Examining Ultrafast Lasers in Carbon Fiber Reinforcement Processes.

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Technology Evolution and Objectives

Ultrafast laser technology has evolved significantly over the past three decades, transforming from laboratory curiosities to essential industrial tools. The journey began in the 1980s with the development of the first femtosecond lasers, which initially found applications primarily in scientific research. By the late 1990s, these systems had become more reliable and compact, enabling their gradual transition into industrial settings. The early 2000s marked a pivotal moment with the commercialization of industrial-grade ultrafast laser systems, featuring increased power outputs and improved beam quality.

The evolution of ultrafast lasers for carbon fiber reinforcement processes specifically gained momentum around 2010, when researchers began exploring alternatives to conventional thermal processing methods. Traditional carbon fiber manufacturing and processing techniques often introduced thermal damage and structural weaknesses, limiting the material's performance potential. Ultrafast lasers offered a revolutionary approach by delivering energy in extremely short pulses, minimizing heat-affected zones and enabling precise material modification at the microscopic level.

Recent technological advancements have focused on increasing average power while maintaining ultrashort pulse durations, with modern systems capable of delivering kilowatt-level average powers with pulse durations in the femtosecond to picosecond range. This has dramatically improved processing speeds, making ultrafast laser technology increasingly viable for large-scale carbon fiber manufacturing applications. Parallel developments in beam delivery systems, scanning technologies, and process monitoring capabilities have further enhanced the precision and reliability of these systems.

The primary objective of ultrafast laser technology in carbon fiber reinforcement processes is to enhance the mechanical properties and performance characteristics of carbon fiber composites without compromising their structural integrity. Specific goals include improving fiber-matrix interfacial bonding, creating controlled surface modifications to enhance adhesion properties, and developing novel joining techniques for carbon fiber components. Additionally, researchers aim to optimize laser parameters for different types of carbon fiber materials and composite structures.

Looking forward, the technology roadmap focuses on several key objectives: developing more energy-efficient ultrafast laser systems with higher wall-plug efficiency, creating more robust and maintenance-free industrial systems suitable for 24/7 manufacturing environments, and integrating advanced process monitoring and control capabilities through machine learning algorithms. There is also significant interest in scaling the technology for larger processing areas while maintaining precision, which would enable more widespread adoption in automotive, aerospace, and renewable energy sectors.

The ultimate goal is to establish ultrafast laser processing as a standard manufacturing technology for next-generation carbon fiber composites, enabling lighter, stronger, and more durable materials that can meet the increasing performance demands of various high-tech industries.

The evolution of ultrafast lasers for carbon fiber reinforcement processes specifically gained momentum around 2010, when researchers began exploring alternatives to conventional thermal processing methods. Traditional carbon fiber manufacturing and processing techniques often introduced thermal damage and structural weaknesses, limiting the material's performance potential. Ultrafast lasers offered a revolutionary approach by delivering energy in extremely short pulses, minimizing heat-affected zones and enabling precise material modification at the microscopic level.

Recent technological advancements have focused on increasing average power while maintaining ultrashort pulse durations, with modern systems capable of delivering kilowatt-level average powers with pulse durations in the femtosecond to picosecond range. This has dramatically improved processing speeds, making ultrafast laser technology increasingly viable for large-scale carbon fiber manufacturing applications. Parallel developments in beam delivery systems, scanning technologies, and process monitoring capabilities have further enhanced the precision and reliability of these systems.

The primary objective of ultrafast laser technology in carbon fiber reinforcement processes is to enhance the mechanical properties and performance characteristics of carbon fiber composites without compromising their structural integrity. Specific goals include improving fiber-matrix interfacial bonding, creating controlled surface modifications to enhance adhesion properties, and developing novel joining techniques for carbon fiber components. Additionally, researchers aim to optimize laser parameters for different types of carbon fiber materials and composite structures.

Looking forward, the technology roadmap focuses on several key objectives: developing more energy-efficient ultrafast laser systems with higher wall-plug efficiency, creating more robust and maintenance-free industrial systems suitable for 24/7 manufacturing environments, and integrating advanced process monitoring and control capabilities through machine learning algorithms. There is also significant interest in scaling the technology for larger processing areas while maintaining precision, which would enable more widespread adoption in automotive, aerospace, and renewable energy sectors.

The ultimate goal is to establish ultrafast laser processing as a standard manufacturing technology for next-generation carbon fiber composites, enabling lighter, stronger, and more durable materials that can meet the increasing performance demands of various high-tech industries.

Market Analysis for Laser-Based Carbon Fiber Manufacturing

The global market for laser-based carbon fiber manufacturing technologies has experienced significant growth over the past decade, driven primarily by increasing demand for lightweight, high-strength materials across multiple industries. The market value reached approximately $2.3 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 8.7% through 2028, potentially reaching $3.8 billion by that time.

Aerospace and automotive sectors currently dominate the demand landscape, collectively accounting for over 65% of market share. The aerospace industry's push toward fuel-efficient aircraft has been particularly influential, with major manufacturers like Boeing and Airbus increasingly incorporating carbon fiber components processed using advanced laser technologies. The automotive sector follows closely behind, with premium and electric vehicle manufacturers leading adoption rates as they seek to reduce vehicle weight while maintaining structural integrity.

Regional analysis reveals that North America and Europe currently lead the market with approximately 37% and 32% market share respectively, primarily due to their established aerospace and automotive manufacturing bases. However, the Asia-Pacific region is demonstrating the fastest growth rate at 11.2% annually, driven by rapid industrialization in China, Japan, and South Korea, along with significant government investments in advanced manufacturing technologies.

Consumer demand patterns indicate a growing preference for products with enhanced performance-to-weight ratios, creating downstream market pull for laser-processed carbon fiber components. This trend is particularly evident in sporting goods, where high-end products command premium prices based on weight reduction and performance advantages.

Key market restraints include the high initial capital investment required for ultrafast laser systems, with typical industrial-grade systems ranging from $500,000 to over $2 million depending on specifications. Additionally, technical expertise requirements create barriers to entry for smaller manufacturers, contributing to market consolidation among larger players with established R&D capabilities.

Emerging application areas showing promising growth potential include renewable energy (particularly wind turbine blade manufacturing), medical devices, and construction materials. The wind energy sector specifically is projected to increase its consumption of laser-processed carbon fiber materials by 14.3% annually through 2027, representing one of the fastest-growing vertical markets.

Aerospace and automotive sectors currently dominate the demand landscape, collectively accounting for over 65% of market share. The aerospace industry's push toward fuel-efficient aircraft has been particularly influential, with major manufacturers like Boeing and Airbus increasingly incorporating carbon fiber components processed using advanced laser technologies. The automotive sector follows closely behind, with premium and electric vehicle manufacturers leading adoption rates as they seek to reduce vehicle weight while maintaining structural integrity.

Regional analysis reveals that North America and Europe currently lead the market with approximately 37% and 32% market share respectively, primarily due to their established aerospace and automotive manufacturing bases. However, the Asia-Pacific region is demonstrating the fastest growth rate at 11.2% annually, driven by rapid industrialization in China, Japan, and South Korea, along with significant government investments in advanced manufacturing technologies.

Consumer demand patterns indicate a growing preference for products with enhanced performance-to-weight ratios, creating downstream market pull for laser-processed carbon fiber components. This trend is particularly evident in sporting goods, where high-end products command premium prices based on weight reduction and performance advantages.

Key market restraints include the high initial capital investment required for ultrafast laser systems, with typical industrial-grade systems ranging from $500,000 to over $2 million depending on specifications. Additionally, technical expertise requirements create barriers to entry for smaller manufacturers, contributing to market consolidation among larger players with established R&D capabilities.

Emerging application areas showing promising growth potential include renewable energy (particularly wind turbine blade manufacturing), medical devices, and construction materials. The wind energy sector specifically is projected to increase its consumption of laser-processed carbon fiber materials by 14.3% annually through 2027, representing one of the fastest-growing vertical markets.

Current Challenges in Ultrafast Laser-CFRP Integration

Despite significant advancements in ultrafast laser technology for carbon fiber reinforced polymer (CFRP) processing, several critical challenges continue to impede widespread industrial adoption. The primary technical obstacle remains the complex interaction between ultrafast laser pulses and the heterogeneous structure of CFRP materials. The distinct thermal and optical properties of carbon fibers versus polymer matrices create inconsistent ablation thresholds, resulting in processing windows that are often too narrow for reliable manufacturing environments.

Heat-affected zone (HAZ) management presents another significant challenge. While ultrafast lasers theoretically minimize thermal damage through cold ablation mechanisms, practical implementation reveals that complete elimination of thermal effects is unachievable in production settings. This is particularly problematic at interfaces between fiber and matrix, where thermal conductivity differences can lead to delamination, fiber pull-out, and compromised mechanical properties in the final component.

Process scaling represents a substantial hurdle for industrial implementation. Current ultrafast laser systems capable of processing CFRP with acceptable quality operate at throughput rates significantly below those required for high-volume manufacturing. The fundamental trade-off between processing speed and quality remains unresolved, with higher pulse repetition rates often leading to heat accumulation effects that negate the cold ablation advantages.

Quality monitoring and process control systems lag behind the technology itself. Real-time monitoring of ultrafast laser-CFRP interactions is exceptionally difficult due to the speed of the process and the complex material response. The lack of reliable in-process quality assurance tools forces manufacturers to rely heavily on post-process inspection, increasing production costs and limiting adoption in quality-critical sectors like aerospace.

Material-specific optimization presents ongoing difficulties. The wide variety of CFRP formulations—with different fiber types, orientations, resin systems, and fiber volume fractions—necessitates extensive parameter development for each material variant. This lack of processing universality significantly increases implementation costs and technical barriers to entry.

Environmental and safety concerns also pose challenges. The ablation process generates potentially hazardous particulates and vapors that require sophisticated extraction and filtration systems. Additionally, the high-power laser systems demand comprehensive safety protocols and specialized operator training, further complicating industrial integration.

Cost justification remains perhaps the most significant barrier. The capital investment for ultrafast laser systems capable of CFRP processing exceeds conventional alternatives by orders of magnitude. Without clearly demonstrated productivity advantages or unique capabilities that enable new product features, many manufacturers struggle to build compelling business cases for adoption.

Heat-affected zone (HAZ) management presents another significant challenge. While ultrafast lasers theoretically minimize thermal damage through cold ablation mechanisms, practical implementation reveals that complete elimination of thermal effects is unachievable in production settings. This is particularly problematic at interfaces between fiber and matrix, where thermal conductivity differences can lead to delamination, fiber pull-out, and compromised mechanical properties in the final component.

Process scaling represents a substantial hurdle for industrial implementation. Current ultrafast laser systems capable of processing CFRP with acceptable quality operate at throughput rates significantly below those required for high-volume manufacturing. The fundamental trade-off between processing speed and quality remains unresolved, with higher pulse repetition rates often leading to heat accumulation effects that negate the cold ablation advantages.

Quality monitoring and process control systems lag behind the technology itself. Real-time monitoring of ultrafast laser-CFRP interactions is exceptionally difficult due to the speed of the process and the complex material response. The lack of reliable in-process quality assurance tools forces manufacturers to rely heavily on post-process inspection, increasing production costs and limiting adoption in quality-critical sectors like aerospace.

Material-specific optimization presents ongoing difficulties. The wide variety of CFRP formulations—with different fiber types, orientations, resin systems, and fiber volume fractions—necessitates extensive parameter development for each material variant. This lack of processing universality significantly increases implementation costs and technical barriers to entry.

Environmental and safety concerns also pose challenges. The ablation process generates potentially hazardous particulates and vapors that require sophisticated extraction and filtration systems. Additionally, the high-power laser systems demand comprehensive safety protocols and specialized operator training, further complicating industrial integration.

Cost justification remains perhaps the most significant barrier. The capital investment for ultrafast laser systems capable of CFRP processing exceeds conventional alternatives by orders of magnitude. Without clearly demonstrated productivity advantages or unique capabilities that enable new product features, many manufacturers struggle to build compelling business cases for adoption.

Existing Ultrafast Laser Applications in CFRP Processing

01 Ultrafast laser pulse generation and control

Ultrafast lasers generate extremely short pulses in the femtosecond to picosecond range. These systems employ various techniques for pulse generation, including mode-locking, Q-switching, and cavity design optimization. Advanced control mechanisms allow for precise manipulation of pulse characteristics such as duration, repetition rate, and spectral properties. These technologies enable applications requiring high temporal resolution and peak power.- Ultrafast laser pulse generation and control: Ultrafast lasers generate extremely short pulses, typically in the femtosecond to picosecond range. These systems employ various techniques for pulse generation, including mode-locking, Q-switching, and cavity dumping. Advanced control mechanisms allow for precise manipulation of pulse characteristics such as duration, repetition rate, and energy. These technologies enable applications requiring high temporal precision and peak power.

- Medical and surgical applications of ultrafast lasers: Ultrafast lasers offer significant advantages in medical procedures due to their minimal thermal effects on surrounding tissues. These lasers enable precise ablation and cutting with reduced collateral damage, making them particularly valuable in ophthalmology, dermatology, and microsurgery. The non-linear optical effects of ultrafast pulses allow for targeted treatment below tissue surfaces without damaging intervening layers, enabling novel therapeutic approaches.

- Materials processing with ultrafast lasers: Ultrafast lasers enable high-precision materials processing with minimal heat-affected zones. The extremely short pulse duration allows for material removal through non-thermal ablation processes, preventing melting and thermal damage. These capabilities make ultrafast lasers ideal for micromachining, drilling sub-micron holes, surface texturing, and processing of heat-sensitive materials. The technology enables manufacturing features at scales not achievable with conventional laser systems.

- Ultrafast laser amplification systems: Amplification systems for ultrafast lasers employ specialized techniques to increase pulse energy while maintaining short duration. Chirped pulse amplification (CPA) stretches pulses temporally before amplification and recompresses them afterward, avoiding damage to optical components. Optical parametric amplification provides another approach for increasing pulse energy. These systems incorporate advanced optical components including specialized gain media, dispersion management devices, and pulse stretcher/compressor arrangements.

- Ultrafast laser imaging and spectroscopy: Ultrafast lasers enable advanced imaging and spectroscopy techniques with exceptional temporal resolution. These applications include pump-probe spectroscopy for studying ultrafast chemical reactions, time-resolved microscopy for observing dynamic processes, and frequency comb spectroscopy for precise frequency measurements. The short pulse duration allows for capturing transient phenomena occurring on femtosecond timescales, providing insights into fundamental physical and chemical processes not observable with conventional techniques.

02 Medical and surgical applications of ultrafast lasers

Ultrafast lasers offer significant advantages in medical procedures due to their minimal thermal effects on surrounding tissues. These lasers enable precise ablation and cutting with reduced collateral damage, making them valuable for ophthalmology, dermatology, and microsurgery. The controlled energy deposition allows for treatment of sensitive tissues while preserving adjacent structures, resulting in improved patient outcomes and reduced recovery times.Expand Specific Solutions03 Material processing with ultrafast lasers

Ultrafast lasers enable precise material processing with minimal heat-affected zones. The extremely short pulse duration allows for cold ablation processes where material is removed before heat can diffuse to surrounding areas. This capability is particularly valuable for processing heat-sensitive materials, creating micro/nano-scale features, and achieving high-precision cuts. Applications include semiconductor manufacturing, glass processing, and micromachining of various materials.Expand Specific Solutions04 Optical amplification and beam delivery systems

Specialized optical amplification techniques are essential for ultrafast laser systems to achieve high peak powers while maintaining short pulse durations. These include chirped pulse amplification, optical parametric amplification, and regenerative amplification methods. Complementary beam delivery systems incorporate specialized optics, scanning mechanisms, and dispersion compensation to preserve pulse characteristics from the laser source to the target application area.Expand Specific Solutions05 Imaging and sensing applications

Ultrafast lasers enable advanced imaging and sensing techniques with unprecedented temporal and spatial resolution. Applications include multiphoton microscopy, pump-probe spectroscopy, and terahertz generation for non-destructive testing. The short pulse duration allows for time-resolved studies of ultrafast phenomena in physics, chemistry, and biology. These capabilities provide insights into molecular dynamics, carrier transport, and other rapid processes that occur on femtosecond to picosecond timescales.Expand Specific Solutions

Leading Manufacturers and Research Institutions in the Field

The ultrafast laser market in carbon fiber reinforcement processes is in a growth phase, with increasing adoption across aerospace, automotive, and industrial sectors. The market is projected to expand significantly due to rising demand for lightweight, high-strength materials. Technologically, the field shows varying maturity levels among key players. Industry leaders like Coherent, IPG Photonics, and TRUMPF have established advanced ultrafast laser solutions specifically for composite materials processing. Research institutions including Beijing Institute of Technology, University of Rochester, and Zhejiang University are driving fundamental innovations. Meanwhile, materials specialists such as Teijin and Mitsubishi Heavy Industries are integrating these technologies into manufacturing workflows. Collaboration between laser manufacturers and materials companies represents a critical trend as the technology moves toward broader industrial implementation.

TeraXion, Inc.

Technical Solution: TeraXion has developed specialized fiber Bragg grating (FBG) components that enable precise control of ultrafast laser pulses for carbon fiber reinforcement applications. Their PureSpectrum-VLMTM technology provides dispersion compensation crucial for maintaining femtosecond pulse integrity throughout the beam delivery path, ensuring consistent material interaction quality. TeraXion's proprietary semiconductor saturable absorber mirror (SESAM) designs enable self-starting mode-locking with exceptional stability, critical for industrial carbon fiber processing environments where system reliability is paramount[9]. Their integrated photonic solutions include specialized pulse pickers and temporal shapers that allow precise control over pulse trains, enabling selective energy deposition patterns that optimize fiber-matrix interfacial properties. TeraXion has also developed specialized fiber-coupled components that maintain polarization integrity throughout complex beam delivery paths, ensuring consistent processing quality across large carbon fiber structures[10].

Strengths: Industry-leading expertise in fiber optic components for ultrafast lasers; components designed specifically for industrial reliability; customization capabilities for specific application requirements. Weaknesses: Focuses primarily on components rather than complete systems; requires integration with other manufacturers' platforms; limited direct application engineering support compared to full-system providers.

TRUMPF Laser UK Ltd.

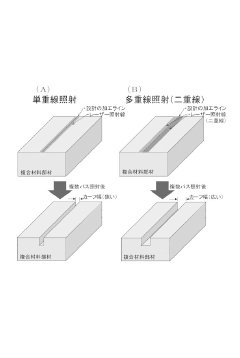

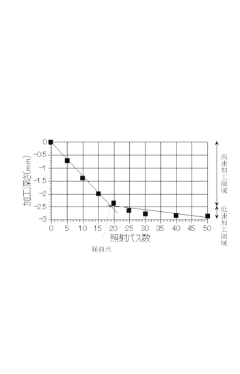

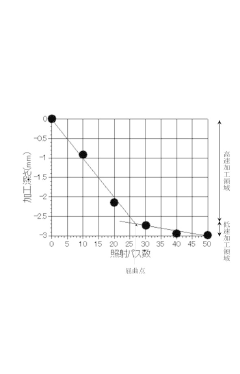

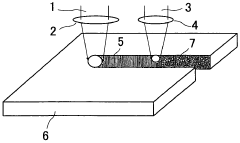

Technical Solution: TRUMPF has developed advanced ultrafast laser systems specifically optimized for carbon fiber reinforced polymer (CFRP) processing. Their TruMicro Series incorporates picosecond and femtosecond lasers with pulse durations below 10ps and repetition rates up to 1MHz, enabling precise ablation with minimal heat-affected zones. TRUMPF's technology utilizes beam shaping techniques to optimize energy distribution across the material surface, resulting in clean cuts with reduced fiber fraying and delamination. Their systems employ sophisticated process monitoring with real-time feedback control that adjusts laser parameters based on material response[1]. TRUMPF has also pioneered multi-pass processing strategies that maintain fiber integrity while achieving high throughput rates in industrial CFRP applications[3].

Strengths: Industry-leading beam quality control and process monitoring capabilities; extensive experience in industrial laser applications; comprehensive service network. Weaknesses: Higher initial investment costs compared to conventional systems; requires specialized operator training; technology primarily optimized for high-volume manufacturing environments.

Key Patents and Breakthroughs in Laser-Composite Interaction

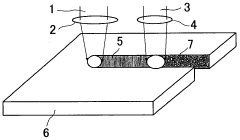

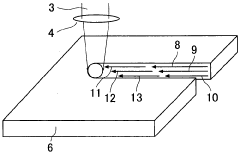

High-speed laser processing method for fiber reinforced composite material and high-speed laser processing apparatus for the same

PatentActiveJP2016107574A

Innovation

- A high-speed laser processing method involving a single high-output power laser device that switches from multi-line to single-line irradiation based on processing depth, optimizing the transition timing to achieve high-quality and efficient cutting, drilling, or trimming of thick fiber-reinforced composite materials.

Method of laser machining of fiber-reinforced composite material and product made by the method

PatentWO2010119995A1

Innovation

- A laser processing method utilizing ultra-short pulse lasers (picosecond or nanosecond pulses) that cuts, drills, and grooves with high precision and speed, preventing fiber scattering and minimizing thermal effects by rapidly heating and vaporizing material surfaces, allowing for high-quality and cost-effective processing.

Environmental Impact Assessment of Laser-Based Manufacturing

The integration of ultrafast laser technology in carbon fiber reinforcement processes presents significant environmental considerations that warrant comprehensive assessment. Traditional manufacturing methods for carbon fiber reinforced polymers (CFRPs) typically involve energy-intensive processes and chemical treatments that generate substantial waste and emissions. Ultrafast laser processing offers a potentially more environmentally sustainable alternative, though its full ecological impact requires careful evaluation.

Energy consumption represents a primary environmental concern in laser-based manufacturing. While ultrafast lasers require considerable power during operation, their precision and efficiency may result in net energy savings compared to conventional methods. Recent studies indicate that femtosecond laser systems, when optimized for CFRP processing, can reduce overall energy consumption by 15-30% through minimized material waste and decreased processing time. However, the environmental benefits are highly dependent on the energy source powering these systems, with renewable energy integration significantly enhancing sustainability profiles.

Waste reduction constitutes another critical environmental advantage of ultrafast laser technology. The precision of ultrafast lasers enables near-net-shape manufacturing, substantially reducing material waste compared to traditional cutting and machining processes. Quantitative analyses demonstrate that laser-based CFRP processing can decrease material waste by up to 40%, with corresponding reductions in embedded carbon footprint. Additionally, the non-contact nature of laser processing eliminates the need for cooling lubricants and cutting fluids, further reducing environmental contamination risks.

Air quality impacts from laser-based manufacturing require particular attention. The ablation of carbon fiber materials can generate ultrafine particulates and potentially hazardous volatile organic compounds (VOCs). Effective extraction and filtration systems are essential to mitigate these emissions. Recent advancements in closed-loop processing environments have demonstrated capability to capture over 99% of particulate matter, though the energy requirements of these systems must be factored into overall environmental assessments.

Water resource implications of ultrafast laser processing are generally favorable compared to conventional methods. Traditional CFRP manufacturing often involves water-intensive processes for cooling and cleaning, whereas laser-based approaches typically require minimal water usage. This represents a significant environmental advantage in regions facing water scarcity challenges, with potential water consumption reductions of 60-80% in manufacturing operations.

Life cycle assessment (LCA) studies examining the complete environmental footprint of ultrafast laser systems in CFRP processing indicate promising sustainability benefits, particularly when considering extended equipment lifespan and reduced maintenance requirements. However, comprehensive environmental optimization requires holistic consideration of system design, operational parameters, and end-of-life management strategies for both the manufacturing equipment and resulting composite products.

Energy consumption represents a primary environmental concern in laser-based manufacturing. While ultrafast lasers require considerable power during operation, their precision and efficiency may result in net energy savings compared to conventional methods. Recent studies indicate that femtosecond laser systems, when optimized for CFRP processing, can reduce overall energy consumption by 15-30% through minimized material waste and decreased processing time. However, the environmental benefits are highly dependent on the energy source powering these systems, with renewable energy integration significantly enhancing sustainability profiles.

Waste reduction constitutes another critical environmental advantage of ultrafast laser technology. The precision of ultrafast lasers enables near-net-shape manufacturing, substantially reducing material waste compared to traditional cutting and machining processes. Quantitative analyses demonstrate that laser-based CFRP processing can decrease material waste by up to 40%, with corresponding reductions in embedded carbon footprint. Additionally, the non-contact nature of laser processing eliminates the need for cooling lubricants and cutting fluids, further reducing environmental contamination risks.

Air quality impacts from laser-based manufacturing require particular attention. The ablation of carbon fiber materials can generate ultrafine particulates and potentially hazardous volatile organic compounds (VOCs). Effective extraction and filtration systems are essential to mitigate these emissions. Recent advancements in closed-loop processing environments have demonstrated capability to capture over 99% of particulate matter, though the energy requirements of these systems must be factored into overall environmental assessments.

Water resource implications of ultrafast laser processing are generally favorable compared to conventional methods. Traditional CFRP manufacturing often involves water-intensive processes for cooling and cleaning, whereas laser-based approaches typically require minimal water usage. This represents a significant environmental advantage in regions facing water scarcity challenges, with potential water consumption reductions of 60-80% in manufacturing operations.

Life cycle assessment (LCA) studies examining the complete environmental footprint of ultrafast laser systems in CFRP processing indicate promising sustainability benefits, particularly when considering extended equipment lifespan and reduced maintenance requirements. However, comprehensive environmental optimization requires holistic consideration of system design, operational parameters, and end-of-life management strategies for both the manufacturing equipment and resulting composite products.

Quality Control Standards for Laser-Processed Carbon Composites

Quality control standards for laser-processed carbon composites have evolved significantly with the integration of ultrafast laser technologies in carbon fiber reinforcement processes. These standards now encompass multiple dimensions of quality assurance, reflecting the precision demands of high-performance composite applications in aerospace, automotive, and renewable energy sectors.

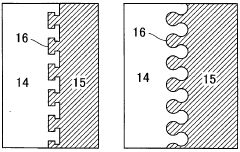

The fundamental quality parameters for laser-processed carbon composites include surface integrity, ablation precision, heat-affected zone minimization, and structural uniformity. Industry standards such as ASTM D7136 for damage resistance and ASTM D6484 for open-hole compression properties have been adapted specifically for laser-processed composites, with additional considerations for the unique material interactions that occur during ultrafast laser processing.

Non-destructive testing (NDT) methodologies have been refined to address the specific characteristics of ultrafast laser-processed carbon composites. Advanced techniques including laser shearography, digital image correlation, and terahertz imaging now complement traditional ultrasonic testing and X-ray computed tomography. These methods enable real-time monitoring of potential defects such as delamination, fiber misalignment, and micro-cracks that may occur during laser processing.

Process validation protocols for ultrafast laser applications in carbon fiber reinforcement have been standardized through ISO 9001:2015 quality management systems, with specialized addenda for composite manufacturing. These protocols typically require statistical process control (SPC) implementation, with defined control limits for laser parameters including pulse duration, energy density, and scanning speed.

Material certification requirements have become increasingly stringent, with manufacturers now required to document comprehensive material property data for laser-processed composites. This includes interlaminar shear strength (ILSS), glass transition temperature (Tg), and fatigue performance metrics that must meet application-specific thresholds established by regulatory bodies such as the FAA, EASA, and automotive industry standards organizations.

In-line monitoring systems represent the cutting edge of quality control for laser-processed carbon composites. These systems integrate multiple sensor technologies—including high-speed thermal imaging, spectroscopic analysis, and acoustic emission detection—to provide real-time feedback on process parameters and material response during laser processing. Machine learning algorithms increasingly analyze this multi-sensor data to predict potential quality issues before they manifest in the finished component.

Traceability requirements have also expanded, with each laser-processed component now typically requiring a digital twin that documents its complete processing history, including all laser parameters, environmental conditions, and quality inspection results throughout its lifecycle.

The fundamental quality parameters for laser-processed carbon composites include surface integrity, ablation precision, heat-affected zone minimization, and structural uniformity. Industry standards such as ASTM D7136 for damage resistance and ASTM D6484 for open-hole compression properties have been adapted specifically for laser-processed composites, with additional considerations for the unique material interactions that occur during ultrafast laser processing.

Non-destructive testing (NDT) methodologies have been refined to address the specific characteristics of ultrafast laser-processed carbon composites. Advanced techniques including laser shearography, digital image correlation, and terahertz imaging now complement traditional ultrasonic testing and X-ray computed tomography. These methods enable real-time monitoring of potential defects such as delamination, fiber misalignment, and micro-cracks that may occur during laser processing.

Process validation protocols for ultrafast laser applications in carbon fiber reinforcement have been standardized through ISO 9001:2015 quality management systems, with specialized addenda for composite manufacturing. These protocols typically require statistical process control (SPC) implementation, with defined control limits for laser parameters including pulse duration, energy density, and scanning speed.

Material certification requirements have become increasingly stringent, with manufacturers now required to document comprehensive material property data for laser-processed composites. This includes interlaminar shear strength (ILSS), glass transition temperature (Tg), and fatigue performance metrics that must meet application-specific thresholds established by regulatory bodies such as the FAA, EASA, and automotive industry standards organizations.

In-line monitoring systems represent the cutting edge of quality control for laser-processed carbon composites. These systems integrate multiple sensor technologies—including high-speed thermal imaging, spectroscopic analysis, and acoustic emission detection—to provide real-time feedback on process parameters and material response during laser processing. Machine learning algorithms increasingly analyze this multi-sensor data to predict potential quality issues before they manifest in the finished component.

Traceability requirements have also expanded, with each laser-processed component now typically requiring a digital twin that documents its complete processing history, including all laser parameters, environmental conditions, and quality inspection results throughout its lifecycle.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!