How Ultrafast Lasers Improve High-Frequency Electronics Production.

SEP 4, 202510 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Technology Evolution and Objectives

Ultrafast laser technology has evolved significantly over the past three decades, transforming from laboratory curiosities to essential industrial tools. The journey began in the 1980s with the development of femtosecond lasers, which initially found applications primarily in scientific research. By the 1990s, these systems became more reliable but remained bulky and complex, limiting their industrial adoption. The 2000s marked a turning point with the introduction of fiber-based ultrafast lasers, dramatically improving stability and reducing maintenance requirements.

The evolution accelerated in the 2010s with the commercialization of industrial-grade ultrafast laser systems specifically designed for precision manufacturing. These systems featured higher average powers, improved beam quality, and enhanced pulse control mechanisms. Recent developments have focused on increasing repetition rates while maintaining ultrashort pulse durations, crucial for high-frequency electronics production.

Today's state-of-the-art ultrafast lasers operate at pulse durations below 400 femtoseconds with repetition rates exceeding 2 MHz, providing unprecedented precision for micromachining applications. This technological progression has been driven by the growing demands of the electronics industry, particularly for components operating at frequencies above 100 GHz.

The primary objective of ultrafast laser technology in high-frequency electronics production is to enable the fabrication of increasingly miniaturized and complex components with minimal thermal damage. Unlike conventional laser processing, ultrafast lasers achieve "cold ablation," removing material through direct vaporization before heat can diffuse to surrounding areas. This capability is essential for processing temperature-sensitive materials commonly used in high-frequency electronics.

Another critical objective is improving manufacturing throughput while maintaining nanometer-level precision. Current research focuses on developing multi-beam processing techniques and optimizing scanning strategies to increase production efficiency without compromising quality. Parallel processing approaches using spatial light modulators show particular promise for scaling production volumes.

Looking forward, the technology aims to achieve even shorter pulse durations (approaching attosecond range) and higher pulse energies while reducing system footprint and cost. Integration with advanced monitoring and control systems represents another important objective, enabling real-time process optimization through machine learning algorithms that can adjust laser parameters on-the-fly based on material response.

The convergence of ultrafast laser technology with high-frequency electronics production addresses the fundamental challenge of creating increasingly sophisticated electronic components that can operate at terahertz frequencies, potentially revolutionizing communication systems, sensing technologies, and computing architectures.

The evolution accelerated in the 2010s with the commercialization of industrial-grade ultrafast laser systems specifically designed for precision manufacturing. These systems featured higher average powers, improved beam quality, and enhanced pulse control mechanisms. Recent developments have focused on increasing repetition rates while maintaining ultrashort pulse durations, crucial for high-frequency electronics production.

Today's state-of-the-art ultrafast lasers operate at pulse durations below 400 femtoseconds with repetition rates exceeding 2 MHz, providing unprecedented precision for micromachining applications. This technological progression has been driven by the growing demands of the electronics industry, particularly for components operating at frequencies above 100 GHz.

The primary objective of ultrafast laser technology in high-frequency electronics production is to enable the fabrication of increasingly miniaturized and complex components with minimal thermal damage. Unlike conventional laser processing, ultrafast lasers achieve "cold ablation," removing material through direct vaporization before heat can diffuse to surrounding areas. This capability is essential for processing temperature-sensitive materials commonly used in high-frequency electronics.

Another critical objective is improving manufacturing throughput while maintaining nanometer-level precision. Current research focuses on developing multi-beam processing techniques and optimizing scanning strategies to increase production efficiency without compromising quality. Parallel processing approaches using spatial light modulators show particular promise for scaling production volumes.

Looking forward, the technology aims to achieve even shorter pulse durations (approaching attosecond range) and higher pulse energies while reducing system footprint and cost. Integration with advanced monitoring and control systems represents another important objective, enabling real-time process optimization through machine learning algorithms that can adjust laser parameters on-the-fly based on material response.

The convergence of ultrafast laser technology with high-frequency electronics production addresses the fundamental challenge of creating increasingly sophisticated electronic components that can operate at terahertz frequencies, potentially revolutionizing communication systems, sensing technologies, and computing architectures.

Market Demand for Advanced High-Frequency Electronics

The high-frequency electronics market is experiencing unprecedented growth driven by the rapid expansion of 5G networks, satellite communications, autonomous vehicles, and advanced radar systems. Current market projections indicate that the global high-frequency electronics sector will reach $73.8 billion by 2026, with a compound annual growth rate of 8.4% from 2021. This accelerated growth reflects the increasing demand for devices capable of operating at frequencies above 24 GHz, particularly in millimeter-wave applications.

Telecommunications represents the largest market segment, with 5G infrastructure deployment creating substantial demand for high-frequency components that can support multi-gigabit data transmission rates. Network providers are investing heavily in equipment that can operate efficiently in the 28 GHz, 39 GHz, and even higher frequency bands to deliver the promised performance improvements of next-generation networks.

The automotive industry has emerged as another significant driver of demand, with advanced driver assistance systems (ADAS) and autonomous driving technologies requiring sophisticated high-frequency radar systems operating at 77 GHz and above. Market research indicates that the automotive radar segment alone is growing at 21% annually, creating substantial opportunities for high-frequency electronic component manufacturers.

Aerospace and defense applications continue to be critical markets for high-frequency electronics, with modern military systems requiring increasingly sophisticated electronic warfare capabilities, secure communications, and high-resolution radar systems. These applications demand components with exceptional reliability, performance, and precision manufacturing.

Consumer electronics manufacturers are also driving demand for miniaturized high-frequency components as smartphones and wearable devices incorporate more wireless connectivity options operating at higher frequencies. This trend is pushing manufacturers to develop smaller, more efficient components that can be integrated into compact consumer devices.

The industrial Internet of Things (IoT) represents an emerging market segment with significant growth potential. As industrial automation systems become more sophisticated, the need for high-speed, reliable wireless communication between sensors, controllers, and central systems is creating new applications for high-frequency electronics.

A critical market challenge is the increasing demand for components with tighter tolerances, higher performance, and lower costs. Traditional manufacturing methods struggle to meet these requirements cost-effectively at scale, creating a technology gap that ultrafast laser processing is uniquely positioned to address. Industry surveys indicate that manufacturers are willing to invest in advanced production technologies that can deliver higher yields and better performance characteristics while reducing long-term production costs.

Telecommunications represents the largest market segment, with 5G infrastructure deployment creating substantial demand for high-frequency components that can support multi-gigabit data transmission rates. Network providers are investing heavily in equipment that can operate efficiently in the 28 GHz, 39 GHz, and even higher frequency bands to deliver the promised performance improvements of next-generation networks.

The automotive industry has emerged as another significant driver of demand, with advanced driver assistance systems (ADAS) and autonomous driving technologies requiring sophisticated high-frequency radar systems operating at 77 GHz and above. Market research indicates that the automotive radar segment alone is growing at 21% annually, creating substantial opportunities for high-frequency electronic component manufacturers.

Aerospace and defense applications continue to be critical markets for high-frequency electronics, with modern military systems requiring increasingly sophisticated electronic warfare capabilities, secure communications, and high-resolution radar systems. These applications demand components with exceptional reliability, performance, and precision manufacturing.

Consumer electronics manufacturers are also driving demand for miniaturized high-frequency components as smartphones and wearable devices incorporate more wireless connectivity options operating at higher frequencies. This trend is pushing manufacturers to develop smaller, more efficient components that can be integrated into compact consumer devices.

The industrial Internet of Things (IoT) represents an emerging market segment with significant growth potential. As industrial automation systems become more sophisticated, the need for high-speed, reliable wireless communication between sensors, controllers, and central systems is creating new applications for high-frequency electronics.

A critical market challenge is the increasing demand for components with tighter tolerances, higher performance, and lower costs. Traditional manufacturing methods struggle to meet these requirements cost-effectively at scale, creating a technology gap that ultrafast laser processing is uniquely positioned to address. Industry surveys indicate that manufacturers are willing to invest in advanced production technologies that can deliver higher yields and better performance characteristics while reducing long-term production costs.

Current Capabilities and Limitations of Ultrafast Laser Processing

Ultrafast laser processing has revolutionized high-frequency electronics manufacturing with its precision micromachining capabilities. Current systems can achieve feature sizes down to sub-micron levels, with positioning accuracy in the nanometer range. The femtosecond and picosecond pulse durations minimize heat-affected zones, enabling clean ablation of materials without thermal damage—a critical advantage for sensitive electronic components.

Processing speeds have significantly improved, with modern systems capable of handling millions of pulses per second. This translates to throughput rates suitable for industrial production environments, though still lower than traditional manufacturing methods for large-scale operations. The technology excels in selective material removal, allowing for precise structuring of multilayer electronic components without affecting underlying layers.

Despite these capabilities, several limitations persist. Cost remains a significant barrier, with high-end ultrafast laser systems requiring investments of several hundred thousand dollars, plus maintenance expenses. This restricts widespread adoption, particularly among smaller manufacturers. The technology also faces challenges in processing certain materials relevant to high-frequency electronics, such as specific ceramic composites and some advanced semiconductor compounds.

Beam delivery systems present another limitation. While galvanometer scanners offer excellent speed, they struggle with maintaining consistent focus across large work areas. This necessitates complex optical setups or multiple processing steps for larger components. Energy efficiency is another concern, as ultrafast lasers typically convert only 15-30% of input power to usable laser output, resulting in high operational costs.

Integration challenges exist when incorporating ultrafast laser processing into established production lines. The technology often requires specialized environments with strict temperature and vibration control, complicating seamless integration with existing manufacturing workflows. Additionally, process monitoring and quality control systems for ultrafast laser processing are still evolving, with real-time feedback mechanisms not yet fully mature.

The learning curve associated with parameter optimization represents another limitation. Achieving optimal results requires precise tuning of numerous parameters including pulse energy, repetition rate, scanning speed, and focal position. This complexity necessitates specialized expertise and often extensive experimentation, increasing setup times and costs for new applications or materials.

While ultrafast laser processing offers unprecedented precision for high-frequency electronics production, addressing these limitations—particularly cost reduction, material processing capabilities, and integration flexibility—will be crucial for broader industrial adoption and maximizing the technology's potential.

Processing speeds have significantly improved, with modern systems capable of handling millions of pulses per second. This translates to throughput rates suitable for industrial production environments, though still lower than traditional manufacturing methods for large-scale operations. The technology excels in selective material removal, allowing for precise structuring of multilayer electronic components without affecting underlying layers.

Despite these capabilities, several limitations persist. Cost remains a significant barrier, with high-end ultrafast laser systems requiring investments of several hundred thousand dollars, plus maintenance expenses. This restricts widespread adoption, particularly among smaller manufacturers. The technology also faces challenges in processing certain materials relevant to high-frequency electronics, such as specific ceramic composites and some advanced semiconductor compounds.

Beam delivery systems present another limitation. While galvanometer scanners offer excellent speed, they struggle with maintaining consistent focus across large work areas. This necessitates complex optical setups or multiple processing steps for larger components. Energy efficiency is another concern, as ultrafast lasers typically convert only 15-30% of input power to usable laser output, resulting in high operational costs.

Integration challenges exist when incorporating ultrafast laser processing into established production lines. The technology often requires specialized environments with strict temperature and vibration control, complicating seamless integration with existing manufacturing workflows. Additionally, process monitoring and quality control systems for ultrafast laser processing are still evolving, with real-time feedback mechanisms not yet fully mature.

The learning curve associated with parameter optimization represents another limitation. Achieving optimal results requires precise tuning of numerous parameters including pulse energy, repetition rate, scanning speed, and focal position. This complexity necessitates specialized expertise and often extensive experimentation, increasing setup times and costs for new applications or materials.

While ultrafast laser processing offers unprecedented precision for high-frequency electronics production, addressing these limitations—particularly cost reduction, material processing capabilities, and integration flexibility—will be crucial for broader industrial adoption and maximizing the technology's potential.

Contemporary Ultrafast Laser Processing Methodologies

01 Optimization of laser cavity design

Improving ultrafast laser production through optimized cavity design involves enhancing resonator configurations, implementing advanced mirror systems, and refining optical path arrangements. These design improvements lead to better beam quality, increased power output, and improved pulse stability. Optimized cavity designs can reduce manufacturing costs while maintaining or improving performance specifications, making ultrafast lasers more commercially viable for industrial applications.- Pulse control and optimization techniques: Advanced pulse control techniques are essential for improving ultrafast laser production. These include methods for generating, shaping, and stabilizing ultrashort pulses to enhance laser performance. Optimization of pulse parameters such as duration, energy, and repetition rate can significantly improve the efficiency and quality of ultrafast laser systems. These techniques often involve sophisticated electronic control systems and feedback mechanisms to maintain pulse stability during operation.

- Thermal management and cooling systems: Effective thermal management is crucial for maintaining stable operation and extending the lifespan of ultrafast laser systems. Advanced cooling techniques help dissipate heat generated during high-power operation, preventing thermal lensing and other temperature-related issues that can degrade beam quality. Innovations in this area include improved heat sink designs, liquid cooling systems, and thermally conductive materials that efficiently transfer heat away from critical components, allowing for higher average powers and more reliable operation.

- Optical component improvements: Enhancements in optical components significantly impact ultrafast laser production quality. This includes development of high-damage-threshold mirrors, specialized coatings, and advanced dispersion compensation elements. Improved optical materials with better thermal properties and lower nonlinear effects enable higher power handling capabilities. Novel optical designs that minimize losses and maintain beam quality throughout the laser system contribute to overall performance improvements and manufacturing consistency.

- Manufacturing process automation: Automation of the manufacturing process for ultrafast lasers improves production efficiency and consistency. Automated alignment systems, robotic assembly, and computer-controlled testing procedures reduce human error and increase throughput. Advanced process monitoring and quality control systems ensure that each laser meets performance specifications. Integration of machine learning algorithms can optimize production parameters in real-time, leading to higher yields and more consistent product quality.

- Novel gain media and amplification techniques: Development of new gain media materials and innovative amplification techniques enables significant improvements in ultrafast laser performance. These advancements allow for higher output powers, broader bandwidth operation, and more efficient energy conversion. Techniques such as chirped pulse amplification, optical parametric amplification, and thin-disk architectures have revolutionized ultrafast laser capabilities. Novel doping materials and optimized crystal growing methods contribute to better beam quality and increased reliability in production environments.

02 Advanced pulse control techniques

Implementing sophisticated pulse control techniques enhances ultrafast laser production efficiency. These methods include mode-locking optimization, chirped pulse amplification refinements, and precise temporal control systems. By improving pulse characteristics such as duration, shape, and timing, manufacturers can achieve more consistent output quality and higher processing precision. These advancements enable ultrafast lasers to perform more complex material processing tasks with greater reliability.Expand Specific Solutions03 Thermal management innovations

Effective thermal management is crucial for improving ultrafast laser production. Innovations include advanced cooling systems, heat-dissipating materials, and thermal stabilization techniques that prevent performance degradation during operation. These solutions address heat-related issues that can affect beam quality, pulse stability, and component longevity. By implementing superior thermal management, manufacturers can increase operational uptime, extend laser system lifespan, and maintain consistent performance under varying conditions.Expand Specific Solutions04 Manufacturing process automation

Automating the manufacturing process of ultrafast lasers significantly improves production efficiency and consistency. Implementation of robotic assembly, automated alignment systems, and computerized quality control reduces human error and increases throughput. Advanced monitoring systems enable real-time adjustments during production, ensuring each laser meets precise specifications. These automation technologies streamline the manufacturing workflow, reduce production costs, and enable scalable production of high-quality ultrafast laser systems.Expand Specific Solutions05 Novel materials and component integration

Incorporating novel materials and advanced component integration techniques enhances ultrafast laser production capabilities. This includes using specialized gain media, innovative optical coatings, and next-generation semiconductor materials. Modular design approaches facilitate easier assembly and maintenance while improving performance. Integration of photonic integrated circuits and micro-optical components enables more compact and energy-efficient laser systems. These material and integration advancements lead to ultrafast lasers with superior performance characteristics and reduced manufacturing complexity.Expand Specific Solutions

Leading Manufacturers and Research Institutions in Ultrafast Laser Technology

Ultrafast laser technology in high-frequency electronics production is currently in a growth phase, with the market expanding rapidly due to increasing demand for miniaturized and high-performance electronic components. The global market size for ultrafast laser systems in electronics manufacturing is estimated to reach several billion dollars by 2025, driven by applications in semiconductor processing and microelectronics. Leading companies like Coherent, IPG Photonics, and Han's Laser Technology are at the forefront of technological innovation, while established electronics manufacturers such as Mitsubishi Electric and Panasonic are integrating these advanced laser systems into their production lines. Research institutions including Kyoto University and the University of Tokyo are collaborating with industry players like SCHOTT AG and Infineon Technologies to develop next-generation ultrafast laser applications, pushing the technology toward greater precision and efficiency in high-frequency electronics manufacturing.

Coherent, Inc.

Technical Solution: Coherent's ultrafast laser technology for high-frequency electronics production centers on their Monaco and Vitara systems, which deliver femtosecond pulses with exceptional precision. Their proprietary InSync technology synchronizes multiple lasers with timing jitter below 100 femtoseconds, critical for advanced semiconductor manufacturing. The company's HyperRapid NXT series specifically targets high-frequency electronics with pulse durations under 15 picoseconds and repetition rates up to 2MHz, enabling cold ablation processes that minimize heat-affected zones to less than 5μm. This precision allows for micromachining of sensitive RF components with feature sizes below 10μm. Coherent has also pioneered beam shaping technology that transforms Gaussian beams into flat-top profiles, improving energy distribution uniformity by over 90% across the processing area, which is essential for consistent via drilling in high-frequency PCBs.

Strengths: Industry-leading pulse stability (<0.5% RMS) enables consistent processing quality; proprietary InSync technology allows multi-beam processing that increases throughput by up to 400%. Weaknesses: Higher initial capital investment compared to conventional laser systems; requires specialized technical expertise for operation and maintenance.

Electro Scientific Industries, Inc.

Technical Solution: ESI's ultrafast laser technology for high-frequency electronics production is centered around their Geode and Garnet platforms, which utilize picosecond and femtosecond lasers to achieve precision micromachining of RF components. Their proprietary PulseSense technology dynamically adjusts laser parameters in real-time based on material feedback, maintaining consistent ablation quality even with material variations. For high-frequency applications, ESI has developed specialized beam delivery systems that achieve spot sizes below 5μm with positioning accuracy of ±0.5μm, enabling the creation of fine features required in 5G and mmWave components. Their systems incorporate patented AccuShape technology that provides programmable pulse shaping capabilities, allowing engineers to optimize energy delivery for different materials used in RF circuits, from LTCC to thin-film metals. ESI's latest systems incorporate parallel processing capabilities with up to 100 beams simultaneously, increasing throughput by orders of magnitude compared to single-beam systems while maintaining feature quality. This is particularly valuable for high-volume manufacturing of filters, antennas, and waveguides used in advanced communication systems.

Strengths: Comprehensive process development support with material-specific recipes reduces implementation time; integrated metrology systems enable closed-loop quality control during production. Weaknesses: More complex user interface compared to competitors requires longer operator training; system footprint is larger than some competing solutions, requiring more factory floor space.

Critical Patents and Innovations in Ultrafast Laser Applications

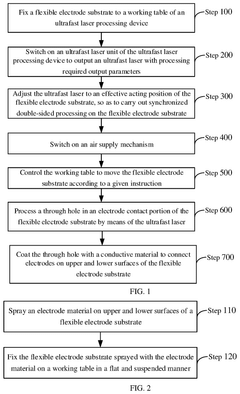

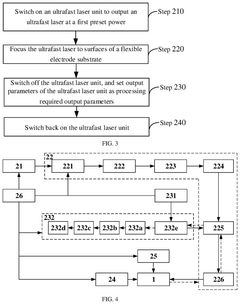

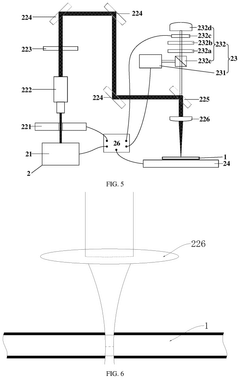

Ultrafast laser processing method for flexible double-sided electrodes

PatentPendingUS20250128350A1

Innovation

- An ultrafast laser processing method for flexible double-sided electrodes, which involves fixing a flexible electrode substrate to an ultrafast laser processing device, adjusting the laser to an effective acting position for synchronized double-sided processing, and optionally processing through holes and coating with conductive material.

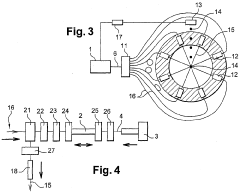

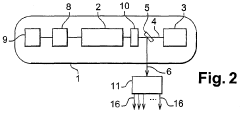

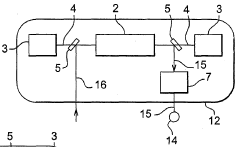

Device for generating laser impulses amplified by optical fibres provided with photon layers

PatentWO2006111684A2

Innovation

- A device utilizing a distributed amplification system across multiple photonic fibers (MPF) with a master laser beam spatially multiplexed into sub-sources, each amplified by optical amplifiers with photonic layers, ensuring synchronized pulse arrival at a common focusing volume for enhanced energy concentration and beam quality.

Material Science Considerations for Laser-Material Interactions

The interaction between ultrafast lasers and various materials represents a critical domain in high-frequency electronics production. Material selection significantly influences the effectiveness of laser processing, as different materials exhibit unique absorption characteristics, thermal conductivity properties, and damage thresholds when exposed to ultrafast laser pulses. Semiconductor materials such as silicon, gallium arsenide, and silicon carbide demonstrate distinct behaviors under femtosecond laser irradiation, necessitating tailored processing parameters for optimal results.

Thermal considerations play a paramount role in laser-material interactions. Unlike conventional lasers, ultrafast lasers deposit energy in timeframes shorter than thermal diffusion processes, creating what scientists term "cold ablation." This phenomenon minimizes heat-affected zones (HAZ) and enables precision micromachining of temperature-sensitive electronic components. For high-frequency electronics, where dimensional precision directly impacts performance, this thermal advantage translates to superior device characteristics and reliability.

The crystalline structure and orientation of materials significantly impact laser processing outcomes. Research indicates that crystal orientation can affect ablation thresholds by up to 30% in certain semiconductor materials. Furthermore, dopant concentrations in semiconductors alter optical absorption properties, requiring adjustments to laser parameters for consistent processing results across wafers with varying dopant profiles.

Surface modifications induced by ultrafast lasers extend beyond mere topographical changes. Studies reveal that femtosecond laser processing can alter electronic band structures, surface chemistry, and wettability properties. These modifications prove particularly valuable for high-frequency electronics, where surface characteristics directly influence signal propagation and component integration. Controlled laser-induced periodic surface structures (LIPSS) can enhance electrical conductivity along specific directions, offering novel approaches to directional signal management.

Multi-material systems present unique challenges and opportunities in ultrafast laser processing. High-frequency electronics often incorporate diverse material combinations—metals, ceramics, polymers, and semiconductors—with vastly different optical and thermal properties. Ultrafast lasers demonstrate remarkable versatility in processing these heterogeneous structures without delamination or interface damage, a capability attributed to their minimal thermal impact and precise energy deposition.

Recent advancements in material science have introduced specialized composites and metamaterials designed specifically for optimal interaction with ultrafast lasers. These engineered materials feature controlled absorption characteristics and enhanced thermal management properties, enabling more efficient and precise laser processing for next-generation high-frequency electronic components.

Thermal considerations play a paramount role in laser-material interactions. Unlike conventional lasers, ultrafast lasers deposit energy in timeframes shorter than thermal diffusion processes, creating what scientists term "cold ablation." This phenomenon minimizes heat-affected zones (HAZ) and enables precision micromachining of temperature-sensitive electronic components. For high-frequency electronics, where dimensional precision directly impacts performance, this thermal advantage translates to superior device characteristics and reliability.

The crystalline structure and orientation of materials significantly impact laser processing outcomes. Research indicates that crystal orientation can affect ablation thresholds by up to 30% in certain semiconductor materials. Furthermore, dopant concentrations in semiconductors alter optical absorption properties, requiring adjustments to laser parameters for consistent processing results across wafers with varying dopant profiles.

Surface modifications induced by ultrafast lasers extend beyond mere topographical changes. Studies reveal that femtosecond laser processing can alter electronic band structures, surface chemistry, and wettability properties. These modifications prove particularly valuable for high-frequency electronics, where surface characteristics directly influence signal propagation and component integration. Controlled laser-induced periodic surface structures (LIPSS) can enhance electrical conductivity along specific directions, offering novel approaches to directional signal management.

Multi-material systems present unique challenges and opportunities in ultrafast laser processing. High-frequency electronics often incorporate diverse material combinations—metals, ceramics, polymers, and semiconductors—with vastly different optical and thermal properties. Ultrafast lasers demonstrate remarkable versatility in processing these heterogeneous structures without delamination or interface damage, a capability attributed to their minimal thermal impact and precise energy deposition.

Recent advancements in material science have introduced specialized composites and metamaterials designed specifically for optimal interaction with ultrafast lasers. These engineered materials feature controlled absorption characteristics and enhanced thermal management properties, enabling more efficient and precise laser processing for next-generation high-frequency electronic components.

Quality Control and Precision Measurement Techniques

Quality control and precision measurement are critical aspects of high-frequency electronics production using ultrafast lasers. The implementation of advanced metrology systems enables manufacturers to maintain exceptional standards throughout the production process. Laser-based measurement techniques provide non-contact, high-resolution inspection capabilities that can detect defects at the micro and nano scales, which is essential for high-frequency components where even minor imperfections can significantly impact performance.

Optical coherence tomography (OCT) has emerged as a powerful tool for quality assurance in ultrafast laser processing. This technique allows for real-time monitoring of material modifications during laser ablation, providing immediate feedback on process quality. The integration of OCT with ultrafast laser systems creates a closed-loop manufacturing environment where adjustments can be made instantaneously to maintain precision.

Interferometric measurement systems complement ultrafast laser manufacturing by offering sub-nanometer resolution for surface profiling. These systems are particularly valuable for verifying the dimensional accuracy of high-frequency waveguides and resonant structures where wavelength-scale precision is required. The data collected from interferometric measurements can be used to fine-tune laser parameters for optimal processing results.

Spectroscopic analysis techniques provide insights into the chemical composition and structural integrity of processed materials. By analyzing the spectral response of materials before and after laser processing, manufacturers can verify that no unwanted chemical changes or structural defects have been introduced. This is particularly important for high-frequency electronics where material purity and homogeneity directly influence signal propagation characteristics.

Machine vision systems equipped with high-resolution cameras and advanced image processing algorithms enable automated inspection of laser-processed components. These systems can detect surface irregularities, alignment errors, and other defects that might compromise the performance of high-frequency electronic devices. The integration of artificial intelligence enhances the capability of these systems to identify subtle patterns and anomalies that might escape human inspection.

In-situ monitoring technologies have revolutionized quality control in ultrafast laser processing by providing real-time feedback during the manufacturing process. Sensors that measure plasma emission, acoustic signals, and thermal signatures can detect process deviations before they result in defective components. This proactive approach to quality control significantly reduces waste and improves overall production efficiency.

Statistical process control methodologies applied to ultrafast laser manufacturing help maintain consistent quality across production batches. By continuously monitoring key process parameters and analyzing trends, manufacturers can identify and address potential issues before they affect product quality. This data-driven approach to quality management is essential for high-volume production of high-frequency electronic components.

Optical coherence tomography (OCT) has emerged as a powerful tool for quality assurance in ultrafast laser processing. This technique allows for real-time monitoring of material modifications during laser ablation, providing immediate feedback on process quality. The integration of OCT with ultrafast laser systems creates a closed-loop manufacturing environment where adjustments can be made instantaneously to maintain precision.

Interferometric measurement systems complement ultrafast laser manufacturing by offering sub-nanometer resolution for surface profiling. These systems are particularly valuable for verifying the dimensional accuracy of high-frequency waveguides and resonant structures where wavelength-scale precision is required. The data collected from interferometric measurements can be used to fine-tune laser parameters for optimal processing results.

Spectroscopic analysis techniques provide insights into the chemical composition and structural integrity of processed materials. By analyzing the spectral response of materials before and after laser processing, manufacturers can verify that no unwanted chemical changes or structural defects have been introduced. This is particularly important for high-frequency electronics where material purity and homogeneity directly influence signal propagation characteristics.

Machine vision systems equipped with high-resolution cameras and advanced image processing algorithms enable automated inspection of laser-processed components. These systems can detect surface irregularities, alignment errors, and other defects that might compromise the performance of high-frequency electronic devices. The integration of artificial intelligence enhances the capability of these systems to identify subtle patterns and anomalies that might escape human inspection.

In-situ monitoring technologies have revolutionized quality control in ultrafast laser processing by providing real-time feedback during the manufacturing process. Sensors that measure plasma emission, acoustic signals, and thermal signatures can detect process deviations before they result in defective components. This proactive approach to quality control significantly reduces waste and improves overall production efficiency.

Statistical process control methodologies applied to ultrafast laser manufacturing help maintain consistent quality across production batches. By continuously monitoring key process parameters and analyzing trends, manufacturers can identify and address potential issues before they affect product quality. This data-driven approach to quality management is essential for high-volume production of high-frequency electronic components.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!