Ultrafast Laser Strategies in Creating High-Precision Optics.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Technology Evolution and Objectives

Ultrafast laser technology has undergone remarkable evolution since its inception in the 1960s with the development of mode-locked lasers. The initial systems, characterized by millisecond pulse durations, have progressively advanced to today's femtosecond and attosecond capabilities. This technological progression has been driven by breakthroughs in laser medium materials, cavity design, and pulse compression techniques, enabling unprecedented precision in materials processing applications.

The 1990s marked a pivotal era with the commercialization of titanium-sapphire lasers, which revolutionized ultrafast laser technology by offering reliable femtosecond pulses with high peak powers. Subsequently, the development of chirped pulse amplification, recognized by the 2018 Nobel Prize in Physics, overcame power limitations and enabled industrial-scale applications of ultrafast lasers in precision optics manufacturing.

Recent advancements have focused on enhancing beam quality, stability, and operational efficiency. Modern ultrafast laser systems incorporate sophisticated beam shaping technologies, adaptive optics, and real-time monitoring systems that maintain processing precision across varying environmental conditions. The integration of artificial intelligence for parameter optimization has further refined the capabilities of these systems in creating high-precision optical components.

The primary objective of ultrafast laser technology in precision optics manufacturing is to achieve sub-micron feature sizes with minimal heat-affected zones. This goal addresses the increasing demand for miniaturized optical components in telecommunications, medical devices, and quantum computing applications. Additionally, the technology aims to enable multi-material processing capabilities, allowing for the creation of complex optical structures with gradient properties.

Another critical objective is to enhance processing speed while maintaining precision, addressing the industrial need for high-throughput manufacturing of precision optics. This includes developing parallel processing techniques and optimizing scanning strategies to reduce production time without compromising quality. The technology also aims to minimize post-processing requirements, creating optical surfaces that meet specifications directly after laser processing.

Looking forward, the field is moving toward greater integration with complementary technologies such as additive manufacturing and nanoimprinting. The convergence of these approaches promises to expand the design space for optical components, enabling previously unattainable geometries and functionalities. Furthermore, sustainability objectives are gaining prominence, with efforts focused on reducing energy consumption and material waste in the manufacturing process.

The 1990s marked a pivotal era with the commercialization of titanium-sapphire lasers, which revolutionized ultrafast laser technology by offering reliable femtosecond pulses with high peak powers. Subsequently, the development of chirped pulse amplification, recognized by the 2018 Nobel Prize in Physics, overcame power limitations and enabled industrial-scale applications of ultrafast lasers in precision optics manufacturing.

Recent advancements have focused on enhancing beam quality, stability, and operational efficiency. Modern ultrafast laser systems incorporate sophisticated beam shaping technologies, adaptive optics, and real-time monitoring systems that maintain processing precision across varying environmental conditions. The integration of artificial intelligence for parameter optimization has further refined the capabilities of these systems in creating high-precision optical components.

The primary objective of ultrafast laser technology in precision optics manufacturing is to achieve sub-micron feature sizes with minimal heat-affected zones. This goal addresses the increasing demand for miniaturized optical components in telecommunications, medical devices, and quantum computing applications. Additionally, the technology aims to enable multi-material processing capabilities, allowing for the creation of complex optical structures with gradient properties.

Another critical objective is to enhance processing speed while maintaining precision, addressing the industrial need for high-throughput manufacturing of precision optics. This includes developing parallel processing techniques and optimizing scanning strategies to reduce production time without compromising quality. The technology also aims to minimize post-processing requirements, creating optical surfaces that meet specifications directly after laser processing.

Looking forward, the field is moving toward greater integration with complementary technologies such as additive manufacturing and nanoimprinting. The convergence of these approaches promises to expand the design space for optical components, enabling previously unattainable geometries and functionalities. Furthermore, sustainability objectives are gaining prominence, with efforts focused on reducing energy consumption and material waste in the manufacturing process.

Market Demand for High-Precision Optical Components

The high-precision optical components market is experiencing robust growth driven by increasing demand across multiple industries. The global market for precision optics was valued at approximately $13.5 billion in 2022 and is projected to reach $28.7 billion by 2030, growing at a CAGR of 9.8% during the forecast period. This growth trajectory is primarily fueled by advancements in technologies requiring superior optical performance.

Semiconductor manufacturing represents one of the largest demand segments, with extreme ultraviolet (EUV) lithography systems requiring optical components with surface accuracy in the sub-nanometer range. As chip manufacturers continue to pursue smaller node sizes, the need for ultra-precise optical elements has become critical to industry advancement. The semiconductor equipment market alone is expected to consume over 35% of high-precision optics production.

The medical and life sciences sector presents another significant market driver, with surgical microscopes, endoscopes, and diagnostic imaging systems requiring increasingly sophisticated optical components. Minimally invasive surgical procedures and advanced diagnostic techniques have created demand for optics with exceptional clarity, precision, and durability. Market analysis indicates this sector will grow at 11.2% annually through 2028.

Aerospace and defense applications constitute a premium segment of the market, where high-precision optical components are essential for satellite imaging systems, targeting equipment, and reconnaissance technologies. These applications demand optics that can withstand extreme environmental conditions while maintaining nanometer-level precision. Government spending in this sector remains strong, with defense budgets allocating increasing portions to optical technologies.

Consumer electronics represents an expanding market segment, particularly with the rise of augmented reality (AR) and virtual reality (VR) devices. These applications require compact, lightweight optical components with exceptional performance characteristics. Industry forecasts suggest the AR/VR market will consume precision optics worth $3.2 billion annually by 2025.

Industrial laser processing systems represent another significant market segment, with manufacturing industries adopting high-power laser systems for cutting, welding, and surface modification. These applications require beam-shaping optics and focusing elements with exceptional thermal stability and damage resistance.

Market research indicates that customers across all segments are increasingly prioritizing optical components with longer lifespans, higher damage thresholds, and reduced maintenance requirements. This trend aligns perfectly with the capabilities of ultrafast laser processing, which can produce optical surfaces with superior mechanical and thermal properties compared to conventional manufacturing methods.

Semiconductor manufacturing represents one of the largest demand segments, with extreme ultraviolet (EUV) lithography systems requiring optical components with surface accuracy in the sub-nanometer range. As chip manufacturers continue to pursue smaller node sizes, the need for ultra-precise optical elements has become critical to industry advancement. The semiconductor equipment market alone is expected to consume over 35% of high-precision optics production.

The medical and life sciences sector presents another significant market driver, with surgical microscopes, endoscopes, and diagnostic imaging systems requiring increasingly sophisticated optical components. Minimally invasive surgical procedures and advanced diagnostic techniques have created demand for optics with exceptional clarity, precision, and durability. Market analysis indicates this sector will grow at 11.2% annually through 2028.

Aerospace and defense applications constitute a premium segment of the market, where high-precision optical components are essential for satellite imaging systems, targeting equipment, and reconnaissance technologies. These applications demand optics that can withstand extreme environmental conditions while maintaining nanometer-level precision. Government spending in this sector remains strong, with defense budgets allocating increasing portions to optical technologies.

Consumer electronics represents an expanding market segment, particularly with the rise of augmented reality (AR) and virtual reality (VR) devices. These applications require compact, lightweight optical components with exceptional performance characteristics. Industry forecasts suggest the AR/VR market will consume precision optics worth $3.2 billion annually by 2025.

Industrial laser processing systems represent another significant market segment, with manufacturing industries adopting high-power laser systems for cutting, welding, and surface modification. These applications require beam-shaping optics and focusing elements with exceptional thermal stability and damage resistance.

Market research indicates that customers across all segments are increasingly prioritizing optical components with longer lifespans, higher damage thresholds, and reduced maintenance requirements. This trend aligns perfectly with the capabilities of ultrafast laser processing, which can produce optical surfaces with superior mechanical and thermal properties compared to conventional manufacturing methods.

Current Capabilities and Barriers in Ultrafast Laser Processing

Ultrafast laser processing has revolutionized high-precision optics manufacturing, offering unprecedented capabilities in material modification at micro and nano scales. Current femtosecond and picosecond laser systems can achieve pulse durations below 10 femtoseconds and repetition rates exceeding 1 MHz, enabling precise ablation with minimal heat-affected zones. This technology excels in creating complex 3D microstructures with feature sizes down to 100 nanometers, significantly outperforming conventional machining methods.

The processing speed has improved dramatically, with modern systems capable of scanning speeds up to 10 m/s, allowing for efficient production of microoptical components. Surface roughness values below 10 nm Ra can be achieved through optimized parameters, meeting the stringent requirements of high-performance optical applications. Additionally, ultrafast lasers demonstrate exceptional versatility across various optical materials including fused silica, sapphire, and specialized optical glasses.

Despite these advancements, several significant barriers limit wider industrial adoption. Throughput remains a critical challenge, as the fundamental physics of ultrafast laser-material interaction creates a trade-off between processing quality and speed. The high equipment costs, typically ranging from $250,000 to over $1 million for industrial-grade systems, present a substantial barrier to entry for many manufacturers.

Thermal management during high-repetition-rate processing creates complications in maintaining precision, particularly when working with thermally sensitive optical materials. The heat accumulation effect can lead to undesired material modifications beyond the intended processing zone. Process reliability and reproducibility also remain challenging, with environmental factors and beam stability affecting consistency across production batches.

Parameter optimization presents another significant hurdle, as the complex interplay between pulse energy, repetition rate, scanning speed, and material properties requires extensive experimentation. This often results in time-consuming development cycles before production can begin. The lack of standardized processing protocols across different material systems further complicates implementation.

Energy efficiency concerns persist, with most ultrafast laser systems operating at electrical-to-optical conversion efficiencies below 30%. This inefficiency contributes to higher operational costs and environmental impact. Additionally, the specialized knowledge required for system operation and maintenance creates workforce challenges, as the technology demands highly trained personnel with interdisciplinary expertise in optics, materials science, and precision engineering.

The processing speed has improved dramatically, with modern systems capable of scanning speeds up to 10 m/s, allowing for efficient production of microoptical components. Surface roughness values below 10 nm Ra can be achieved through optimized parameters, meeting the stringent requirements of high-performance optical applications. Additionally, ultrafast lasers demonstrate exceptional versatility across various optical materials including fused silica, sapphire, and specialized optical glasses.

Despite these advancements, several significant barriers limit wider industrial adoption. Throughput remains a critical challenge, as the fundamental physics of ultrafast laser-material interaction creates a trade-off between processing quality and speed. The high equipment costs, typically ranging from $250,000 to over $1 million for industrial-grade systems, present a substantial barrier to entry for many manufacturers.

Thermal management during high-repetition-rate processing creates complications in maintaining precision, particularly when working with thermally sensitive optical materials. The heat accumulation effect can lead to undesired material modifications beyond the intended processing zone. Process reliability and reproducibility also remain challenging, with environmental factors and beam stability affecting consistency across production batches.

Parameter optimization presents another significant hurdle, as the complex interplay between pulse energy, repetition rate, scanning speed, and material properties requires extensive experimentation. This often results in time-consuming development cycles before production can begin. The lack of standardized processing protocols across different material systems further complicates implementation.

Energy efficiency concerns persist, with most ultrafast laser systems operating at electrical-to-optical conversion efficiencies below 30%. This inefficiency contributes to higher operational costs and environmental impact. Additionally, the specialized knowledge required for system operation and maintenance creates workforce challenges, as the technology demands highly trained personnel with interdisciplinary expertise in optics, materials science, and precision engineering.

Contemporary Ultrafast Laser Fabrication Methodologies

01 Ultrafast laser systems for high-precision material processing

Ultrafast laser systems utilize femtosecond or picosecond pulses to achieve high-precision material processing. These systems can perform micromachining, cutting, and ablation with minimal heat-affected zones. The ultrashort pulses allow for cold ablation processes where material is removed before heat can diffuse to surrounding areas, resulting in extremely precise features with clean edges and minimal collateral damage.- Ultrafast laser micromachining and material processing: Ultrafast lasers enable high-precision micromachining and material processing with minimal thermal effects. These systems use femtosecond or picosecond pulses to remove material through ablation rather than melting, resulting in cleaner cuts, higher precision, and reduced heat-affected zones. This technology is particularly valuable for processing sensitive materials and creating microstructures with sub-micron precision.

- Pulse control and beam shaping technologies: Advanced pulse control and beam shaping technologies enhance the precision of ultrafast laser systems. These include techniques for controlling pulse duration, repetition rate, and energy distribution across the beam profile. Spatial light modulators, acousto-optic modulators, and other beam shaping devices allow for customized energy distribution, enabling more precise material interaction and improved processing outcomes.

- Ultrafast laser systems for medical applications: High-precision ultrafast lasers are increasingly used in medical procedures where precision is critical. These systems enable minimally invasive surgeries, ophthalmological procedures, and dermatological treatments with reduced collateral damage to surrounding tissues. The ultrashort pulses allow for precise tissue ablation without thermal damage, improving patient outcomes and recovery times.

- Multi-axis positioning and scanning systems: High-precision ultrafast laser applications rely on advanced positioning and scanning systems. These include multi-axis galvanometer scanners, piezoelectric stages, and hybrid positioning systems that combine different motion technologies. Such systems enable precise beam positioning with nanometer-level accuracy, allowing for complex 3D structures to be fabricated with high repeatability and throughput.

- Monitoring and feedback control systems: Real-time monitoring and feedback control systems are essential for maintaining high precision in ultrafast laser processing. These systems incorporate sensors that detect process parameters such as beam quality, focus position, and material response. The feedback mechanisms automatically adjust laser parameters to compensate for variations, ensuring consistent processing quality even under changing conditions or when processing heterogeneous materials.

02 Pulse control techniques for enhanced precision

Advanced pulse control techniques are employed to enhance the precision of ultrafast laser processing. These include chirped pulse amplification, pulse shaping, and temporal control methods that optimize the interaction between laser pulses and target materials. By precisely controlling pulse duration, energy, and repetition rate, these techniques enable processing at sub-micron scales with high repeatability and quality.Expand Specific Solutions03 Beam delivery and focusing systems for high-precision applications

Specialized beam delivery and focusing systems are crucial for achieving high-precision with ultrafast lasers. These systems incorporate advanced optics, scanners, and positioning mechanisms to direct and focus the laser beam with nanometer-level accuracy. Adaptive optics, beam shaping elements, and precision motion control systems work together to maintain beam quality and positioning precision throughout the processing area.Expand Specific Solutions04 Medical and biological applications of ultrafast lasers

Ultrafast lasers enable high-precision interventions in medical and biological applications. The ability to deliver energy in ultrashort pulses allows for precise tissue ablation, microsurgery, and cellular manipulation without thermal damage to surrounding tissues. These capabilities are particularly valuable in ophthalmology, neurosurgery, dermatology, and cellular research where precision is paramount.Expand Specific Solutions05 Industrial manufacturing and microfabrication techniques

Ultrafast laser technology has revolutionized industrial manufacturing and microfabrication processes. These lasers enable the creation of microfluidic channels, waveguides, microelectronic components, and precision mechanical parts with features at the micro and nano scales. The high-precision capabilities allow for complex 3D structures to be fabricated directly from various materials including metals, semiconductors, ceramics, and polymers without the need for masks or chemical etching.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Ultrafast Lasers

The ultrafast laser market for high-precision optics is currently in a growth phase, with increasing adoption across microelectronics, medical, and industrial applications. Market size is expanding rapidly, projected to reach several billion dollars by 2025, driven by demand for higher precision manufacturing capabilities. Technologically, companies demonstrate varying maturity levels: established leaders like Coherent, Corning, and Electro Scientific Industries offer commercial systems with proven reliability, while emerging players such as Applied Energetics and Cyber Laser focus on specialized applications. Academic institutions including University of Michigan, Chinese University of Hong Kong, and Shanghai Institute of Optics & Fine Mechanics are advancing fundamental research. The competitive landscape features traditional optics manufacturers expanding into ultrafast technologies alongside specialized laser companies developing proprietary solutions for next-generation precision optics manufacturing.

Electro Scientific Industries, Inc.

Technical Solution: ESI has developed a comprehensive ultrafast laser platform specifically for high-precision optics manufacturing. Their technology centers on picosecond and femtosecond laser systems with pulse durations ranging from 500fs to 10ps, optimized for different optical materials. ESI's approach incorporates proprietary beam delivery systems featuring advanced galvanometer scanners capable of positioning accuracy better than ±1μm across the entire work area. Their systems utilize sophisticated pulse shaping technology that can dynamically adjust pulse characteristics during processing, enabling optimal material interaction for different zones of complex optical components. ESI has pioneered multi-wavelength processing capabilities, allowing simultaneous or sequential processing with fundamental, second, and third harmonic wavelengths to optimize ablation characteristics for different material layers[2]. Their systems also feature real-time optical coherence tomography monitoring that provides in-process feedback for quality control, achieving dimensional tolerances within 0.1μm for critical optical surfaces. ESI's technology includes specialized algorithms for controlling laser-induced periodic surface structures (LIPSS) to create functional optical surfaces with controlled diffraction properties[4].

Strengths: Exceptional positioning accuracy with proprietary high-precision galvanometer technology; versatile multi-wavelength processing capabilities; advanced in-process monitoring systems enabling closed-loop quality control. Weaknesses: Systems require frequent calibration to maintain highest precision levels; limited effectiveness for certain exotic optical materials; higher operating costs compared to conventional laser processing.

Corning Research & Development Corp.

Technical Solution: Corning has developed proprietary ultrafast laser technology specifically optimized for processing specialty glass and ceramic materials used in high-precision optics. Their approach utilizes femtosecond laser systems with pulse durations below 300fs, combined with sophisticated beam shaping optics that create non-Gaussian beam profiles optimized for specific material interactions. Corning's technology incorporates advanced process monitoring using spectroscopic analysis of the laser-induced plasma, providing real-time feedback on material modification quality. Their systems feature proprietary multi-pass writing strategies that can create three-dimensional optical structures within the bulk of transparent materials with index of refraction modifications precise to 10^-4. Corning has developed specialized techniques for creating waveguides in glass with propagation losses below 0.1dB/cm, enabling the fabrication of integrated photonic circuits directly within optical substrates[5]. Their technology also includes advanced algorithms for compensating material-specific nonlinear effects during deep processing, maintaining consistent feature quality regardless of processing depth. Additionally, Corning has pioneered selective etching techniques that combine ultrafast laser modification with subsequent chemical processing to create complex microfluidic and micro-optical structures with aspect ratios exceeding 100:1[6].

Strengths: Unparalleled expertise in processing specialty glass materials; proprietary beam shaping technology enables unique material modifications; integrated process monitoring systems ensure consistent quality. Weaknesses: Technology optimized primarily for Corning's own material portfolio; systems require specialized knowledge of material-specific processing parameters; higher complexity in operation compared to conventional laser systems.

Breakthrough Patents in Femtosecond Laser Optics Processing

Laser-assisted additive manufacture of optics using thermally curable materials

PatentInactiveUS20200030879A1

Innovation

- The use of ultrafast infrared (IR) lasers and pulse IR radiation to locally solidify thermally-curable optical materials like optical silicones, combined with in situ metrology for real-time feedback and precise control of the printing process, allowing for the fabrication of freeform optics with high accuracy and surface quality.

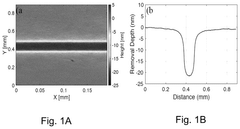

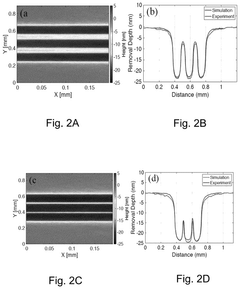

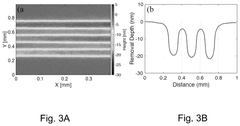

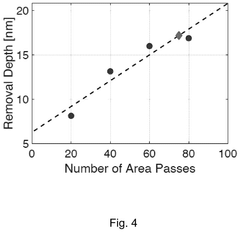

Ultrafast-laser-based figuring and mid-spatial frequency error correction

PatentPendingUS20250242443A1

Innovation

- Utilizing ultrafast lasers for non-contact material removal, measuring and quantifying MSF errors, and removing material with nanometer precision to correct these errors by generating and overlapping grooves according to a predicted pattern, achieving single-digit-nanometer surface roughness.

Material Science Considerations for Advanced Optical Fabrication

The selection of appropriate materials for ultrafast laser processing is critical to achieving high-precision optical components. Different materials respond uniquely to ultrafast laser pulses, with varying ablation thresholds, thermal conductivity, and optical properties that significantly impact the final quality of fabricated optics.

Glass materials, particularly fused silica and borosilicate glasses, remain dominant in high-precision optics due to their excellent optical transparency, thermal stability, and chemical resistance. When processed with ultrafast lasers, these materials exhibit minimal heat-affected zones, allowing for sub-micron feature creation without compromising structural integrity.

Crystalline materials such as sapphire, calcium fluoride, and silicon present different challenges in ultrafast laser processing. Their ordered atomic structure results in anisotropic properties that must be considered during fabrication. Recent advances in pulse shaping techniques have enabled more controlled material removal in crystalline substrates, expanding the range of achievable optical designs.

Polymer-based optical materials have gained attention for their flexibility and cost-effectiveness. PMMA, polycarbonate, and optical-grade epoxies respond well to ultrafast laser processing, though they typically require lower pulse energies to prevent thermal damage. The precision achievable in polymers has improved significantly with the development of specialized laser parameters that account for their lower damage thresholds.

Composite and hybrid materials represent an emerging frontier in optical fabrication. Glass-ceramic composites, for instance, combine the processability of glass with enhanced mechanical properties. Ultrafast lasers can selectively modify specific phases within these materials, creating gradient-index structures impossible to achieve through conventional methods.

Surface coating materials also play a crucial role in advanced optics. Anti-reflective coatings, high-reflectivity metals, and dielectric multilayers can be precisely patterned using ultrafast lasers without damaging underlying substrates. This capability enables the creation of diffractive optical elements and metasurfaces with unprecedented performance characteristics.

Material response to ultrafast laser pulses is heavily influenced by wavelength selection. While near-infrared wavelengths (800-1064nm) remain standard, frequency-doubled and tripled beams offer advantages for certain materials due to higher photon energies and improved absorption characteristics. The material-wavelength relationship must be carefully optimized for each application to achieve desired feature resolution and surface quality.

Glass materials, particularly fused silica and borosilicate glasses, remain dominant in high-precision optics due to their excellent optical transparency, thermal stability, and chemical resistance. When processed with ultrafast lasers, these materials exhibit minimal heat-affected zones, allowing for sub-micron feature creation without compromising structural integrity.

Crystalline materials such as sapphire, calcium fluoride, and silicon present different challenges in ultrafast laser processing. Their ordered atomic structure results in anisotropic properties that must be considered during fabrication. Recent advances in pulse shaping techniques have enabled more controlled material removal in crystalline substrates, expanding the range of achievable optical designs.

Polymer-based optical materials have gained attention for their flexibility and cost-effectiveness. PMMA, polycarbonate, and optical-grade epoxies respond well to ultrafast laser processing, though they typically require lower pulse energies to prevent thermal damage. The precision achievable in polymers has improved significantly with the development of specialized laser parameters that account for their lower damage thresholds.

Composite and hybrid materials represent an emerging frontier in optical fabrication. Glass-ceramic composites, for instance, combine the processability of glass with enhanced mechanical properties. Ultrafast lasers can selectively modify specific phases within these materials, creating gradient-index structures impossible to achieve through conventional methods.

Surface coating materials also play a crucial role in advanced optics. Anti-reflective coatings, high-reflectivity metals, and dielectric multilayers can be precisely patterned using ultrafast lasers without damaging underlying substrates. This capability enables the creation of diffractive optical elements and metasurfaces with unprecedented performance characteristics.

Material response to ultrafast laser pulses is heavily influenced by wavelength selection. While near-infrared wavelengths (800-1064nm) remain standard, frequency-doubled and tripled beams offer advantages for certain materials due to higher photon energies and improved absorption characteristics. The material-wavelength relationship must be carefully optimized for each application to achieve desired feature resolution and surface quality.

Industrial Integration and Automation of Ultrafast Laser Systems

The integration of ultrafast laser systems into industrial manufacturing processes represents a significant advancement in precision optics production. Current industrial implementations focus on automating the entire workflow, from material handling to quality control, creating seamless production lines that maximize efficiency while maintaining exceptional precision standards.

Leading manufacturers have developed sophisticated robotic systems specifically designed to work in conjunction with ultrafast laser platforms. These systems handle delicate optical components throughout the fabrication process, eliminating human error and reducing contamination risks in cleanroom environments. Advanced motion control systems with nanometer-level precision ensure perfect alignment between the workpiece and laser beam, critical for high-precision optics manufacturing.

Real-time monitoring systems have become standard in industrial ultrafast laser setups, utilizing high-speed cameras and spectroscopic sensors to analyze the laser-material interaction during processing. This data feeds into closed-loop control systems that can make instantaneous adjustments to laser parameters, ensuring consistent quality across production batches. Machine learning algorithms increasingly enhance these systems by predicting optimal processing parameters based on material characteristics and desired specifications.

Industry 4.0 principles are being widely implemented in ultrafast laser manufacturing facilities. Digital twins of production systems allow for virtual testing and optimization before physical implementation. Cloud-based platforms collect and analyze production data across multiple facilities, identifying opportunities for process improvement and predictive maintenance. These interconnected systems significantly reduce downtime and increase overall equipment effectiveness.

Standardization efforts across the industry are establishing common interfaces and protocols for ultrafast laser systems, enabling easier integration with existing manufacturing infrastructure. This trend is particularly evident in the semiconductor and medical device industries, where ultrafast lasers are becoming integral components of larger production ecosystems rather than standalone tools.

Energy efficiency improvements represent another key development in industrial integration. New system designs incorporate energy recovery mechanisms and optimized beam delivery systems that reduce power consumption while maintaining processing capabilities. This addresses both environmental concerns and operational cost considerations for manufacturers implementing these technologies at scale.

Human-machine interfaces have evolved to become more intuitive, allowing technicians with limited laser physics knowledge to operate complex ultrafast laser systems effectively. Augmented reality interfaces provide visual guidance for setup and maintenance procedures, reducing training requirements and minimizing the risk of operator error in production environments.

Leading manufacturers have developed sophisticated robotic systems specifically designed to work in conjunction with ultrafast laser platforms. These systems handle delicate optical components throughout the fabrication process, eliminating human error and reducing contamination risks in cleanroom environments. Advanced motion control systems with nanometer-level precision ensure perfect alignment between the workpiece and laser beam, critical for high-precision optics manufacturing.

Real-time monitoring systems have become standard in industrial ultrafast laser setups, utilizing high-speed cameras and spectroscopic sensors to analyze the laser-material interaction during processing. This data feeds into closed-loop control systems that can make instantaneous adjustments to laser parameters, ensuring consistent quality across production batches. Machine learning algorithms increasingly enhance these systems by predicting optimal processing parameters based on material characteristics and desired specifications.

Industry 4.0 principles are being widely implemented in ultrafast laser manufacturing facilities. Digital twins of production systems allow for virtual testing and optimization before physical implementation. Cloud-based platforms collect and analyze production data across multiple facilities, identifying opportunities for process improvement and predictive maintenance. These interconnected systems significantly reduce downtime and increase overall equipment effectiveness.

Standardization efforts across the industry are establishing common interfaces and protocols for ultrafast laser systems, enabling easier integration with existing manufacturing infrastructure. This trend is particularly evident in the semiconductor and medical device industries, where ultrafast lasers are becoming integral components of larger production ecosystems rather than standalone tools.

Energy efficiency improvements represent another key development in industrial integration. New system designs incorporate energy recovery mechanisms and optimized beam delivery systems that reduce power consumption while maintaining processing capabilities. This addresses both environmental concerns and operational cost considerations for manufacturers implementing these technologies at scale.

Human-machine interfaces have evolved to become more intuitive, allowing technicians with limited laser physics knowledge to operate complex ultrafast laser systems effectively. Augmented reality interfaces provide visual guidance for setup and maintenance procedures, reducing training requirements and minimizing the risk of operator error in production environments.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!