Employing Ultrafast Lasers for High-Purity Metal Refining.

SEP 4, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Ultrafast Laser Metal Refining Background and Objectives

Ultrafast laser technology has evolved significantly over the past three decades, transforming from laboratory curiosities to practical industrial tools. Initially developed in the 1980s, these lasers have undergone remarkable refinement in terms of power, precision, and reliability. The evolution trajectory shows a clear trend toward higher pulse energies, shorter pulse durations, and increased repetition rates, making them increasingly suitable for sophisticated material processing applications.

Metal refining processes have traditionally relied on pyrometallurgical and hydrometallurgical methods, which often involve high energy consumption, significant environmental impact, and limitations in achieving ultra-high purity levels. The intersection of ultrafast laser technology with metallurgy represents a promising frontier that could potentially revolutionize metal purification techniques.

The fundamental principle behind ultrafast laser metal refining lies in the unique interaction between femtosecond or picosecond laser pulses and metallic materials. Unlike conventional laser processing, ultrafast pulses deliver energy faster than the thermal diffusion time in metals, resulting in precise material ablation with minimal heat-affected zones. This characteristic enables selective removal of impurities at the atomic or molecular level without compromising the bulk material properties.

Recent advancements in ultrafast laser systems, including the development of high-power fiber lasers and thin-disk technology, have significantly enhanced the commercial viability of laser-based metal refining. These developments have addressed previous limitations related to processing speed, energy efficiency, and system reliability, making industrial implementation increasingly feasible.

The primary objective of ultrafast laser metal refining technology is to establish a novel, environmentally sustainable process for producing high-purity metals with impurity levels below parts per billion (ppb). This approach aims to overcome the limitations of conventional refining methods, particularly for critical metals used in semiconductor manufacturing, aerospace applications, and advanced electronics.

Additional technical goals include developing precise control mechanisms for selective impurity removal, optimizing process parameters for different metal types, and creating scalable systems capable of handling industrial production volumes. The technology also seeks to reduce energy consumption compared to traditional refining methods while minimizing waste generation and environmental impact.

The long-term vision encompasses the integration of ultrafast laser refining into existing metallurgical processes, creating hybrid systems that combine the strengths of conventional methods with the precision of laser processing. This integration could potentially transform metal production chains, particularly for high-value, high-purity applications where material quality directly impacts product performance and reliability.

Metal refining processes have traditionally relied on pyrometallurgical and hydrometallurgical methods, which often involve high energy consumption, significant environmental impact, and limitations in achieving ultra-high purity levels. The intersection of ultrafast laser technology with metallurgy represents a promising frontier that could potentially revolutionize metal purification techniques.

The fundamental principle behind ultrafast laser metal refining lies in the unique interaction between femtosecond or picosecond laser pulses and metallic materials. Unlike conventional laser processing, ultrafast pulses deliver energy faster than the thermal diffusion time in metals, resulting in precise material ablation with minimal heat-affected zones. This characteristic enables selective removal of impurities at the atomic or molecular level without compromising the bulk material properties.

Recent advancements in ultrafast laser systems, including the development of high-power fiber lasers and thin-disk technology, have significantly enhanced the commercial viability of laser-based metal refining. These developments have addressed previous limitations related to processing speed, energy efficiency, and system reliability, making industrial implementation increasingly feasible.

The primary objective of ultrafast laser metal refining technology is to establish a novel, environmentally sustainable process for producing high-purity metals with impurity levels below parts per billion (ppb). This approach aims to overcome the limitations of conventional refining methods, particularly for critical metals used in semiconductor manufacturing, aerospace applications, and advanced electronics.

Additional technical goals include developing precise control mechanisms for selective impurity removal, optimizing process parameters for different metal types, and creating scalable systems capable of handling industrial production volumes. The technology also seeks to reduce energy consumption compared to traditional refining methods while minimizing waste generation and environmental impact.

The long-term vision encompasses the integration of ultrafast laser refining into existing metallurgical processes, creating hybrid systems that combine the strengths of conventional methods with the precision of laser processing. This integration could potentially transform metal production chains, particularly for high-value, high-purity applications where material quality directly impacts product performance and reliability.

Market Demand Analysis for High-Purity Metals

The high-purity metals market has experienced substantial growth in recent years, driven primarily by increasing demand from advanced technology sectors. The global high-purity metals market was valued at approximately $2.3 billion in 2022 and is projected to reach $3.7 billion by 2028, representing a compound annual growth rate of 8.2%. This growth trajectory underscores the critical importance of these materials in modern industrial applications.

Electronics manufacturing constitutes the largest demand segment, accounting for nearly 40% of the high-purity metals market. The semiconductor industry, in particular, requires metals with purity levels exceeding 99.9999% (6N) for advanced chip fabrication. As semiconductor devices continue to shrink in size while increasing in complexity, the demand for ultra-high-purity metals such as copper, aluminum, and precious metals has intensified significantly.

The renewable energy sector represents another rapidly expanding market for high-purity metals. Solar photovoltaic manufacturing requires high-purity silicon, while advanced battery technologies for energy storage systems demand high-purity lithium, cobalt, and nickel. Market analysis indicates that demand from this sector is growing at approximately 12% annually, outpacing the overall market growth rate.

Aerospace and defense applications form a premium segment of the high-purity metals market, where performance requirements justify higher material costs. These industries require metals with exceptional mechanical properties and resistance to extreme conditions, driving demand for high-purity titanium, aluminum alloys, and specialty metals. This segment is expected to grow at 7.5% annually through 2028.

Medical technology represents an emerging application area with stringent purity requirements. Implantable devices, diagnostic equipment, and advanced medical instruments increasingly utilize high-purity metals to ensure biocompatibility and reliability. Market research indicates this segment will expand at 9.3% annually over the next five years.

Geographically, Asia-Pacific dominates the high-purity metals market, accounting for approximately 45% of global demand, primarily due to the concentration of electronics manufacturing in countries like China, South Korea, Japan, and Taiwan. North America and Europe follow with market shares of 25% and 20% respectively, driven by aerospace, defense, and medical technology applications.

The market exhibits a clear trend toward increasingly stringent purity specifications across all application areas. Five years ago, 5N purity (99.999%) was considered sufficient for most advanced applications, but today's cutting-edge technologies frequently require 6N or even 7N purity levels. This escalation in purity requirements presents both challenges and opportunities for refining technologies like ultrafast laser processing.

Electronics manufacturing constitutes the largest demand segment, accounting for nearly 40% of the high-purity metals market. The semiconductor industry, in particular, requires metals with purity levels exceeding 99.9999% (6N) for advanced chip fabrication. As semiconductor devices continue to shrink in size while increasing in complexity, the demand for ultra-high-purity metals such as copper, aluminum, and precious metals has intensified significantly.

The renewable energy sector represents another rapidly expanding market for high-purity metals. Solar photovoltaic manufacturing requires high-purity silicon, while advanced battery technologies for energy storage systems demand high-purity lithium, cobalt, and nickel. Market analysis indicates that demand from this sector is growing at approximately 12% annually, outpacing the overall market growth rate.

Aerospace and defense applications form a premium segment of the high-purity metals market, where performance requirements justify higher material costs. These industries require metals with exceptional mechanical properties and resistance to extreme conditions, driving demand for high-purity titanium, aluminum alloys, and specialty metals. This segment is expected to grow at 7.5% annually through 2028.

Medical technology represents an emerging application area with stringent purity requirements. Implantable devices, diagnostic equipment, and advanced medical instruments increasingly utilize high-purity metals to ensure biocompatibility and reliability. Market research indicates this segment will expand at 9.3% annually over the next five years.

Geographically, Asia-Pacific dominates the high-purity metals market, accounting for approximately 45% of global demand, primarily due to the concentration of electronics manufacturing in countries like China, South Korea, Japan, and Taiwan. North America and Europe follow with market shares of 25% and 20% respectively, driven by aerospace, defense, and medical technology applications.

The market exhibits a clear trend toward increasingly stringent purity specifications across all application areas. Five years ago, 5N purity (99.999%) was considered sufficient for most advanced applications, but today's cutting-edge technologies frequently require 6N or even 7N purity levels. This escalation in purity requirements presents both challenges and opportunities for refining technologies like ultrafast laser processing.

Current Metal Refining Technologies and Challenges

Metal refining technologies have evolved significantly over centuries, from primitive smelting methods to sophisticated industrial processes. Currently, the metal refining industry relies primarily on pyrometallurgical and hydrometallurgical techniques. Pyrometallurgical processes involve high-temperature treatments such as smelting, roasting, and calcination, which separate metals from their ores through thermal reactions. Hydrometallurgical methods utilize aqueous solutions to extract and separate metals through processes like leaching, solvent extraction, and electrowinning.

Electrorefining represents another critical technology, particularly for achieving high-purity metals like copper, gold, and silver. This process uses electrolysis to transfer metal ions from an impure anode to a pure cathode in an electrolyte solution. While effective, these conventional methods face significant challenges including high energy consumption, substantial carbon emissions, and generation of hazardous waste materials.

The increasing demand for ultra-high-purity metals in advanced electronics, aerospace applications, and renewable energy technologies has exposed the limitations of traditional refining methods. Current technologies struggle to remove trace impurities efficiently, particularly when dealing with complex ore compositions or recycled materials. The semiconductor industry, for instance, requires metals with 99.9999% purity (6N) or higher, which conventional methods cannot consistently deliver without multiple refining cycles.

Environmental concerns present another major challenge. Traditional refining processes generate significant pollution, including sulfur dioxide emissions, heavy metal contamination, and toxic slag production. Regulatory pressures and sustainability goals are pushing the industry toward cleaner alternatives, yet economically viable solutions remain elusive. The trade-off between purity, cost, and environmental impact continues to challenge metal producers worldwide.

Energy efficiency represents a persistent issue, with conventional refining methods consuming between 5-15% of global industrial energy. The temperature requirements for pyrometallurgical processes (often exceeding 1000°C) contribute significantly to operational costs and carbon footprints. Additionally, the industry faces diminishing ore grades, requiring more energy-intensive processing to extract the same amount of metal.

Technical limitations also include the inability to process certain complex materials efficiently, long processing times, and challenges in scaling production while maintaining quality. The recovery rates for valuable trace elements during refining remain suboptimal, resulting in economic losses and resource inefficiency.

These challenges collectively highlight the need for innovative approaches to metal refining. Ultrafast laser technology presents a promising alternative, potentially offering precision control at the atomic level, reduced energy consumption, and minimal waste generation. The ability of ultrafast lasers to deliver extremely short, high-intensity pulses could revolutionize selective removal of impurities without bulk heating, addressing many of the limitations inherent in conventional refining technologies.

Electrorefining represents another critical technology, particularly for achieving high-purity metals like copper, gold, and silver. This process uses electrolysis to transfer metal ions from an impure anode to a pure cathode in an electrolyte solution. While effective, these conventional methods face significant challenges including high energy consumption, substantial carbon emissions, and generation of hazardous waste materials.

The increasing demand for ultra-high-purity metals in advanced electronics, aerospace applications, and renewable energy technologies has exposed the limitations of traditional refining methods. Current technologies struggle to remove trace impurities efficiently, particularly when dealing with complex ore compositions or recycled materials. The semiconductor industry, for instance, requires metals with 99.9999% purity (6N) or higher, which conventional methods cannot consistently deliver without multiple refining cycles.

Environmental concerns present another major challenge. Traditional refining processes generate significant pollution, including sulfur dioxide emissions, heavy metal contamination, and toxic slag production. Regulatory pressures and sustainability goals are pushing the industry toward cleaner alternatives, yet economically viable solutions remain elusive. The trade-off between purity, cost, and environmental impact continues to challenge metal producers worldwide.

Energy efficiency represents a persistent issue, with conventional refining methods consuming between 5-15% of global industrial energy. The temperature requirements for pyrometallurgical processes (often exceeding 1000°C) contribute significantly to operational costs and carbon footprints. Additionally, the industry faces diminishing ore grades, requiring more energy-intensive processing to extract the same amount of metal.

Technical limitations also include the inability to process certain complex materials efficiently, long processing times, and challenges in scaling production while maintaining quality. The recovery rates for valuable trace elements during refining remain suboptimal, resulting in economic losses and resource inefficiency.

These challenges collectively highlight the need for innovative approaches to metal refining. Ultrafast laser technology presents a promising alternative, potentially offering precision control at the atomic level, reduced energy consumption, and minimal waste generation. The ability of ultrafast lasers to deliver extremely short, high-intensity pulses could revolutionize selective removal of impurities without bulk heating, addressing many of the limitations inherent in conventional refining technologies.

Current Ultrafast Laser Metal Purification Solutions

01 Ultrafast laser systems for high-purity material processing

Ultrafast laser systems can be used for high-precision material processing applications requiring high purity. These systems typically employ femtosecond or picosecond pulse durations that minimize heat-affected zones and contamination during processing. The ultrashort pulses enable clean ablation of materials without introducing impurities, making them ideal for applications where material purity is critical, such as semiconductor manufacturing and medical device fabrication.- Ultrafast laser systems for high-purity material processing: Ultrafast lasers with femtosecond or picosecond pulse durations are used for high-precision material processing applications requiring high purity. These laser systems minimize heat-affected zones and enable clean ablation of materials without contamination. The ultrashort pulses allow for cold processing, which is particularly beneficial for sensitive materials where thermal effects must be avoided to maintain purity standards.

- High-purity crystal growth for ultrafast laser applications: The development of high-purity crystals is essential for ultrafast laser performance. These crystals serve as gain media or optical components in ultrafast laser systems. Advanced growth techniques ensure minimal defects and impurities, which is critical for achieving the desired optical properties, power handling capabilities, and overall laser performance. High-purity crystal materials enable more efficient and stable ultrafast laser operation.

- Purification methods for ultrafast laser components: Various purification techniques are employed to achieve the high-purity materials required for ultrafast laser components. These methods include chemical vapor deposition, zone refining, and advanced filtration processes. The purification processes remove contaminants that could otherwise cause optical losses, damage thresholds reduction, or degradation of laser performance. These techniques are crucial for manufacturing optical fibers, mirrors, and other components used in ultrafast laser systems.

- High-purity gas systems for ultrafast laser operation: High-purity gas handling systems are essential for certain types of ultrafast lasers, particularly gas-based systems or those requiring controlled atmospheres. These systems maintain the purity of gases used in laser operation, preventing contamination that could lead to beam degradation or damage to optical components. Advanced gas purification, monitoring, and delivery systems ensure consistent laser performance and extend the operational lifetime of sensitive components.

- Quality control and measurement techniques for ultrafast laser purity: Specialized measurement and quality control techniques are employed to verify the purity of materials and components used in ultrafast laser systems. These include spectroscopic analysis, interferometry, and high-precision optical testing methods. Real-time monitoring systems can detect impurities or defects that might affect laser performance. These quality control processes are critical throughout the manufacturing and operation of ultrafast laser systems to maintain the required high-purity standards.

02 High-purity crystal growth for ultrafast laser applications

The development of high-purity crystals is essential for ultrafast laser applications. These crystals serve as gain media or nonlinear optical components in ultrafast laser systems. Advanced growth techniques ensure minimal defects and impurities, resulting in improved laser performance characteristics such as higher power, better beam quality, and reduced thermal effects. The purity of these crystals directly impacts the stability and efficiency of ultrafast laser operations.Expand Specific Solutions03 Purification methods for ultrafast laser components

Various purification methods are employed to achieve high-purity components for ultrafast laser systems. These include chemical vapor deposition, zone refining, and advanced filtration techniques. The purification processes remove contaminants that could otherwise cause optical losses, damage thresholds reduction, or wavelength instabilities in ultrafast laser systems. These methods are crucial for manufacturing optical components that can withstand the high intensities characteristic of ultrafast lasers.Expand Specific Solutions04 High-purity gas systems for ultrafast laser operation

High-purity gas systems are essential for certain types of ultrafast lasers, particularly gas-based systems or those requiring controlled atmospheres. These systems utilize specialized gas purification and delivery methods to maintain the required purity levels. Contaminants in gas systems can lead to plasma instabilities, optical breakdown, or degradation of laser components. Advanced gas handling techniques ensure consistent laser performance and extended operational lifetime in ultrafast laser applications.Expand Specific Solutions05 Quality control and measurement techniques for high-purity ultrafast lasers

Specialized quality control and measurement techniques are employed to verify and maintain high-purity standards in ultrafast laser systems. These include spectroscopic analysis, interferometric methods, and advanced imaging techniques that can detect impurities or defects at extremely low concentrations. Real-time monitoring systems help maintain purity during laser operation, while post-processing analysis ensures that processed materials meet high-purity specifications. These techniques are critical for applications in scientific research, medical procedures, and precision manufacturing.Expand Specific Solutions

Key Industry Players in Ultrafast Laser and Metal Refining

The ultrafast laser metal refining market is in its early growth phase, characterized by increasing adoption across high-precision manufacturing sectors. The market size is projected to expand significantly as industries seek higher purity metal processing solutions, with current estimates suggesting a compound annual growth rate of 15-20%. Technologically, the field shows varying maturity levels, with established players like IMRA America and Mitsubishi Electric demonstrating commercial viability, while research institutions such as Huazhong University of Science & Technology and Tsinghua University drive fundamental innovation. Companies like Han's Laser and Femto Blanc are advancing application-specific solutions, while newer entrants like Beijing Insight Technology are focusing on commercialization pathways. The competitive landscape features a mix of specialized laser manufacturers, diversified industrial conglomerates, and academic-industrial partnerships accelerating technology transfer.

IMRA America, Inc.

Technical Solution: IMRA America has developed proprietary FCPA (Fiber Chirped Pulse Amplification) technology for ultrafast laser applications in metal refining. Their approach utilizes femtosecond laser pulses with durations of 100-900 fs at high repetition rates (up to 1 MHz) to achieve precise material processing with minimal heat-affected zones. The company's DE-Series lasers specifically target high-purity metal applications, using wavelengths of 1040-1060 nm that can be frequency-doubled to increase absorption in reflective metals. IMRA's technology enables cold ablation processes that remove impurities from metal surfaces without altering the bulk material properties, achieving purification rates of up to 99.999% for certain metals. Their integrated beam delivery systems incorporate galvanometer scanners and precision optics to maintain beam quality across large processing areas, essential for industrial-scale metal refining operations.

Strengths: Proprietary fiber laser technology offers exceptional beam quality and stability; scalable to industrial production levels; minimal thermal effects preserve metal properties. Weaknesses: Higher initial capital investment compared to conventional refining methods; limited to surface and near-surface purification; requires sophisticated control systems and specialized expertise for operation and maintenance.

Femto Blanc, Inc.

Technical Solution: Femto Blanc specializes in ultrafast laser technology for high-precision material processing, including metal refining applications. Their approach centers on their patented "Pulse Shaping Technology" that enables precise control over temporal pulse characteristics, allowing for optimization of laser-material interactions specific to different metal types. For high-purity metal refining, Femto Blanc employs burst-mode processing with controlled pulse spacing (1-100 ns between sub-pulses) to enhance ablation efficiency while minimizing heat accumulation. Their systems operate primarily in the near-infrared spectrum but incorporate frequency conversion modules to generate wavelengths optimized for specific metals' absorption characteristics. The company has demonstrated selective removal of surface contaminants and trace elements from precious metals with spatial resolution below 10 μm, enabling purification without bulk melting. Their integrated process monitoring system uses spectroscopic analysis to provide real-time feedback on ablation products, allowing for adaptive control of the purification process.

Strengths: Highly customizable pulse parameters allow optimization for different metals and impurity types; real-time process monitoring enables quality control; minimal material waste compared to traditional refining. Weaknesses: Processing throughput remains lower than conventional bulk refining methods; technology is relatively new to industrial-scale implementation; requires significant expertise to properly configure for specific metal purification applications.

Critical Patents and Research in Ultrafast Laser Metal Refining

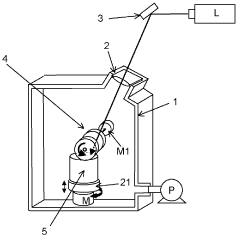

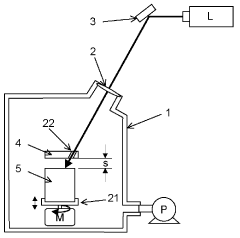

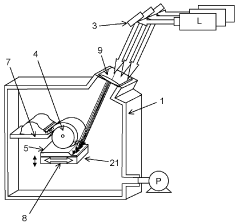

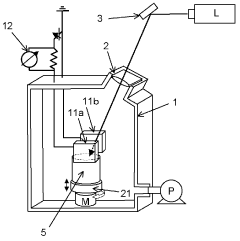

Laser refining apparatus and laser refining method

PatentWO2010050450A1

Innovation

- A laser refining apparatus that uses a laser to heat metal oxides above their boiling point, with an adhesion medium to capture non-oxygen vapors and prevent re-oxidation, employing inert gases and electric or magnetic fields to separate and collect the metals effectively.

Environmental Impact and Sustainability Considerations

The integration of ultrafast laser technology in metal refining processes presents significant environmental and sustainability implications that warrant careful consideration. Traditional metal refining methods typically involve energy-intensive processes with substantial carbon footprints, including pyrometallurgical techniques that consume vast amounts of fossil fuels and emit greenhouse gases. In contrast, ultrafast laser-based refining offers potential for dramatically reduced energy consumption through precise, targeted energy delivery that minimizes waste heat generation.

Waste reduction represents another critical environmental advantage of laser-based refining. Conventional methods often produce substantial slag and other byproducts requiring disposal, whereas ultrafast laser processing can achieve higher material utilization rates. The precision of laser technology enables selective removal of impurities without generating excessive waste streams, potentially reducing landfill burden and associated environmental contamination risks.

Water conservation emerges as a notable sustainability benefit, as laser-based refining typically requires minimal water compared to hydrometallurgical processes. This advantage becomes increasingly significant amid growing global water scarcity concerns and stricter regulations on industrial water usage and discharge quality. The reduced water footprint could prove particularly valuable in water-stressed regions where metal refining operations are common.

Chemical usage reduction constitutes another environmental advantage of ultrafast laser technology. Traditional refining often relies on harsh chemicals including acids, bases, and organic solvents that pose environmental hazards throughout their lifecycle. Laser-based approaches can potentially eliminate or substantially reduce dependence on these chemicals, minimizing associated pollution risks and hazardous waste management challenges.

Life cycle assessment (LCA) considerations must extend beyond operational impacts to include manufacturing and end-of-life management of laser equipment. While the technology offers operational environmental benefits, the production of sophisticated laser systems involves rare earth elements and specialized components with their own environmental footprints. Developing robust recycling pathways for these systems represents an important sustainability challenge.

Regulatory compliance and certification opportunities should also factor into environmental assessments. As environmental regulations tighten globally, metal producers implementing cleaner laser-based technologies may gain competitive advantages through reduced compliance costs and access to green certification programs. This could translate to market premiums for metals produced through environmentally superior processes, creating economic incentives that align with sustainability goals.

Waste reduction represents another critical environmental advantage of laser-based refining. Conventional methods often produce substantial slag and other byproducts requiring disposal, whereas ultrafast laser processing can achieve higher material utilization rates. The precision of laser technology enables selective removal of impurities without generating excessive waste streams, potentially reducing landfill burden and associated environmental contamination risks.

Water conservation emerges as a notable sustainability benefit, as laser-based refining typically requires minimal water compared to hydrometallurgical processes. This advantage becomes increasingly significant amid growing global water scarcity concerns and stricter regulations on industrial water usage and discharge quality. The reduced water footprint could prove particularly valuable in water-stressed regions where metal refining operations are common.

Chemical usage reduction constitutes another environmental advantage of ultrafast laser technology. Traditional refining often relies on harsh chemicals including acids, bases, and organic solvents that pose environmental hazards throughout their lifecycle. Laser-based approaches can potentially eliminate or substantially reduce dependence on these chemicals, minimizing associated pollution risks and hazardous waste management challenges.

Life cycle assessment (LCA) considerations must extend beyond operational impacts to include manufacturing and end-of-life management of laser equipment. While the technology offers operational environmental benefits, the production of sophisticated laser systems involves rare earth elements and specialized components with their own environmental footprints. Developing robust recycling pathways for these systems represents an important sustainability challenge.

Regulatory compliance and certification opportunities should also factor into environmental assessments. As environmental regulations tighten globally, metal producers implementing cleaner laser-based technologies may gain competitive advantages through reduced compliance costs and access to green certification programs. This could translate to market premiums for metals produced through environmentally superior processes, creating economic incentives that align with sustainability goals.

Economic Feasibility and Implementation Costs

The implementation of ultrafast laser technology for high-purity metal refining presents significant economic considerations that must be thoroughly evaluated before industrial adoption. Initial capital investment for ultrafast laser systems remains substantial, with industrial-grade femtosecond laser setups ranging from $500,000 to $2 million, depending on power specifications, pulse characteristics, and auxiliary equipment requirements. These costs significantly exceed conventional refining methods, creating a considerable barrier to entry for smaller operations.

Operational expenses also warrant careful analysis. While ultrafast lasers offer precision that potentially reduces material waste by 15-30% compared to traditional methods, they consume substantial electrical power—approximately 20-50 kW for industrial-scale systems. This consumption translates to operational costs of $50,000-$120,000 annually, depending on regional energy prices and system utilization rates.

Maintenance requirements constitute another significant cost factor. Ultrafast laser systems require specialized technical expertise for calibration and service, with annual maintenance contracts typically representing 8-12% of the initial system cost. Critical components such as gain media and optical elements require periodic replacement, adding $30,000-$70,000 in annual expenses for high-throughput industrial applications.

Return on investment calculations suggest a break-even timeline of 3-5 years for most implementations, contingent upon production volume and the value differential between standard and high-purity metals. Industries producing high-value metals like platinum, palladium, or specialized semiconductor-grade materials may achieve faster returns due to significant price premiums for ultra-high purity products.

Scalability considerations reveal that while initial implementation costs are high, economies of scale become apparent as production volumes increase. Multi-beam systems and parallel processing configurations can improve throughput without proportional cost increases, enhancing economic viability for larger operations.

Financing options have emerged to mitigate initial investment barriers, including equipment leasing arrangements, vendor financing programs, and technology-specific grants from governmental industrial development initiatives. These mechanisms can transform prohibitive capital expenditures into manageable operational costs, improving cash flow during implementation phases.

Risk assessment must account for technology obsolescence, as the ultrafast laser field continues to evolve rapidly. Modular system designs that allow for component upgrades rather than complete system replacement offer protection against premature obsolescence and improve long-term economic feasibility.

Operational expenses also warrant careful analysis. While ultrafast lasers offer precision that potentially reduces material waste by 15-30% compared to traditional methods, they consume substantial electrical power—approximately 20-50 kW for industrial-scale systems. This consumption translates to operational costs of $50,000-$120,000 annually, depending on regional energy prices and system utilization rates.

Maintenance requirements constitute another significant cost factor. Ultrafast laser systems require specialized technical expertise for calibration and service, with annual maintenance contracts typically representing 8-12% of the initial system cost. Critical components such as gain media and optical elements require periodic replacement, adding $30,000-$70,000 in annual expenses for high-throughput industrial applications.

Return on investment calculations suggest a break-even timeline of 3-5 years for most implementations, contingent upon production volume and the value differential between standard and high-purity metals. Industries producing high-value metals like platinum, palladium, or specialized semiconductor-grade materials may achieve faster returns due to significant price premiums for ultra-high purity products.

Scalability considerations reveal that while initial implementation costs are high, economies of scale become apparent as production volumes increase. Multi-beam systems and parallel processing configurations can improve throughput without proportional cost increases, enhancing economic viability for larger operations.

Financing options have emerged to mitigate initial investment barriers, including equipment leasing arrangements, vendor financing programs, and technology-specific grants from governmental industrial development initiatives. These mechanisms can transform prohibitive capital expenditures into manageable operational costs, improving cash flow during implementation phases.

Risk assessment must account for technology obsolescence, as the ultrafast laser field continues to evolve rapidly. Modular system designs that allow for component upgrades rather than complete system replacement offer protection against premature obsolescence and improve long-term economic feasibility.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!