How Ultrafast Lasers Facilitate Advanced Wear-Resistant Coatings.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Coating Technology Background and Objectives

Ultrafast laser technology has evolved significantly over the past three decades, transforming from laboratory curiosities to essential industrial tools. The journey began in the 1980s with the development of femtosecond lasers, which have since revolutionized material processing capabilities. These lasers operate with pulse durations in the femtosecond to picosecond range, allowing for unprecedented precision in material interaction without the thermal damage associated with conventional laser systems.

The application of ultrafast lasers in wear-resistant coating technology represents a convergence of advanced photonics and materials science. Traditional coating methods such as physical vapor deposition (PVD), chemical vapor deposition (CVD), and thermal spraying have limitations in terms of coating adhesion, uniformity, and the ability to process heat-sensitive substrates. Ultrafast laser technology offers solutions to these challenges through precise energy delivery mechanisms.

The technical evolution trajectory shows a clear progression from basic material ablation applications to sophisticated surface engineering techniques. Early applications focused on simple material removal, while current implementations enable complex surface texturing, nanoparticle generation, and controlled modification of surface chemistry. This progression has been driven by advances in laser stability, beam quality, and increasing average powers while maintaining ultrashort pulse characteristics.

The primary objective in this field is to develop coating processes that significantly enhance wear resistance while maintaining or improving other critical properties such as corrosion resistance, thermal stability, and mechanical performance. Specifically, the industry aims to achieve coating solutions that extend component lifetimes by factors of 5-10x in extreme operating environments, particularly for applications in aerospace, automotive, and manufacturing sectors.

Current research goals include developing ultrafast laser-based processes that can create multi-functional coatings with hierarchical structures spanning from nano to microscale. These structures aim to simultaneously address multiple wear mechanisms including abrasion, adhesion, erosion, and fatigue wear. Additionally, there is significant focus on making these advanced coating technologies economically viable for mass production environments.

The technological trajectory is moving toward hybrid approaches that combine ultrafast laser surface preparation with subsequent coating deposition techniques. This synergistic approach leverages the unique capabilities of ultrafast lasers to create optimized interfaces and surface structures that enhance coating adhesion and performance. The ultimate goal is to establish standardized processes that can be readily implemented across various industrial sectors, providing consistent and predictable performance improvements.

The application of ultrafast lasers in wear-resistant coating technology represents a convergence of advanced photonics and materials science. Traditional coating methods such as physical vapor deposition (PVD), chemical vapor deposition (CVD), and thermal spraying have limitations in terms of coating adhesion, uniformity, and the ability to process heat-sensitive substrates. Ultrafast laser technology offers solutions to these challenges through precise energy delivery mechanisms.

The technical evolution trajectory shows a clear progression from basic material ablation applications to sophisticated surface engineering techniques. Early applications focused on simple material removal, while current implementations enable complex surface texturing, nanoparticle generation, and controlled modification of surface chemistry. This progression has been driven by advances in laser stability, beam quality, and increasing average powers while maintaining ultrashort pulse characteristics.

The primary objective in this field is to develop coating processes that significantly enhance wear resistance while maintaining or improving other critical properties such as corrosion resistance, thermal stability, and mechanical performance. Specifically, the industry aims to achieve coating solutions that extend component lifetimes by factors of 5-10x in extreme operating environments, particularly for applications in aerospace, automotive, and manufacturing sectors.

Current research goals include developing ultrafast laser-based processes that can create multi-functional coatings with hierarchical structures spanning from nano to microscale. These structures aim to simultaneously address multiple wear mechanisms including abrasion, adhesion, erosion, and fatigue wear. Additionally, there is significant focus on making these advanced coating technologies economically viable for mass production environments.

The technological trajectory is moving toward hybrid approaches that combine ultrafast laser surface preparation with subsequent coating deposition techniques. This synergistic approach leverages the unique capabilities of ultrafast lasers to create optimized interfaces and surface structures that enhance coating adhesion and performance. The ultimate goal is to establish standardized processes that can be readily implemented across various industrial sectors, providing consistent and predictable performance improvements.

Market Demand Analysis for Advanced Wear-Resistant Coatings

The global market for advanced wear-resistant coatings has experienced significant growth in recent years, driven by increasing demands across multiple industrial sectors. The automotive industry represents one of the largest markets, where these coatings are essential for extending the lifespan of engine components, reducing friction, and improving fuel efficiency. According to market research, the automotive coating segment alone is projected to grow at a compound annual growth rate of 6.2% through 2028.

Aerospace applications constitute another critical market segment, where ultrafast laser-facilitated coatings provide exceptional protection against extreme temperatures, corrosion, and mechanical wear. The aerospace coating market is particularly focused on solutions that can reduce maintenance frequency and extend component life while meeting stringent safety regulations.

Manufacturing and machining industries demonstrate strong demand for advanced wear-resistant coatings to enhance tool performance and longevity. Cutting tools, dies, and molds treated with ultrafast laser-facilitated coatings show dramatically improved service life, sometimes exceeding 300% compared to uncoated tools. This translates directly to reduced downtime and lower operational costs, making the value proposition particularly compelling.

The medical device industry represents an emerging but rapidly growing market segment. Surgical instruments, implants, and diagnostic equipment benefit from wear-resistant coatings that offer both durability and biocompatibility. The medical coating market segment is expected to grow substantially as aging populations worldwide drive increased demand for implantable devices.

Energy sector applications, particularly in oil and gas extraction and renewable energy systems, show increasing adoption of advanced wear-resistant coatings. Components operating in harsh environments with exposure to abrasive materials, high temperatures, and corrosive substances require exceptional protection to maintain operational integrity.

Consumer electronics manufacturers are increasingly incorporating wear-resistant coatings in high-touch components and displays. This market segment values coatings that can provide both functional protection and aesthetic qualities, with particular emphasis on scratch resistance and tactile properties.

Market analysis indicates that the global advanced wear-resistant coating market is consolidating around solutions that offer multiple performance benefits simultaneously: wear resistance combined with corrosion protection, thermal stability, and reduced friction. Ultrafast laser-facilitated coatings are uniquely positioned to address these complex requirements through precise material modification at the micro and nano scales.

Geographically, North America and Europe currently lead in adoption, but the Asia-Pacific region shows the highest growth rate, driven by rapid industrialization and manufacturing expansion in China, India, and Southeast Asian countries.

Aerospace applications constitute another critical market segment, where ultrafast laser-facilitated coatings provide exceptional protection against extreme temperatures, corrosion, and mechanical wear. The aerospace coating market is particularly focused on solutions that can reduce maintenance frequency and extend component life while meeting stringent safety regulations.

Manufacturing and machining industries demonstrate strong demand for advanced wear-resistant coatings to enhance tool performance and longevity. Cutting tools, dies, and molds treated with ultrafast laser-facilitated coatings show dramatically improved service life, sometimes exceeding 300% compared to uncoated tools. This translates directly to reduced downtime and lower operational costs, making the value proposition particularly compelling.

The medical device industry represents an emerging but rapidly growing market segment. Surgical instruments, implants, and diagnostic equipment benefit from wear-resistant coatings that offer both durability and biocompatibility. The medical coating market segment is expected to grow substantially as aging populations worldwide drive increased demand for implantable devices.

Energy sector applications, particularly in oil and gas extraction and renewable energy systems, show increasing adoption of advanced wear-resistant coatings. Components operating in harsh environments with exposure to abrasive materials, high temperatures, and corrosive substances require exceptional protection to maintain operational integrity.

Consumer electronics manufacturers are increasingly incorporating wear-resistant coatings in high-touch components and displays. This market segment values coatings that can provide both functional protection and aesthetic qualities, with particular emphasis on scratch resistance and tactile properties.

Market analysis indicates that the global advanced wear-resistant coating market is consolidating around solutions that offer multiple performance benefits simultaneously: wear resistance combined with corrosion protection, thermal stability, and reduced friction. Ultrafast laser-facilitated coatings are uniquely positioned to address these complex requirements through precise material modification at the micro and nano scales.

Geographically, North America and Europe currently lead in adoption, but the Asia-Pacific region shows the highest growth rate, driven by rapid industrialization and manufacturing expansion in China, India, and Southeast Asian countries.

Current State and Challenges in Ultrafast Laser Surface Engineering

Ultrafast laser surface engineering has witnessed significant advancements globally, with research centers across North America, Europe, and Asia making substantial contributions. The current state of this technology demonstrates remarkable capabilities in creating wear-resistant coatings with unprecedented precision and material properties. Leading research institutions such as MIT, Fraunhofer Institute, and the Chinese Academy of Sciences have established dedicated facilities for ultrafast laser processing, indicating the technology's strategic importance.

Despite these advancements, several technical challenges persist in the widespread industrial adoption of ultrafast laser-facilitated wear-resistant coatings. The primary limitation remains the processing speed, with current systems typically operating at rates insufficient for high-volume manufacturing environments. Even the most advanced systems struggle to achieve processing speeds beyond a few square centimeters per minute for complex surface patterns, creating a significant bottleneck for industrial-scale implementation.

Energy efficiency represents another major challenge, as ultrafast laser systems typically operate at 10-20% wall-plug efficiency. This inefficiency translates to high operational costs and substantial cooling requirements, limiting their deployment in energy-conscious manufacturing settings. The high initial capital investment for ultrafast laser equipment—often exceeding $500,000 for industrial-grade systems—further restricts adoption to large corporations and specialized research facilities.

Material-specific challenges also exist, particularly when processing certain ceramics, superalloys, and composite materials critical for advanced wear applications. These materials often exhibit unpredictable ablation thresholds and heat-affected zone characteristics when subjected to ultrafast laser processing. Additionally, the complex physics of ultrafast laser-material interactions remains incompletely understood, especially regarding the formation of unique nanostructures that contribute to enhanced wear resistance.

Quality control and process monitoring represent significant technical hurdles. Current in-situ monitoring technologies lack the temporal resolution necessary to provide real-time feedback during ultrafast laser processing, making it difficult to ensure consistent coating quality across large surface areas. The absence of standardized testing protocols for ultrafast laser-produced coatings further complicates quality assurance and industry adoption.

Geographical disparities in technology access are evident, with advanced ultrafast laser surface engineering capabilities concentrated in developed economies. This concentration creates barriers to global technology diffusion and implementation. Furthermore, the interdisciplinary nature of the field requires expertise spanning materials science, laser physics, and surface engineering—a combination that remains scarce in the current workforce, creating a human resource challenge that limits broader implementation.

Despite these advancements, several technical challenges persist in the widespread industrial adoption of ultrafast laser-facilitated wear-resistant coatings. The primary limitation remains the processing speed, with current systems typically operating at rates insufficient for high-volume manufacturing environments. Even the most advanced systems struggle to achieve processing speeds beyond a few square centimeters per minute for complex surface patterns, creating a significant bottleneck for industrial-scale implementation.

Energy efficiency represents another major challenge, as ultrafast laser systems typically operate at 10-20% wall-plug efficiency. This inefficiency translates to high operational costs and substantial cooling requirements, limiting their deployment in energy-conscious manufacturing settings. The high initial capital investment for ultrafast laser equipment—often exceeding $500,000 for industrial-grade systems—further restricts adoption to large corporations and specialized research facilities.

Material-specific challenges also exist, particularly when processing certain ceramics, superalloys, and composite materials critical for advanced wear applications. These materials often exhibit unpredictable ablation thresholds and heat-affected zone characteristics when subjected to ultrafast laser processing. Additionally, the complex physics of ultrafast laser-material interactions remains incompletely understood, especially regarding the formation of unique nanostructures that contribute to enhanced wear resistance.

Quality control and process monitoring represent significant technical hurdles. Current in-situ monitoring technologies lack the temporal resolution necessary to provide real-time feedback during ultrafast laser processing, making it difficult to ensure consistent coating quality across large surface areas. The absence of standardized testing protocols for ultrafast laser-produced coatings further complicates quality assurance and industry adoption.

Geographical disparities in technology access are evident, with advanced ultrafast laser surface engineering capabilities concentrated in developed economies. This concentration creates barriers to global technology diffusion and implementation. Furthermore, the interdisciplinary nature of the field requires expertise spanning materials science, laser physics, and surface engineering—a combination that remains scarce in the current workforce, creating a human resource challenge that limits broader implementation.

Current Ultrafast Laser Coating Technical Solutions

01 Ultrafast laser deposition techniques for wear-resistant coatings

Ultrafast lasers are used in advanced deposition techniques to create wear-resistant coatings with superior properties. These techniques include pulsed laser deposition (PLD) and femtosecond laser deposition, which allow for precise control over coating thickness and composition. The extremely short pulse duration of ultrafast lasers minimizes heat-affected zones and enables the deposition of high-quality coatings with excellent adhesion to the substrate. These methods can produce nanostructured coatings with enhanced hardness and wear resistance.- Ultrafast laser deposition techniques for wear-resistant coatings: Ultrafast lasers are used for depositing wear-resistant coatings through techniques such as pulsed laser deposition (PLD) and laser ablation. These methods allow for precise control over coating thickness and composition, resulting in high-quality wear-resistant layers. The ultrashort pulses minimize heat-affected zones and enable the deposition of complex materials including ceramics, diamond-like carbon, and metal alloys with enhanced hardness and durability.

- Surface texturing and microstructure modification using ultrafast lasers: Ultrafast lasers can create specific surface textures and microstructures that enhance wear resistance. By generating controlled patterns, micro-dimples, or ripple structures on coating surfaces, these modifications improve tribological properties by reducing friction, enhancing lubrication retention, and distributing contact stresses. The precise nature of ultrafast laser processing allows for customization of surface features at micro and nano scales without compromising the bulk material properties.

- Multi-layer and composite coatings produced with ultrafast laser assistance: Advanced wear-resistant coatings often utilize multi-layer or composite structures that can be precisely engineered using ultrafast laser technologies. These layered systems combine different materials to achieve superior wear resistance through complementary properties. The ultrafast laser processing enables the creation of gradient interfaces between layers, improving adhesion and reducing delamination risks. Such composite structures can be tailored to specific wear conditions by optimizing the composition and thickness of each layer.

- Ultrafast laser surface hardening and transformation: Ultrafast lasers can induce rapid thermal cycles that transform the surface microstructure of materials, creating wear-resistant phases without affecting the bulk properties. This process involves extremely quick heating and cooling rates that produce unique microstructures not achievable through conventional heat treatment methods. The resulting surfaces exhibit enhanced hardness, improved wear resistance, and better fatigue properties while maintaining the toughness of the underlying material.

- Novel coating materials and compositions optimized for ultrafast laser processing: Research has led to the development of specialized coating materials specifically designed to be processed with ultrafast lasers for maximum wear resistance. These materials include nanocomposites, metastable phases, and advanced ceramic formulations that exhibit exceptional hardness and durability when deposited or modified using ultrafast laser techniques. The unique interaction between ultrafast laser pulses and these materials creates structures with optimized grain size, density, and phase composition that significantly enhance wear performance.

02 Surface texturing and modification using ultrafast lasers

Ultrafast lasers can be used to create specific surface textures and modifications that enhance the wear resistance of coatings. The high-intensity, short-duration pulses can generate micro and nano-scale patterns on surfaces that reduce friction and improve tribological properties. This surface engineering approach can create hydrophobic or oleophobic surfaces that resist contamination and wear. The precise control offered by ultrafast lasers allows for customized surface structures tailored to specific wear conditions and environments.Expand Specific Solutions03 Multi-layer and composite coatings produced with ultrafast laser processing

Ultrafast laser processing enables the creation of multi-layer and composite wear-resistant coatings with gradient properties. These coatings combine different materials to achieve optimal performance characteristics, such as a hard outer layer for wear resistance with a more ductile underlayer for impact resistance. The precise energy control of ultrafast lasers allows for the formation of unique microstructures and interfaces between layers that would not be possible with conventional coating methods. These composite structures can significantly extend the service life of components exposed to severe wear conditions.Expand Specific Solutions04 Ultrafast laser-induced phase transformations for enhanced hardness

Ultrafast lasers can induce rapid phase transformations in materials to create wear-resistant coatings with enhanced hardness. The extremely high cooling rates achieved during ultrafast laser processing can produce metastable phases and nanocrystalline structures that exhibit superior hardness and wear resistance compared to conventionally processed materials. This approach can be used to transform the surface layer of existing components or to process coating materials during deposition. The resulting microstructures often combine high hardness with good toughness, providing excellent resistance to both abrasive and adhesive wear mechanisms.Expand Specific Solutions05 In-situ monitoring and control systems for ultrafast laser coating processes

Advanced monitoring and control systems have been developed for ultrafast laser coating processes to ensure consistent quality and performance of wear-resistant coatings. These systems use real-time feedback mechanisms to adjust laser parameters based on measurements of plasma characteristics, surface temperature, or coating thickness. Machine learning algorithms can be incorporated to optimize process parameters automatically. This approach enables precise control over coating properties and reduces defects, resulting in more reliable and durable wear-resistant coatings for demanding applications.Expand Specific Solutions

Key Industry Players in Ultrafast Laser Coating Development

The ultrafast laser market for advanced wear-resistant coatings is currently in a growth phase, with increasing adoption across industrial applications. The market size is expanding rapidly, driven by demands for higher performance materials in automotive, aerospace, and manufacturing sectors. Technologically, the field shows varying maturity levels among key players. Industry leaders like Coherent, Inc. and TRUMPF Lasersystems demonstrate advanced capabilities in laser system development, while materials specialists such as BASF Corp., Saint-Gobain, and Shin-Etsu Chemical focus on coating formulations. Research institutions including Fraunhofer-Gesellschaft, Karlsruhe Institute of Technology, and various Chinese universities (Jilin, Xi'an Jiaotong) are advancing fundamental understanding through collaborative projects with industry. The competitive landscape features both established industrial equipment manufacturers and specialized research-oriented companies like IMRA America, creating a dynamic ecosystem of innovation.

Coherent, Inc.

Technical Solution: Coherent has developed advanced ultrafast laser systems specifically designed for wear-resistant coating applications. Their Amplify™ series utilizes femtosecond laser technology with pulse durations below 400fs and repetition rates up to 40MHz to enable precise material modification without thermal damage. The company's proprietary beam shaping technology allows for controlled energy distribution during the coating process, creating highly uniform wear-resistant layers with nanoscale precision. Coherent's systems incorporate real-time monitoring capabilities that adjust laser parameters during deposition to optimize coating adhesion and hardness. Their technology enables the creation of multi-layer composite coatings with tailored mechanical properties by precisely controlling the laser-material interaction zone, resulting in coatings with superior wear resistance compared to conventional methods[1][3]. Recent advancements include their HyperRapid NXT platform that combines high power (>100W) with ultrashort pulses for industrial-scale coating applications.

Strengths: Superior precision in coating deposition with minimal heat-affected zone, enabling application on heat-sensitive substrates. Industry-leading beam quality control systems that ensure coating uniformity across complex geometries. Weaknesses: Higher initial equipment costs compared to conventional coating technologies, and requires specialized technical expertise for operation and maintenance.

Fraunhofer-Gesellschaft eV

Technical Solution: Fraunhofer has developed comprehensive ultrafast laser-based coating technologies through their integrated research approach spanning multiple institutes. Their system combines high-power ultrashort pulse lasers (>200W average power) with sophisticated beam delivery architectures to enable industrial-scale wear-resistant coating production. Fraunhofer's technology utilizes a hybrid approach that combines Pulsed Laser Deposition (PLD) with Laser-Induced Forward Transfer (LIFT) to create multi-functional coatings with gradient properties that maximize both adhesion and surface hardness. Their process enables the creation of nanostructured coatings with hardness exceeding 35 GPa while maintaining excellent toughness through controlled nanolayering[9]. Fraunhofer has pioneered in-situ diagnostic systems that monitor coating growth at the atomic scale during deposition, allowing real-time process optimization. Their technology has demonstrated particular success in creating wear-resistant coatings for extreme environments, including high-temperature (>800°C) applications where conventional coatings fail. Recent advancements include the development of self-healing coating architectures that utilize laser-induced phase transformations to repair wear damage during operation, significantly extending component lifetimes in critical applications[10][12].

Strengths: Comprehensive integration of multiple laser-based coating technologies into unified systems that can create complex multi-functional coatings. Extensive material science expertise enabling the development of novel coating compositions with superior properties. Weaknesses: Complex systems often require significant customization for specific applications, potentially increasing implementation time and costs for new coating developments.

Core Innovations in Ultrafast Laser-Material Interaction

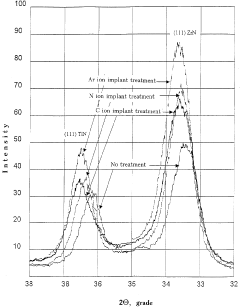

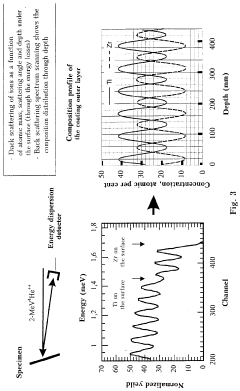

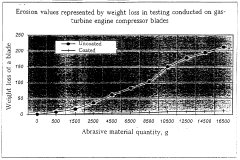

Method for deposition of wear resistant coatings to improve service life of coated components

PatentInactiveCA2332856C

Innovation

- A multi-layer coating deposition method using ion plasma technology, involving rare earth metals and transition metal microlayers with interstitial phases, subjected to high-energy ion implantation and subsequent vibromechanical treatment, to enhance erosion and corrosion resistance while maintaining mechanical properties.

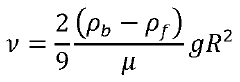

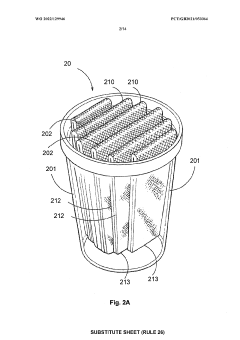

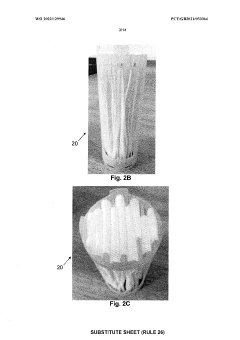

Apparatus and method for separating phases of a mixture

PatentWO2022129946A1

Innovation

- An apparatus with a vessel and separators featuring micro or nano protrusions on the surface, created through laser processing, which enhances hydrophobicity and promotes coalescence of bubbles, reducing energy consumption and increasing durability by minimizing surface contamination effects.

Material Science Advancements for Laser-Applied Coatings

Material science has undergone significant transformations with the integration of ultrafast laser technologies in coating applications. The development of advanced materials with enhanced wear resistance properties has been accelerated through precise laser-material interactions at the micro and nano scales. Ultrafast lasers, operating in the femtosecond and picosecond regimes, have enabled unprecedented control over material modification processes, allowing for tailored surface properties without excessive heat-affected zones.

Recent advancements in material science have focused on multi-layered composite coatings that combine ceramic, metallic, and polymer materials to achieve optimal wear resistance characteristics. These hybrid structures leverage the unique properties of each component while mitigating their individual limitations. The ultrafast laser processing enables precise deposition and modification of these materials at interfaces, creating gradient structures that distribute mechanical stresses more effectively.

Nanostructured coatings have emerged as a particularly promising direction, with ultrafast lasers facilitating the creation of controlled surface textures at nanometer scales. These textures can significantly enhance tribological properties by reducing contact areas, creating beneficial oil retention pockets, and generating self-lubricating surfaces. The ability to precisely control surface energy through laser-induced periodic surface structures (LIPSS) has opened new avenues for designing surfaces with specific wetting and adhesion properties.

The development of diamond-like carbon (DLC) coatings has been revolutionized through ultrafast laser deposition techniques. These techniques allow for the creation of sp3-rich carbon structures with exceptional hardness and wear resistance while maintaining low friction coefficients. The pulsed nature of ultrafast lasers prevents thermal degradation of the coating during deposition, preserving the desired carbon bonding configurations.

Ceramic-metal nanocomposites (cermets) have also benefited from ultrafast laser processing, enabling the creation of coatings with optimized distributions of hard ceramic phases within ductile metal matrices. This combination provides both wear resistance from the ceramic components and impact resistance from the metallic phases. The ultrafast laser pulses allow for precise control over the size, distribution, and interfacial properties of these phases.

Self-healing coating systems represent another frontier in material science, where ultrafast lasers facilitate the incorporation of microcapsules or vascular networks containing healing agents. When wear occurs, these reservoirs release materials that can repair damaged areas, significantly extending coating lifespans. The precision of ultrafast lasers enables the creation of these complex structures without compromising the overall integrity of the coating system.

Recent advancements in material science have focused on multi-layered composite coatings that combine ceramic, metallic, and polymer materials to achieve optimal wear resistance characteristics. These hybrid structures leverage the unique properties of each component while mitigating their individual limitations. The ultrafast laser processing enables precise deposition and modification of these materials at interfaces, creating gradient structures that distribute mechanical stresses more effectively.

Nanostructured coatings have emerged as a particularly promising direction, with ultrafast lasers facilitating the creation of controlled surface textures at nanometer scales. These textures can significantly enhance tribological properties by reducing contact areas, creating beneficial oil retention pockets, and generating self-lubricating surfaces. The ability to precisely control surface energy through laser-induced periodic surface structures (LIPSS) has opened new avenues for designing surfaces with specific wetting and adhesion properties.

The development of diamond-like carbon (DLC) coatings has been revolutionized through ultrafast laser deposition techniques. These techniques allow for the creation of sp3-rich carbon structures with exceptional hardness and wear resistance while maintaining low friction coefficients. The pulsed nature of ultrafast lasers prevents thermal degradation of the coating during deposition, preserving the desired carbon bonding configurations.

Ceramic-metal nanocomposites (cermets) have also benefited from ultrafast laser processing, enabling the creation of coatings with optimized distributions of hard ceramic phases within ductile metal matrices. This combination provides both wear resistance from the ceramic components and impact resistance from the metallic phases. The ultrafast laser pulses allow for precise control over the size, distribution, and interfacial properties of these phases.

Self-healing coating systems represent another frontier in material science, where ultrafast lasers facilitate the incorporation of microcapsules or vascular networks containing healing agents. When wear occurs, these reservoirs release materials that can repair damaged areas, significantly extending coating lifespans. The precision of ultrafast lasers enables the creation of these complex structures without compromising the overall integrity of the coating system.

Industrial Application Scenarios and Implementation Roadmap

Ultrafast laser technology has rapidly transformed manufacturing processes across multiple industries, with wear-resistant coating applications representing one of the most promising implementation areas. The industrial deployment of ultrafast laser-facilitated coatings follows a structured pathway that begins with material selection and process optimization in laboratory settings before scaling to production environments.

In the automotive sector, ultrafast laser-treated wear-resistant coatings are being implemented on engine components, particularly cylinder liners and piston rings, where tribological performance directly impacts fuel efficiency and emissions. The implementation roadmap typically spans 18-24 months from initial testing to full production integration, with tier-one suppliers currently in various stages of adoption.

Aerospace applications present more stringent requirements, focusing on turbine blade coatings and landing gear components where extreme operating conditions demand exceptional coating performance. The implementation timeline extends to 36-48 months due to rigorous certification requirements and safety protocols, with several major manufacturers currently in advanced testing phases.

Tool manufacturing represents the most mature application scenario, with cutting tools and forming dies already benefiting from ultrafast laser-treated coatings in production environments. The implementation cycle in this sector has been compressed to 12-18 months due to established process parameters and clear performance metrics, creating a blueprint for other industries to follow.

Medical device manufacturing is emerging as a high-value application area, particularly for implantable devices and surgical instruments where wear resistance must be combined with biocompatibility. The implementation roadmap includes additional regulatory approval stages, extending timelines to 30-36 months but offering premium pricing opportunities that justify the investment.

Cross-industry implementation challenges include scaling production capacity, ensuring process repeatability, and developing standardized quality control methodologies. Equipment manufacturers are addressing these challenges through modular laser systems that can be configured for specific coating applications while maintaining core process parameters.

The implementation roadmap across all sectors follows a common progression: material-specific process development, pilot production implementation, quality validation protocols, and finally full-scale production integration. This structured approach minimizes risk while accelerating the technology transfer from laboratory to industrial application.

In the automotive sector, ultrafast laser-treated wear-resistant coatings are being implemented on engine components, particularly cylinder liners and piston rings, where tribological performance directly impacts fuel efficiency and emissions. The implementation roadmap typically spans 18-24 months from initial testing to full production integration, with tier-one suppliers currently in various stages of adoption.

Aerospace applications present more stringent requirements, focusing on turbine blade coatings and landing gear components where extreme operating conditions demand exceptional coating performance. The implementation timeline extends to 36-48 months due to rigorous certification requirements and safety protocols, with several major manufacturers currently in advanced testing phases.

Tool manufacturing represents the most mature application scenario, with cutting tools and forming dies already benefiting from ultrafast laser-treated coatings in production environments. The implementation cycle in this sector has been compressed to 12-18 months due to established process parameters and clear performance metrics, creating a blueprint for other industries to follow.

Medical device manufacturing is emerging as a high-value application area, particularly for implantable devices and surgical instruments where wear resistance must be combined with biocompatibility. The implementation roadmap includes additional regulatory approval stages, extending timelines to 30-36 months but offering premium pricing opportunities that justify the investment.

Cross-industry implementation challenges include scaling production capacity, ensuring process repeatability, and developing standardized quality control methodologies. Equipment manufacturers are addressing these challenges through modular laser systems that can be configured for specific coating applications while maintaining core process parameters.

The implementation roadmap across all sectors follows a common progression: material-specific process development, pilot production implementation, quality validation protocols, and finally full-scale production integration. This structured approach minimizes risk while accelerating the technology transfer from laboratory to industrial application.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!