Ultrafast Laser Methods for Anti-Microbial Surface Creation.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Antimicrobial Surface Technology Background and Objectives

Ultrafast laser technology for creating antimicrobial surfaces represents a significant advancement in the intersection of photonics, materials science, and microbiology. This technology has evolved considerably over the past two decades, transitioning from laboratory curiosity to practical industrial application. The fundamental principle involves using ultrashort laser pulses, typically in the femtosecond to picosecond range, to modify surface properties at the micro and nanoscale, creating structures that naturally repel or destroy microorganisms without relying on chemical agents.

The historical development of this technology can be traced back to the early 2000s when researchers first observed that certain laser-induced surface patterns could inhibit bacterial adhesion. By 2010, significant advancements in ultrafast laser systems, particularly in terms of reliability, cost-effectiveness, and processing speed, enabled more sophisticated surface engineering approaches. The field gained substantial momentum after 2015 when several breakthrough studies demonstrated the efficacy of laser-textured surfaces against a broad spectrum of pathogens, including antibiotic-resistant strains.

Current technological trends indicate a shift toward more precise control over surface topography at multiple scales, combining micro and nanostructures to maximize antimicrobial efficacy while maintaining other desirable material properties. There is also growing interest in developing process parameters that can be applied to diverse substrate materials, including metals, ceramics, polymers, and composites, expanding the potential application domains.

The primary technical objectives for advancing ultrafast laser antimicrobial surface technology include: optimizing laser parameters (pulse duration, energy, repetition rate, scanning strategy) to achieve maximum antimicrobial efficacy; developing scalable manufacturing processes suitable for industrial implementation; ensuring long-term stability of antimicrobial properties under real-world conditions; and minimizing environmental impact through reduced reliance on chemical antimicrobial agents.

Additionally, there are important secondary objectives related to cost reduction, process speed enhancement, and integration with existing manufacturing workflows. The technology aims to address the growing global challenge of antimicrobial resistance by providing physical rather than chemical approaches to controlling microbial contamination on surfaces in healthcare facilities, public spaces, food processing environments, and consumer products.

Looking forward, the field is expected to evolve toward multi-functional surfaces that combine antimicrobial properties with other desirable characteristics such as anti-fouling, self-cleaning, or enhanced wear resistance. The ultimate goal is to develop a versatile platform technology that can be tailored to specific application requirements while maintaining cost-effectiveness and scalability for widespread adoption across multiple industries.

The historical development of this technology can be traced back to the early 2000s when researchers first observed that certain laser-induced surface patterns could inhibit bacterial adhesion. By 2010, significant advancements in ultrafast laser systems, particularly in terms of reliability, cost-effectiveness, and processing speed, enabled more sophisticated surface engineering approaches. The field gained substantial momentum after 2015 when several breakthrough studies demonstrated the efficacy of laser-textured surfaces against a broad spectrum of pathogens, including antibiotic-resistant strains.

Current technological trends indicate a shift toward more precise control over surface topography at multiple scales, combining micro and nanostructures to maximize antimicrobial efficacy while maintaining other desirable material properties. There is also growing interest in developing process parameters that can be applied to diverse substrate materials, including metals, ceramics, polymers, and composites, expanding the potential application domains.

The primary technical objectives for advancing ultrafast laser antimicrobial surface technology include: optimizing laser parameters (pulse duration, energy, repetition rate, scanning strategy) to achieve maximum antimicrobial efficacy; developing scalable manufacturing processes suitable for industrial implementation; ensuring long-term stability of antimicrobial properties under real-world conditions; and minimizing environmental impact through reduced reliance on chemical antimicrobial agents.

Additionally, there are important secondary objectives related to cost reduction, process speed enhancement, and integration with existing manufacturing workflows. The technology aims to address the growing global challenge of antimicrobial resistance by providing physical rather than chemical approaches to controlling microbial contamination on surfaces in healthcare facilities, public spaces, food processing environments, and consumer products.

Looking forward, the field is expected to evolve toward multi-functional surfaces that combine antimicrobial properties with other desirable characteristics such as anti-fouling, self-cleaning, or enhanced wear resistance. The ultimate goal is to develop a versatile platform technology that can be tailored to specific application requirements while maintaining cost-effectiveness and scalability for widespread adoption across multiple industries.

Market Analysis for Antimicrobial Surface Solutions

The global market for antimicrobial surfaces is experiencing robust growth, driven primarily by increasing healthcare-associated infections and growing awareness of hygiene across multiple sectors. Currently valued at approximately $3.6 billion in 2023, the market is projected to reach $6.5 billion by 2028, representing a compound annual growth rate (CAGR) of 12.5%.

Healthcare remains the dominant application sector, accounting for nearly 45% of the total market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting antimicrobial surfaces to reduce nosocomial infections and comply with stringent regulatory standards. The COVID-19 pandemic has significantly accelerated this trend, creating heightened awareness about surface transmission of pathogens.

Food processing and packaging industries constitute the second-largest market segment at 20%, where antimicrobial surfaces help extend shelf life and ensure food safety. Consumer electronics (10%), public transportation (8%), and residential applications (7%) represent emerging sectors with substantial growth potential.

Regionally, North America leads the market with 38% share, followed by Europe (30%) and Asia-Pacific (22%). The latter is expected to witness the fastest growth rate of 15.3% annually through 2028, driven by rapid healthcare infrastructure development and increasing disposable income in countries like China and India.

Traditional chemical-based antimicrobial solutions currently dominate the market (65%), but physical modification approaches, including laser-treated surfaces, are gaining traction due to their durability and reduced environmental impact. Ultrafast laser-created antimicrobial surfaces specifically represent a nascent but rapidly growing segment, currently estimated at $180 million but projected to grow at 18% annually—significantly outpacing the overall market.

Key customer demands include long-term efficacy (cited by 78% of potential buyers), environmental sustainability (65%), cost-effectiveness (62%), and compatibility with existing manufacturing processes (58%). Notably, 72% of healthcare procurement specialists expressed willingness to pay premium prices for solutions demonstrating superior performance in reducing infection rates.

Market challenges include high initial implementation costs, with laser-based solutions typically commanding a 30-40% premium over conventional treatments. Regulatory hurdles also present significant barriers, as antimicrobial claims require extensive testing and certification, typically taking 12-18 months for approval in major markets.

The competitive landscape features both established players expanding their portfolios and innovative startups focusing exclusively on advanced antimicrobial technologies. Industry consolidation is evident, with 14 significant acquisitions recorded in the past three years as larger corporations seek to incorporate cutting-edge antimicrobial technologies into their offerings.

Healthcare remains the dominant application sector, accounting for nearly 45% of the total market share. Hospitals, clinics, and medical device manufacturers are increasingly adopting antimicrobial surfaces to reduce nosocomial infections and comply with stringent regulatory standards. The COVID-19 pandemic has significantly accelerated this trend, creating heightened awareness about surface transmission of pathogens.

Food processing and packaging industries constitute the second-largest market segment at 20%, where antimicrobial surfaces help extend shelf life and ensure food safety. Consumer electronics (10%), public transportation (8%), and residential applications (7%) represent emerging sectors with substantial growth potential.

Regionally, North America leads the market with 38% share, followed by Europe (30%) and Asia-Pacific (22%). The latter is expected to witness the fastest growth rate of 15.3% annually through 2028, driven by rapid healthcare infrastructure development and increasing disposable income in countries like China and India.

Traditional chemical-based antimicrobial solutions currently dominate the market (65%), but physical modification approaches, including laser-treated surfaces, are gaining traction due to their durability and reduced environmental impact. Ultrafast laser-created antimicrobial surfaces specifically represent a nascent but rapidly growing segment, currently estimated at $180 million but projected to grow at 18% annually—significantly outpacing the overall market.

Key customer demands include long-term efficacy (cited by 78% of potential buyers), environmental sustainability (65%), cost-effectiveness (62%), and compatibility with existing manufacturing processes (58%). Notably, 72% of healthcare procurement specialists expressed willingness to pay premium prices for solutions demonstrating superior performance in reducing infection rates.

Market challenges include high initial implementation costs, with laser-based solutions typically commanding a 30-40% premium over conventional treatments. Regulatory hurdles also present significant barriers, as antimicrobial claims require extensive testing and certification, typically taking 12-18 months for approval in major markets.

The competitive landscape features both established players expanding their portfolios and innovative startups focusing exclusively on advanced antimicrobial technologies. Industry consolidation is evident, with 14 significant acquisitions recorded in the past three years as larger corporations seek to incorporate cutting-edge antimicrobial technologies into their offerings.

Current State and Challenges in Laser Surface Modification

Ultrafast laser surface modification technology has evolved significantly over the past decade, with current applications spanning from medical devices to industrial components. The state-of-the-art techniques employ femtosecond and picosecond lasers operating at pulse durations below 10 picoseconds, enabling precise material removal without significant heat-affected zones. This precision has revolutionized the creation of antimicrobial surfaces by allowing controlled micro and nanostructuring at scales relevant to bacterial interaction.

Despite these advancements, several technical challenges persist in the field. Scalability remains a primary concern, as most current ultrafast laser systems operate at relatively low throughput compared to conventional manufacturing processes. The typical processing speeds of 100-1000 mm²/min are insufficient for large-scale industrial implementation, particularly in medical device manufacturing where antimicrobial surfaces are highly valuable.

Energy efficiency presents another significant challenge. Ultrafast laser systems typically operate at 5-15% wall-plug efficiency, resulting in high energy consumption relative to the actual energy delivered to the workpiece. This inefficiency translates to increased operational costs and environmental impact, limiting widespread adoption in cost-sensitive industries.

The reproducibility and long-term stability of laser-created antimicrobial surfaces constitute another critical challenge. Research indicates that surface properties can degrade over time due to environmental exposure, mechanical wear, and biological interactions. Studies show that antimicrobial efficacy may decrease by 30-50% after extended use in clinical environments, raising concerns about the long-term viability of these solutions.

Geographically, ultrafast laser technology development shows distinct regional characteristics. North America and Europe lead in fundamental research and high-end system development, with approximately 65% of patents originating from these regions. Meanwhile, East Asian countries, particularly Japan and South Korea, have made significant strides in application-specific implementations, focusing on cost reduction and integration with existing manufacturing processes.

Material limitations further constrain the application scope. While ultrafast lasers work effectively on metals and certain polymers, processing transparent materials and composites remains challenging. The physics of light-matter interaction at ultrashort timescales varies significantly across material classes, necessitating material-specific parameter optimization that complicates universal implementation.

Regulatory hurdles also impede progress, particularly for medical applications. The novel nature of laser-textured antimicrobial surfaces means that standardized testing protocols and regulatory frameworks are still evolving, creating uncertainty for manufacturers and extending time-to-market for new products.

Despite these advancements, several technical challenges persist in the field. Scalability remains a primary concern, as most current ultrafast laser systems operate at relatively low throughput compared to conventional manufacturing processes. The typical processing speeds of 100-1000 mm²/min are insufficient for large-scale industrial implementation, particularly in medical device manufacturing where antimicrobial surfaces are highly valuable.

Energy efficiency presents another significant challenge. Ultrafast laser systems typically operate at 5-15% wall-plug efficiency, resulting in high energy consumption relative to the actual energy delivered to the workpiece. This inefficiency translates to increased operational costs and environmental impact, limiting widespread adoption in cost-sensitive industries.

The reproducibility and long-term stability of laser-created antimicrobial surfaces constitute another critical challenge. Research indicates that surface properties can degrade over time due to environmental exposure, mechanical wear, and biological interactions. Studies show that antimicrobial efficacy may decrease by 30-50% after extended use in clinical environments, raising concerns about the long-term viability of these solutions.

Geographically, ultrafast laser technology development shows distinct regional characteristics. North America and Europe lead in fundamental research and high-end system development, with approximately 65% of patents originating from these regions. Meanwhile, East Asian countries, particularly Japan and South Korea, have made significant strides in application-specific implementations, focusing on cost reduction and integration with existing manufacturing processes.

Material limitations further constrain the application scope. While ultrafast lasers work effectively on metals and certain polymers, processing transparent materials and composites remains challenging. The physics of light-matter interaction at ultrashort timescales varies significantly across material classes, necessitating material-specific parameter optimization that complicates universal implementation.

Regulatory hurdles also impede progress, particularly for medical applications. The novel nature of laser-textured antimicrobial surfaces means that standardized testing protocols and regulatory frameworks are still evolving, creating uncertainty for manufacturers and extending time-to-market for new products.

Current Ultrafast Laser Surface Texturing Methodologies

01 Ultrafast laser surface texturing for antimicrobial properties

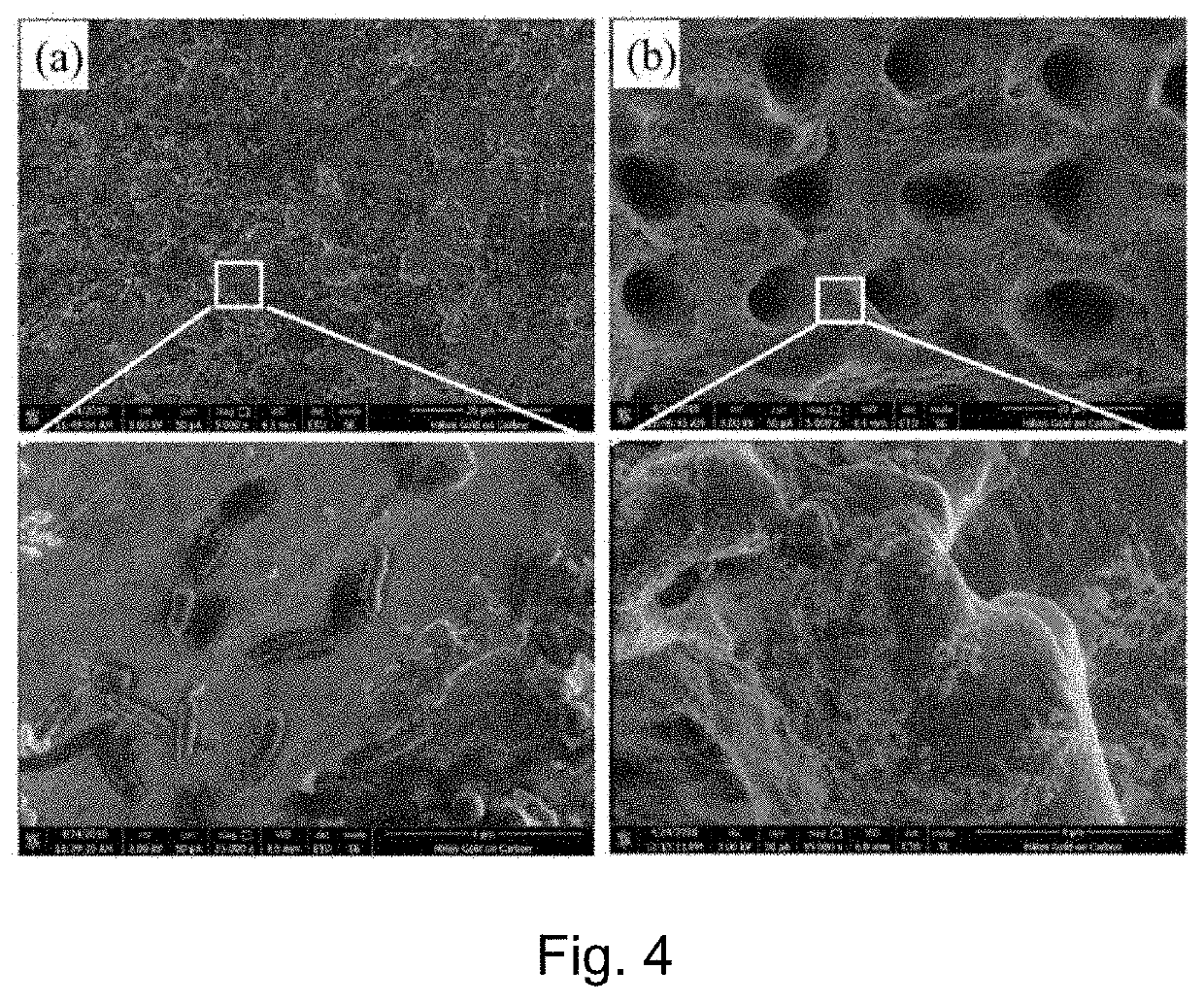

Ultrafast lasers can be used to create micro and nano-scale textures on material surfaces that inhibit bacterial adhesion and growth. These precisely engineered surface patterns disrupt bacterial colonization by creating unfavorable topographies. The texturing process can be applied to various materials including metals, polymers, and ceramics, creating permanent antimicrobial surfaces without requiring chemical coatings or additives.- Ultrafast laser surface texturing for antimicrobial properties: Ultrafast lasers can be used to create micro and nano-scale textures on material surfaces that inhibit bacterial adhesion and growth. These precisely engineered surface patterns disrupt biofilm formation and create structures that physically damage bacterial cell membranes. The texturing process can be applied to various materials including metals, polymers, and ceramics, creating permanent antimicrobial properties without requiring chemical coatings or additives.

- Laser-induced surface functionalization with antimicrobial agents: Ultrafast laser processing can be used to functionalize surfaces with antimicrobial agents. The high-energy, short-duration pulses create reactive surface sites that can bond with antimicrobial compounds or nanoparticles. This technique allows for precise spatial control of antimicrobial properties and can incorporate silver, copper, or zinc nanoparticles that provide long-lasting protection against a broad spectrum of pathogens.

- Femtosecond laser processing for medical device surfaces: Femtosecond laser technology is particularly valuable for creating antimicrobial surfaces on medical devices and implants. The ultrashort pulses minimize thermal damage to surrounding materials while creating precise surface modifications that reduce infection risk. This approach can be used to process temperature-sensitive biomaterials and create hierarchical structures that both promote tissue integration while preventing bacterial colonization.

- Laser-induced periodic surface structures (LIPSS) with antimicrobial properties: Ultrafast lasers can generate Laser-Induced Periodic Surface Structures (LIPSS) with nanoscale ripples and patterns that exhibit antimicrobial properties. These self-organized structures can be tuned by adjusting laser parameters such as fluence, pulse duration, and scanning strategy. The resulting surfaces demonstrate hydrophobic or hydrophilic properties that can prevent bacterial attachment and provide passive antimicrobial functionality without chemical agents.

- Hybrid laser processing techniques for multifunctional antimicrobial surfaces: Combining ultrafast laser processing with other techniques creates multifunctional antimicrobial surfaces. These hybrid approaches may include laser processing followed by chemical treatment, plasma deposition, or the incorporation of photocatalytic materials. The resulting surfaces can provide both passive antimicrobial properties through physical structuring and active antimicrobial effects through photocatalytic reactions or controlled release of antimicrobial agents.

02 Laser-induced chemical modification of surfaces

Ultrafast laser processing can induce chemical changes on material surfaces that confer antimicrobial properties. The high-energy, short-duration pulses can trigger oxidation, reduction, or other chemical reactions that modify surface chemistry. These modifications can create surfaces that are inherently hostile to microorganisms through mechanisms such as reactive oxygen species generation or altered surface charge, providing long-lasting antimicrobial functionality.Expand Specific Solutions03 Femtosecond laser processing for medical device surfaces

Femtosecond lasers offer precise control for creating antimicrobial surfaces on medical devices. The ultrashort pulses minimize thermal effects, allowing for clean surface modification without damaging sensitive materials. This technology enables the production of implants, surgical instruments, and other medical devices with built-in antimicrobial properties, reducing the risk of healthcare-associated infections without relying on antibiotic coatings that could contribute to resistance.Expand Specific Solutions04 Laser-assisted deposition of antimicrobial materials

Ultrafast lasers can facilitate the deposition and integration of antimicrobial materials onto surfaces. The high-energy pulses can be used to embed silver, copper, or other antimicrobial agents into substrate materials, creating a durable composite surface. This technique allows for precise control over the concentration and distribution of antimicrobial agents, optimizing efficacy while minimizing material usage and potential environmental impacts.Expand Specific Solutions05 Optical system configurations for antimicrobial surface processing

Specialized optical systems and beam delivery configurations enhance the effectiveness of ultrafast laser processing for antimicrobial surfaces. These systems may include beam shaping optics, scanning mechanisms, and pulse control technologies that optimize the interaction between laser and material. Advanced optical configurations enable high-throughput processing of complex three-dimensional surfaces, making the technology commercially viable for mass production of antimicrobial products across various industries.Expand Specific Solutions

Key Industry Players in Antimicrobial Surface Manufacturing

Ultrafast laser methods for anti-microbial surface creation are in an emerging growth phase, with the global market expected to reach significant scale as healthcare-associated infections drive demand. The technology is approaching commercial maturity, with academic institutions (Tsinghua University, Beihang University) conducting foundational research while specialized companies (IMRA America, Fraunhofer-Gesellschaft) lead industrial applications. Major corporations like Philips, Bosch, and Volkswagen are exploring integration into consumer and medical products. The competitive landscape features a balanced mix of academic research centers, specialized laser technology firms, and large corporations seeking to incorporate this technology into their product ecosystems.

IMRA America, Inc.

Technical Solution: IMRA America has developed a proprietary ultrafast laser surface texturing technology that creates hierarchical micro/nano structures on metal surfaces to achieve antimicrobial properties. Their approach utilizes femtosecond laser pulses with precisely controlled parameters to generate self-organized structures that physically disrupt bacterial cell membranes. The company's FCPA (Fiber Chirped Pulse Amplification) technology delivers high-energy ultrashort pulses at high repetition rates, enabling efficient large-area processing. Their process creates surfaces with dual-scale roughness: microscale features (1-10 μm) combined with nanoscale ripples (100-500 nm) that effectively kill bacteria through mechanical contact rather than chemical means[1]. This technology has been demonstrated to achieve >99.9% reduction in bacterial colonization for common pathogens including S. aureus and E. coli without using antibiotics or metal ions, making it particularly suitable for medical implants and devices.

Strengths: Long-lasting antimicrobial effect without chemical leaching; compatible with existing medical-grade materials; scalable manufacturing process. Weaknesses: Higher initial equipment costs compared to chemical treatments; requires precise control of laser parameters; potential for reduced effectiveness against certain bacterial strains with adaptive mechanisms.

Koninklijke Philips NV

Technical Solution: Philips has developed an advanced ultrafast laser surface modification platform specifically targeting healthcare applications. Their technology employs picosecond and femtosecond lasers to create precisely controlled micro and nanoscale topographies on medical device surfaces. The process involves direct laser writing with beam shaping optics that enable the creation of biomimetic surface patterns inspired by naturally antimicrobial surfaces like cicada wings and shark skin. Philips' approach combines physical surface modification with optional functionalization steps where the laser-modified surfaces can be further enhanced with antimicrobial agents that bond more effectively to the textured surface[2]. Their system incorporates real-time monitoring and closed-loop control to ensure consistent surface quality across complex 3D medical components. Clinical studies have shown their laser-textured surfaces reduce biofilm formation by up to 97.8% on respiratory and cardiovascular devices while maintaining biocompatibility with human tissue[3].

Strengths: Highly customizable surface patterns; integration with existing medical device manufacturing workflows; comprehensive quality control systems. Weaknesses: Higher production costs compared to conventional surface treatments; technology primarily focused on specific medical applications rather than broader industrial use; requires specialized expertise for implementation.

Critical Patents and Research in Antimicrobial Surface Creation

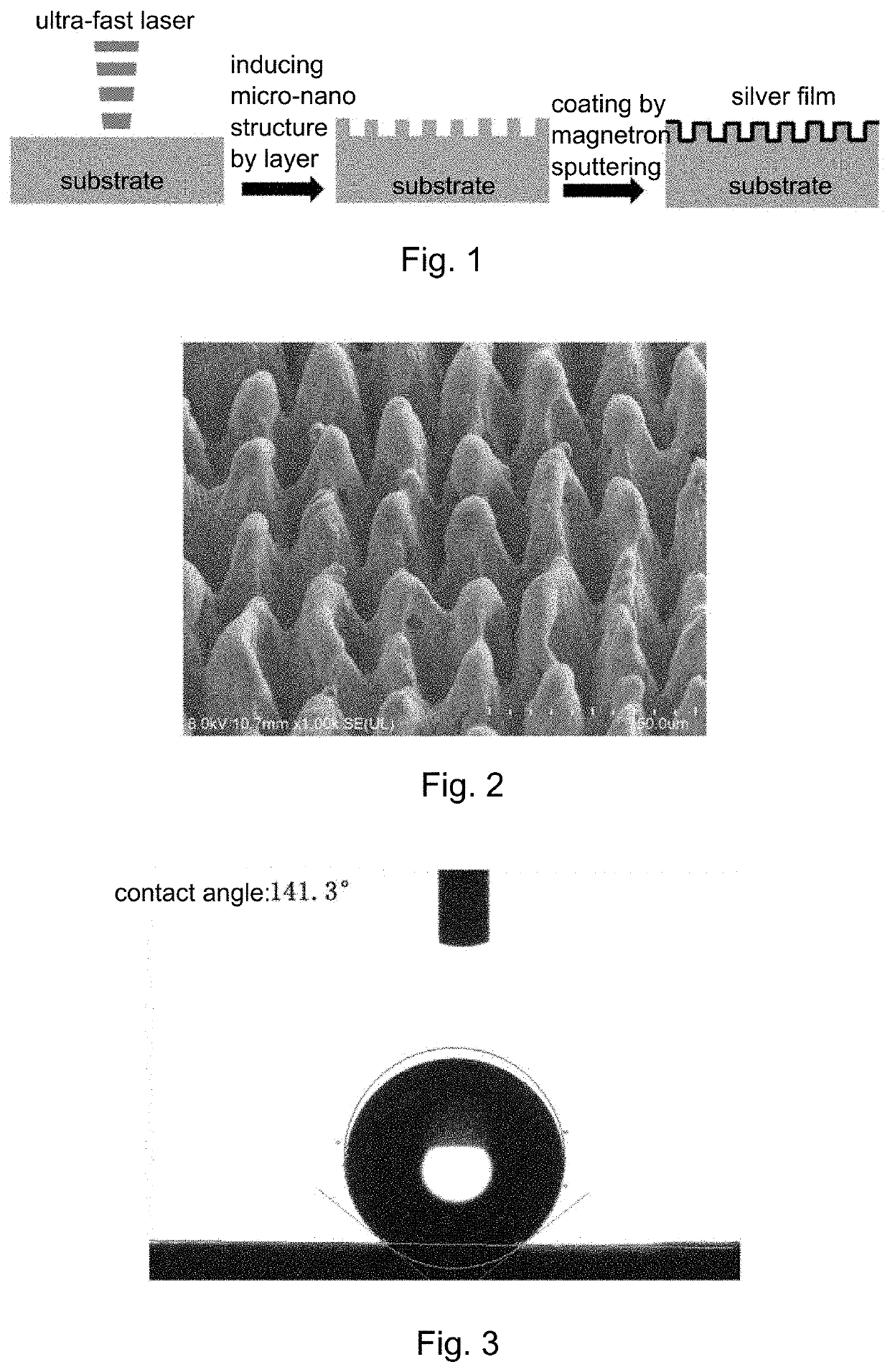

Method for preparing antibacterial surface on medical instrument

PatentInactiveCN109079446A

Innovation

- Ultrafast laser induces large-area micro-nano structures on the surface of medical devices, and combines the coating process to deposit metal nanoparticles to construct a hydrophobic film with anti-bacterial adhesion and sterilization functions, achieving an organic combination of anti-bacterial adhesion and sterilization.

Preparation of antimicrobial surface for medical devices

PatentActiveUS20200009687A1

Innovation

- A method using a single-stop ultrafast laser to produce micro/nano patterns on medical device surfaces, followed by the deposition of metal nanoparticles like silver and copper to create a bactericidal film, combining anti-adhesion and bactericidal properties while maintaining material integrity and reducing toxicity.

Biocompatibility and Safety Considerations

The biocompatibility and safety of ultrafast laser-treated antimicrobial surfaces represent critical considerations for their practical implementation, particularly in medical and consumer applications. These surfaces must not only effectively eliminate microbial threats but also remain safe for human contact and environmental exposure. Current research indicates that the nano and microstructures created through ultrafast laser ablation generally exhibit favorable biocompatibility profiles when properly designed and manufactured.

Primary safety considerations include the potential release of nanoparticles from treated surfaces, which could pose inhalation or ingestion risks if dislodged. Studies have demonstrated that properly engineered laser-textured surfaces can maintain structural integrity under normal use conditions, with minimal particle shedding. However, long-term durability testing remains essential, particularly for applications involving frequent physical contact or cleaning regimens.

Cytotoxicity assessments of ultrafast laser-treated surfaces have shown promising results, with most properly processed materials exhibiting minimal adverse effects on mammalian cell viability. This is particularly important for medical implants and devices where direct tissue contact occurs. The specific surface chemistry modifications resulting from laser treatment must be carefully characterized, as oxidation states and potential leachable compounds can significantly impact biocompatibility.

Inflammatory responses represent another critical safety parameter. Research indicates that optimized laser-textured surfaces can reduce foreign body responses compared to conventional materials, potentially due to specific topographical features that influence protein adsorption and subsequent cellular interactions. However, these responses vary significantly based on the base material, laser parameters, and resulting surface morphology.

Regulatory pathways for these antimicrobial surfaces require comprehensive biocompatibility testing according to ISO 10993 standards for medical applications. This includes genotoxicity, sensitization, and hemocompatibility assessments depending on the intended use case. Consumer product applications face different regulatory frameworks but still require thorough safety evaluations.

Environmental considerations must also be addressed, particularly regarding the end-of-life disposal of laser-treated materials. The potential ecological impact of nano-structured surfaces remains an active research area, with current evidence suggesting minimal environmental risks when properly managed. However, more comprehensive lifecycle assessments are needed to fully characterize potential environmental implications.

Future research directions should focus on standardizing biocompatibility testing protocols specifically for laser-textured antimicrobial surfaces, as current methodologies may not adequately capture the unique interactions between these structured surfaces and biological systems. Additionally, developing accelerated aging protocols to predict long-term safety profiles will be essential for widespread adoption of this promising technology.

Primary safety considerations include the potential release of nanoparticles from treated surfaces, which could pose inhalation or ingestion risks if dislodged. Studies have demonstrated that properly engineered laser-textured surfaces can maintain structural integrity under normal use conditions, with minimal particle shedding. However, long-term durability testing remains essential, particularly for applications involving frequent physical contact or cleaning regimens.

Cytotoxicity assessments of ultrafast laser-treated surfaces have shown promising results, with most properly processed materials exhibiting minimal adverse effects on mammalian cell viability. This is particularly important for medical implants and devices where direct tissue contact occurs. The specific surface chemistry modifications resulting from laser treatment must be carefully characterized, as oxidation states and potential leachable compounds can significantly impact biocompatibility.

Inflammatory responses represent another critical safety parameter. Research indicates that optimized laser-textured surfaces can reduce foreign body responses compared to conventional materials, potentially due to specific topographical features that influence protein adsorption and subsequent cellular interactions. However, these responses vary significantly based on the base material, laser parameters, and resulting surface morphology.

Regulatory pathways for these antimicrobial surfaces require comprehensive biocompatibility testing according to ISO 10993 standards for medical applications. This includes genotoxicity, sensitization, and hemocompatibility assessments depending on the intended use case. Consumer product applications face different regulatory frameworks but still require thorough safety evaluations.

Environmental considerations must also be addressed, particularly regarding the end-of-life disposal of laser-treated materials. The potential ecological impact of nano-structured surfaces remains an active research area, with current evidence suggesting minimal environmental risks when properly managed. However, more comprehensive lifecycle assessments are needed to fully characterize potential environmental implications.

Future research directions should focus on standardizing biocompatibility testing protocols specifically for laser-textured antimicrobial surfaces, as current methodologies may not adequately capture the unique interactions between these structured surfaces and biological systems. Additionally, developing accelerated aging protocols to predict long-term safety profiles will be essential for widespread adoption of this promising technology.

Scalability and Cost-Effectiveness Analysis

The scalability of ultrafast laser methods for creating antimicrobial surfaces represents a critical factor in their industrial adoption. Current implementation costs remain significantly higher than conventional surface treatment technologies, with initial equipment investment ranging from $500,000 to over $2 million for high-end femtosecond laser systems. This substantial capital expenditure creates a barrier to entry for small and medium enterprises seeking to incorporate this technology.

Operational expenses present additional challenges, with maintenance costs averaging 8-12% of the initial investment annually. Energy consumption during operation, while relatively modest compared to some industrial processes at 5-15 kW, still contributes to ongoing expenses. The specialized technical expertise required for system operation further increases implementation costs through higher personnel expenses or extensive training programs.

Production throughput represents a significant limitation in current systems. Processing speeds typically range from 100-500 mm²/min for high-precision antimicrobial surface creation, substantially slower than conventional chemical treatments or mechanical texturing methods. This throughput constraint directly impacts unit economics, with current cost estimates ranging from $0.50-2.00 per square centimeter of treated surface, depending on complexity and precision requirements.

Recent technological advancements show promising directions for improved cost-effectiveness. Multi-beam processing systems have demonstrated throughput increases of 300-400% in laboratory settings, though commercial implementations remain limited. Automation advancements, particularly in workpiece handling and quality control, have reduced labor costs by 30-45% in pilot production environments. Additionally, the development of more energy-efficient laser sources has decreased operational costs by 15-25% compared to previous generation systems.

Economic viability varies significantly across application sectors. Medical device manufacturing, where product margins are higher and regulatory requirements stringent, shows the strongest economic case with ROI periods of 2-3 years. Consumer electronics applications demonstrate moderate viability with 3-5 year ROI periods. General industrial applications currently show the weakest economic case, with ROI periods often exceeding 5 years unless specific high-value applications are targeted.

For broader market adoption, the technology requires further cost reduction by approximately 40-60%. This might be achieved through economies of scale in laser system production, improved process efficiency, and the development of specialized systems optimized for specific antimicrobial surface applications rather than utilizing general-purpose ultrafast laser platforms.

Operational expenses present additional challenges, with maintenance costs averaging 8-12% of the initial investment annually. Energy consumption during operation, while relatively modest compared to some industrial processes at 5-15 kW, still contributes to ongoing expenses. The specialized technical expertise required for system operation further increases implementation costs through higher personnel expenses or extensive training programs.

Production throughput represents a significant limitation in current systems. Processing speeds typically range from 100-500 mm²/min for high-precision antimicrobial surface creation, substantially slower than conventional chemical treatments or mechanical texturing methods. This throughput constraint directly impacts unit economics, with current cost estimates ranging from $0.50-2.00 per square centimeter of treated surface, depending on complexity and precision requirements.

Recent technological advancements show promising directions for improved cost-effectiveness. Multi-beam processing systems have demonstrated throughput increases of 300-400% in laboratory settings, though commercial implementations remain limited. Automation advancements, particularly in workpiece handling and quality control, have reduced labor costs by 30-45% in pilot production environments. Additionally, the development of more energy-efficient laser sources has decreased operational costs by 15-25% compared to previous generation systems.

Economic viability varies significantly across application sectors. Medical device manufacturing, where product margins are higher and regulatory requirements stringent, shows the strongest economic case with ROI periods of 2-3 years. Consumer electronics applications demonstrate moderate viability with 3-5 year ROI periods. General industrial applications currently show the weakest economic case, with ROI periods often exceeding 5 years unless specific high-value applications are targeted.

For broader market adoption, the technology requires further cost reduction by approximately 40-60%. This might be achieved through economies of scale in laser system production, improved process efficiency, and the development of specialized systems optimized for specific antimicrobial surface applications rather than utilizing general-purpose ultrafast laser platforms.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!