrounding areas. This capability significantly reduces energy waste and eliminates many post-processing requirements, thereby decreasing the overall energy footprint of manufacturing operations.

Additional objectives include achieving higher precision in micro-machining applications, enabling the processing of increasingly complex materials including composites and temperature-sensitive substrates, and developing more flexible production systems capable of rapid reconfiguration. The technology aims to support Industry 4.0 initiatives through integration with digital manufacturing platforms and real-time process control systems.

Looking forward, the field is moving toward even shorter pulse durations, higher repetition rates, and more sophisticated beam shaping capabilities. Research efforts are increasingly focused on developing application-specific laser parameters that optimize energy efficiency for particular materials and processes. The ultimate goal is to establish ultrafast laser technology as a cornerstone of sustainable manufacturing, capable of reducing industrial energy consumption while simultaneously improving product quality and production flexibility.

The early 2000s marked a pivotal shift with the commercialization of fiber-based ultrafast lasers, which dramatically improved reliability and reduced maintenance requirements compared to their solid-state counterparts. This transition enabled the expansion of ultrafast laser applications beyond research laboratories into industrial settings. The subsequent decade witnessed significant advancements in pulse energy, average power, and beam quality, making these systems increasingly viable for manufacturing processes.

Recent technological breakthroughs have focused on enhancing energy efficiency, with modern ultrafast laser systems achieving wall-plug efficiencies exceeding 30%, compared to less than 10% a decade ago. This improvement directly addresses the growing industrial demand for sustainable manufacturing technologies. Parallel developments in beam delivery systems, scanning technologies, and process monitoring capabilities have further expanded the practical applications of ultrafast lasers in production environments.

The primary objective of ultrafast laser implementation in energy-efficient production processes is to minimize the heat-affected zone during material processing. Unlike conventional lasers, ultrafast systems deliver energy in extremely short pulses (picoseconds to femtoseconds), allowing for "cold ablation" where material is removed before heat can diffuse to surrounding areas. This capability significantly reduces energy waste and eliminates many post-processing requirements, thereby decreasing the overall energy footprint of manufacturing operations.

Additional objectives include achieving higher precision in micro-machining applications, enabling the processing of increasingly complex materials including composites and temperature-sensitive substrates, and developing more flexible production systems capable of rapid reconfiguration. The technology aims to support Industry 4.0 initiatives through integration with digital manufacturing platforms and real-time process control systems.

Looking forward, the field is moving toward even shorter pulse durations, higher repetition rates, and more sophisticated beam shaping capabilities. Research efforts are increasingly focused on developing application-specific laser parameters that optimize energy efficiency for particular materials and processes. The ultimate goal is to establish ultrafast laser technology as a cornerstone of sustainable manufacturing, capable of reducing industrial energy consumption while simultaneously improving product quality and production flexibility.

Market Demand for Energy-Efficient Manufacturing Solutions

The global manufacturing sector is experiencing a significant shift towards energy-efficient production processes, driven by increasing energy costs, stringent environmental regulations, and growing corporate sustainability commitments. Market research indicates that energy consumption in manufacturing accounts for approximately 30% of global energy usage, creating substantial demand for technologies that can reduce this footprint while maintaining or improving productivity.

Manufacturing industries, particularly automotive, aerospace, electronics, and medical device sectors, are actively seeking solutions that can reduce energy consumption without compromising production quality or throughput. This demand is reflected in the compound annual growth rate of energy-efficient manufacturing technologies, which has been steadily increasing at around 8% since 2018.

Ultrafast laser processing has emerged as a particularly promising technology in this landscape. Traditional manufacturing processes often require multiple steps, high temperatures, and significant energy inputs. In contrast, ultrafast laser methods offer precise material processing with minimal heat-affected zones, reducing the need for secondary finishing operations and associated energy consumption.

Market surveys reveal that manufacturers are willing to invest in advanced laser technologies when the return on investment can be demonstrated through energy savings, reduced material waste, and improved product quality. The potential for ultrafast lasers to process traditionally difficult materials like ceramics, composites, and high-strength alloys without thermal damage has created significant market pull, especially in high-value manufacturing sectors.

Regional analysis shows varying levels of market readiness. Europe leads in adoption, driven by the EU's ambitious carbon reduction targets and high energy costs. North America follows with strong demand from aerospace and medical device manufacturers, while Asia-Pacific represents the fastest-growing market, particularly in countries like China, Japan, and South Korea where manufacturing modernization initiatives are well-funded.

Customer requirements indicate that ideal energy-efficient laser solutions must demonstrate at least 20-30% energy savings compared to conventional processes, maintain or improve processing speeds, and integrate seamlessly with existing production lines. Additionally, manufacturers are increasingly seeking comprehensive solutions that include process monitoring and optimization capabilities to further enhance energy efficiency through data-driven approaches.

The service and support ecosystem surrounding ultrafast laser technologies is also evolving rapidly, with growing demand for training, maintenance, and process development services. This indicates that the market values not just the hardware technology but the complete solution package that enables successful implementation of energy-efficient manufacturing processes.

Manufacturing industries, particularly automotive, aerospace, electronics, and medical device sectors, are actively seeking solutions that can reduce energy consumption without compromising production quality or throughput. This demand is reflected in the compound annual growth rate of energy-efficient manufacturing technologies, which has been steadily increasing at around 8% since 2018.

Ultrafast laser processing has emerged as a particularly promising technology in this landscape. Traditional manufacturing processes often require multiple steps, high temperatures, and significant energy inputs. In contrast, ultrafast laser methods offer precise material processing with minimal heat-affected zones, reducing the need for secondary finishing operations and associated energy consumption.

Market surveys reveal that manufacturers are willing to invest in advanced laser technologies when the return on investment can be demonstrated through energy savings, reduced material waste, and improved product quality. The potential for ultrafast lasers to process traditionally difficult materials like ceramics, composites, and high-strength alloys without thermal damage has created significant market pull, especially in high-value manufacturing sectors.

Regional analysis shows varying levels of market readiness. Europe leads in adoption, driven by the EU's ambitious carbon reduction targets and high energy costs. North America follows with strong demand from aerospace and medical device manufacturers, while Asia-Pacific represents the fastest-growing market, particularly in countries like China, Japan, and South Korea where manufacturing modernization initiatives are well-funded.

Customer requirements indicate that ideal energy-efficient laser solutions must demonstrate at least 20-30% energy savings compared to conventional processes, maintain or improve processing speeds, and integrate seamlessly with existing production lines. Additionally, manufacturers are increasingly seeking comprehensive solutions that include process monitoring and optimization capabilities to further enhance energy efficiency through data-driven approaches.

The service and support ecosystem surrounding ultrafast laser technologies is also evolving rapidly, with growing demand for training, maintenance, and process development services. This indicates that the market values not just the hardware technology but the complete solution package that enables successful implementation of energy-efficient manufacturing processes.

Current State and Challenges in Ultrafast Laser Applications

Ultrafast laser technology has witnessed remarkable advancements globally, with significant research and development efforts concentrated in North America, Europe, and East Asia. The current state of ultrafast laser applications in energy-efficient production processes demonstrates considerable maturity in certain sectors while remaining nascent in others. Industrial implementation has gained momentum particularly in precision manufacturing, semiconductor processing, and medical device fabrication, where traditional thermal processes are being replaced by cold ablation techniques.

The technology landscape is characterized by a growing ecosystem of specialized equipment manufacturers, research institutions, and end-users collaborating to overcome implementation barriers. Current ultrafast laser systems typically operate with pulse durations in the femtosecond to picosecond range, with power capabilities ranging from several watts to kilowatts depending on the application requirements. The market has seen significant improvements in beam quality, pulse stability, and overall system reliability over the past decade.

Despite these advancements, several critical challenges persist in the widespread adoption of ultrafast laser methods for energy-efficient production. Cost remains a primary barrier, with high-performance systems requiring substantial capital investment that smaller manufacturers find difficult to justify. The total cost of ownership, including maintenance, specialized operator training, and potential production line reconfiguration, further compounds this challenge.

Technical limitations also present significant hurdles. Scaling ultrafast laser processes for high-volume manufacturing environments remains problematic, with current throughput rates often insufficient for mass production scenarios. Energy efficiency paradoxically becomes a concern, as the electrical-to-optical conversion efficiency of many ultrafast laser systems remains relatively low, somewhat counteracting the energy savings achieved in the actual processing.

Material-specific challenges exist across different application domains. Certain materials exhibit unpredictable behavior under ultrafast laser processing, requiring extensive parameter optimization that increases implementation complexity. The development of standardized processing parameters and protocols lags behind the technology itself, creating barriers to adoption for potential new users.

Integration challenges with existing production systems represent another significant obstacle. Many manufacturing facilities face difficulties incorporating ultrafast laser systems into established production lines without disrupting workflows or requiring extensive reconfiguration. The lack of standardized interfaces and control systems complicates seamless integration with industry 4.0 environments and automated production systems.

Knowledge gaps among potential adopters further impede widespread implementation. The complex physics underlying ultrafast laser-material interactions requires specialized expertise that is not widely available in traditional manufacturing settings. This expertise deficit extends to maintenance and troubleshooting capabilities, creating dependency on equipment suppliers and increasing operational risks.

The technology landscape is characterized by a growing ecosystem of specialized equipment manufacturers, research institutions, and end-users collaborating to overcome implementation barriers. Current ultrafast laser systems typically operate with pulse durations in the femtosecond to picosecond range, with power capabilities ranging from several watts to kilowatts depending on the application requirements. The market has seen significant improvements in beam quality, pulse stability, and overall system reliability over the past decade.

Despite these advancements, several critical challenges persist in the widespread adoption of ultrafast laser methods for energy-efficient production. Cost remains a primary barrier, with high-performance systems requiring substantial capital investment that smaller manufacturers find difficult to justify. The total cost of ownership, including maintenance, specialized operator training, and potential production line reconfiguration, further compounds this challenge.

Technical limitations also present significant hurdles. Scaling ultrafast laser processes for high-volume manufacturing environments remains problematic, with current throughput rates often insufficient for mass production scenarios. Energy efficiency paradoxically becomes a concern, as the electrical-to-optical conversion efficiency of many ultrafast laser systems remains relatively low, somewhat counteracting the energy savings achieved in the actual processing.

Material-specific challenges exist across different application domains. Certain materials exhibit unpredictable behavior under ultrafast laser processing, requiring extensive parameter optimization that increases implementation complexity. The development of standardized processing parameters and protocols lags behind the technology itself, creating barriers to adoption for potential new users.

Integration challenges with existing production systems represent another significant obstacle. Many manufacturing facilities face difficulties incorporating ultrafast laser systems into established production lines without disrupting workflows or requiring extensive reconfiguration. The lack of standardized interfaces and control systems complicates seamless integration with industry 4.0 environments and automated production systems.

Knowledge gaps among potential adopters further impede widespread implementation. The complex physics underlying ultrafast laser-material interactions requires specialized expertise that is not widely available in traditional manufacturing settings. This expertise deficit extends to maintenance and troubleshooting capabilities, creating dependency on equipment suppliers and increasing operational risks.

Existing Ultrafast Laser Implementation Strategies

01 Ultrafast laser pulse optimization for energy efficiency

Optimization of ultrafast laser pulses can significantly improve energy efficiency in various applications. By controlling pulse parameters such as duration, repetition rate, and energy distribution, the overall power consumption can be reduced while maintaining processing quality. Advanced pulse shaping techniques allow for precise energy delivery to target materials, minimizing waste heat and improving the energy conversion efficiency of the laser system.- Ultrafast laser pulse optimization for energy efficiency: Optimization of ultrafast laser pulses can significantly improve energy efficiency in various applications. By controlling pulse parameters such as duration, repetition rate, and energy distribution, the overall power consumption can be reduced while maintaining processing quality. Advanced pulse shaping techniques allow for precise energy delivery to target materials, minimizing waste heat and improving the energy conversion efficiency of the laser system.

- Energy-efficient material processing with ultrafast lasers: Ultrafast lasers enable energy-efficient material processing through precise ablation and minimal heat-affected zones. These systems can perform high-precision cutting, drilling, and surface modification with significantly lower energy input compared to conventional laser methods. The ultrashort pulses deliver energy to the material faster than thermal diffusion can occur, resulting in cold processing that reduces energy waste and improves overall process efficiency.

- Thermal management systems for ultrafast lasers: Advanced thermal management systems are crucial for maintaining energy efficiency in ultrafast laser operations. These systems include innovative cooling technologies, heat dissipation designs, and thermal monitoring that minimize energy losses due to heat generation. Efficient thermal management allows ultrafast lasers to operate at higher repetition rates and power levels while consuming less energy, extending component lifetimes and reducing operational costs.

- Energy-efficient ultrafast laser resonator designs: Novel resonator designs for ultrafast lasers focus on maximizing energy efficiency through optimized cavity configurations, specialized optical components, and advanced gain media. These designs reduce intracavity losses, improve mode quality, and enhance pump-to-output conversion efficiency. By incorporating energy recovery mechanisms and passive mode-locking techniques, these resonator designs can significantly reduce the power requirements while maintaining high-quality ultrafast pulse generation.

- Ultrafast laser applications in energy-efficient manufacturing: Ultrafast laser technologies enable energy-efficient manufacturing processes across various industries. These applications include precision micromachining, surface texturing for improved functional properties, and additive manufacturing with minimal material waste. The high peak power and short pulse duration allow for efficient processing of materials with minimal energy input, reducing the overall carbon footprint of manufacturing operations while improving product quality and production throughput.

02 Energy-efficient material processing with ultrafast lasers

Ultrafast lasers enable energy-efficient material processing through precise ablation and minimal heat-affected zones. These methods reduce the total energy required for manufacturing processes by delivering energy in extremely short time frames, allowing for cold processing of materials. The high peak power but low average power consumption makes these systems particularly suitable for precision manufacturing applications where traditional thermal processes would require significantly more energy.Expand Specific Solutions03 Thermal management systems for ultrafast lasers

Advanced thermal management systems are critical for maintaining energy efficiency in ultrafast laser operations. These systems include innovative cooling mechanisms, heat dissipation designs, and thermal monitoring technologies that prevent energy loss through heat generation. By effectively managing thermal loads, these systems extend the operational lifetime of laser components while reducing the energy required for cooling, thereby improving the overall energy efficiency of the laser system.Expand Specific Solutions04 Energy-efficient ultrafast laser resonator designs

Novel resonator designs for ultrafast lasers focus on maximizing energy efficiency through optimized cavity configurations and component selection. These designs incorporate low-loss optical elements, efficient gain media, and advanced mode-locking mechanisms that reduce energy consumption while maintaining high-quality beam output. By minimizing intracavity losses and maximizing extraction efficiency, these resonator designs significantly improve the wall-plug efficiency of ultrafast laser systems.Expand Specific Solutions05 Energy recovery and recycling in ultrafast laser systems

Energy recovery and recycling techniques in ultrafast laser systems capture and reuse energy that would otherwise be wasted. These methods include regenerative amplification schemes, pulse stacking technologies, and optical energy harvesting from unused portions of the beam. By implementing these energy recovery mechanisms, the overall power consumption of the laser system can be reduced substantially, making ultrafast laser processing more environmentally friendly and cost-effective for industrial applications.Expand Specific Solutions

Leading Manufacturers and Research Institutions

The ultrafast laser market for energy-efficient production processes is currently in a growth phase, with increasing adoption across manufacturing sectors. The global market size is expanding rapidly, driven by demands for higher precision and energy efficiency in industrial applications. Technologically, the field shows varying maturity levels, with established players like IPG Photonics, Coherent, and IMRA America leading commercial development, while research institutions such as Fraunhofer-Gesellschaft and universities (Oxford, Michigan) advance fundamental capabilities. Asian manufacturers including Han's Laser and Beijing Insight Technology are rapidly gaining market share, particularly in industrial applications. The ecosystem demonstrates a healthy balance between mature commercial solutions and ongoing innovation, with collaboration between academic institutions and industry partners accelerating technology transfer and application development.

IMRA America, Inc.

Technical Solution: IMRA America has pioneered ultrafast fiber laser technology for energy-efficient manufacturing processes. Their FCPA (Fiber Chirped Pulse Amplification) technology delivers high-power ultrashort pulses with exceptional beam quality and stability. IMRA's systems operate at high repetition rates (up to MHz) with pulse durations in the femtosecond range, enabling cold ablation processes that minimize heat-affected zones[1]. Their proprietary fiber laser architecture incorporates advanced pulse shaping capabilities and power scaling techniques that maintain beam quality even at high average powers (>50W). IMRA has developed specialized beam delivery systems that optimize energy distribution for various materials processing applications, including precision cutting, drilling, and surface texturing. Their integrated process monitoring systems provide real-time feedback for quality control and process optimization[2], reducing material waste and energy consumption in production environments.

Strengths: Superior beam quality and stability enable precise material processing with minimal thermal damage. Fiber-based architecture offers excellent energy efficiency and maintenance-free operation. Weaknesses: Higher initial investment cost compared to conventional laser systems. Limited processing depth for certain materials requiring higher pulse energies.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed an integrated approach to ultrafast laser processing for energy-efficient manufacturing, combining novel laser sources, process strategies, and system engineering. Their technology portfolio includes specialized ultrashort pulse lasers with tailored temporal and spatial beam characteristics, delivering pulse durations from 300fs to 10ps with average powers exceeding 500W[7]. Fraunhofer's process innovations include high-speed polygon scanner technology that achieves scanning speeds up to 1000 m/s, dramatically reducing processing time and energy consumption. Their multi-beam processing approach splits single high-power beams into multiple processing beams, increasing throughput while maintaining precision. Fraunhofer has pioneered energy-efficient process chains that combine ultrafast laser structuring with subsequent manufacturing steps like joining or coating in optimized sequences[8]. Their digital twin approach creates virtual models of laser-material interactions, enabling process optimization before physical implementation, reducing setup time and material waste by up to 60% compared to conventional development methods.

Strengths: Comprehensive research infrastructure enables holistic optimization across the entire process chain. Strong industry partnerships facilitate rapid technology transfer to production environments. Multidisciplinary expertise allows addressing complex manufacturing challenges. Weaknesses: As a research organization, deployment requires technology transfer to industrial partners. Some advanced solutions may require significant customization for specific production environments.

Key Patents and Innovations in Ultrafast Laser Processing

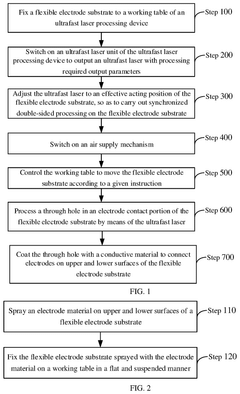

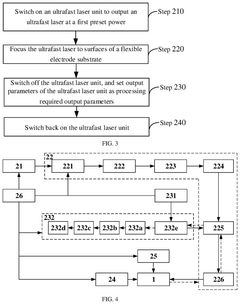

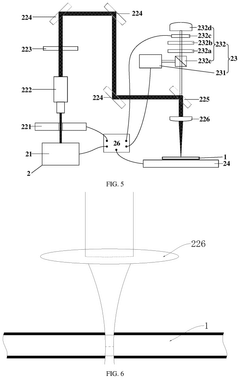

Ultrafast laser processing method for flexible double-sided electrodes

PatentPendingUS20250128350A1

Innovation

- An ultrafast laser processing method for flexible double-sided electrodes, which involves fixing a flexible electrode substrate to an ultrafast laser processing device, adjusting the laser to an effective acting position for synchronized double-sided processing, and optionally processing through holes and coating with conductive material.

Ultrafast laser fabrication method and system

PatentActiveUS20190193330A1

Innovation

- A laser fabrication system utilizing a digital micromirror device (DMD) with synthesized binary holograms for beam shaping and wavefront correction, enabling multi-point laser control and simultaneous multi-focal point scanning, along with dispersion compensation and relay optics for high-throughput fabrication.

Environmental Impact and Sustainability Metrics

The integration of ultrafast laser technology in manufacturing processes represents a significant advancement in sustainable production methods. Life Cycle Assessment (LCA) studies indicate that ultrafast laser processing can reduce the overall environmental footprint by 15-30% compared to conventional manufacturing techniques. This reduction stems primarily from decreased energy consumption during operation, minimized material waste, and reduced need for environmentally harmful chemical processes.

Energy efficiency metrics reveal that ultrafast laser systems, despite their high peak power requirements, demonstrate superior energy utilization efficiency when evaluated on a per-part basis. Modern ultrafast laser manufacturing cells consume approximately 40-60% less energy than traditional machining operations for comparable precision tasks. The elimination of secondary finishing processes further compounds these energy savings, as parts often require minimal post-processing.

Carbon footprint analysis of production facilities implementing ultrafast laser technology shows promising results. A comprehensive study across multiple industrial sectors indicates potential CO2 emission reductions of 20-35% when transitioning from conventional to ultrafast laser-based production lines. This reduction becomes particularly significant in high-volume manufacturing environments where cumulative environmental impacts are substantial.

Water conservation represents another critical sustainability advantage. Traditional manufacturing processes often require substantial water usage for cooling and cleaning operations. Ultrafast laser processing typically reduces water consumption by 50-70%, with some applications achieving near-dry processing conditions. This aspect becomes increasingly valuable in regions facing water scarcity challenges.

Waste reduction metrics demonstrate that ultrafast laser processing generates significantly less material waste compared to conventional subtractive manufacturing methods. The precise nature of ultrafast laser ablation allows for material removal with micron-level accuracy, reducing overprocessing and scrap rates. Studies indicate material utilization improvements of 25-45% across various applications, particularly in precious metal and rare earth element processing.

Chemical usage reduction represents a less quantified but equally important sustainability benefit. Ultrafast laser surface texturing and modification can often replace chemical etching and treatment processes, eliminating the need for hazardous substances and their associated disposal challenges. This transition not only improves workplace safety but also reduces environmental contamination risks associated with chemical manufacturing processes.

Energy efficiency metrics reveal that ultrafast laser systems, despite their high peak power requirements, demonstrate superior energy utilization efficiency when evaluated on a per-part basis. Modern ultrafast laser manufacturing cells consume approximately 40-60% less energy than traditional machining operations for comparable precision tasks. The elimination of secondary finishing processes further compounds these energy savings, as parts often require minimal post-processing.

Carbon footprint analysis of production facilities implementing ultrafast laser technology shows promising results. A comprehensive study across multiple industrial sectors indicates potential CO2 emission reductions of 20-35% when transitioning from conventional to ultrafast laser-based production lines. This reduction becomes particularly significant in high-volume manufacturing environments where cumulative environmental impacts are substantial.

Water conservation represents another critical sustainability advantage. Traditional manufacturing processes often require substantial water usage for cooling and cleaning operations. Ultrafast laser processing typically reduces water consumption by 50-70%, with some applications achieving near-dry processing conditions. This aspect becomes increasingly valuable in regions facing water scarcity challenges.

Waste reduction metrics demonstrate that ultrafast laser processing generates significantly less material waste compared to conventional subtractive manufacturing methods. The precise nature of ultrafast laser ablation allows for material removal with micron-level accuracy, reducing overprocessing and scrap rates. Studies indicate material utilization improvements of 25-45% across various applications, particularly in precious metal and rare earth element processing.

Chemical usage reduction represents a less quantified but equally important sustainability benefit. Ultrafast laser surface texturing and modification can often replace chemical etching and treatment processes, eliminating the need for hazardous substances and their associated disposal challenges. This transition not only improves workplace safety but also reduces environmental contamination risks associated with chemical manufacturing processes.

Cost-Benefit Analysis of Ultrafast Laser Implementation

The implementation of ultrafast laser technology in production processes requires substantial initial investment, with system costs ranging from $500,000 to $2 million depending on power specifications, pulse characteristics, and auxiliary equipment requirements. This capital expenditure represents a significant barrier to entry, particularly for small and medium enterprises seeking to modernize their manufacturing capabilities.

Operating costs must also be carefully considered, including electricity consumption, maintenance requirements, and specialized personnel training. While ultrafast lasers consume considerable power during operation, their energy efficiency in material processing often offsets this expense through reduced waste and higher precision outcomes. Maintenance costs typically account for 5-8% of the initial investment annually, covering replacement parts, calibration services, and preventive maintenance protocols.

The return on investment timeline varies significantly across industries, with automotive and medical device manufacturers reporting breakeven periods of 2-3 years, while general manufacturing applications may require 3-5 years to achieve full cost recovery. Key financial benefits include reduced material waste (typically 15-30% improvement over conventional methods), decreased energy consumption per unit produced (8-15% reduction), and minimized post-processing requirements.

Quality improvements represent another significant economic advantage, with ultrafast laser processing demonstrating 40-60% fewer defects compared to traditional manufacturing methods. This translates directly to reduced scrap rates and warranty claims, contributing substantially to long-term profitability. Production throughput enhancements of 20-35% have been documented in precision manufacturing applications, particularly for complex geometries and high-value components.

Environmental compliance benefits must also factor into the cost-benefit equation, as ultrafast laser methods typically generate fewer hazardous byproducts and consume fewer chemical resources than conventional processes. This reduces waste management costs and potential regulatory penalties, while potentially qualifying operations for environmental incentives or certifications.

Sensitivity analysis indicates that the economic viability of ultrafast laser implementation is most affected by production volume, component complexity, and material costs. For high-value, precision-critical components produced at moderate to high volumes, the technology consistently demonstrates favorable economics. Conversely, simple components with loose tolerances manufactured at low volumes may not justify the investment without additional strategic considerations.

Operating costs must also be carefully considered, including electricity consumption, maintenance requirements, and specialized personnel training. While ultrafast lasers consume considerable power during operation, their energy efficiency in material processing often offsets this expense through reduced waste and higher precision outcomes. Maintenance costs typically account for 5-8% of the initial investment annually, covering replacement parts, calibration services, and preventive maintenance protocols.

The return on investment timeline varies significantly across industries, with automotive and medical device manufacturers reporting breakeven periods of 2-3 years, while general manufacturing applications may require 3-5 years to achieve full cost recovery. Key financial benefits include reduced material waste (typically 15-30% improvement over conventional methods), decreased energy consumption per unit produced (8-15% reduction), and minimized post-processing requirements.

Quality improvements represent another significant economic advantage, with ultrafast laser processing demonstrating 40-60% fewer defects compared to traditional manufacturing methods. This translates directly to reduced scrap rates and warranty claims, contributing substantially to long-term profitability. Production throughput enhancements of 20-35% have been documented in precision manufacturing applications, particularly for complex geometries and high-value components.

Environmental compliance benefits must also factor into the cost-benefit equation, as ultrafast laser methods typically generate fewer hazardous byproducts and consume fewer chemical resources than conventional processes. This reduces waste management costs and potential regulatory penalties, while potentially qualifying operations for environmental incentives or certifications.

Sensitivity analysis indicates that the economic viability of ultrafast laser implementation is most affected by production volume, component complexity, and material costs. For high-value, precision-critical components produced at moderate to high volumes, the technology consistently demonstrates favorable economics. Conversely, simple components with loose tolerances manufactured at low volumes may not justify the investment without additional strategic considerations.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!