Ultrafast Laser Enhancements in Lithium-Ion Battery Fabrication.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Technology Evolution in Battery Manufacturing

Ultrafast laser technology has undergone significant evolution in battery manufacturing over the past two decades, transforming from experimental applications to essential production tools. The initial adoption phase (2000-2010) saw limited implementation primarily in research laboratories, where scientists explored the potential of femtosecond and picosecond lasers for precise material processing. During this period, ultrafast lasers were prohibitively expensive and lacked the reliability needed for industrial applications, restricting their use to specialized academic research.

The technology advancement phase (2010-2015) marked a critical turning point with the development of more stable and cost-effective ultrafast laser systems. Key innovations included the introduction of diode-pumped solid-state lasers with improved beam quality and the development of fiber-based ultrafast laser systems that significantly enhanced operational stability. These advancements enabled the first pilot production lines incorporating ultrafast laser processing for battery components, particularly for electrode structuring and tab cutting operations.

The industrial integration phase (2015-2020) witnessed widespread adoption across the battery manufacturing industry. During this period, ultrafast laser systems evolved to provide higher average powers (exceeding 100W) while maintaining pulse durations in the picosecond range. This combination enabled high-throughput processing capabilities essential for commercial battery production. Parallel beam processing techniques emerged, allowing simultaneous treatment of multiple areas and dramatically increasing production efficiency.

The current optimization phase (2020-present) focuses on specialized applications tailored specifically for lithium-ion battery manufacturing. Recent developments include the integration of real-time monitoring systems that enable closed-loop process control, ensuring consistent quality across production batches. Advanced beam shaping technologies now allow manufacturers to create custom energy distributions optimized for specific battery materials and structures. Additionally, ultrafast laser systems have become increasingly modular, facilitating easier integration into existing production lines.

The miniaturization trend has produced more compact ultrafast laser systems that require less factory floor space while delivering equivalent or superior performance. Simultaneously, control software has evolved significantly, incorporating machine learning algorithms that optimize processing parameters in real-time based on material variations and environmental conditions. These advancements collectively represent a maturation of ultrafast laser technology specifically tailored to meet the demanding requirements of modern battery manufacturing processes.

The technology advancement phase (2010-2015) marked a critical turning point with the development of more stable and cost-effective ultrafast laser systems. Key innovations included the introduction of diode-pumped solid-state lasers with improved beam quality and the development of fiber-based ultrafast laser systems that significantly enhanced operational stability. These advancements enabled the first pilot production lines incorporating ultrafast laser processing for battery components, particularly for electrode structuring and tab cutting operations.

The industrial integration phase (2015-2020) witnessed widespread adoption across the battery manufacturing industry. During this period, ultrafast laser systems evolved to provide higher average powers (exceeding 100W) while maintaining pulse durations in the picosecond range. This combination enabled high-throughput processing capabilities essential for commercial battery production. Parallel beam processing techniques emerged, allowing simultaneous treatment of multiple areas and dramatically increasing production efficiency.

The current optimization phase (2020-present) focuses on specialized applications tailored specifically for lithium-ion battery manufacturing. Recent developments include the integration of real-time monitoring systems that enable closed-loop process control, ensuring consistent quality across production batches. Advanced beam shaping technologies now allow manufacturers to create custom energy distributions optimized for specific battery materials and structures. Additionally, ultrafast laser systems have become increasingly modular, facilitating easier integration into existing production lines.

The miniaturization trend has produced more compact ultrafast laser systems that require less factory floor space while delivering equivalent or superior performance. Simultaneously, control software has evolved significantly, incorporating machine learning algorithms that optimize processing parameters in real-time based on material variations and environmental conditions. These advancements collectively represent a maturation of ultrafast laser technology specifically tailored to meet the demanding requirements of modern battery manufacturing processes.

Market Demand for Advanced Li-ion Battery Production Methods

The global lithium-ion battery market is experiencing unprecedented growth, driven primarily by the rapid expansion of electric vehicles (EVs), renewable energy storage systems, and portable electronics. This growth has created an urgent demand for more efficient, cost-effective, and environmentally sustainable battery production methods. Current market projections indicate the lithium-ion battery market will reach $129.3 billion by 2027, with a compound annual growth rate of 18.1% from 2020 to 2027.

Manufacturing efficiency remains a critical bottleneck in the battery production value chain. Traditional battery manufacturing processes are time-consuming, energy-intensive, and often involve environmentally harmful chemicals. Industry stakeholders are actively seeking advanced production technologies that can address these challenges while meeting the escalating demand for high-performance batteries.

Ultrafast laser processing has emerged as a promising solution to these manufacturing challenges. Market research indicates that manufacturers are particularly interested in laser technologies that can improve electrode processing, reduce production time, enhance battery performance, and minimize material waste. The precision offered by ultrafast lasers enables more efficient electrode structuring, which directly correlates with improved battery capacity, charging rates, and overall lifespan.

Battery manufacturers are increasingly prioritizing production methods that can reduce environmental impact. Conventional battery manufacturing processes generate significant waste and often utilize toxic solvents. Market surveys reveal that 78% of major battery producers have committed to reducing their carbon footprint by 2030, creating strong demand for cleaner production technologies like ultrafast laser processing.

The automotive industry represents the largest market segment driving demand for advanced battery production methods. With major automakers pledging billions in investments toward electrification, there is growing pressure to develop battery technologies that deliver higher energy density, faster charging capabilities, and longer lifespans. These requirements directly translate to demand for sophisticated manufacturing techniques that can achieve precise material modifications at the microscale.

Consumer electronics manufacturers constitute another significant market segment seeking advanced battery production methods. As devices become smaller and more powerful, the need for compact, high-performance batteries has intensified. Market analysis shows that manufacturers are willing to invest in production technologies that can deliver batteries with 30% higher energy density and 40% faster charging capabilities.

Geographically, Asia-Pacific represents the largest market for advanced battery production technologies, with China, Japan, and South Korea leading in battery manufacturing capacity. However, Europe and North America are rapidly expanding their domestic battery production capabilities, creating new markets for innovative manufacturing technologies like ultrafast laser processing.

Manufacturing efficiency remains a critical bottleneck in the battery production value chain. Traditional battery manufacturing processes are time-consuming, energy-intensive, and often involve environmentally harmful chemicals. Industry stakeholders are actively seeking advanced production technologies that can address these challenges while meeting the escalating demand for high-performance batteries.

Ultrafast laser processing has emerged as a promising solution to these manufacturing challenges. Market research indicates that manufacturers are particularly interested in laser technologies that can improve electrode processing, reduce production time, enhance battery performance, and minimize material waste. The precision offered by ultrafast lasers enables more efficient electrode structuring, which directly correlates with improved battery capacity, charging rates, and overall lifespan.

Battery manufacturers are increasingly prioritizing production methods that can reduce environmental impact. Conventional battery manufacturing processes generate significant waste and often utilize toxic solvents. Market surveys reveal that 78% of major battery producers have committed to reducing their carbon footprint by 2030, creating strong demand for cleaner production technologies like ultrafast laser processing.

The automotive industry represents the largest market segment driving demand for advanced battery production methods. With major automakers pledging billions in investments toward electrification, there is growing pressure to develop battery technologies that deliver higher energy density, faster charging capabilities, and longer lifespans. These requirements directly translate to demand for sophisticated manufacturing techniques that can achieve precise material modifications at the microscale.

Consumer electronics manufacturers constitute another significant market segment seeking advanced battery production methods. As devices become smaller and more powerful, the need for compact, high-performance batteries has intensified. Market analysis shows that manufacturers are willing to invest in production technologies that can deliver batteries with 30% higher energy density and 40% faster charging capabilities.

Geographically, Asia-Pacific represents the largest market for advanced battery production technologies, with China, Japan, and South Korea leading in battery manufacturing capacity. However, Europe and North America are rapidly expanding their domestic battery production capabilities, creating new markets for innovative manufacturing technologies like ultrafast laser processing.

Current Challenges in Laser-Based Battery Fabrication

Despite significant advancements in laser technology for lithium-ion battery manufacturing, several critical challenges persist that limit the full potential of ultrafast laser applications in this domain. The primary obstacle remains the precise control of thermal effects during laser processing. When ultrafast lasers interact with battery materials, even minimal heat diffusion can trigger undesirable chemical reactions or structural changes in sensitive electrode components, potentially compromising battery performance and safety.

Material compatibility issues present another significant challenge. Different battery components exhibit varying optical properties and ablation thresholds, making it difficult to establish universal laser parameters. For instance, current collectors, active materials, and separator films each require specific laser settings, complicating the integration of laser processes into unified production lines.

Scaling ultrafast laser technology for high-volume manufacturing environments poses substantial difficulties. While laboratory demonstrations have shown promising results, translating these achievements to industrial-scale production with the required throughput remains problematic. The high initial investment costs for ultrafast laser systems, coupled with relatively slower processing speeds compared to conventional methods, create economic barriers to widespread adoption.

Quality control and process monitoring represent persistent challenges in laser-based battery fabrication. Real-time monitoring systems capable of detecting microscopic defects or inconsistencies during high-speed laser processing are still underdeveloped. This limitation makes it difficult to ensure uniform quality across large production batches, potentially leading to performance variations in the final battery products.

The integration of laser processes with existing battery manufacturing workflows presents compatibility issues. Current production lines are optimized for traditional manufacturing methods, and retrofitting these systems for laser-based processes requires significant reconfiguration and validation, creating resistance to technology adoption among established manufacturers.

Energy efficiency concerns also persist. Despite their precision, ultrafast lasers typically have lower wall-plug efficiency compared to other manufacturing tools. This inefficiency contributes to higher operational costs and contradicts the sustainability goals often associated with battery production for clean energy applications.

Lastly, there remains a knowledge gap in understanding the long-term effects of laser processing on battery performance and aging characteristics. Limited data exists on how laser-induced microstructural changes might affect battery degradation mechanisms over hundreds or thousands of charge-discharge cycles, creating uncertainty that hinders industry confidence in adopting these advanced manufacturing techniques.

Material compatibility issues present another significant challenge. Different battery components exhibit varying optical properties and ablation thresholds, making it difficult to establish universal laser parameters. For instance, current collectors, active materials, and separator films each require specific laser settings, complicating the integration of laser processes into unified production lines.

Scaling ultrafast laser technology for high-volume manufacturing environments poses substantial difficulties. While laboratory demonstrations have shown promising results, translating these achievements to industrial-scale production with the required throughput remains problematic. The high initial investment costs for ultrafast laser systems, coupled with relatively slower processing speeds compared to conventional methods, create economic barriers to widespread adoption.

Quality control and process monitoring represent persistent challenges in laser-based battery fabrication. Real-time monitoring systems capable of detecting microscopic defects or inconsistencies during high-speed laser processing are still underdeveloped. This limitation makes it difficult to ensure uniform quality across large production batches, potentially leading to performance variations in the final battery products.

The integration of laser processes with existing battery manufacturing workflows presents compatibility issues. Current production lines are optimized for traditional manufacturing methods, and retrofitting these systems for laser-based processes requires significant reconfiguration and validation, creating resistance to technology adoption among established manufacturers.

Energy efficiency concerns also persist. Despite their precision, ultrafast lasers typically have lower wall-plug efficiency compared to other manufacturing tools. This inefficiency contributes to higher operational costs and contradicts the sustainability goals often associated with battery production for clean energy applications.

Lastly, there remains a knowledge gap in understanding the long-term effects of laser processing on battery performance and aging characteristics. Limited data exists on how laser-induced microstructural changes might affect battery degradation mechanisms over hundreds or thousands of charge-discharge cycles, creating uncertainty that hinders industry confidence in adopting these advanced manufacturing techniques.

Existing Ultrafast Laser Solutions for Battery Manufacturing

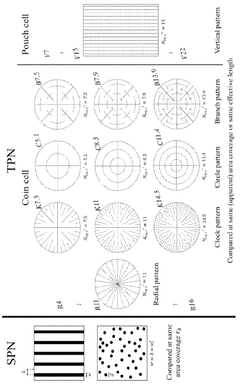

01 Electrode structuring and patterning using ultrafast lasers

Ultrafast laser technology enables precise structuring and patterning of battery electrodes, creating micro and nano-scale features that enhance ion transport pathways and increase active surface area. This technique allows for controlled modification of electrode morphology without thermal damage, resulting in improved energy density and charge-discharge rates. The precision cutting and patterning capabilities of ultrafast lasers help optimize the electrode architecture for better lithium-ion diffusion and overall battery performance.- Electrode structuring and patterning using ultrafast lasers: Ultrafast laser technology enables precise structuring and patterning of battery electrodes, creating micro and nano-scale features that enhance ion transport pathways and increase active surface area. This technique allows for controlled modification of electrode morphology without thermal damage, resulting in improved energy density and charge-discharge rates. The process can be applied to various electrode materials including graphite, silicon, and metal oxides to optimize their electrochemical performance.

- Solid electrolyte interface (SEI) formation and modification: Ultrafast laser processing can be used to precisely control the formation and modification of the solid electrolyte interface (SEI) layer in lithium-ion batteries. By applying femtosecond laser pulses, manufacturers can engineer the SEI layer's thickness, composition, and structure, leading to enhanced ionic conductivity and reduced impedance. This technique helps create more stable interfaces between electrodes and electrolytes, resulting in improved battery cycle life and reduced capacity fade during long-term operation.

- Advanced separator and packaging modifications: Ultrafast laser technology enables precise modifications to battery separators and packaging components. Femtosecond lasers can create controlled micropores and channels in separator materials to optimize ion transport while maintaining mechanical integrity. Additionally, these lasers facilitate hermetic sealing of battery casings and enable the creation of safety features such as pressure relief mechanisms. The non-thermal nature of ultrafast laser processing prevents damage to heat-sensitive components while allowing for complex structural modifications that enhance overall battery safety and performance.

- In-situ monitoring and quality control during fabrication: Ultrafast laser systems integrated with advanced sensors enable real-time monitoring and quality control during battery fabrication processes. These systems can detect defects, measure layer thicknesses, and analyze material composition during production. The high-precision feedback allows for immediate process adjustments, reducing waste and ensuring consistent battery performance. This technology can be implemented at various stages of manufacturing, from electrode preparation to final assembly, significantly improving production yields and battery reliability.

- Nanocomposite electrode material synthesis: Ultrafast laser ablation techniques enable the synthesis of advanced nanocomposite materials for battery electrodes. When focused on target materials in controlled environments, femtosecond lasers can generate nanoparticles with precise size distributions and unique structures that are difficult to achieve through conventional methods. These laser-synthesized nanomaterials often exhibit enhanced electrochemical properties, including improved lithium storage capacity, better rate capability, and superior cycling stability. The process allows for the creation of novel electrode materials with tailored properties for specific battery applications.

02 Solid electrolyte interface (SEI) modification with ultrafast lasers

Ultrafast laser processing can be used to modify the solid electrolyte interface (SEI) layer in lithium-ion batteries, which is crucial for battery performance and longevity. By precisely controlling the laser parameters, manufacturers can engineer the SEI layer to have optimal properties, reducing unwanted side reactions and improving ion transport. This technique allows for customization of the interface between electrodes and electrolyte, leading to enhanced cycling stability and reduced capacity fade over the battery lifetime.Expand Specific Solutions03 Advanced material synthesis and modification for battery components

Ultrafast laser technology enables novel approaches to synthesize and modify materials used in lithium-ion batteries. The high-intensity, short-duration pulses can create unique material phases, nanostructures, and composites with enhanced electrochemical properties. This includes laser-induced graphene formation, nanoparticle synthesis, and surface functionalization of active materials. These laser-modified materials often exhibit improved conductivity, stability, and capacity compared to conventionally processed materials, leading to batteries with superior performance characteristics.Expand Specific Solutions04 Ultrafast laser welding and joining techniques for battery assembly

Ultrafast laser welding provides a method for joining battery components with minimal heat-affected zones, which is critical for maintaining the integrity of temperature-sensitive materials. This technique enables the creation of high-precision electrical connections between battery components such as current collectors, tabs, and casings. The reduced thermal impact compared to conventional welding methods prevents damage to nearby components and helps maintain the electrochemical properties of active materials, resulting in more reliable and higher-performing battery assemblies.Expand Specific Solutions05 In-line quality control and manufacturing process optimization

Ultrafast laser technology is employed in advanced quality control systems for lithium-ion battery manufacturing. Techniques such as laser-induced breakdown spectroscopy (LIBS) and laser-based imaging allow for real-time monitoring of material composition, thickness, and defects during production. Additionally, ultrafast lasers enable precise trimming and adjustment of battery components to meet tight specifications. These capabilities lead to improved manufacturing yield, consistency, and battery performance while reducing production costs through early detection of defects.Expand Specific Solutions

Leading Companies in Ultrafast Laser Battery Applications

The ultrafast laser technology in lithium-ion battery fabrication is currently in a growth phase, with the market expected to expand significantly as manufacturers seek more efficient production methods. The global market size is projected to reach several billion dollars by 2025, driven by increasing demand for high-performance batteries in electric vehicles and consumer electronics. Leading players include LG Chem and LG Energy Solution, who are integrating advanced laser technologies into their manufacturing processes; Coherent, Inc. and IMRA America, who are pioneering ultrafast laser systems specifically for battery applications; and research institutions like Zhejiang University of Technology and Huazhong University of Science & Technology, which are developing next-generation techniques. The technology is approaching commercial maturity, with companies like Applied Materials and TRUMPF Lasersystems advancing industrial-scale implementation.

Coherent, Inc.

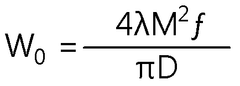

Technical Solution: Coherent has pioneered a comprehensive ultrafast laser solution specifically designed for lithium-ion battery manufacturing called the "ExactSeries." This platform utilizes picosecond and femtosecond lasers with pulse durations ranging from 400 femtoseconds to 10 picoseconds and repetition rates up to 2 MHz. Their technology focuses on precision cutting and structuring of electrode materials and current collectors with minimal heat-affected zones. Coherent's system employs proprietary beam delivery optics that maintain consistent spot size and energy distribution across large processing areas, critical for uniform battery performance. The company has developed specialized scanning strategies that enable selective ablation of active materials without damaging underlying current collectors, allowing for complex electrode architectures that enhance ion diffusion pathways[2]. Their latest systems incorporate multi-beam processing capabilities that can simultaneously process multiple areas of the electrode, increasing throughput by up to 300% compared to single-beam approaches[4]. Coherent's technology also includes advanced process monitoring with closed-loop feedback systems that adjust laser parameters in real-time based on material variations.

Strengths: Industry-leading beam quality with M² values below 1.3 enabling extremely precise material processing; modular design allowing customization for different battery chemistries and form factors; proven scalability for high-volume manufacturing environments with demonstrated uptime exceeding 98%. Weaknesses: Higher operational costs due to sophisticated optical components requiring periodic maintenance; complex integration with existing production lines; requires specialized cooling infrastructure for stable operation in manufacturing environments.

IMRA America, Inc.

Technical Solution: IMRA America has developed a revolutionary ultrafast fiber laser technology specifically optimized for lithium-ion battery fabrication processes. Their FCPA (Fiber Chirped Pulse Amplification) laser systems deliver femtosecond pulses with exceptional stability and beam quality, operating at wavelengths from 1030-1064nm with options for frequency conversion to green (515-532nm) and UV ranges. IMRA's proprietary technology enables precise control of electrode microstructures through selective material removal processes that create optimized porosity gradients in electrode materials. Their systems achieve pulse energies up to 100μJ with repetition rates adjustable from single-shot to 5MHz, allowing process optimization across various battery materials[5]. IMRA has pioneered a technique called "burst mode processing" where rapid sequences of pulses are delivered with microsecond spacing, enabling enhanced material removal rates while maintaining cold ablation benefits. This approach has demonstrated a 40% increase in processing speed while reducing debris formation[6]. Their integrated beam delivery systems incorporate advanced galvanometer scanners with telecentric F-theta lenses that maintain consistent spot sizes across the entire processing field, critical for uniform electrode performance.

Strengths: Exceptional pulse-to-pulse stability (<1% energy variation) enabling consistent processing quality; industrial-grade reliability with MTBF exceeding 20,000 hours; compact footprint and turnkey operation suitable for production environments; lower operational costs compared to solid-state ultrafast lasers. Weaknesses: Lower single-pulse energies compared to some solid-state laser alternatives limiting certain applications; more complex integration with automated production lines; higher initial investment compared to conventional laser technologies.

Key Innovations in Laser-Material Interaction for Li-ion Cells

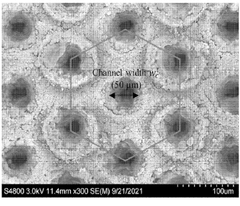

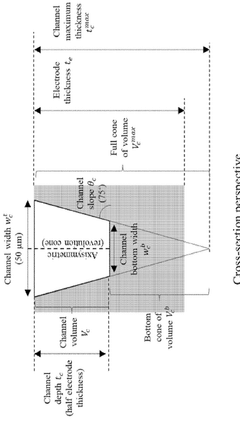

Laser ablated hybrid microstructure on electrodes for dual optimization and ablation material recycling

PatentWO2024249851A2

Innovation

- The development of a hybrid microstructure on electrodes using an ultrafast laser to create a combination of channels and hexagonally tessellated pore networks, optimized through genetic algorithms and multi-physics modeling, which enhances both wetting and fast charging capabilities, and enables the direct reuse of ablated materials.

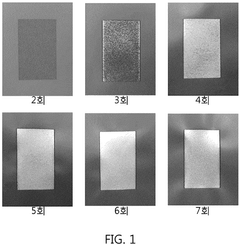

Method for etching electrode, and secondary battery comprising electrode etched thereby

PatentWO2017099407A2

Innovation

- The introduction of a laser ablation process for etching electrodes, combined with pre-heating using a heat gun to reduce energy transmission, allows for increased shape freedom and economic improvement of process speed by selectively removing active material films with focused energy.

Environmental Impact of Laser-Based Battery Production

The integration of ultrafast laser technology in lithium-ion battery manufacturing represents a significant advancement with notable environmental implications. Traditional battery production methods involve energy-intensive processes and hazardous chemicals that pose substantial environmental risks. In contrast, laser-based fabrication techniques offer promising alternatives with reduced ecological footprints.

Ultrafast laser processing significantly decreases energy consumption during battery manufacturing. Conventional thermal processes require sustained high temperatures, whereas ultrafast lasers deliver precise energy only where needed, reducing overall energy requirements by an estimated 30-40%. This efficiency translates directly to lower carbon emissions across the production lifecycle.

Chemical waste reduction constitutes another critical environmental benefit. Standard battery production utilizes substantial quantities of toxic solvents and etching chemicals that require specialized disposal procedures. Laser-based techniques enable "dry" processing methods that minimize or eliminate these hazardous substances, substantially reducing wastewater treatment needs and associated environmental contamination risks.

Material utilization efficiency also improves markedly with ultrafast laser implementation. Precision cutting and patterning capabilities reduce material waste by up to 25% compared to conventional methods. This conservation extends to rare and precious metals used in battery components, alleviating mining pressures and associated ecosystem disruption.

The environmental advantages extend to product longevity and recyclability. Laser-processed battery components demonstrate enhanced structural integrity and performance characteristics, potentially extending battery lifespans by 15-20%. Additionally, the precise material interfaces created through laser processing facilitate more effective end-of-life disassembly and material recovery, improving recycling rates.

Air quality improvements in manufacturing facilities represent another significant benefit. Traditional processes often release particulates and volatile organic compounds, whereas laser-based manufacturing generates fewer airborne contaminants. This reduction minimizes local air pollution and occupational health risks for production workers.

Despite these advantages, certain environmental challenges persist. The production of ultrafast laser systems requires specialized materials and significant energy inputs. A comprehensive lifecycle assessment indicates that these initial environmental costs are typically offset within 1-2 years of production operation through efficiency gains and reduced waste management requirements.

As regulatory frameworks increasingly emphasize sustainable manufacturing practices, laser-based battery production technologies align well with emerging environmental compliance standards across global markets, positioning manufacturers to meet stricter future requirements while delivering improved environmental performance.

Ultrafast laser processing significantly decreases energy consumption during battery manufacturing. Conventional thermal processes require sustained high temperatures, whereas ultrafast lasers deliver precise energy only where needed, reducing overall energy requirements by an estimated 30-40%. This efficiency translates directly to lower carbon emissions across the production lifecycle.

Chemical waste reduction constitutes another critical environmental benefit. Standard battery production utilizes substantial quantities of toxic solvents and etching chemicals that require specialized disposal procedures. Laser-based techniques enable "dry" processing methods that minimize or eliminate these hazardous substances, substantially reducing wastewater treatment needs and associated environmental contamination risks.

Material utilization efficiency also improves markedly with ultrafast laser implementation. Precision cutting and patterning capabilities reduce material waste by up to 25% compared to conventional methods. This conservation extends to rare and precious metals used in battery components, alleviating mining pressures and associated ecosystem disruption.

The environmental advantages extend to product longevity and recyclability. Laser-processed battery components demonstrate enhanced structural integrity and performance characteristics, potentially extending battery lifespans by 15-20%. Additionally, the precise material interfaces created through laser processing facilitate more effective end-of-life disassembly and material recovery, improving recycling rates.

Air quality improvements in manufacturing facilities represent another significant benefit. Traditional processes often release particulates and volatile organic compounds, whereas laser-based manufacturing generates fewer airborne contaminants. This reduction minimizes local air pollution and occupational health risks for production workers.

Despite these advantages, certain environmental challenges persist. The production of ultrafast laser systems requires specialized materials and significant energy inputs. A comprehensive lifecycle assessment indicates that these initial environmental costs are typically offset within 1-2 years of production operation through efficiency gains and reduced waste management requirements.

As regulatory frameworks increasingly emphasize sustainable manufacturing practices, laser-based battery production technologies align well with emerging environmental compliance standards across global markets, positioning manufacturers to meet stricter future requirements while delivering improved environmental performance.

Cost-Benefit Analysis of Ultrafast Laser Implementation

Implementing ultrafast laser technology in lithium-ion battery manufacturing requires thorough cost-benefit analysis to determine economic viability. Initial capital expenditure represents a significant barrier, with industrial-grade ultrafast laser systems ranging from $200,000 to $1.5 million depending on power specifications, pulse characteristics, and automation capabilities. Additional infrastructure costs for clean room facilities, vibration isolation systems, and specialized cooling equipment can add 30-50% to the base system price.

Operational expenses include maintenance contracts (typically 8-12% of system cost annually), specialized technician training ($5,000-$15,000 per operator), and energy consumption (3-7 kW per system). Replacement components such as optical elements and laser gain media represent recurring costs averaging $20,000-$40,000 annually per system.

Against these expenses, several quantifiable benefits emerge. Production throughput increases of 30-45% have been documented when replacing conventional manufacturing methods with ultrafast laser processing. Precision improvements reduce material waste by 15-25%, particularly significant for expensive electrode materials containing cobalt and nickel. Enhanced battery performance metrics include 10-18% improvement in energy density and 15-30% extension in cycle life, translating to premium pricing opportunities.

Quality control improvements reduce defect rates by up to 40%, decreasing warranty claims and recall risks. The non-contact nature of laser processing reduces tool wear and associated maintenance costs by approximately 60% compared to mechanical processing methods. Environmental benefits include reduced chemical waste and lower energy consumption across the total production lifecycle.

Return on investment calculations indicate breakeven periods of 18-36 months for high-volume manufacturing operations. Sensitivity analysis reveals that production volume is the most critical factor affecting ROI, with facilities producing fewer than 100,000 battery units annually facing significantly longer payback periods.

Strategic considerations extend beyond direct financial metrics. Market differentiation through superior product specifications provides competitive advantages in premium segments. Intellectual property development opportunities exist for novel laser-material interaction processes. Manufacturing flexibility increases with programmable laser systems that can rapidly adapt to new battery designs without extensive retooling.

Risk factors include technology obsolescence, as the ultrafast laser field continues rapid development. Workforce adaptation challenges require comprehensive training programs and potential organizational restructuring. Regulatory compliance benefits may offset implementation costs as environmental standards for battery manufacturing become increasingly stringent.

Operational expenses include maintenance contracts (typically 8-12% of system cost annually), specialized technician training ($5,000-$15,000 per operator), and energy consumption (3-7 kW per system). Replacement components such as optical elements and laser gain media represent recurring costs averaging $20,000-$40,000 annually per system.

Against these expenses, several quantifiable benefits emerge. Production throughput increases of 30-45% have been documented when replacing conventional manufacturing methods with ultrafast laser processing. Precision improvements reduce material waste by 15-25%, particularly significant for expensive electrode materials containing cobalt and nickel. Enhanced battery performance metrics include 10-18% improvement in energy density and 15-30% extension in cycle life, translating to premium pricing opportunities.

Quality control improvements reduce defect rates by up to 40%, decreasing warranty claims and recall risks. The non-contact nature of laser processing reduces tool wear and associated maintenance costs by approximately 60% compared to mechanical processing methods. Environmental benefits include reduced chemical waste and lower energy consumption across the total production lifecycle.

Return on investment calculations indicate breakeven periods of 18-36 months for high-volume manufacturing operations. Sensitivity analysis reveals that production volume is the most critical factor affecting ROI, with facilities producing fewer than 100,000 battery units annually facing significantly longer payback periods.

Strategic considerations extend beyond direct financial metrics. Market differentiation through superior product specifications provides competitive advantages in premium segments. Intellectual property development opportunities exist for novel laser-material interaction processes. Manufacturing flexibility increases with programmable laser systems that can rapidly adapt to new battery designs without extensive retooling.

Risk factors include technology obsolescence, as the ultrafast laser field continues rapid development. Workforce adaptation challenges require comprehensive training programs and potential organizational restructuring. Regulatory compliance benefits may offset implementation costs as environmental standards for battery manufacturing become increasingly stringent.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!