The Application of Ultrafast Lasers in Smart Textile Production.

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Technology Background and Objectives

Ultrafast laser technology has evolved significantly over the past three decades, transforming from laboratory curiosities to essential industrial tools. The development trajectory began with the invention of mode-locked lasers in the 1960s, followed by chirped pulse amplification in the 1980s, which enabled unprecedented peak powers without damaging optical components. Since 2000, ultrafast lasers have steadily migrated from scientific research into industrial applications, with pulse durations decreasing from picoseconds to femtoseconds while average powers have increased from watts to kilowatts.

In the context of smart textiles, ultrafast lasers represent a revolutionary manufacturing approach. These lasers operate with extremely short pulse durations (typically 10^-15 to 10^-12 seconds), enabling precise material processing with minimal heat-affected zones. This characteristic is particularly valuable for delicate textile substrates that cannot withstand conventional thermal processing methods. The technology allows for micromachining, surface modification, and functional patterning at scales previously unattainable in textile manufacturing.

The global trend toward wearable technology and functional fabrics has created a pressing need for advanced manufacturing techniques that can integrate electronic components, sensors, and actuators directly into textile structures. Ultrafast laser processing offers a solution to this integration challenge by enabling non-contact, high-precision modification of textile surfaces and embedded components without compromising the fabric's inherent properties such as flexibility, breathability, and comfort.

Current research indicates that ultrafast laser technology is approaching a critical inflection point where technical capabilities align with the manufacturing requirements of smart textiles. Fiber lasers with high beam quality, excellent stability, and industrial reliability are becoming more accessible, while advances in beam delivery systems and scanning technologies are improving processing speeds and precision.

The primary technical objectives for ultrafast laser applications in smart textile production include: developing selective ablation processes for creating conductive pathways on textile substrates; establishing parameters for functional surface modifications that enhance properties like hydrophobicity or antibacterial characteristics; optimizing laser-material interactions for embedding sensors within fabric structures; and creating scalable manufacturing protocols that can transition from laboratory demonstrations to industrial production.

Additionally, there is significant focus on reducing the cost and complexity of ultrafast laser systems to make them more accessible to the textile industry, which traditionally operates on thin margins. This includes the development of more robust, user-friendly systems that require less specialized knowledge to operate and maintain, as well as the creation of standardized processes that can be readily adopted by textile manufacturers.

In the context of smart textiles, ultrafast lasers represent a revolutionary manufacturing approach. These lasers operate with extremely short pulse durations (typically 10^-15 to 10^-12 seconds), enabling precise material processing with minimal heat-affected zones. This characteristic is particularly valuable for delicate textile substrates that cannot withstand conventional thermal processing methods. The technology allows for micromachining, surface modification, and functional patterning at scales previously unattainable in textile manufacturing.

The global trend toward wearable technology and functional fabrics has created a pressing need for advanced manufacturing techniques that can integrate electronic components, sensors, and actuators directly into textile structures. Ultrafast laser processing offers a solution to this integration challenge by enabling non-contact, high-precision modification of textile surfaces and embedded components without compromising the fabric's inherent properties such as flexibility, breathability, and comfort.

Current research indicates that ultrafast laser technology is approaching a critical inflection point where technical capabilities align with the manufacturing requirements of smart textiles. Fiber lasers with high beam quality, excellent stability, and industrial reliability are becoming more accessible, while advances in beam delivery systems and scanning technologies are improving processing speeds and precision.

The primary technical objectives for ultrafast laser applications in smart textile production include: developing selective ablation processes for creating conductive pathways on textile substrates; establishing parameters for functional surface modifications that enhance properties like hydrophobicity or antibacterial characteristics; optimizing laser-material interactions for embedding sensors within fabric structures; and creating scalable manufacturing protocols that can transition from laboratory demonstrations to industrial production.

Additionally, there is significant focus on reducing the cost and complexity of ultrafast laser systems to make them more accessible to the textile industry, which traditionally operates on thin margins. This includes the development of more robust, user-friendly systems that require less specialized knowledge to operate and maintain, as well as the creation of standardized processes that can be readily adopted by textile manufacturers.

Smart Textile Market Demand Analysis

The smart textile market is experiencing significant growth driven by increasing consumer demand for wearable technology with enhanced functionality. Current market analysis indicates that the global smart textile market is projected to reach $9.3 billion by 2024, growing at a CAGR of approximately 12% from 2019. This growth is primarily fueled by applications in healthcare monitoring, sports and fitness, military and defense, and fashion industries.

Consumer preferences are shifting toward textiles that offer multifunctionality while maintaining comfort and aesthetic appeal. The integration of ultrafast laser technology in smart textile production addresses this demand by enabling precise micro-processing of fabrics without compromising their inherent properties. Market research shows that consumers are willing to pay premium prices for smart textiles that seamlessly integrate technology while maintaining traditional textile characteristics.

Healthcare represents one of the largest market segments for smart textiles, with particular demand for remote patient monitoring solutions. Ultrafast laser-processed textiles can incorporate sensors for vital signs monitoring while maintaining breathability and comfort, critical factors for patient compliance. The aging population in developed countries further drives this demand, with the market for health-monitoring textiles expected to grow at 15% annually.

The sports and fitness sector demonstrates strong demand for performance-enhancing smart textiles. Athletes and fitness enthusiasts seek garments that can monitor physiological parameters while providing comfort during activity. Ultrafast laser technology enables the creation of breathable, lightweight fabrics with integrated sensing capabilities, meeting this specific market need.

Military and defense applications constitute another significant market segment, with requirements for protective clothing that incorporates communication systems, environmental sensors, and health monitoring capabilities. The precision of ultrafast laser processing allows for the integration of these technologies without compromising the protective qualities of the textiles.

Fashion and consumer electronics convergence represents an emerging market trend, with major apparel brands partnering with technology companies to develop everyday smart clothing. Consumer surveys indicate growing acceptance of technology-embedded clothing, particularly among younger demographics, with 68% of millennials expressing interest in smart textile products.

Regional analysis shows North America and Europe leading in smart textile adoption, while Asia-Pacific represents the fastest-growing market due to expanding manufacturing capabilities and increasing consumer purchasing power. The application of ultrafast lasers in production processes is particularly relevant in these regions where manufacturing innovation is prioritized to meet growing market demands.

Consumer preferences are shifting toward textiles that offer multifunctionality while maintaining comfort and aesthetic appeal. The integration of ultrafast laser technology in smart textile production addresses this demand by enabling precise micro-processing of fabrics without compromising their inherent properties. Market research shows that consumers are willing to pay premium prices for smart textiles that seamlessly integrate technology while maintaining traditional textile characteristics.

Healthcare represents one of the largest market segments for smart textiles, with particular demand for remote patient monitoring solutions. Ultrafast laser-processed textiles can incorporate sensors for vital signs monitoring while maintaining breathability and comfort, critical factors for patient compliance. The aging population in developed countries further drives this demand, with the market for health-monitoring textiles expected to grow at 15% annually.

The sports and fitness sector demonstrates strong demand for performance-enhancing smart textiles. Athletes and fitness enthusiasts seek garments that can monitor physiological parameters while providing comfort during activity. Ultrafast laser technology enables the creation of breathable, lightweight fabrics with integrated sensing capabilities, meeting this specific market need.

Military and defense applications constitute another significant market segment, with requirements for protective clothing that incorporates communication systems, environmental sensors, and health monitoring capabilities. The precision of ultrafast laser processing allows for the integration of these technologies without compromising the protective qualities of the textiles.

Fashion and consumer electronics convergence represents an emerging market trend, with major apparel brands partnering with technology companies to develop everyday smart clothing. Consumer surveys indicate growing acceptance of technology-embedded clothing, particularly among younger demographics, with 68% of millennials expressing interest in smart textile products.

Regional analysis shows North America and Europe leading in smart textile adoption, while Asia-Pacific represents the fastest-growing market due to expanding manufacturing capabilities and increasing consumer purchasing power. The application of ultrafast lasers in production processes is particularly relevant in these regions where manufacturing innovation is prioritized to meet growing market demands.

Current State and Challenges of Ultrafast Lasers in Textiles

Ultrafast lasers have emerged as a transformative technology in smart textile production, with significant advancements occurring globally over the past decade. Currently, the implementation of ultrafast lasers in textile manufacturing is concentrated primarily in developed economies, with research clusters in Europe, North America, and East Asia leading innovation. The technology has progressed from laboratory experimentation to limited industrial applications, though widespread adoption remains constrained by several factors.

The current state of ultrafast laser technology in textiles is characterized by precision micro-processing capabilities that enable functionalization without compromising fabric integrity. Femtosecond and picosecond lasers operating at pulse durations below 10 picoseconds have demonstrated superior performance in creating microscale patterns, surface modifications, and functional elements on delicate textile substrates. These systems can achieve feature sizes below 10 micrometers while minimizing the heat-affected zone to less than 5 micrometers, representing a significant advancement over conventional laser processing.

Despite these promising developments, several technical challenges impede broader implementation. Foremost among these is the high capital investment required for ultrafast laser systems, with industrial-grade equipment typically costing between $200,000 and $500,000, making the technology prohibitively expensive for many textile manufacturers. This economic barrier has limited adoption primarily to high-value technical textile applications rather than mainstream production.

Processing speed remains another significant limitation. Current ultrafast laser systems operate at relatively slow scanning speeds (typically 1-5 m/min) compared to conventional textile processing methods (20-100 m/min), creating a production bottleneck that hampers industrial scalability. The complex beam delivery systems and precise motion control requirements further complicate integration into existing high-throughput textile manufacturing lines.

Material compatibility presents additional challenges, as the interaction between ultrafast laser pulses and diverse textile substrates (natural fibers, synthetics, and blends) remains incompletely characterized. Research indicates significant variability in processing outcomes across different materials, necessitating extensive parameter optimization for each application. The lack of standardized processing parameters and quality control metrics further complicates industrial implementation.

Energy efficiency concerns also persist, with most systems demonstrating wall-plug efficiencies below 20%. This inefficiency contributes to higher operational costs and environmental impact, contradicting sustainability goals increasingly prioritized in modern textile manufacturing. Additionally, the complex maintenance requirements and limited service life of certain optical components increase the total cost of ownership.

Regulatory uncertainties regarding worker safety, environmental impact, and product safety standards for laser-processed textiles represent non-technical barriers to adoption. The absence of harmonized international standards specifically addressing ultrafast laser processing in textiles creates market hesitation and potential liability concerns for early adopters.

The current state of ultrafast laser technology in textiles is characterized by precision micro-processing capabilities that enable functionalization without compromising fabric integrity. Femtosecond and picosecond lasers operating at pulse durations below 10 picoseconds have demonstrated superior performance in creating microscale patterns, surface modifications, and functional elements on delicate textile substrates. These systems can achieve feature sizes below 10 micrometers while minimizing the heat-affected zone to less than 5 micrometers, representing a significant advancement over conventional laser processing.

Despite these promising developments, several technical challenges impede broader implementation. Foremost among these is the high capital investment required for ultrafast laser systems, with industrial-grade equipment typically costing between $200,000 and $500,000, making the technology prohibitively expensive for many textile manufacturers. This economic barrier has limited adoption primarily to high-value technical textile applications rather than mainstream production.

Processing speed remains another significant limitation. Current ultrafast laser systems operate at relatively slow scanning speeds (typically 1-5 m/min) compared to conventional textile processing methods (20-100 m/min), creating a production bottleneck that hampers industrial scalability. The complex beam delivery systems and precise motion control requirements further complicate integration into existing high-throughput textile manufacturing lines.

Material compatibility presents additional challenges, as the interaction between ultrafast laser pulses and diverse textile substrates (natural fibers, synthetics, and blends) remains incompletely characterized. Research indicates significant variability in processing outcomes across different materials, necessitating extensive parameter optimization for each application. The lack of standardized processing parameters and quality control metrics further complicates industrial implementation.

Energy efficiency concerns also persist, with most systems demonstrating wall-plug efficiencies below 20%. This inefficiency contributes to higher operational costs and environmental impact, contradicting sustainability goals increasingly prioritized in modern textile manufacturing. Additionally, the complex maintenance requirements and limited service life of certain optical components increase the total cost of ownership.

Regulatory uncertainties regarding worker safety, environmental impact, and product safety standards for laser-processed textiles represent non-technical barriers to adoption. The absence of harmonized international standards specifically addressing ultrafast laser processing in textiles creates market hesitation and potential liability concerns for early adopters.

Current Ultrafast Laser Integration Solutions for Smart Textiles

01 Ultrafast laser pulse generation and control

Ultrafast lasers generate extremely short pulses, typically in the femtosecond to picosecond range. These systems incorporate specialized components for pulse generation, amplification, and control. Key technologies include mode-locking mechanisms, dispersion compensation, and pulse shaping techniques that allow precise control over pulse duration, energy, and repetition rate. These capabilities enable applications requiring high temporal resolution and peak power.- Ultrafast laser pulse generation and control: Ultrafast lasers generate extremely short pulses, typically in the femtosecond to picosecond range. These systems employ various techniques for pulse generation, including mode-locking, Q-switching, and cavity dumping. Advanced control mechanisms allow for precise manipulation of pulse characteristics such as duration, repetition rate, and energy. These technologies enable applications requiring high temporal precision and peak power while maintaining beam quality and stability.

- Medical and surgical applications of ultrafast lasers: Ultrafast lasers offer significant advantages in medical procedures due to their minimal thermal effects on surrounding tissues. These lasers enable precise ablation and cutting with reduced collateral damage, making them ideal for delicate procedures in ophthalmology, dermatology, and neurosurgery. The non-linear absorption properties of ultrafast pulses allow for subsurface tissue modification without damaging intervening layers, enabling novel therapeutic approaches and improved surgical outcomes.

- Material processing with ultrafast lasers: Ultrafast lasers enable high-precision material processing with minimal heat-affected zones. The extremely short pulse duration allows for cold ablation processes where material is removed before heat can diffuse to surrounding areas. This capability is particularly valuable for processing heat-sensitive materials, creating micro and nano-scale features, and achieving clean cuts with reduced post-processing requirements. Applications include micromachining, surface texturing, and transparent material processing.

- Ultrafast laser systems and components: Advanced ultrafast laser systems incorporate specialized components to generate, amplify, and deliver femtosecond pulses. These systems typically include seed oscillators, pulse stretchers, amplifiers, and compressors arranged in chirped pulse amplification configurations. Key components include specialized optical fibers, dispersion management elements, saturable absorbers, and nonlinear crystals. Recent innovations focus on improving system reliability, reducing complexity, and enabling more compact designs suitable for industrial and field applications.

- Imaging and sensing applications of ultrafast lasers: Ultrafast lasers enable advanced imaging and sensing techniques with unprecedented temporal and spatial resolution. Applications include multiphoton microscopy, pump-probe spectroscopy, terahertz generation, and ultrafast spectroscopy. The short pulse duration allows for capturing dynamic processes occurring on femtosecond timescales, such as molecular vibrations and electronic transitions. These capabilities have revolutionized fields including biomedical imaging, materials characterization, and fundamental scientific research.

02 Material processing applications of ultrafast lasers

Ultrafast lasers enable precise material processing with minimal heat-affected zones due to their extremely short pulse durations. These lasers can perform micromachining, cutting, drilling, and surface modification on various materials including metals, semiconductors, ceramics, and polymers. The non-thermal ablation process allows for high-precision manufacturing of microstructures and nanostructures with applications in electronics, medical devices, and optical components.Expand Specific Solutions03 Medical and biological applications of ultrafast lasers

Ultrafast lasers have revolutionized medical procedures and biological imaging. Their precise energy delivery enables minimally invasive surgeries including ophthalmology procedures like LASIK, dermatological treatments, and neurosurgery. In imaging, they facilitate multiphoton microscopy and optical coherence tomography with unprecedented resolution. The ability to deliver energy in ultrashort pulses minimizes collateral tissue damage while allowing targeted treatment of specific structures.Expand Specific Solutions04 Ultrafast laser system architecture and components

Advanced ultrafast laser systems incorporate specialized optical components and architectures to generate, amplify, and deliver ultrashort pulses. These systems typically include seed oscillators, amplifiers, pulse stretchers and compressors, and beam delivery optics. Recent innovations focus on improving stability, reliability, and beam quality while reducing system complexity and size. Developments include integrated photonic components, novel gain media, and advanced cooling systems to enable higher average powers and repetition rates.Expand Specific Solutions05 Frequency conversion and spectral manipulation in ultrafast lasers

Ultrafast lasers can be used for frequency conversion and spectral manipulation through nonlinear optical processes. These techniques enable generation of wavelengths from ultraviolet to terahertz through processes like harmonic generation, optical parametric amplification, and supercontinuum generation. The broad spectral bandwidth of ultrafast pulses allows for applications in spectroscopy, frequency comb generation, and attosecond physics. Advanced phase matching techniques and specialized nonlinear crystals enhance conversion efficiency and spectral coverage.Expand Specific Solutions

Key Industry Players in Ultrafast Laser and Smart Textile Sectors

The ultrafast laser application in smart textile production is in an early growth phase, characterized by emerging technological innovations and expanding market opportunities. The global market is projected to grow significantly as industries recognize the potential for precision manufacturing, functional textiles, and sustainable production methods. Technologically, companies like Toptica Photonics SE and IPG Photonics are leading with advanced laser systems, while Coherent, Inc. and SEI SpA offer specialized textile applications. Traditional textile manufacturers including Levi Strauss & Co. and Arvind Ltd. are exploring integration possibilities. Academic institutions such as Donghua University, Zhejiang Sci-Tech University, and North Carolina State University are driving fundamental research, creating a dynamic ecosystem where commercial applications are developing alongside scientific advancements.

Toptica Photonics SE

Technical Solution: Toptica Photonics has pioneered frequency-comb-based ultrafast laser technology specifically for smart textile applications. Their FemtoFiber series delivers precisely controlled femtosecond pulses with exceptional timing stability (jitter <10fs), enabling unprecedented precision in textile surface modification. Toptica's systems feature proprietary pulse shaping technology that allows dynamic adjustment of laser parameters during processing, critical for treating textiles with varying compositions and structures. Their technology enables selective modification of specific fiber types within blended textiles through wavelength tuning (700-1500nm), creating multi-functional properties within a single fabric. Toptica has developed specialized scanning solutions that maintain consistent energy delivery across curved textile surfaces, addressing a key challenge in industrial implementation. Their systems also incorporate real-time spectroscopic monitoring that detects chemical changes during processing, ensuring precise functional modification.

Strengths: Exceptional pulse stability and reproducibility; wavelength tunability for selective material processing; compact design suitable for integration into existing production lines. Weaknesses: Lower average power compared to industrial fiber lasers; more sensitive to environmental conditions; higher cost per watt compared to competing technologies.

IPG Photonics Corp.

Technical Solution: IPG Photonics has developed advanced ultrafast fiber laser systems specifically optimized for smart textile production. Their technology utilizes picosecond and femtosecond pulse durations to enable precise material processing without thermal damage to delicate textile fibers. The company's proprietary YLPF series features pulse durations as short as 400 femtoseconds with average powers up to 50W, allowing for high-precision micro-machining of textile materials. Their systems incorporate beam delivery solutions that maintain beam quality across large processing areas, essential for industrial-scale textile production. IPG has also pioneered multi-beam processing techniques that significantly increase throughput while maintaining precision, enabling functional pattern creation on textiles at speeds compatible with modern manufacturing requirements.

Strengths: Industry-leading beam quality and stability; scalable power levels suitable for various textile applications; robust industrial design for 24/7 operation. Weaknesses: Higher initial investment compared to conventional laser systems; requires specialized knowledge for operation and maintenance; limited flexibility for rapid process changes.

Core Patents and Innovations in Ultrafast Laser Textile Processing

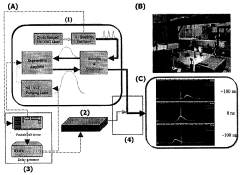

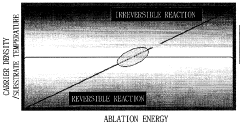

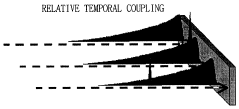

Laser processing method and processing apparatus based on conventional laser-induced material changes

PatentWO2007100176A1

Innovation

- A laser processing method and apparatus that combines an ultrafast laser with a nanosecond laser for temporal and spatial coupling, allowing reversible changes in material status by controlling the relative positions and focus of the laser pulses to increase processing speed and reduce surface roughness.

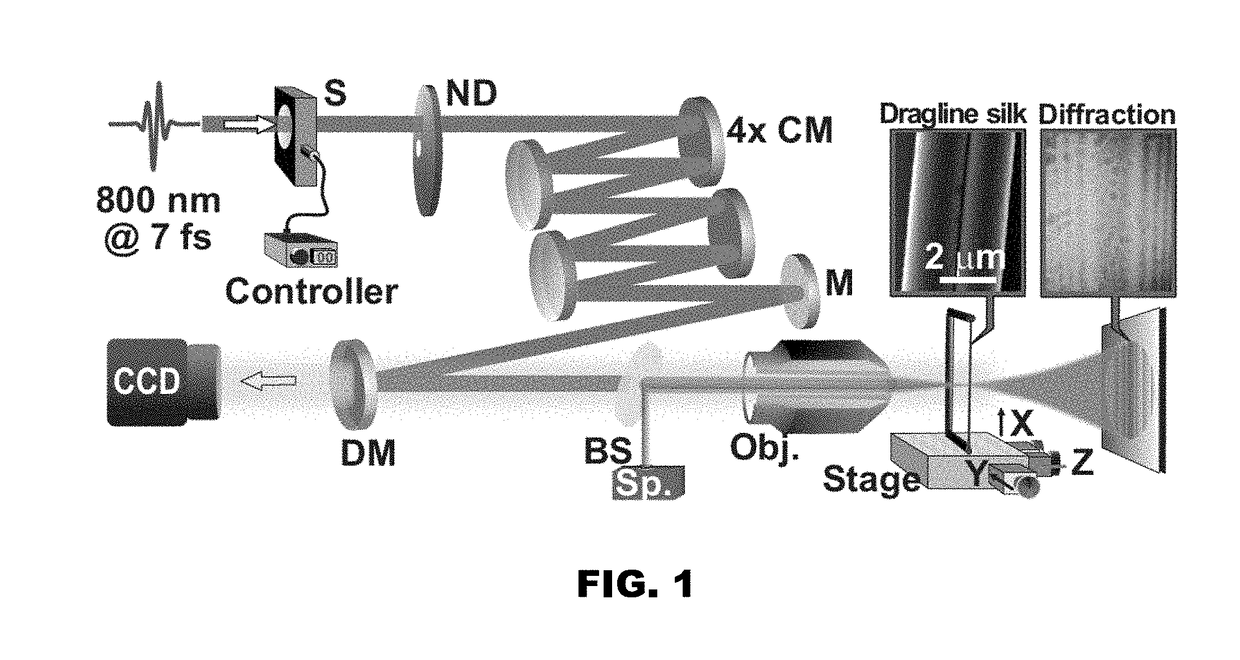

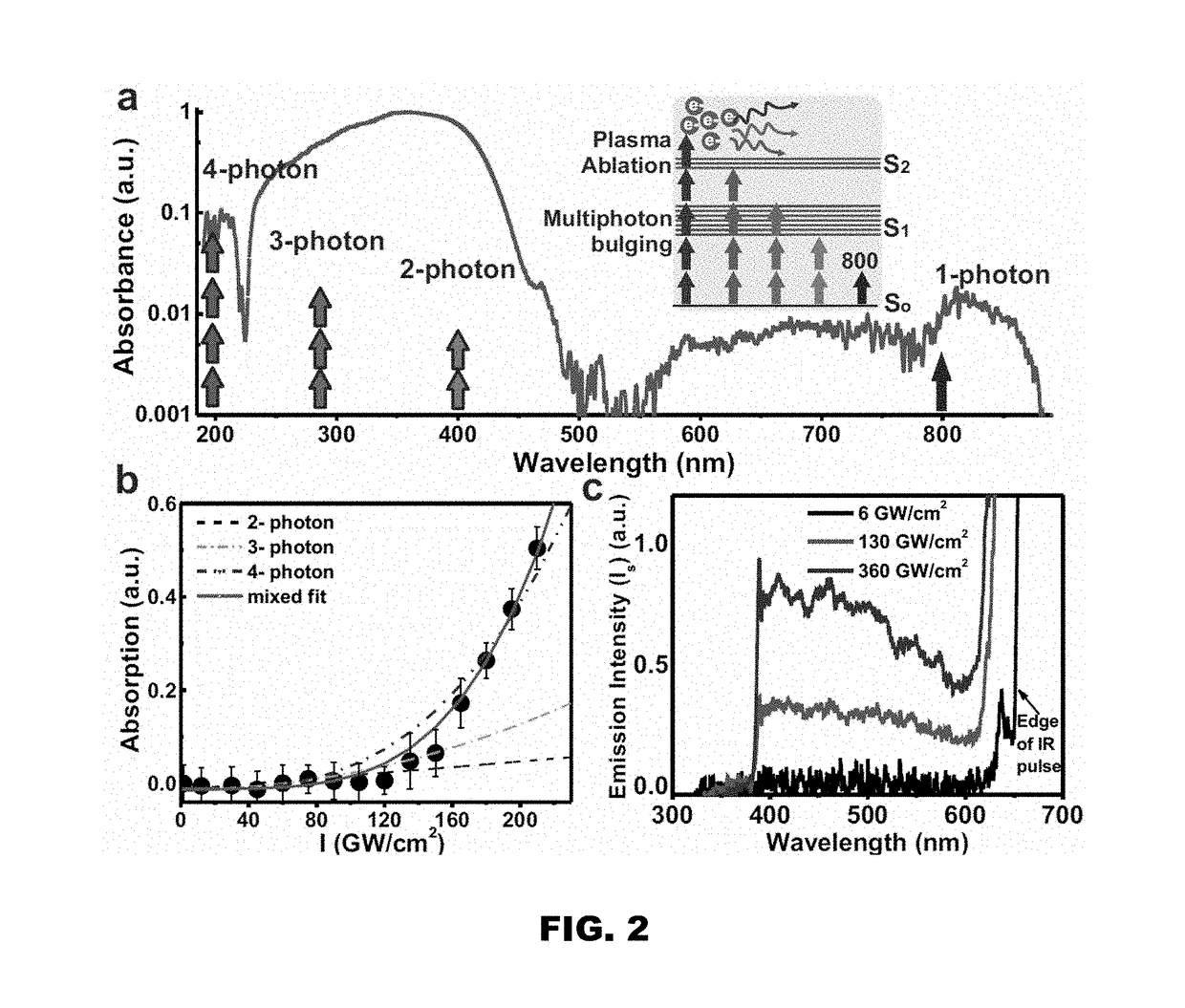

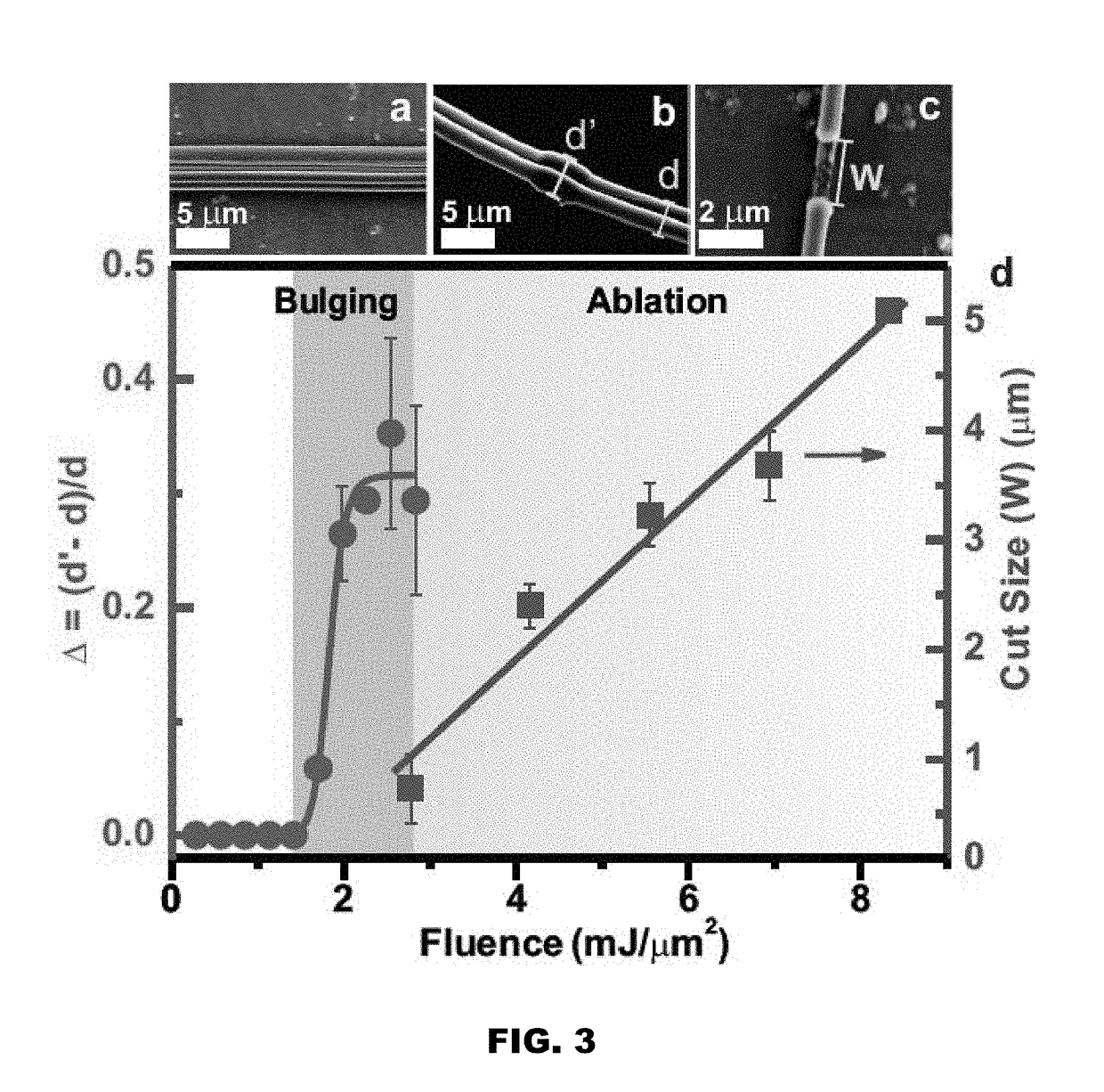

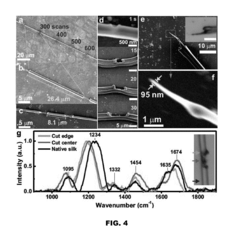

Nanoprocessing and heterostructuring of silk

PatentInactiveUS20180354066A1

Innovation

- The use of few-cycle femtosecond laser pulses for nanoprocessing and heterostructuring of spider silk, allowing for non-invasive localized nanoshaping and seamless welding with artificial and biological materials, such as Cu, glass, and synthetic polymers, while maintaining the silk's molecular structure and properties.

Environmental Impact and Sustainability Considerations

The integration of ultrafast laser technology in smart textile production presents significant environmental implications that warrant careful consideration. Traditional textile manufacturing processes are notorious for their substantial environmental footprint, including high water consumption, chemical pollution, and energy usage. Ultrafast laser processing offers a promising alternative that can substantially reduce these environmental impacts through precision manufacturing techniques that minimize waste and resource consumption.

Energy efficiency represents a key environmental advantage of ultrafast laser systems in textile production. Despite their high peak power, these lasers operate with remarkably low average power consumption compared to conventional textile processing methods. The precise nature of ultrafast laser pulses enables targeted material modification without generating excessive heat, thereby reducing overall energy requirements. Recent advancements have improved the wall-plug efficiency of these systems by approximately 30% over the past five years, further enhancing their sustainability profile.

Water conservation constitutes another critical environmental benefit. Conventional textile dyeing and finishing processes typically consume between 100-150 liters of water per kilogram of textile material. Ultrafast laser-based coloration and surface modification techniques can achieve similar aesthetic and functional results with virtually no water usage, potentially reducing the industry's water footprint by up to 90% when implemented at scale.

Chemical reduction represents a third significant environmental advantage. Laser-based processing can eliminate or substantially reduce the need for harsh chemicals commonly used in textile treatment. This transition not only decreases the environmental burden of chemical production and disposal but also improves workplace safety conditions. Studies indicate that laser-based textile processing can reduce chemical usage by 70-85% compared to conventional methods.

Waste minimization is achieved through the precision of ultrafast laser technology. The ability to create microscale and nanoscale modifications with extreme accuracy results in significantly less material waste. Additionally, the non-contact nature of laser processing extends textile lifespan by reducing physical wear during manufacturing, potentially increasing product durability by 15-25%.

Despite these benefits, several sustainability challenges remain. The production of ultrafast laser systems involves rare earth elements and specialized materials with their own environmental extraction and processing impacts. Additionally, the high-tech components require significant energy for manufacturing and may present end-of-life recycling challenges. A comprehensive life cycle assessment indicates that the environmental payback period for implementing ultrafast laser systems in textile production ranges from 2-4 years, depending on production volume and specific applications.

Energy efficiency represents a key environmental advantage of ultrafast laser systems in textile production. Despite their high peak power, these lasers operate with remarkably low average power consumption compared to conventional textile processing methods. The precise nature of ultrafast laser pulses enables targeted material modification without generating excessive heat, thereby reducing overall energy requirements. Recent advancements have improved the wall-plug efficiency of these systems by approximately 30% over the past five years, further enhancing their sustainability profile.

Water conservation constitutes another critical environmental benefit. Conventional textile dyeing and finishing processes typically consume between 100-150 liters of water per kilogram of textile material. Ultrafast laser-based coloration and surface modification techniques can achieve similar aesthetic and functional results with virtually no water usage, potentially reducing the industry's water footprint by up to 90% when implemented at scale.

Chemical reduction represents a third significant environmental advantage. Laser-based processing can eliminate or substantially reduce the need for harsh chemicals commonly used in textile treatment. This transition not only decreases the environmental burden of chemical production and disposal but also improves workplace safety conditions. Studies indicate that laser-based textile processing can reduce chemical usage by 70-85% compared to conventional methods.

Waste minimization is achieved through the precision of ultrafast laser technology. The ability to create microscale and nanoscale modifications with extreme accuracy results in significantly less material waste. Additionally, the non-contact nature of laser processing extends textile lifespan by reducing physical wear during manufacturing, potentially increasing product durability by 15-25%.

Despite these benefits, several sustainability challenges remain. The production of ultrafast laser systems involves rare earth elements and specialized materials with their own environmental extraction and processing impacts. Additionally, the high-tech components require significant energy for manufacturing and may present end-of-life recycling challenges. A comprehensive life cycle assessment indicates that the environmental payback period for implementing ultrafast laser systems in textile production ranges from 2-4 years, depending on production volume and specific applications.

Manufacturing Scalability and Cost Analysis

The current manufacturing landscape for ultrafast laser integration in smart textile production presents significant scalability challenges. Traditional textile manufacturing operates at high throughput rates, processing hundreds of meters per minute, while ultrafast laser systems typically function at much slower processing speeds. This fundamental mismatch creates a production bottleneck that must be addressed through innovative engineering solutions such as parallel processing systems, continuous-flow manufacturing adaptations, or the development of specialized high-speed scanning systems.

Cost analysis reveals that ultrafast laser systems represent a substantial capital investment, with industrial-grade femtosecond laser systems ranging from $200,000 to over $1 million depending on power specifications and precision requirements. This high initial investment creates a significant barrier to entry for smaller textile manufacturers and necessitates careful return-on-investment calculations based on production volume and value-added capabilities.

Operational expenses further impact the economic feasibility of ultrafast laser integration. These systems require specialized maintenance protocols, highly trained technical staff, and regular calibration procedures. Energy consumption, while improving with newer generations of lasers, remains considerably higher than conventional textile processing equipment, adding to the total cost of ownership.

The economic viability of ultrafast laser implementation varies significantly across different market segments. High-value technical textiles for medical, aerospace, and advanced wearable applications can justify the premium manufacturing costs through enhanced functionality and performance characteristics. Conversely, mass-market consumer textiles face more stringent price constraints, limiting the feasibility of widespread adoption without substantial cost reductions.

Recent technological developments suggest promising pathways toward improved manufacturing economics. Advancements in laser source technology have reduced system costs by approximately 15-20% over the past five years, while simultaneously improving energy efficiency. Multi-beam processing techniques and advanced beam steering mechanisms have demonstrated potential throughput improvements of 300-400% in laboratory settings, though commercial implementation remains limited.

Strategic partnerships between laser system manufacturers and textile equipment providers are emerging as a key approach to addressing scalability challenges. These collaborations focus on developing integrated production lines that optimize the interface between conventional textile processing and laser modification steps, potentially reducing implementation costs by 25-30% compared to retrofitted solutions.

Cost analysis reveals that ultrafast laser systems represent a substantial capital investment, with industrial-grade femtosecond laser systems ranging from $200,000 to over $1 million depending on power specifications and precision requirements. This high initial investment creates a significant barrier to entry for smaller textile manufacturers and necessitates careful return-on-investment calculations based on production volume and value-added capabilities.

Operational expenses further impact the economic feasibility of ultrafast laser integration. These systems require specialized maintenance protocols, highly trained technical staff, and regular calibration procedures. Energy consumption, while improving with newer generations of lasers, remains considerably higher than conventional textile processing equipment, adding to the total cost of ownership.

The economic viability of ultrafast laser implementation varies significantly across different market segments. High-value technical textiles for medical, aerospace, and advanced wearable applications can justify the premium manufacturing costs through enhanced functionality and performance characteristics. Conversely, mass-market consumer textiles face more stringent price constraints, limiting the feasibility of widespread adoption without substantial cost reductions.

Recent technological developments suggest promising pathways toward improved manufacturing economics. Advancements in laser source technology have reduced system costs by approximately 15-20% over the past five years, while simultaneously improving energy efficiency. Multi-beam processing techniques and advanced beam steering mechanisms have demonstrated potential throughput improvements of 300-400% in laboratory settings, though commercial implementation remains limited.

Strategic partnerships between laser system manufacturers and textile equipment providers are emerging as a key approach to addressing scalability challenges. These collaborations focus on developing integrated production lines that optimize the interface between conventional textile processing and laser modification steps, potentially reducing implementation costs by 25-30% compared to retrofitted solutions.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!